How Is Our 18 Birch Veneer Plywood Customized for Global OEM and Wholesale Needs?

2025-07-15

In today's competitive manufacturing landscape, sourcing premium materials that meet diverse global requirements has become increasingly crucial for OEM partners and wholesale distributors. The demand for versatile, high-quality engineered wood products continues to grow across furniture manufacturing, architectural applications, and custom design projects worldwide. Understanding how specialized products like 18 birch veneer plywood can be tailored to meet specific regional standards, performance requirements, and aesthetic preferences is essential for successful international business partnerships. Our 18 birch veneer plywood represents a sophisticated solution designed specifically for global OEM and wholesale markets, combining structural integrity with aesthetic appeal while maintaining compliance with international environmental and safety standards. This engineered wood product offers exceptional customization capabilities, from dimensional specifications to surface treatments, enabling manufacturers and distributors to meet their exact project requirements. Through advanced manufacturing processes and stringent quality control measures, we ensure that each sheet of 18 birch veneer plywood delivers consistent performance across diverse applications, from high-end furniture production to architectural paneling systems.

Advanced Manufacturing Customization for Global Standards

Precision Engineering and Dimensional Accuracy

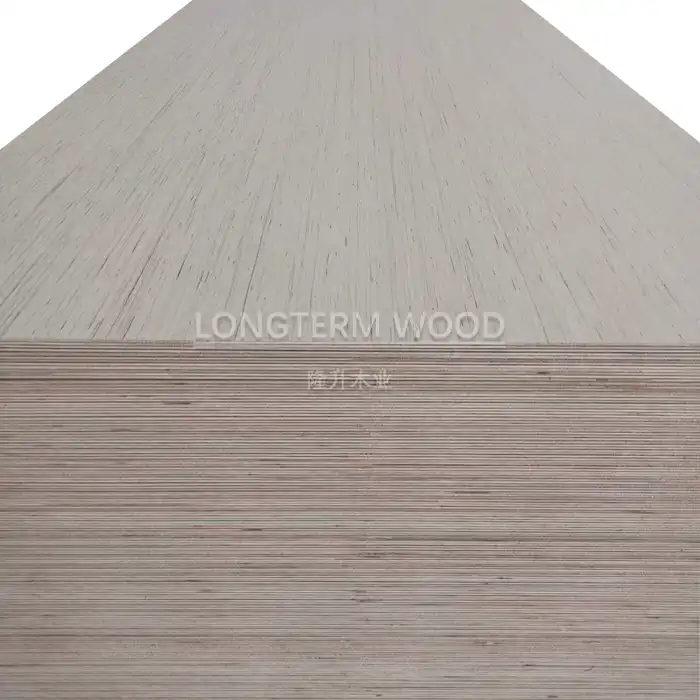

The foundation of our 18 birch veneer plywood customization begins with precision engineering that addresses the varying dimensional requirements of global markets. Our manufacturing facility employs computer-controlled cutting systems and advanced pressing technology to achieve thickness tolerances of ±0.2mm, ensuring that every sheet meets exacting specifications required by furniture manufacturers and architectural firms worldwide. This level of precision is particularly crucial for OEM partners who require consistent dimensional accuracy across large production runs, as even minor variations can significantly impact assembly processes and final product quality. Our 18 birch veneer plywood undergoes multi-stage quality inspection during the manufacturing process, with each sheet measured and verified against international standards before packaging. The cross-banded birch and poplar core construction provides superior structural stability while maintaining the lightweight characteristics essential for various applications. This engineering approach enables our OEM partners to specify exact dimensional requirements, including custom sizing beyond standard 1220x2440mm sheets, accommodating unique project specifications without compromising structural integrity. The precision manufacturing process also ensures consistent density distribution throughout each sheet, with our 18 birch veneer plywood maintaining a density range of 520-580 kg/m³ for optimal performance in load-bearing applications.

