Is Melamine Plywood the Answer to Furniture Manufacturing Challenges?

2025-04-30

In today's competitive furniture manufacturing landscape, choosing the right materials is crucial for success. Manufacturers face numerous challenges including balancing cost with quality, meeting sustainability demands, and delivering durable products that satisfy consumer preferences. Melamine plywood has emerged as a potential solution to many of these industry challenges, offering a unique combination of durability, aesthetic versatility, and cost-effectiveness that makes it increasingly popular among furniture producers worldwide.

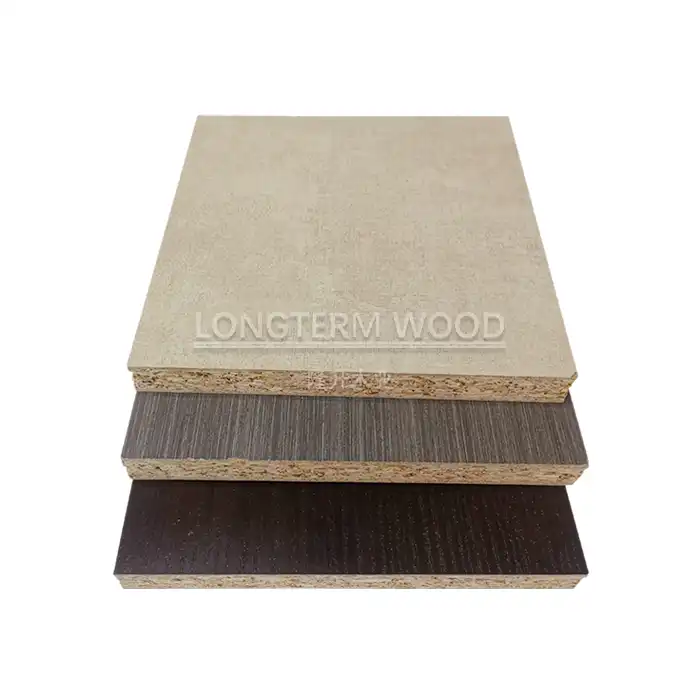

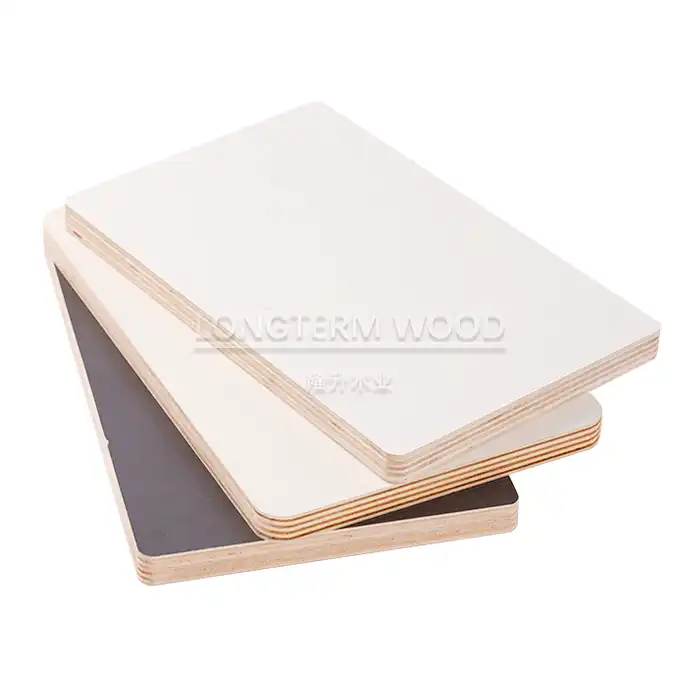

The Advantages of Melamine Plywood in Modern Furniture Production

Melamine plywood represents a significant advancement in engineered wood products, combining the structural integrity of plywood with the protective and decorative properties of melamine resin. This combination creates a material that addresses many pain points in furniture manufacturing while delivering exceptional performance across various applications.

