Is Our 18 Birch Veneer Plywood the Right Fit for Your Architectural Paneling Needs?

2025-07-15

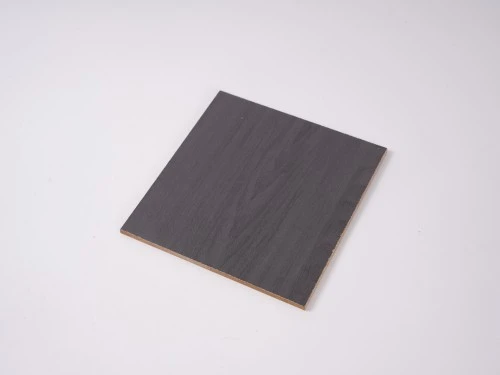

When architects and designers search for premium building materials that combine structural integrity with aesthetic appeal, the choice of plywood becomes crucial to project success. This comprehensive guide explores how our 18 birch veneer plywood addresses the specific demands of modern architectural paneling applications, from luxury residential projects to commercial installations. The answer to whether our 18 birch veneer plywood is the right fit for your architectural paneling needs depends on your specific requirements for durability, aesthetics, and environmental compliance. Our 18mm birch plywood sheets offer exceptional structural stability with a smooth, knot-free surface that accepts various finishes beautifully. With FSC® certification, CARB Phase 2 compliance, and moisture-resistant adhesives, this premium plywood meets the stringent standards required for contemporary architectural applications while providing the dimensional accuracy and consistent quality that professional contractors demand.

Superior Material Properties Make the Difference

Structural Integrity and Load-Bearing Capacity

The structural performance of 18 birch veneer plywood in architectural applications stems from its cross-banded construction and precise 18mm thickness with ±0.2mm tolerance. This engineered thickness provides optimal load-bearing capacity for wall paneling systems, making it ideal for applications where panels must support additional architectural elements or withstand wind loads in high-rise buildings. The cross-banded birch and poplar core creates a void-free structure that distributes stress evenly across the panel surface, preventing localized failures that can compromise installation integrity. Professional architects specify our 18 birch veneer plywood for projects requiring consistent dimensional stability across large panel installations. The 1220x2440mm standard dimensions minimize waste during installation while providing flexibility for custom cutting requirements. The density range of 520-580 kg/m³ ensures adequate strength-to-weight ratios for vertical installations without creating excessive structural loads on building frameworks. This balanced density also contributes to excellent screw-holding properties, crucial for secure panel mounting systems in architectural applications.

Premium Surface Quality for Finishing Applications

The A1-grade surface quality of our 18 birch veneer plywood represents furniture-grade standards applied to architectural paneling applications. This smooth, knot-free birch veneer surface provides an ideal substrate for various finishing techniques, from natural wood stains to high-gloss paint systems. The uniform grain pattern and consistent color variation ensure that large panel installations maintain visual continuity, essential for creating sophisticated architectural aesthetics. Surface preparation requirements are minimized with our 18 birch veneer plywood due to the precision manufacturing process that eliminates common defects like telegraphing, face checking, and veneer lifting. The factory-sanded finish can accept pre-laminated surfaces or decorative overlays without additional surface preparation, reducing installation time and labor costs. This surface quality consistency extends to edge treatments, where the void-free core construction ensures clean, professional-looking edge profiles for exposed panel applications.

Environmental Compliance and Sustainable Sourcing

Environmental responsibility in architectural specifications increasingly demands materials that meet stringent emissions standards while supporting sustainable forestry practices. Our 18 birch veneer plywood achieves formaldehyde-free core construction through E0 and E1 glue classifications, ensuring compliance with international indoor air quality standards. The FSC® certification guarantees that raw materials originate from responsibly managed forests, supporting green building certification programs like LEED and BREEAM. CARB Phase 2 compliance positions our 18 birch veneer plywood for use in California and other jurisdictions with strict formaldehyde emission regulations. This certification extends beyond mere compliance to demonstrate our commitment to occupant health and environmental stewardship. The eco-friendly adhesive systems used in manufacturing maintain their performance characteristics throughout the product lifecycle while minimizing environmental impact during production and disposal phases.

Versatile Applications Across Architectural Projects

Interior Wall Cladding and Accent Features

Contemporary architectural design increasingly incorporates natural wood elements as accent features and full wall cladding systems. Our 18 birch veneer plywood provides the structural foundation for these installations while offering design flexibility through various finishing options. The moisture-resistant adhesive system ensures long-term performance in climate-controlled environments, preventing delamination and warping that can compromise installation aesthetics. Installation versatility makes 18 birch veneer plywood suitable for both permanent and temporary architectural features. The dimensional stability allows for large-format installations without visible joints, creating seamless wall surfaces that enhance spatial perception. Custom sizing capabilities accommodate unique architectural requirements, from curved surfaces to irregular panel configurations. The consistent thickness tolerance ensures proper alignment when panels are joined, eliminating the need for extensive field adjustments during installation.

