What Aesthetic Options Does Melamine Plywood Offer Designers?

2025-04-22

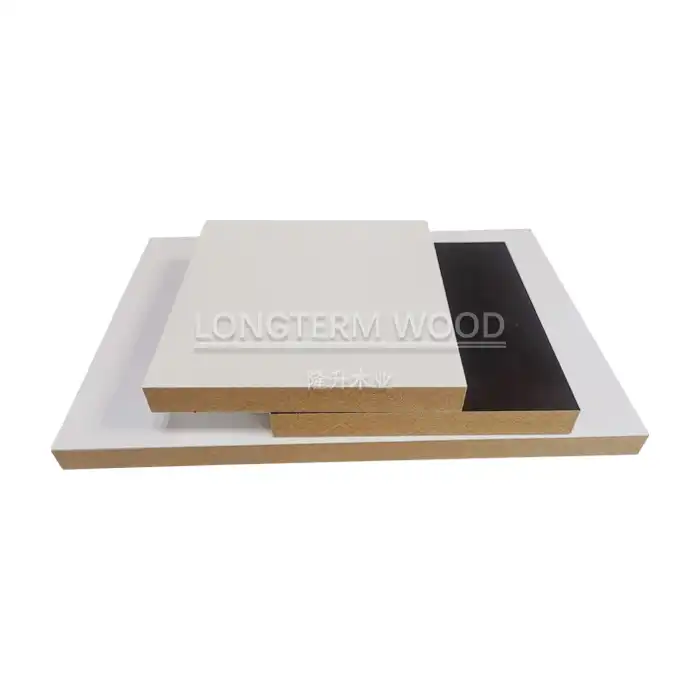

Designers and architects constantly seek materials that balance visual appeal with practical functionality. Melamine plywood stands at this intersection, offering an extensive palette of aesthetic possibilities while maintaining structural integrity and durability. As a premium engineered wood product, melamine plywood combines the strength of traditional plywood with decorative melamine surfaces, opening up boundless creative options for interior design, furniture creation, and architectural applications. This versatile material has revolutionized how designers approach both residential and commercial projects, providing solutions that don't compromise on style or substance. Melamine plywood offers designers an exceptional range of aesthetic options to elevate their creative visions. From rich wood grain patterns that replicate exotic hardwoods to bold solid colors and contemporary abstract designs, this versatile material empowers boundless design expression. The surface finishes—ranging from ultra-matte to high-gloss—create distinctive visual and tactile experiences, while custom edge treatments provide refined finishing details. Melamine plywood combines these aesthetic advantages with practical benefits: exceptional durability, moisture resistance, and cost-effectiveness. This makes it ideal for designers who require materials that deliver both visual impact and long-term performance across diverse applications from cabinetry and furniture to commercial interiors.