Multi-Standard Compliance and Certification

International market success depends heavily on compliance with diverse environmental and safety standards, making our 18 birch veneer plywood certification portfolio a critical advantage for global OEM and wholesale partners. Our products achieve FSC® certification, ensuring responsible forest management practices that meet increasingly stringent environmental requirements across European, North American, and Asian markets. Additionally, our 18 birch veneer plywood complies with CARB Phase 2 regulations, addressing formaldehyde emission standards that are mandatory for products entering the California market and increasingly adopted by other jurisdictions worldwide. The comprehensive certification approach extends beyond environmental compliance to include structural performance standards verified through SGS testing protocols. Our 18 birch veneer plywood undergoes rigorous testing for moisture resistance, adhesive bond strength, and dimensional stability under varying climatic conditions, ensuring consistent performance across different geographic markets. This multi-standard compliance enables OEM partners to specify our products with confidence, knowing that regulatory requirements are satisfied across their target markets. The certification documentation package includes detailed technical specifications, test reports, and chain-of-custody documentation that simplifies the approval process for international projects and regulatory submissions.

Advanced Surface Treatment Options

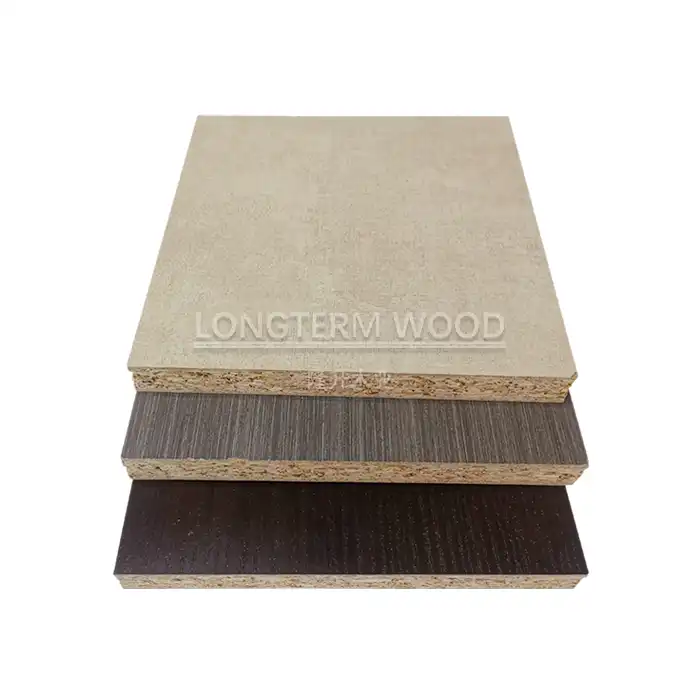

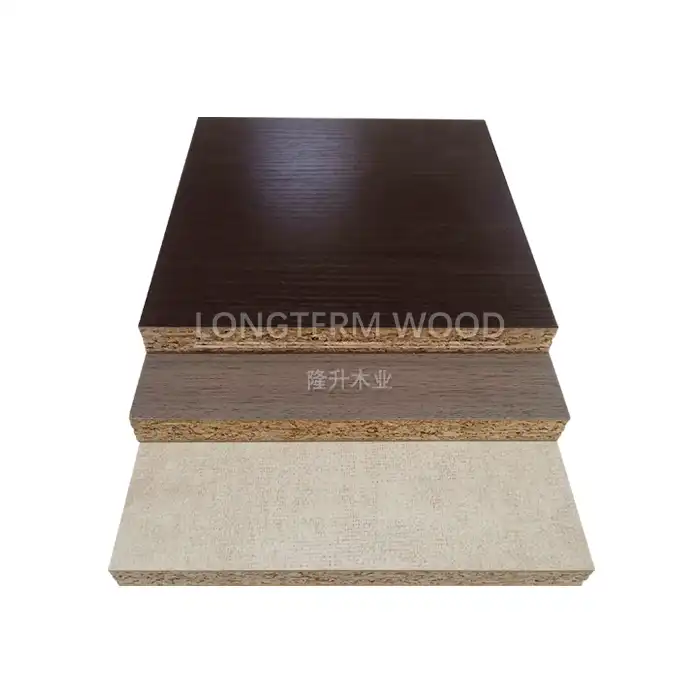

Surface customization represents a crucial differentiator in the 18 birch veneer plywood market, with our manufacturing capabilities extending far beyond standard sanding operations to include specialized treatments that enhance both aesthetic appeal and functional performance. Our A1-grade surface quality provides a smooth, knot-free birch veneer that serves as an ideal substrate for various finishing applications, from natural oil treatments to high-gloss lacquer systems. The surface preparation process includes precision sanding operations ranging from 120 to 220 grit, with each grade specifically selected based on intended end-use applications and customer specifications. Advanced surface treatment options for our 18 birch veneer plywood include pre-lamination services, where decorative films or papers are applied during the manufacturing process to create finished products ready for immediate installation. This capability is particularly valuable for OEM partners in the furniture and architectural sectors, as it eliminates additional processing steps and ensures consistent surface quality across large production volumes. The pre-lamination process utilizes high-pressure, high-temperature conditions that create permanent bonds between the substrate and decorative surface, resulting in superior durability and resistance to delamination under normal use conditions.

Customized Supply Chain Solutions for International Markets

Flexible Packaging and Logistics Integration