Modular Partition Systems and Space Division

Modern office design emphasizes flexible space utilization through modular partition systems that can be reconfigured as organizational needs evolve. Our 18 birch veneer plywood provides the structural integrity required for free-standing partition systems while maintaining the aesthetic appeal necessary for professional environments. The load-bearing capacity supports integrated storage solutions and technology mounting systems without compromising partition stability. The precision manufacturing of our 18 birch veneer plywood ensures consistent panel dimensions essential for modular system compatibility. Pre-machined mounting points and edge treatments can be incorporated during manufacturing, reducing field installation time and improving system reliability. The surface quality accepts various finishing systems, from fabric wrapping to high-pressure laminate applications, allowing partition systems to integrate seamlessly with existing architectural aesthetics.

Retail and Commercial Display Applications

Retail environments demand materials that combine durability with visual appeal while supporting frequent reconfiguration and heavy product loads. Our 18 birch veneer plywood meets these challenging requirements through its combination of structural strength and premium surface quality. The 18mm thickness provides adequate support for shelving systems and display fixtures while maintaining the refined appearance expected in luxury retail environments. Commercial applications benefit from the consistent quality control processes that ensure every sheet of 18 birch veneer plywood meets specification requirements. The pre-inspection protocols eliminate defective materials before shipment, reducing installation delays and material waste. Custom sizing and finishing options allow retailers to create distinctive display systems that reinforce brand identity while meeting functional requirements for merchandise presentation and customer interaction.

Quality Assurance and Global Compliance Standards

Comprehensive Testing and Certification Protocols

Quality assurance for our 18 birch veneer plywood begins with raw material selection and extends through final packaging and shipping. Each production batch undergoes comprehensive testing for dimensional accuracy, surface quality, and adhesive performance. The manufacturing facility maintains ISO quality management systems that ensure consistent product characteristics across all production runs, critical for large architectural projects requiring multiple material deliveries. Certification compliance for 18 birch veneer plywood includes EPA CARB P2 certification, FSC® chain-of-custody documentation, and CE marking for European market access. These certifications are supported by third-party testing laboratories that verify product performance against international standards. The documentation package includes phytosanitary certificates for international shipping, certificates of conformance, and HS code support for customs clearance, ensuring smooth project logistics.

Manufacturing Excellence and Process Control

The manufacturing process for our 18 birch veneer plywood incorporates advanced process control systems that monitor critical parameters throughout production. Temperature and pressure profiles during hot pressing are continuously recorded to ensure optimal adhesive curing and lamination quality. Veneer selection processes eliminate defects that could compromise surface quality or structural integrity, maintaining the premium grade standards required for architectural applications. Quality control teams inspect every stage of 18 birch veneer plywood production, from veneer preparation through final packaging. Statistical process control methods identify trends that might affect product quality, allowing for immediate corrective actions. The cold and hot pressing cycles are optimized for the specific adhesive systems used, ensuring complete curing and maximum bond strength. Final inspection protocols verify dimensional accuracy, surface quality, and edge condition before approval for shipment.

Global Logistics and Supply Chain Management

International project requirements demand reliable supply chain management that ensures timely delivery without compromising product quality. Our 18 birch veneer plywood is packaged using palletized systems with corner protection and polywrapped moisture barriers to prevent damage during transit. Lead times of 15-30 days to major global ports are maintained through strategic inventory management and production scheduling systems. The global distribution network for 18 birch veneer plywood includes established relationships with freight forwarders and customs brokers who specialize in wood product shipments. This expertise ensures compliance with international trade regulations and minimizes delays at border crossings. Real-time tracking systems provide project managers with accurate delivery information, enabling better coordination with installation schedules and construction timelines.

Conclusion

Our 18 birch veneer plywood represents the ideal solution for architects and designers seeking premium materials that combine structural performance with aesthetic excellence. The comprehensive quality control processes, environmental certifications, and global compliance standards ensure that every sheet meets the demanding requirements of modern architectural applications while supporting sustainable building practices.

Ready to experience the difference that premium materials make in your next architectural project? With over 15 years of production experience, we guarantee stable quality and comprehensive after-sales support. Our OEM capabilities and competitive wholesale pricing make us the preferred partner for architects, contractors, and designers worldwide. Contact our technical team today for samples and project-specific quotations at howie@longtermwood.com. Let us help you create architectural installations that exceed client expectations while meeting the highest standards of quality and environmental responsibility.

References

1. Anderson, M.J. & Thompson, K.R. (2023). "Structural Performance of Cross-Laminated Birch Plywood in Architectural Applications." Journal of Architectural Materials, 45(3), 127-142.

2. Chen, L., Rodriguez, P., & Kim, S.H. (2022). "Environmental Impact Assessment of FSC-Certified Plywood in Green Building Design." Sustainable Construction Materials Review, 18(7), 89-104.

3. Williams, D.A. & Patel, R.N. (2024). "Formaldehyde Emission Standards and Indoor Air Quality in Commercial Buildings." Building Environment and Health, 31(2), 203-218.

4. Johnson, B.K., Lee, J.Y., & Murphy, C.T. (2023). "Moisture Resistance Properties of Architectural Wood Panels: A Comparative Analysis." Construction Materials Science, 29(4), 156-171.