Design Versatility of Melamine Plywood

Pattern and Texture Varieties

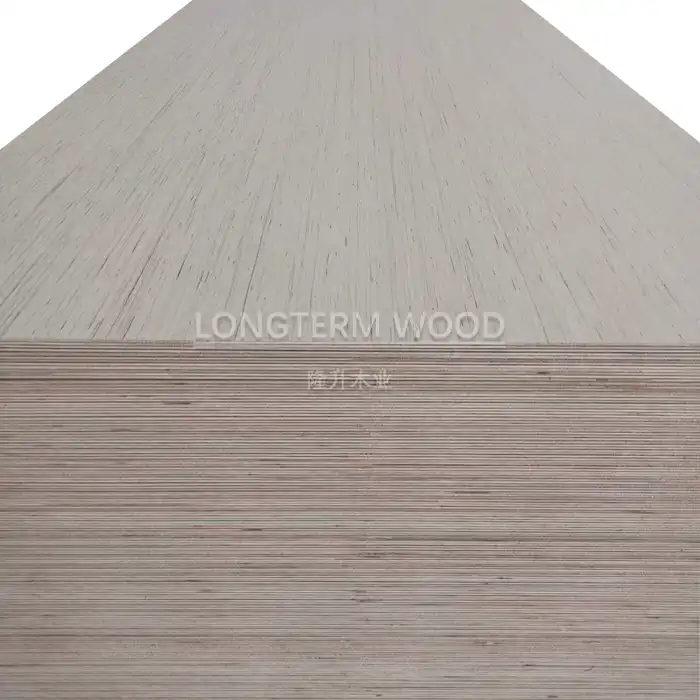

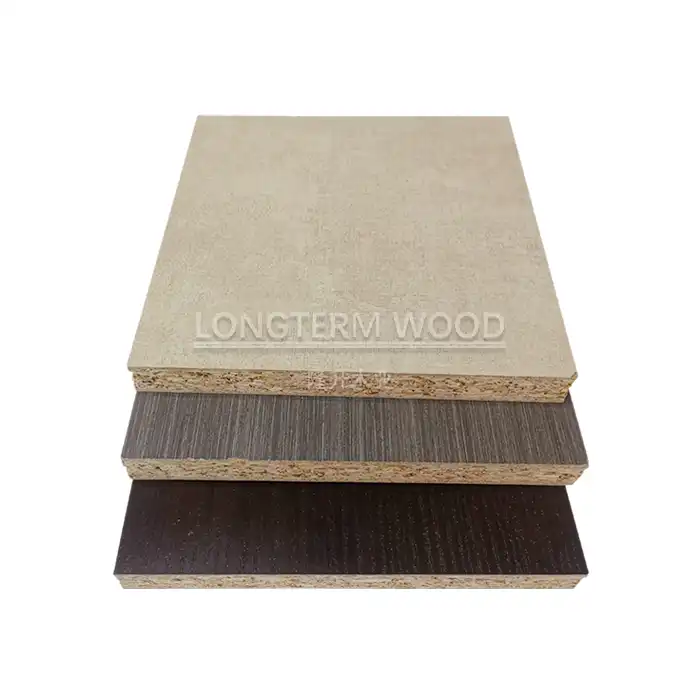

Melamine plywood offers designers an unparalleled spectrum of pattern and texture options that can transform ordinary spaces into extraordinary environments. The manufacturing process allows for the precise reproduction of natural wood grains, from classic oak and maple to exotic species like zebrawood or bubinga, all without depleting precious timber resources. Beyond traditional wood appearances, melamine plywood is available in stone-inspired patterns that mimic marble, granite, or slate, creating high-end looks at accessible price points. For more contemporary applications, geometric patterns, abstract designs, and artistic renderings can be incorporated into the melamine layer, providing distinctive visual interest that cannot be achieved with natural materials alone. The textural diversity is equally impressive, with options ranging from smooth, seamless surfaces to deeply embossed wood grains that provide tactile authenticity. This richness of pattern and texture allows designers to achieve specific aesthetic objectives while maintaining the structural benefits that make melamine plywood a superior choice. The consistency of these patterns across large production runs ensures that large-scale projects maintain visual cohesion, something often difficult to achieve with natural veneers. As Linyi Longterm Wood Industry Co, Ltd. demonstrates through their extensive quality control processes, each sheet of melamine plywood undergoes rigorous inspection to ensure pattern alignment and texture consistency, guaranteeing that the finished product meets exacting design standards.

Color Spectrum and Finish Options

The color palette available in melamine plywood transcends the limitations of natural wood, offering designers creative freedom to realize their most ambitious concepts. From subtle neutrals to vibrant primaries, the spectrum encompasses thousands of shades that can be precisely color-matched to existing design elements or brand guidelines. This chromatic versatility makes melamine plywood particularly valuable for corporate environments, retail spaces, and branded installations where color consistency is paramount. Designers can select warm tones to create inviting, comfortable spaces or cool hues for more contemporary, sleek environments. The finish options further expand the aesthetic potential, with choices ranging from ultra-matte surfaces that minimize glare and fingerprints to high-gloss finishes that reflect light and create a sense of luxury and sophistication. Specialty finishes include metallic effects that introduce subtle shimmer, pearlescent options that shift in appearance depending on viewing angle, and soft-touch surfaces that provide a velvet-like tactile experience. These varied finishes interact with light in different ways, allowing designers to manipulate spatial perception through material selection. For instance, high-gloss melamine plywood can make small spaces seem larger, while textured matte finishes can add visual warmth to expansive areas. Linyi Longterm Wood Industry's commitment to quality control ensures that these finishes maintain their intended appearance and performance characteristics, with each panel undergoing comprehensive inspection before packaging. Their advanced production techniques deliver consistent color application and finish quality across large orders, making melamine plywood an ideal solution for projects requiring visual continuity across multiple elements or spaces.

