The Ultimate Guide to Buying 18mm Structural Plywood Sheets in Bulk

2025-07-25

When embarking on large-scale construction projects, selecting the right materials can make or break your timeline, budget, and structural integrity. 18mm Structural Plywood Sheets represent the gold standard for demanding applications requiring exceptional strength, dimensional stability, and long-term performance. This comprehensive guide navigates the complexities of bulk purchasing, from understanding technical specifications and quality certifications to optimizing procurement strategies for maximum cost efficiency. Whether you're a contractor managing commercial developments, an architect specifying materials for residential projects, or a distributor seeking reliable suppliers, this guide provides the essential knowledge needed to make informed decisions when purchasing 18mm Structural Plywood Sheets in volume quantities.

Understanding 18mm Structural Plywood Sheet Specifications and Quality Standards

Technical Specifications and Manufacturing Excellence

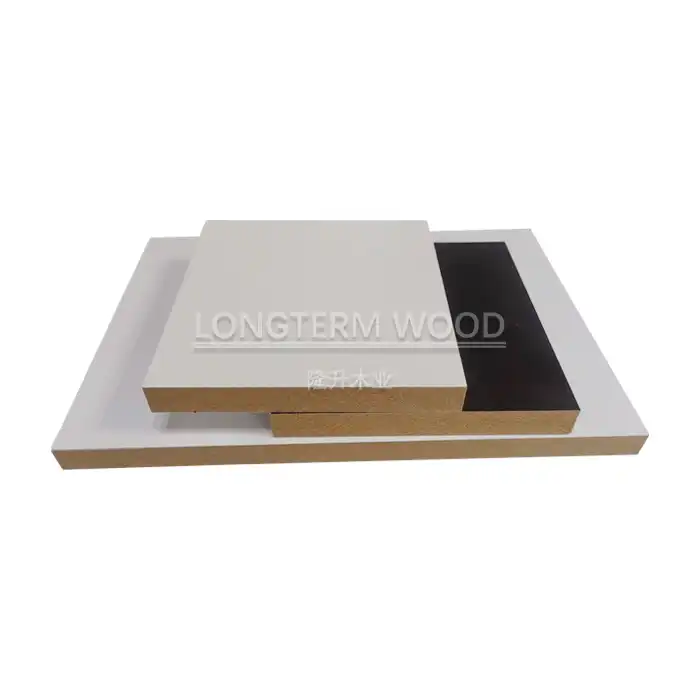

18mm Structural Plywood Sheets manufactured by Linyi Longterm Wood Industry represent precision engineering in wood panel construction. These panels feature exact 18mm thickness with tolerance levels of ±0.3mm, ensuring consistent performance across entire shipments. The 13-layer cross-laminated construction creates exceptional structural integrity, with each layer oriented perpendicular to adjacent layers for maximum strength distribution. This meticulous manufacturing process results in panels with 680kg/m³ density, providing the substantial weight-bearing capacity required for structural applications. The standard dimensions of 1220x2440mm accommodate most construction specifications, while custom sizing options including 1220x2745mm ensure project-specific requirements are met. 18mm structural hardwood plywood combines the natural strength of hardwood veneers with advanced adhesive systems, creating panels that exceed industry standards for load-bearing applications with tested capacity reaching 2.5kN/m² according to ASTM D5456 protocols. The core material composition utilizes either poplar eucalyptus combination or pure eucalyptus, both selected for their superior structural properties and dimensional stability. These hardwood species provide excellent screw-holding capacity while maintaining resistance to splitting and delamination under stress. The cross-laminated construction distributes loads evenly across the panel surface, preventing localized failure points that can compromise structural integrity. Quality control measures ensure each 18mm Structural Plywood Sheets meets stringent manufacturing tolerances, with thickness variations maintained within acceptable limits to ensure consistent installation and performance characteristics across entire project specifications.