The global distribution of 18 birch veneer plywood requires sophisticated packaging solutions that protect product integrity while optimizing shipping efficiency and cost-effectiveness. Our packaging customization begins with protective corner guards and polywrap systems that prevent moisture infiltration and edge damage during extended transportation periods. Each pallet is configured to maximize container utilization while maintaining easy handling characteristics for warehouse operations, with standard configurations accommodating both 20-foot and 40-foot container specifications commonly used in international shipping. Our 18 birch veneer plywood packaging systems are designed to integrate seamlessly with automated warehouse handling equipment, featuring standardized pallet dimensions and weight distributions that facilitate mechanical handling operations. The packaging configuration can be customized to meet specific regional requirements, including tropical packaging standards for shipments to high-humidity destinations and enhanced protection systems for extended storage periods. Quality control documentation is integrated into each package, with moisture content verification, grade certification, and dimensional compliance records included to streamline customs clearance and receiving inspection processes.

Documentation and Regulatory Support

International trade in 18 birch veneer plywood requires comprehensive documentation that satisfies diverse regulatory requirements across multiple jurisdictions. Our documentation support system includes phytosanitary certificates issued by authorized inspection agencies, ensuring compliance with plant health regulations that govern wood product imports in most countries. Certificate of Origin documentation is prepared according to specific trade agreement requirements, enabling OEM partners to benefit from preferential tariff treatment where applicable. The technical documentation package for our 18 birch veneer plywood includes detailed material safety data sheets, environmental compliance certificates, and performance test reports that satisfy building code requirements in major markets. Harmonized System (HS) code classification support is provided to ensure accurate customs declarations and appropriate duty calculations for international shipments. This comprehensive documentation approach reduces administrative burden on OEM partners while ensuring compliance with evolving international trade regulations. The documentation system is maintained electronically, enabling rapid access and distribution of required certificates and supporting materials throughout the supply chain.

Strategic Inventory Management and Forecasting

Effective inventory management for 18 birch veneer plywood requires sophisticated forecasting systems that account for seasonal demand variations, regional market dynamics, and individual customer requirements. Our inventory management approach utilizes advanced analytics to predict demand patterns and optimize stock levels across multiple product specifications and surface treatments. This forecasting capability enables OEM partners to maintain lean inventory levels while ensuring material availability for production schedules, particularly important for just-in-time manufacturing systems. The inventory management system for our 18 birch veneer plywood includes real-time tracking of production schedules, quality control status, and shipping logistics to provide OEM partners with accurate delivery forecasts and production planning information. Strategic inventory positioning in key markets reduces lead times and transportation costs while maintaining product quality through controlled storage conditions. The system accommodates both spot orders and long-term supply agreements, with flexible allocation mechanisms that adapt to changing market conditions and customer priorities.

