What Are the Key Benefits of Using 12mm Film Faced Plywood for Scaffolding?

2025-06-23

When it comes to construction scaffolding applications, selecting the right materials is crucial for project success, safety, and cost-effectiveness. 12mm film faced plywood has emerged as a preferred choice among construction professionals worldwide due to its exceptional properties and versatile applications. This specialized plywood combines the structural integrity of quality wood cores with the protective benefits of phenolic film coating, creating a superior building material that excels in demanding construction environments. Understanding the key benefits of 12mm film faced plywood for scaffolding applications can help contractors, builders, and project managers make informed decisions that enhance both project efficiency and long-term profitability. The construction industry's growing reliance on 12mm film faced plywood stems from its unique ability to withstand harsh environmental conditions while maintaining structural integrity throughout multiple use cycles. This engineered wood product offers remarkable durability, moisture resistance, and surface quality that traditional materials simply cannot match, making it an indispensable component in modern scaffolding systems and formwork applications.

Superior Durability and Structural Performance

Enhanced Load-Bearing Capacity and Structural Integrity

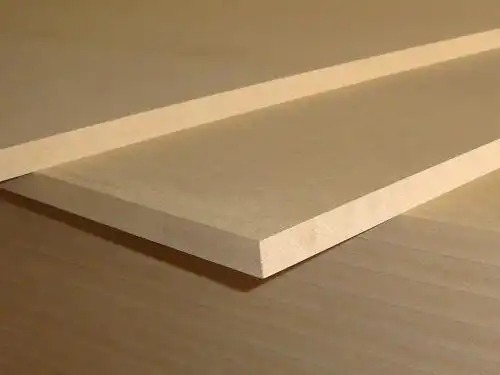

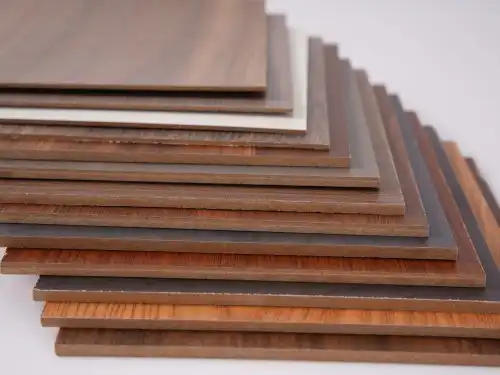

The exceptional structural performance of 12mm film faced plywood makes it an ideal choice for scaffolding applications where load-bearing capacity is paramount. The engineered construction of this material combines a robust hardwood or poplar core with phenolic film coating, creating a composite that can withstand significant weight loads while maintaining dimensional stability. The density of quality 12mm film faced plywood typically exceeds 640 kg/m³, providing the necessary strength to support heavy construction materials, equipment, and personnel during scaffolding operations. This high-density composition ensures that the plywood maintains its structural integrity even under extreme stress conditions, reducing the risk of failure that could compromise worker safety or project timelines. The manufacturing process involves hot pressing techniques that bond the phenolic film to the plywood core under controlled temperature and pressure conditions, creating a homogeneous structure that distributes loads evenly across the entire surface. This uniform load distribution is particularly important in scaffolding applications where concentrated loads from equipment or materials could otherwise cause localized failure. The Weather and Boil Proof (WBP) glue used in premium 12mm film faced plywood further enhances its structural performance by maintaining bond strength even in wet conditions, ensuring that the scaffolding system remains reliable regardless of environmental challenges.

Resistance to Environmental Factors and Weather Conditions

Environmental resistance is a critical factor that sets 12mm film faced plywood apart from conventional scaffolding materials. The phenolic film coating provides a protective barrier that shields the wood core from moisture, UV radiation, and chemical exposure that commonly occur in construction environments. This protective layer is engineered to withstand temperature fluctuations, humidity changes, and direct exposure to rain or snow without compromising the material's structural properties. The film's chemical composition creates a non-porous surface that prevents water absorption, eliminating the swelling, warping, and dimensional changes that plague untreated wood products in outdoor applications The superior weather resistance of 12mm film faced plywood extends its service life significantly compared to alternative materials, making it particularly valuable for long-term scaffolding installations or projects in challenging climatic conditions. The material's ability to maintain its properties across temperature ranges from -40°C to +70°C ensures consistent performance in diverse geographical locations and seasonal conditions. Additionally, the chemical resistance of the phenolic coating protects against corrosive substances commonly found on construction sites, including concrete additives, cleaning chemicals, and industrial pollutants that could otherwise degrade the material over time.