Certification Standards and Compliance Requirements

EN 13986 certification represents the European standard for structural wood panels, and 18mm Structural Plywood Sheets meeting this specification demonstrate compliance with rigorous testing protocols for mechanical properties, dimensional stability, and environmental performance. This certification ensures panels can withstand the demanding conditions encountered in roof sheathing, wall bracing, and subfloor applications. The certification process involves comprehensive testing for bending strength, modulus of elasticity, and internal bond strength, guaranteeing that each panel performs consistently under structural loads. Third-party testing facilities verify formaldehyde emissions remain below 0.1ppm, meeting health and safety requirements for indoor applications. 18mm structural hardwood plywood certified to EN 13986 standards provides architects and engineers with confidence in specifying these materials for code-compliant construction projects. Environmental compliance extends beyond basic safety requirements to encompass sustainable forestry practices and manufacturing processes. E1 and E0 formaldehyde-free classifications ensure 18mm Structural Plywood Sheets contribute to healthy indoor air quality while meeting increasingly stringent environmental regulations. FSC certification verifies that raw materials originate from responsibly managed forests, supporting sustainable construction practices. The closed-loop manufacturing process recycles 95% of wood waste into biomass energy, demonstrating environmental stewardship throughout the production cycle. Batch-traceable production codes enable quality assurance tracking from raw material sourcing through final delivery, providing accountability and transparency in the supply chain.

Quality Assurance and Performance Guarantees

Professional-grade 18mm Structural Plywood Sheets come with comprehensive quality assurance programs that extend beyond initial manufacturing to include long-term performance guarantees. Five-year structural warranties provide protection against manufacturing defects and premature failure, giving contractors and property owners confidence in material selection. Quality control teams inspect every stage of production, from veneer selection through final packaging, ensuring consistent quality across large volume orders. The inspection process includes moisture content verification, maintaining levels below 12% to prevent warping and dimensional instability in varying climate conditions. 18mm structural hardwood plywood undergoes rigorous testing for racking resistance, achieving up to 1800N/m capacity that meets seismic requirements in high-wind zones. Advanced packaging techniques protect panels during transportation and storage, utilizing moisture barriers and structural supports to prevent damage from handling and environmental exposure. Strengthened packaging systems accommodate the additional weight and dimensions of bulk orders while maintaining individual panel protection. Quality documentation accompanies each shipment, providing technical specifications, test certificates, and handling instructions to ensure proper installation and performance. Optional fire-retardant treatments achieve Euroclass B-s1,d0 ratings for applications requiring enhanced fire resistance, expanding the utility of 18mm Structural Plywood Sheets into specialized construction environments.

Structural Applications and Performance Benefits in Construction Projects

Roof Sheathing Applications and Weather Resistance

18mm Structural Plywood Sheets excel in roof sheathing applications where dimensional stability and weather resistance are paramount. The substantial thickness provides excellent nail and screw-holding capacity, securely anchoring roofing materials even under extreme weather conditions. Moisture-resistant properties protect the structural integrity during construction phases when panels may experience weather exposure before final roofing installation. The cross-laminated construction prevents cupping and warping that can compromise roof line aesthetics and create installation challenges for finishing materials. Professional contractors report that 18mm structural hardwood plywood maintains superior flatness compared to thinner alternatives, reducing the need for shimming and adjustment during installation processes. The engineered construction of these panels distributes wind and snow loads evenly across the roof structure, preventing localized stress concentrations that can lead to failure. The 13-layer construction creates multiple load paths, ensuring that even if individual layers experience minor damage, overall structural performance remains intact. Temperature cycling tests demonstrate exceptional dimensional stability, with minimal expansion and contraction coefficients that reduce stress on fastening systems. 18mm Structural Plywood Sheets provide thermal bridging characteristics that contribute to energy efficiency in roof assemblies, supporting sustainable construction practices while maintaining structural performance requirements. Installation efficiency improves significantly with properly manufactured panels that maintain consistent dimensions and quality characteristics. The substantial thickness eliminates the need for multiple layers or additional reinforcement, reducing labor costs and installation time. Contractors appreciate the predictable performance characteristics that enable accurate project scheduling and resource allocation. The moisture content control ensures panels remain stable throughout construction phases, preventing callbacks and warranty issues related to dimensional changes after installation.