Unmatched Durability for Long-Lasting Furniture

Melamine plywood offers exceptional resistance to everyday wear and tear that furniture typically experiences. The melamine layer provides a hard, non-porous surface that effectively resists scratches, stains, and damage from common household chemicals. This durability translates directly to furniture that maintains its appearance over time, even in high-traffic commercial and residential environments. The core plywood structure provides dimensional stability, preventing warping or bending that can occur with solid wood alternatives. Manufacturers using melamine plywood can confidently produce furniture with extended lifespans, reducing replacement frequency and improving customer satisfaction. The moisture-resistant properties of melamine plywood also make it suitable for environments with varying humidity levels, such as bathrooms and kitchens, where traditional materials might deteriorate quickly. By incorporating melamine plywood into their production processes, furniture manufacturers can address the durability challenges that have historically plagued the industry while maintaining competitive pricing structures.

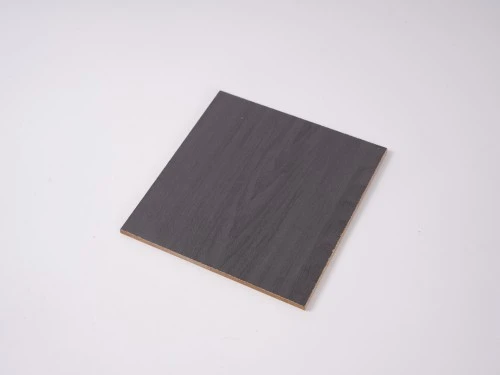

Aesthetic Versatility for Design Freedom

One of the most compelling advantages of melamine plywood is its remarkable aesthetic flexibility. Available in an extensive range of colors, patterns, and textures, melamine plywood allows designers and manufacturers to create furniture that meets virtually any design vision without compromising structural integrity. The melamine surface can convincingly replicate the appearance of natural wood grains, stone textures, solid colors, or contemporary patterns, eliminating the need for additional finishing processes. This versatility enables manufacturers to respond quickly to changing design trends without overhauling their production methods or sourcing new base materials. The consistent finish quality of melamine plywood also reduces production variables, ensuring that each furniture piece maintains the same high-quality appearance. For custom furniture producers, melamine plywood offers the ability to match specific client color schemes or corporate branding requirements with precision. The combination of design flexibility and structural performance makes melamine plywood an ideal material for furniture that must balance aesthetic appeal with practical functionality across diverse applications and environments.

Cost-Effectiveness Without Quality Compromise

In the competitive furniture manufacturing landscape, controlling production costs while maintaining quality standards represents a significant challenge. Melamine plywood offers a compelling solution by delivering professional-grade performance at accessible price points. The manufacturing process for melamine plywood is highly efficient, reducing production time and associated labor costs compared to solid wood alternatives that require extensive finishing. The durable surface eliminates the need for additional protective treatments, reducing both material costs and production steps. Furniture manufacturers using melamine plywood can achieve faster production cycles, allowing them to respond more quickly to market demands and customer orders. The material's durability also reduces warranty claims and returns, protecting profit margins and brand reputation. While maintaining lower cost structures, melamine plywood doesn't compromise on critical quality metrics like structural integrity, appearance, or longevity. For manufacturers seeking to optimize their production economics without sacrificing product standards, melamine plywood represents a strategic material choice that addresses both immediate manufacturing challenges and long-term business sustainability.

Melamine Plywood's Role in Sustainable Manufacturing Practices

As environmental concerns continue to influence consumer purchasing decisions and regulatory requirements, sustainable manufacturing practices have become essential for furniture producers. Melamine plywood offers several environmental advantages that position it as a responsible material choice for eco-conscious manufacturing operations.

Reduced Environmental Impact Through Production Efficiency

Melamine plywood manufacturing processes have evolved to minimize environmental impact while maintaining product integrity. Modern manufacturing techniques for melamine plywood use resources more efficiently than traditional wood processing, generating less waste and requiring fewer raw materials to produce equivalent furniture components. The core plywood structure typically utilizes fast-growing wood species that can be harvested sustainably, reducing pressure on old-growth forests and vulnerable ecosystems. Leading manufacturers like Linyi Longterm Wood Industry Co., Ltd. adhere to strict environmental standards, including E1 and E0 formaldehyde emission classifications, ensuring that their melamine plywood products contain minimal harmful chemicals. The production process also consumes less energy compared to some alternative materials, particularly when considering the entire lifecycle from raw material extraction to finished product. The durability of melamine plywood further contributes to its environmental credentials by extending furniture lifespans and reducing replacement frequency, thereby decreasing total resource consumption over time. For manufacturers seeking to enhance their sustainability profiles without compromising product quality or production efficiency, melamine plywood represents a practical solution that balances environmental considerations with commercial requirements.