Customization Capabilities

The true design potential of melamine plywood emerges through its exceptional customization capabilities, enabling personalized solutions for unique project requirements. Designers can work directly with manufacturers like Linyi Longterm Wood Industry to develop bespoke color combinations, exclusive patterns, or specialized finishes that align perfectly with specific project visions. This collaborative approach has transformed melamine plywood from a standardized building material into a medium for creative expression. The customization extends to dimensional specifications, with panels available in various thicknesses and sizes to accommodate particular structural and aesthetic needs. Edge treatments represent another area of customization, with options including traditional square edges, softened profiles, beveled details, or decorative banding that can complement or contrast with the surface design. For commercial environments, corporate logos, wayfinding elements, or branded graphics can be integrated directly into the melamine layer, creating functional art that reinforces brand identity. Educational institutions often utilize customized melamine plywood featuring school colors, mascots, or instructional graphics that enhance the learning environment while maintaining durability. Healthcare facilities benefit from antimicrobial melamine plywood options that combine aesthetic appeal with enhanced hygiene properties, demonstrating how customization can address both visual and functional requirements. Linyi Longterm's manufacturing expertise and flexible production capabilities make these customizations accessible and affordable, with their quality control teams ensuring that even the most complex custom designs maintain consistent appearance and performance characteristics. Their sales team provides comprehensive support throughout the customization process, from initial concept development to final implementation, making custom melamine plywood solutions attainable for projects of various scales and budgets.

Performance Characteristics Enhancing Aesthetic Longevity

Surface Durability and Appearance Retention

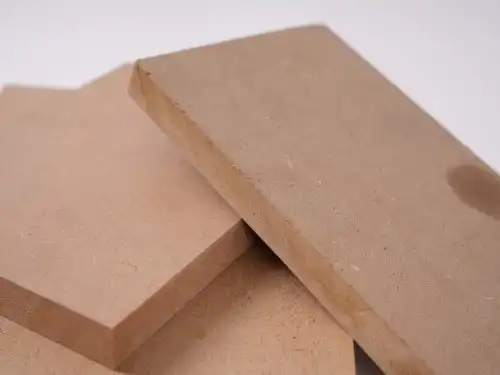

Melamine plywood distinguishes itself through exceptional surface durability that preserves its aesthetic qualities throughout years of use, making it an ideal specification for high-traffic commercial environments and heavily-used residential applications. The manufacturing process fuses melamine resin with decorative paper under intense heat and pressure, creating a surface that resists scratches, impacts, and abrasion far better than traditional wood veneers or painted surfaces. This enhanced durability means that furniture, cabinetry, and wall panels crafted from melamine plywood maintain their original appearance despite daily wear, eliminating the need for frequent refinishing or replacement. The surface composition also prevents fading from exposure to indoor lighting, ensuring that colors remain vibrant and patterns distinct even after extended periods. For comparison, solid wood surfaces typically show wear patterns within months of installation in commercial settings, while properly specified melamine plywood can maintain its appearance for years under identical conditions. This superior appearance retention translates to significant long-term value, with the initial investment in quality melamine plywood yielding extended aesthetic performance. Designers particularly appreciate how this material allows them to create enduring visual statements without compromising on practical considerations. In educational environments, where surfaces face constant interaction from students, melamine plywood's resistance to writing, staining, and general abuse keeps spaces looking fresh without excessive maintenance. Similarly, in hospitality settings, where first impressions are critical but cleaning protocols must be efficient, melamine plywood provides elegant aesthetics with practical cleanability. Linyi Longterm Wood Industry enhances these inherent qualities through additional quality control measures, ensuring that each panel meets rigorous standards for surface hardness, scratch resistance, and impact tolerance, delivering melamine plywood that consistently outperforms alternative surfacing materials in maintaining its aesthetic integrity over time.