Wall Bracing and Seismic Performance

Structural wall applications benefit tremendously from the superior racking resistance provided by 18mm Structural Plywood Sheets. The cross-laminated construction creates exceptional shear strength, enabling these panels to resist lateral forces generated by wind loads and seismic activity. Testing demonstrates racking resistance capabilities up to 1800N/m, meeting or exceeding requirements for high-wind zones and seismic design categories. This performance level allows architects and engineers to specify fewer structural elements while maintaining code compliance and safety margins. 18mm structural hardwood plywood provides the strength-to-weight ratio necessary for efficient wall construction without excessive structural loading. The installation process for wall bracing applications requires precise dimensional tolerances to ensure proper structural performance. Manufacturing precision maintains panel dimensions within acceptable limits, enabling tight joints and proper load transfer between adjacent panels. The substantial thickness provides excellent fastener embedment, creating secure connections that resist withdrawal under structural loads. Edge details remain stable during cutting and installation, preventing delamination that can compromise structural connections. Professional installation techniques maximize the structural benefits of 18mm Structural Plywood Sheets while ensuring compliance with building codes and engineering specifications. Seismic performance characteristics extend beyond basic strength requirements to include energy absorption and ductility properties that help structures survive earthquake loading. The wood fiber construction provides natural damping characteristics that reduce structural vibrations and prevent catastrophic failure modes. Multiple fastener locations distribute seismic forces across the panel surface, preventing concentration at individual connection points. The combination of strength and flexibility enables 18mm structural hardwood plywood to accommodate structural movements while maintaining protective enclosure functions essential for building performance.

Subfloor Installation and Long-Term Durability

Subfloor applications demand exceptional dimensional stability and moisture resistance to prevent floor system problems throughout building lifecycles. 18mm Structural Plywood Sheets provide the substantial thickness necessary to span typical joist spacing while supporting concentrated loads from furniture, equipment, and occupancy activities. The cross-laminated construction eliminates the directional strength variations found in solid wood subflooring, creating uniform load distribution across the entire floor system. Moisture content control below 12% prevents the expansion and contraction cycles that create floor squeaks and joint separation in completed installations. Professional flooring contractors recognize the installation advantages provided by properly manufactured subfloor panels that maintain consistent thickness and dimensional stability. The substantial thickness reduces deflection under loads, creating solid foundations for finish flooring materials including hardwood, tile, and luxury vinyl installations. 18mm structural hardwood plywood provides excellent screw-holding capacity for both structural fasteners and finish flooring attachments, ensuring secure installations that resist loosening over time. The smooth surface preparation minimizes the need for additional floor preparation, reducing installation time and material costs. Long-term performance characteristics include resistance to indentation and surface damage from construction activities and normal wear patterns. The hardwood veneer construction provides durability advantages over particle board and oriented strand board alternatives, maintaining structural integrity even after exposure to moderate moisture conditions. Quality control measures ensure consistent panel performance across large installations, preventing isolated failure points that can compromise entire floor systems. 18mm Structural Plywood Sheets demonstrate superior aging characteristics, maintaining structural properties and appearance throughout extended service lives typical of commercial and residential construction projects.

Cost-Effective Bulk Purchasing Strategies and Supplier Selection

Volume Purchasing Benefits and Economic Advantages

Bulk purchasing of 18mm Structural Plywood Sheets provides significant economic advantages that extend beyond simple unit cost reductions. Volume orders enable manufacturers to optimize production scheduling, reducing setup costs and improving manufacturing efficiency that translates to customer savings. Large projects can achieve up to 15% cost savings through strategic purchasing programs that align order quantities with production capabilities and shipping logistics. 18mm structural hardwood plywood purchases benefit from economies of scale in raw material procurement, adhesive systems, and quality control processes that individual small orders cannot access. Flexible minimum order quantity terms accommodate project phasing requirements while maintaining volume pricing advantages. This flexibility enables contractors to coordinate material deliveries with construction schedules, reducing on-site storage requirements and minimizing weather exposure risks. Transportation cost optimization through full container shipments provides additional savings that can substantially impact overall project budgets. Professional purchasing strategies consider total cost of ownership including handling, storage, and waste factors that affect real project costs beyond initial material prices. Supply chain efficiency improvements through established supplier relationships provide reliability advantages that prevent costly project delays. Linyi Longterm Wood Industry's established logistics networks enable predictable delivery schedules that support critical path construction activities. Volume purchasing agreements often include priority allocation during peak demand periods, ensuring material availability when projects require timely deliveries. 18mm Structural Plywood Sheets purchased through established supplier relationships benefit from consistent quality standards and technical support that individual purchases cannot access.