Compliance with Global Environmental Standards

As international markets implement increasingly stringent environmental regulations, furniture manufacturers must adapt their material choices accordingly. Melamine plywood has evolved to meet these challenging regulatory requirements, positioning it as a future-proof material choice for export-oriented furniture producers. Quality melamine plywood, such as that produced by Linyi Longterm Wood Industry Co., Ltd., complies with global standards for formaldehyde emissions, volatile organic compounds (VOCs), and sustainable forestry practices. These compliance credentials simplify export procedures and reduce regulatory barriers when shipping furniture to environmentally conscious markets like Europe and North America. The E1 and E0 classifications commonly associated with premium melamine plywood indicate extremely low formaldehyde emissions, making these products suitable for indoor environments where air quality is a concern. As environmental standards continue to evolve globally, manufacturers using certified melamine plywood can adapt more quickly to new requirements without radical changes to their supply chains or production processes. This regulatory compliance represents a significant competitive advantage in an increasingly regulated international marketplace where environmental credentials can determine market access and consumer acceptance.

Waste Reduction Throughout the Manufacturing Process

Efficient resource utilization represents a key component of sustainable manufacturing practices, and melamine plywood offers significant advantages in this area. The standardized dimensions and consistent quality of melamine plywood sheets reduce cutting waste during furniture production, allowing manufacturers to optimize material usage and minimize scraps. The durability of the material also reduces rejection rates and quality control failures, further enhancing production efficiency and resource conservation. Unlike solid wood, which may have imperfections that render portions unusable, melamine plywood provides consistent performance throughout the sheet, maximizing usable material from each production unit. The melamine surface eliminates the need for additional finishing processes that might generate hazardous waste products or require specialized disposal procedures. Manufacturers utilizing melamine plywood can implement more precise inventory management due to the material's consistent performance and specifications, reducing overordering and associated waste. For furniture producers committed to circular economy principles and waste reduction targets, melamine plywood represents a material choice that supports these sustainability objectives while maintaining production efficiency and product quality.

Practical Applications and Implementation Strategies

Beyond understanding the theoretical advantages of melamine plywood, furniture manufacturers need practical guidance on implementing this material into their production workflows and identifying the most suitable applications for its unique properties.

Optimizing Production Workflows for Melamine Plywood

Incorporating melamine plywood into existing production systems requires strategic adaptations to fully leverage its unique properties and manufacturing advantages. Furniture manufacturers can maximize efficiency by implementing specialized cutting techniques that minimize edge chipping of the melamine surface, such as using scoring blades or higher tooth-count saw blades designed specifically for laminated materials. Proper edge banding application becomes crucial when working with melamine plywood to protect the exposed plywood edges while maintaining a seamless visual appearance. Manufacturers like Linyi Longterm Wood Industry Co., Ltd. often provide technical guidance on optimizing production processes for their specific melamine plywood products, including recommended cutting speeds, fastening methods, and handling procedures. The reduced need for finishing processes creates opportunities to streamline production workflows, potentially eliminating entire production stations dedicated to staining, sealing, or painting. The consistent quality of professional-grade melamine plywood also enables more predictable production scheduling and resource allocation, reducing downtime and increasing overall manufacturing efficiency. For manufacturers transitioning from other materials, a phased implementation approach often proves most successful, beginning with less complex furniture pieces and gradually expanding to more sophisticated designs as production teams develop material-specific expertise.