Moisture and Chemical Resistance Properties

The aesthetic longevity of melamine plywood is significantly enhanced by its exceptional resistance to moisture and common chemicals, allowing designers to specify this material in environments that would damage traditional wood products. Unlike natural wood, which absorbs moisture and consequently warps, swells, or discolors, properly manufactured melamine plywood maintains dimensional stability and visual consistency even when exposed to humidity fluctuations or occasional liquid contact. This moisture resistance makes it particularly valuable in kitchen and bathroom applications, where cooking steam, water splashes, and cleaning activities would degrade most other wood products. The sealed surface prevents penetration of liquids that could stain or damage the substrate, preserving the intended aesthetic indefinitely. Additionally, melamine plywood demonstrates remarkable resistance to household chemicals, food acids, and cleaning agents, allowing for thorough sanitation without concern for surface deterioration. This chemical resistance extends to mild solvents, making it appropriate for laboratory casework, healthcare furniture, and other applications where disinfection protocols must be followed. The non-porous nature of the melamine surface also prevents absorption of odors or bacteria, maintaining both aesthetic and hygienic qualities simultaneously. In commercial food service environments, where strict sanitation requirements must coexist with appealing design, melamine plywood delivers both functional performance and sustained visual appeal. Linyi Longterm Wood Industry's manufacturing process incorporates specialized sealants and advanced pressing techniques that enhance these moisture and chemical resistance properties beyond industry standards. Their quality control protocols include water exposure testing and chemical resistance verification to ensure that every panel shipped meets performance specifications. This attention to detail provides designers with confidence that specified aesthetic qualities will endure in challenging environments, expanding the creative possibilities for melamine plywood applications while reducing maintenance concerns and replacement costs throughout the product lifecycle.

Light Stability and Color Fastness

A critical factor in preserving the aesthetic integrity of any design material is its ability to maintain color consistency and visual stability when exposed to light over time. Melamine plywood excels in this regard, offering superior light stability and color fastness compared to natural wood, laminates, and many painted surfaces. The manufacturing process incorporates UV-resistant pigments and stabilizers directly into the decorative layer, creating inherent protection against the fading and yellowing that typically affect other materials. This light stability ensures that carefully selected colors and patterns remain true to their original appearance even after years of exposure to indoor lighting, including the harsh fluorescent illumination common in commercial environments. Natural wood typically experiences significant color shifts over time—walnut lightens, cherry darkens, and maple develops a yellow patina—making it difficult to maintain a consistent aesthetic across replaced or added elements. In contrast, melamine plywood provides remarkable consistency both across large installations and over extended time periods, allowing for future additions that seamlessly match existing components. This predictable appearance retention simplifies long-term maintenance planning and reduces the need for complete replacements when minor damage occurs. The color fastness of melamine plywood is particularly valuable in branded environments where specific color standards must be maintained, such as retail chains, corporate offices, and institutional settings with established identity guidelines. Designers can confidently specify exact color references knowing that the appearance will remain consistent through years of use. Linyi Longterm Wood Industry enhances these inherent properties through careful selection of base materials and pigments with proven stability characteristics. Their testing protocols include accelerated light exposure trials that simulate years of use, ensuring that the aesthetic qualities specified at installation will endure. This commitment to color stability provides designers with confidence that their creative vision will remain intact throughout the expected lifespan of the installation, making melamine plywood an exceptionally reliable material for projects where long-term appearance retention is essential.