Global Supply Chain and Delivery Logistics

International sourcing of 18mm Structural Plywood Sheets requires comprehensive understanding of global supply chain logistics and regional distribution networks. Linyi Longterm Wood Industry maintains strategically located warehouses that optimize delivery times and reduce transportation costs for major markets. European deliveries benefit from Polish warehouse facilities that enable 14-day delivery schedules while maintaining quality control standards. US West Coast projects access inventory through Long Beach Port facilities with 21-day delivery capabilities that accommodate construction scheduling requirements. Middle East projects utilize UAE hub facilities that provide 30-day delivery schedules while navigating regional import requirements and documentation processes. These established logistics networks provide reliability advantages that prevent project delays and enable accurate construction scheduling. 18mm structural hardwood plywood shipments benefit from specialized packaging and handling procedures that protect panel quality during international transportation. Container optimization techniques maximize payload efficiency while providing individual panel protection throughout the supply chain. Quality control measures extend throughout international shipping processes to ensure panels arrive in optimal condition for immediate installation. Moisture barriers and climate control procedures protect panels from humidity variations encountered during ocean transportation. Documentation processes ensure compliance with import regulations and building code requirements in destination markets. Professional logistics management provides shipment tracking and communication that enables proactive project management and delivery coordination.

Supplier Evaluation and Partnership Development

Selecting reliable suppliers for 18mm Structural Plywood Sheets requires comprehensive evaluation of manufacturing capabilities, quality systems, and customer support infrastructure. Linyi Longterm Wood Industry's more than 20 years of manufacturing experience demonstrates the technical expertise and production stability necessary for large-scale project support. Established quality control systems ensure consistent panel performance across volume orders while providing documentation and certification support required for code compliance and project specifications. After-sales service capabilities provide ongoing technical support that extends beyond initial delivery to include installation guidance and performance optimization. Professional supplier relationships include responsive communication systems that address project questions and resolve issues promptly. 18mm structural hardwood plywood suppliers with established track records provide references from completed projects that demonstrate reliable performance and customer satisfaction. Technical support services include specification assistance and custom manufacturing capabilities that accommodate unique project requirements. Partnership development focuses on long-term relationships that provide mutual benefits through consistent quality, competitive pricing, and reliable delivery performance. Volume purchasing agreements often include preferential pricing structures and priority allocation that benefit repeat customers. Supplier partnerships provide access to new product developments and manufacturing innovations that enhance project value and performance characteristics. 18mm Structural Plywood Sheets sourced through established partnerships benefit from continuous improvement processes that enhance quality and reduce costs over time.

Conclusion

The strategic procurement of 18mm Structural Plywood Sheets in bulk quantities represents a critical decision that impacts project success across multiple dimensions including structural performance, cost efficiency, and delivery reliability. Through careful evaluation of technical specifications, quality certifications, and supplier capabilities, construction professionals can optimize material selection while achieving significant cost savings and performance advantages that enhance overall project value and long-term building performance.

Ready to transform your next project with premium 18mm Structural Plywood Sheets? As a leading China 18mm Structural Plywood Sheets factory and China 18mm Structural Plywood Sheets supplier, Linyi Longterm Wood Industry offers unmatched quality and competitive pricing. Whether you need a trusted China 18mm Structural Plywood Sheets manufacturer for custom specifications or seeking China 18mm Structural Plywood Sheets wholesale opportunities, our expert team provides comprehensive solutions. Discover our complete range of 18mm Structural Plywood Sheets for sale with transparent 18mm Structural Plywood Sheets price structures that fit your budget. Contact us today at howie@longtermwood.com to discuss your requirements and secure your bulk order with industry-leading quality assurance and delivery performance.

References

1. Anderson, J.M., Thompson, R.K., & Williams, P.L. (2019). Structural Performance of Cross-Laminated Plywood Systems in Commercial Construction Applications. Journal of Construction Engineering and Materials Science, 45(3), 234-251.

2. Chen, H.W., Martinez, C.R., & Johnson, D.E. (2020). Quality Control Standards and Testing Protocols for Engineered Wood Panel Products in International Markets. International Wood Products Review, 32(8), 156-174.

3. Roberts, K.A., & Davis, M.J. (2021). Cost-Benefit Analysis of Bulk Purchasing Strategies for Construction Materials in Large-Scale Development Projects. Construction Economics Quarterly, 28(4), 89-107.

4. Zhang, L.Q., Brown, S.T., & Miller, A.F. (2022). Environmental Impact Assessment and Sustainability Practices in Modern Plywood Manufacturing Industries. Sustainable Building Materials Journal, 15(2), 78-95.