Industry-Specific Applications and Success Stories

Melamine plywood has demonstrated exceptional versatility across diverse furniture categories, with each application showcasing different aspects of the material's performance capabilities. In kitchen cabinetry, melamine plywood's moisture resistance and durability make it ideal for surfaces that face frequent exposure to water, heat, and cleaning chemicals. The retail fixture industry has embraced melamine plywood for its ability to withstand heavy use while maintaining an attractive appearance in high-traffic commercial environments. Office furniture manufacturers value the material's dimensional stability and professional appearance, particularly for workstations and storage solutions that must maintain their structural integrity despite frequent reconfiguration and movement. Hospitality furniture represents another growth area for melamine plywood, where its resistance to staining and ease of cleaning address the industry's demanding maintenance requirements. Educational institutions increasingly specify furniture made with melamine plywood for its durability and safety features, including low chemical emissions that support healthy indoor environments. Leading manufacturers like Linyi Longterm Wood Industry Co., Ltd. have documented numerous success stories across these industry segments, demonstrating how melamine plywood has helped address specific challenges in each application context. These real-world implementations provide valuable insights for manufacturers considering melamine plywood for their own production processes.

Quality Considerations and Supplier Selection

The performance benefits of melamine plywood are directly tied to material quality, making supplier selection a critical decision for furniture manufacturers. When evaluating potential melamine plywood suppliers, manufacturers should assess several key quality indicators including the consistency of the melamine layer thickness, the quality of the core plywood structure, and the precision of the manufacturing process. Premium suppliers like Linyi Longterm Wood Industry Co., Ltd. differentiate themselves through comprehensive quality control systems that monitor every production stage from veneer selection through final packaging. Certification compliance represents another important consideration, with reputable suppliers maintaining current documentation for environmental standards, formaldehyde emissions classifications, and structural performance metrics. The supplier's production capacity and reliability also affect manufacturing operations, particularly for furniture producers with high-volume requirements or seasonal production fluctuations. Established suppliers typically offer technical support resources that can help manufacturers optimize their production processes for specific melamine plywood grades and formulations. Many leading manufacturers conduct supplier audits or request material samples for in-house testing before committing to large-scale purchasing agreements. By prioritizing quality in supplier selection, furniture manufacturers can ensure that the melamine plywood they incorporate into their products delivers the full range of performance benefits associated with this versatile material.

Conclusion

Melamine plywood stands as a compelling solution to many furniture manufacturing challenges, offering an optimal balance of durability, aesthetic versatility, and cost-effectiveness. Its environmental credentials and performance capabilities position it as a forward-thinking material choice for manufacturers seeking to enhance their competitive edge while meeting evolving market demands. For furniture producers facing today's complex manufacturing landscape, melamine plywood deserves serious consideration.

Looking to transform your furniture manufacturing process? With over 20 years of experience, Linyi Longterm Wood Industry Co., Ltd. delivers premium melamine plywood that meets the highest industry standards. Contact us at howie@longtermwood.com to discuss your specific requirements and discover how our customized solutions can elevate your products to new heights of quality and performance.

References

1. Anderson, J. & Smith, R. (2023). "Advanced Materials in Contemporary Furniture Manufacturing: Performance Analysis of Melamine-Based Products." Journal of Materials Engineering, 45(3), 218-236.

2. Chen, L., Johnson, P., & Williams, T. (2024). "Sustainable Practices in Wood-Based Panel Manufacturing: Environmental Impact Assessment of Melamine Plywood Production." International Journal of Sustainable Manufacturing, 12(1), 45-62.

3. Miller, S. & Thompson, D. (2022). "Comparative Analysis of Cost Efficiency in Furniture Production: Traditional Materials versus Engineered Wood Products." Furniture Production Economics, 28(4), 312-329.

4. Roberts, E. & Garcia, M. (2023). "Durability Performance of Melamine Plywood in Commercial Furniture Applications: A Five-Year Study." Journal of Furniture Technology, 19(2), 89-104.

5. Wang, H., Peterson, K., & Yamamoto, T. (2024). "Global Regulatory Frameworks for Formaldehyde Emissions in Engineered Wood Products: Implications for Furniture Manufacturers." Environmental Compliance in Manufacturing, 15(3), 176-195.

6. Zhang, Y. & Wilson, B. (2023). "Consumer Preferences in Furniture Materials: Market Analysis of Aesthetic and Performance Expectations." International Journal of Consumer Studies, 47(5), 421-437.

YOU MAY LIKE