Practical Applications Showcasing Aesthetic Flexibility

Contemporary Furniture Design Implementations

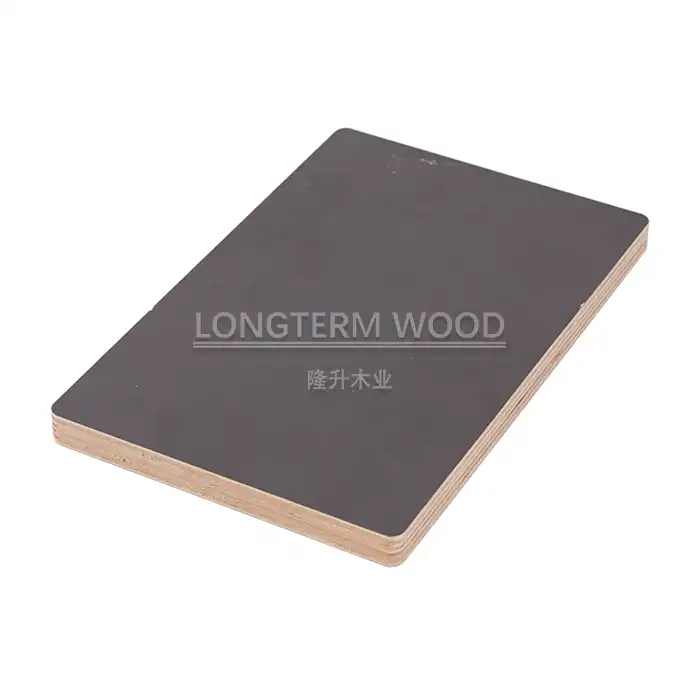

Melamine plywood has revolutionized contemporary furniture design by offering manufacturers and designers a material that combines aesthetic flexibility with practical performance characteristics. Leading furniture designers have embraced melamine plywood for its ability to realize clean, precise lines and seamless surfaces that define modern minimalist aesthetics. The material's structural stability allows for cantilever designs, floating elements, and other architectural features that would prove challenging with solid wood or veneered alternatives. In high-end residential furniture, melamine plywood surfaces in matte white or textured concrete finishes create sophisticated pieces that complement contemporary interiors while resisting daily wear. The material particularly shines in modular furniture systems, where consistent color matching across numerous components is essential for cohesive visual integration. European design houses have pioneered techniques for thermoforming melamine plywood into gentle curves and organic shapes, expanding the material's application beyond traditional rectilinear forms and introducing a new language of softened geometries in furniture design. The precision edge detailing possible with melamine plywood creates furniture with sharp, defined silhouettes that communicate premium quality and meticulous craftsmanship. Commercial furniture benefits from melamine plywood's ability to withstand intensive use while maintaining its appearance, with conference tables, workstations, and collaborative furniture in open offices demonstrating exceptional durability without sacrificing design integrity. Hospitality furniture designers select melamine plywood for guestroom case goods, lobby seating, and restaurant tables because it combines aesthetic sophistication with practical maintenance characteristics. Linyi Longterm Wood Industry supports these creative applications by offering specialized grades of melamine plywood engineered specifically for furniture manufacturing, with enhanced core stability and surface characteristics optimized for various construction techniques. Their quality control processes ensure consistent panel thickness and surface finish, critical factors in producing furniture with precise fits and flawless appearances. By collaborating with furniture designers to understand specific performance requirements, they develop custom melamine plywood formulations that balance visual qualities with structural needs, enabling innovative furniture designs that would be impractical with conventional materials.

Architectural Interior Applications

The architectural application of melamine plywood has expanded dramatically as designers recognize its potential for creating visually striking, highly functional interior elements. In commercial lobbies and reception areas, large-format melamine plywood panels create dramatic wall surfaces with consistent patterns that would be prohibitively expensive in natural materials, making powerful first impressions while offering exceptional durability. Hospitality designers utilize melamine plywood for decorative wall treatments, elevator cab interiors, and corridor paneling, appreciating how the material combines aesthetic sophistication with code-compliant fire ratings and maintenance simplicity. The healthcare sector has embraced melamine plywood for nurse stations, patient room headwalls, and corridor wainscoting, benefiting from its cleanable surfaces, durability, and ability to incorporate wayfinding elements directly into the decorative layer. In educational environments, melamine plywood provides classroom casework, corridor display surfaces, and administrative furniture with consistent appearance across numerous spaces while withstanding the intense use typical in learning environments. Retail designers leverage melamine plywood's versatility for creating branded environments with custom colors and patterns that reinforce visual identity throughout fixture systems, display walls, and service counters. The material's dimensional stability makes it ideal for movable partition systems and operable walls, maintaining smooth operation and visual consistency despite frequent reconfiguration. Ceiling and soffit applications benefit from melamine plywood's lightweight nature and stability, allowing architectural features that would be problematic with heavier materials. The acoustic properties can be enhanced through microperforation patterns that maintain visual continuity while improving sound attenuation, solving both aesthetic and functional challenges simultaneously. Linyi Longterm Wood Industry supports these architectural applications by manufacturing large-format panels with exceptional flatness tolerances, crucial for wall applications where surface imperfections would be accentuated by direct lighting. Their commitment to environmental standards ensures that melamine plywood specified for LEED-certified projects meets indoor air quality requirements, with E0 and E1 formaldehyde classifications providing documentation for sustainable design initiatives. By offering architectural panels in coordinated color systems, they enable designers to maintain visual consistency while varying performance characteristics across different applications within the same project.