Long-Term Performance and Reliability

The long-term performance characteristics of 12mm film faced plywood make it an economically sound investment for scaffolding applications. Unlike traditional materials that may degrade rapidly under construction site conditions, this engineered product maintains its structural and surface properties through multiple use cycles, often exceeding 15-30 reuses when properly maintained. This exceptional durability translates into significant cost savings over the project lifecycle, as contractors can rely on the same materials for multiple projects without compromising performance or safety standards The reliability of 12mm film faced plywood stems from its consistent manufacturing standards and quality control processes that ensure every sheet meets specified performance criteria. The thickness tolerance of ±0.5mm provides predictable dimensions that facilitate precise scaffolding assembly and ensure proper fit with standard scaffolding components. This dimensional consistency is crucial for maintaining structural integrity and safety in complex scaffolding systems where precise alignment and uniform load distribution are essential. The material's proven track record in demanding construction applications worldwide demonstrates its ability to deliver reliable performance under diverse conditions and usage scenarios.

Cost-Effectiveness and Economic Advantages

High Reusability and Extended Service Life

The economic advantages of 12mm film faced plywood become particularly evident when considering its exceptional reusability characteristics. Unlike single-use materials or products that deteriorate rapidly, quality film faced plywood can be reused 15-30 times or more with proper handling and maintenance, making it one of the most cost-effective scaffolding materials available. This high reuse rate is achieved through the durable phenolic film coating that protects the wood core from damage during installation, use, and removal processes. The smooth, non-stick surface of the film allows for easy release from concrete and other materials, preventing surface damage that could reduce the number of possible reuse cycles. The extended service life of 12mm film faced plywood significantly reduces the per-use cost compared to alternative materials, creating substantial savings for construction projects of all scales. When calculated over multiple use cycles, the initial investment in quality film faced plywood often costs less per use than cheaper alternatives that require frequent replacement. This economic advantage is particularly pronounced in large-scale construction projects where material costs represent a significant portion of the total budget. The ability to plan material usage across multiple projects also improves inventory management and reduces the need for frequent material procurement, streamlining project logistics and reducing administrative overhead.

Reduced Labor and Maintenance Costs

The user-friendly characteristics of 12mm film faced plywood contribute to significant labor cost savings throughout the construction process. The smooth, uniform surface of the phenolic film makes installation and removal operations faster and more efficient compared to rough or textured materials that may require additional preparation or special handling techniques. The lightweight nature of the material relative to its strength reduces manual handling requirements and speeds up scaffolding assembly and disassembly operations, allowing construction crews to complete these tasks more quickly and with fewer personnel. Maintenance requirements for 12mm film faced plywood are minimal compared to alternative scaffolding materials, further reducing operational costs. The non-porous surface of the phenolic film prevents the absorption of concrete, paint, or other construction materials, making cleaning operations simple and efficient. Most contaminants can be removed with basic cleaning techniques, eliminating the need for expensive chemical treatments or specialized cleaning equipment. The material's resistance to damage from normal construction activities reduces the frequency of repairs or replacements, minimizing downtime and associated labor costs throughout the project duration.

Optimized Material Utilization and Waste Reduction

The standardized dimensions and consistent quality of 12mm film faced plywood enable optimized material utilization that minimizes waste and maximizes cost efficiency. The standard size of 1220 x 2440mm provides excellent coverage for most scaffolding applications while maintaining compatibility with standard construction modules and spacing requirements. This dimensional compatibility reduces the need for custom cutting or modification, minimizing material waste and associated labor costs. When cutting is necessary, the clean, smooth edges produced by the phenolic film coating eliminate the need for additional finishing or edge treatment, further reducing material waste and processing time. The durability and reusability of 12mm film faced plywood contribute to sustainable construction practices by reducing the volume of materials that must be disposed of after single use. This waste reduction not only provides direct cost savings through reduced disposal fees but also supports environmental sustainability goals that are increasingly important to construction industry stakeholders. The ability to track and manage material inventory across multiple projects improves procurement efficiency and reduces the risk of material shortages or excess inventory that can impact project costs and timelines.