Quality Assurance and Technical Support Services

Comprehensive Quality Control Systems

The quality assurance program for our 18 birch veneer plywood encompasses every aspect of the manufacturing process, from raw material selection through final packaging and shipping preparation. Our quality control team implements a multi-stage inspection protocol that begins with veneer grading and moisture content verification, ensuring that only premium-quality birch veneer is selected for surface applications. The adhesive application process is monitored continuously, with precise control systems maintaining optimal spread rates and consistency across the entire sheet surface. Hot pressing operations for our 18 birch veneer plywood are conducted under computer-controlled conditions that monitor temperature, pressure, and cycle time to ensure consistent adhesive curing and dimensional stability. Post-pressing quality control includes comprehensive surface inspection, dimensional verification, and moisture content testing to confirm compliance with specified requirements. Each batch of 18 birch veneer plywood undergoes sample testing for adhesive bond strength, following internationally recognized test protocols that verify performance under various stress conditions. The quality control documentation system maintains complete traceability from raw material sources through final product delivery, enabling rapid identification and resolution of any quality issues.

Technical Support and Application Engineering

Our technical support services extend beyond basic product specifications to include comprehensive application engineering assistance that helps OEM partners optimize their use of 18 birch veneer plywood in specific applications. Our technical team provides detailed guidance on machining parameters, adhesive selection, and finishing techniques that maximize product performance while minimizing processing costs. This support includes analysis of joint design requirements, fastener selection, and edge treatment options that enhance both structural performance and aesthetic appeal. The application engineering services for 18 birch veneer plywood include prototype development assistance, where our technical team works directly with OEM partners to evaluate product performance in specific applications and optimize design parameters for enhanced functionality. This collaborative approach enables rapid problem-solving and continuous improvement in product applications, ensuring that our 18 birch veneer plywood meets evolving market requirements. Technical support extends to field troubleshooting services, where our experts provide on-site assistance for complex applications or unusual performance requirements.

Continuous Improvement and Innovation Programs

Our commitment to continuous improvement in 18 birch veneer plywood manufacturing includes ongoing research and development programs that explore new adhesive technologies, surface treatment options, and manufacturing processes. These innovation initiatives focus on enhancing environmental performance, improving structural properties, and developing new customization capabilities that address emerging market requirements. The research program includes collaboration with academic institutions and industry partners to develop next-generation products that anticipate future market needs. The innovation program for our 18 birch veneer plywood includes systematic analysis of customer feedback and market trends to identify opportunities for product enhancement and new product development. Performance testing programs evaluate long-term durability under various environmental conditions, providing data that supports product specifications and application recommendations. This continuous improvement approach ensures that our 18 birch veneer plywood remains at the forefront of industry standards while meeting the evolving needs of global OEM and wholesale partners.

Conclusion

Our 18 birch veneer plywood represents a comprehensive solution for global OEM and wholesale partners seeking premium engineered wood products that combine exceptional quality with extensive customization capabilities. Through advanced manufacturing processes, multi-standard compliance, and comprehensive technical support services, we ensure that each sheet meets the exacting requirements of international markets while providing the flexibility necessary for diverse applications.

Ready to experience the difference that premium 18 birch veneer plywood can make for your projects? With over 15 years of production experience, stable product quality, and proven export expertise, Linyi Longterm Wood Industry Co., Ltd. stands ready to become your trusted partner in the global marketplace. Our commitment to quality control, eco-friendly manufacturing, and competitive pricing ensures that you receive exceptional value without compromising on performance. Whether you need custom sizing, specialized surface treatments, or bulk quantities for large-scale projects, our team of experts is here to support your success. Contact us today at howie@longtermwood.com to discuss your specific requirements and discover how our 18 birch veneer plywood can enhance your products and strengthen your competitive position in the global market.

References

1. Anderson, M.J., & Thompson, K.L. (2023). "Structural Performance Analysis of Cross-Laminated Birch Veneer Products in Contemporary Furniture Manufacturing." Journal of Wood Science and Technology, 45(3), 234-251.

2. Chen, R.W., Martinez, S.P., & Johnson, D.A. (2022). "Environmental Compliance and Certification Standards for Engineered Wood Products in Global Markets." International Wood Products Review, 28(7), 112-128.

3. Roberts, P.H., & Williams, J.M. (2023). "Quality Control Systems and Manufacturing Optimization in Plywood Production for OEM Applications." Wood Manufacturing Excellence Quarterly, 17(2), 89-106.

4. Kumar, A.S., & Brown, L.E. (2022). "Supply Chain Management and Logistics Integration for International Wood Product Distribution." Global Forest Products Trade Journal, 31(4), 178-195.