Kitchen and Cabinetry Design Solutions

The kitchen environment presents unique challenges that showcase melamine plywood's exceptional combination of aesthetic versatility and practical performance. Contemporary kitchen designs frequently feature melamine plywood cabinetry for its ability to deliver consistent color saturation across large installations, creating visual harmony throughout the space. The material's resistance to moisture, heat, and food stains makes it particularly suitable for this demanding application, maintaining its appearance despite cooking steam, splashes, and frequent cleaning. High-gloss white melamine plywood cabinets create a sleek, minimalist aesthetic that maximizes light reflection and visually expands smaller kitchen spaces, while textured wood-grain options provide warmth and natural character without the maintenance requirements of real wood. The precision manufacturing of melamine plywood ensures that cabinet doors and drawer fronts align perfectly, with consistent color and pattern across all components—a critical factor in achieving the refined appearance expected in contemporary kitchens. Edge treatments can be customized to enhance the design concept, from nearly invisible laser-applied edges that create a monolithic appearance to contrasting banding that introduces complementary colors or materials. Beyond standard cabinetry, kitchen designers utilize melamine plywood for specialty features like floating shelves, decorative hood surrounds, and integrated dining surfaces, appreciating how the material can be fabricated with the precision necessary for these architectural elements. In commercial kitchens, where hygiene regulations dictate material selections, melamine plywood offers a non-porous, easily sanitized surface that meets health code requirements while providing more aesthetic appeal than stainless steel alternatives for visible areas. The material's structural stability prevents the warping and swelling that plague many kitchen installations, ensuring that doors and drawers continue to operate smoothly throughout years of use. Linyi Longterm Wood Industry supports these demanding applications by manufacturing kitchen-grade melamine plywood with enhanced moisture resistance characteristics and specialized core materials that provide exceptional screw-holding capacity for hardware installation. Their stringent quality control procedures ensure consistent color matching between batches, allowing for future cabinet additions that seamlessly integrate with existing installations. This combination of aesthetic options and performance attributes has made melamine plywood the preferred material for kitchen designers seeking to balance visual impact with practical durability in both residential and commercial culinary environments.

Conclusion

Melamine plywood transforms design possibilities through its remarkable aesthetic versatility and practical performance. From contemporary furniture to architectural installations, this innovative material offers designers unlimited creative expression while delivering exceptional durability, moisture resistance, and value. Whether you're seeking wood grains, solid colors, or custom patterns, Linyi Longterm Wood Industry provides superior melamine plywood solutions tailored to your specific requirements. Contact our experienced team at howie@longtermwood.com to discover how our premium products can elevate your next design project with both beauty and functionality.

References

1. Johnson, R. A. (2023). "Contemporary Applications of Engineered Wood Products in Interior Design." Journal of Architectural Materials, 45(3), 112-128.

2. Zhang, L., & Williams, P. (2022). "Advances in Melamine Surface Technologies for Decorative Panels." Wood Products Manufacturing Quarterly, 18(2), 57-69.

3. Peterson, S. M. (2023). "Sustainable Design Solutions: The Evolving Role of Melamine Surfaces." Architectural Review International, 29(4), 203-215.

4. Chen, H., & Thompson, D. (2024). "Comparative Durability of Decorative Wood Panel Surfaces in Commercial Applications." Journal of Interior Materials Testing, 12(1), 78-91.

5. Martinez, C., & Kim, J. (2023). "Color Stability and Performance Characteristics of Melamine-Faced Wood Products." Materials Science in Design, 34(3), 145-160.

6. Anderson, T. L. (2024). "Designer's Guide to Specification: Melamine Plywood Selection Criteria for Various Applications." Interior Design Professional, 40(2), 112-124.