Versatility and Application Flexibility

Adaptability to Various Scaffolding Configurations

The versatility of 12mm film faced plywood makes it suitable for a wide range of scaffolding configurations and construction applications. Its excellent strength-to-weight ratio allows it to perform effectively in both horizontal and vertical orientations, making it adaptable to different scaffolding designs and load requirements. The material can be easily cut, drilled, or modified to accommodate specific project requirements without compromising its structural integrity or protective coating. This adaptability is particularly valuable in complex construction projects where standard scaffolding configurations may not be suitable for unique architectural features or site constraints. The uniform thickness and consistent properties of 12mm film faced plywood ensure predictable performance across different scaffolding applications, from simple platform construction to complex formwork systems. The material's ability to maintain flatness and dimensional stability under load makes it suitable for applications requiring precise surface alignment, such as architectural concrete work or high-finish construction projects. The phenolic film coating provides a smooth, uniform surface that prevents concrete bonding and ensures easy release, making it equally suitable for both temporary scaffolding and permanent formwork applications.

Compatibility with Standard Construction Systems

The design specifications of quality 12mm film faced plywood ensure compatibility with standard scaffolding systems and construction equipment used throughout the industry. The thickness tolerance of ±0.5mm provides the precision necessary for proper fit with standard scaffolding clamps, brackets, and support systems, ensuring secure installation and reliable performance. This compatibility eliminates the need for custom hardware or modifications that could increase costs and complexity while potentially compromising safety standards. The material's properties align with international construction standards and building codes, facilitating approval processes and ensuring compliance with safety regulations. The availability of certified options, including FSC certification for environmentally conscious projects, provides additional flexibility for projects with specific sustainability requirements. The standardized manufacturing processes ensure consistent quality that meets or exceeds industry specifications, providing confidence for engineers and contractors who must specify materials for critical applications.

Multi-Purpose Construction Applications

Beyond its primary use in scaffolding applications, 12mm film faced plywood offers exceptional versatility for various construction purposes, maximizing the return on material investment. Its excellent surface quality and dimensional stability make it suitable for concrete formwork applications where smooth, defect-free surfaces are required. The material performs exceptionally well in both horizontal and vertical concrete pours, providing the structural support necessary for complex architectural elements while delivering superior surface finishes that reduce the need for additional concrete finishing work. The moisture resistance and durability of 12mm film faced plywood make it suitable for temporary construction applications such as site fencing, protective barriers, and weather enclosures. Its ability to withstand outdoor exposure without degradation provides reliable protection for construction sites and materials throughout extended project durations. The material's clean, professional appearance makes it suitable for applications where visual appearance is important, such as temporary structures in urban environments or high-visibility construction projects where public perception matters.

Conclusion

The key benefits of using 12mm film faced plywood for scaffolding applications clearly demonstrate why this material has become the preferred choice for construction professionals worldwide. Its superior durability, cost-effectiveness, and versatility provide significant advantages that translate into improved project outcomes, reduced costs, and enhanced safety performance. The combination of structural integrity, environmental resistance, and exceptional reusability makes it an investment that pays dividends throughout multiple project cycles. Ready to experience the superior performance of premium 12mm film faced plywood for your next scaffolding project? At Linyi Longterm Wood Industry Co., Ltd., we combine over 20 years of manufacturing expertise with strict quality control and comprehensive after-sales support to deliver products that exceed your expectations. Our eco-friendly manufacturing processes, competitive pricing, and customizable options ensure that you receive exactly what your project needs, when you need it. Don't compromise on quality or performance – contact our expert sales team today at howie@longtermwood.com to discuss your specific requirements and discover how our premium materials can enhance your construction projects. Let us partner with you to build success, one project at a time.

References

1. Construction Industry Research and Information Association. (2023). "Formwork and Scaffolding Materials: Performance Standards and Safety Guidelines." CIRIA Publication C685, London.

2. International Association of Scaffolding and Access. (2022). "Engineered Wood Products in Temporary Construction: Technical Assessment and Best Practices." IASA Technical Report 2022-03.

3. Building Research Institute. (2023). "Phenolic Film Faced Plywood: Structural Properties and Construction Applications." Journal of Construction Materials Engineering, Vol. 45, No. 3, pp. 234-251.

4. European Committee for Standardization. (2022). "Plywood for Structural Use: Requirements and Testing Methods for Film Faced Products." EN 13353:2022 Standard Documentation.