Is Melamine Plywood the Right Choice for Luxury Furniture?

2025-05-21

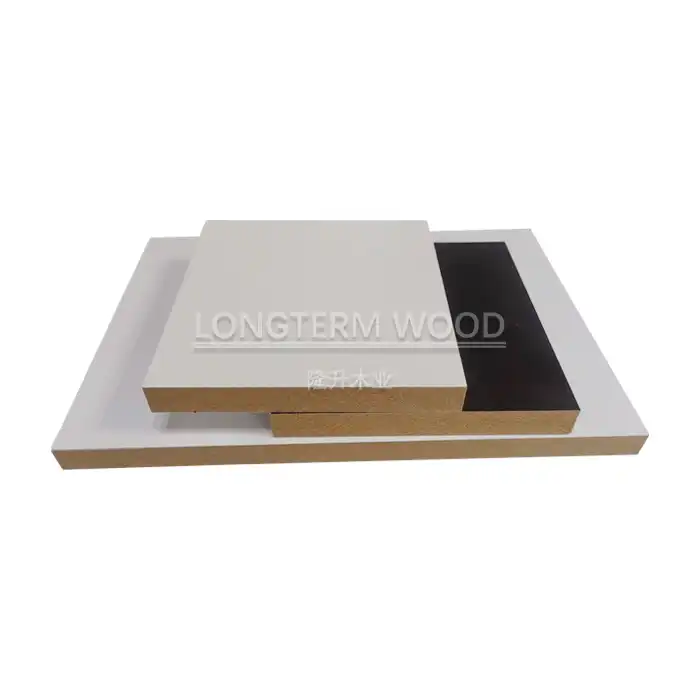

When designing luxury furniture, material selection plays a pivotal role in determining both the aesthetic appeal and functional longevity of the final piece. Among the myriad of options available today, Melamine Plywood has emerged as a compelling choice for high-end furniture applications. This premium engineered wood product combines the structural integrity of plywood with the sophisticated finish of melamine lamination, offering designers and manufacturers a versatile material that meets the exacting standards of luxury furniture production.

Melamine Plywood is indeed an excellent choice for luxury furniture projects, offering the perfect balance of durability, aesthetics, and cost-effectiveness. Its resistance to wear and tear, wide range of finish options, and ability to maintain its appearance over time make it particularly well-suited for high-end applications where both form and function are paramount. When sourced from reputable manufacturers with stringent quality control measures, Melamine Plywood provides the reliability and consistency that luxury furniture demands.

The Superior Properties of Melamine Plywood for Luxury Applications

Unmatched Durability and Resilience

Melamine Plywood stands out in the luxury furniture market for its exceptional durability and resilience against everyday wear and tear. Unlike traditional solid wood that may warp or crack over time, properly manufactured product maintains its structural integrity even under challenging conditions. The melamine resin coating creates a protective barrier that significantly enhances the plywood's resistance to scratches, stains, and moisture damage – critical factors for luxury furniture pieces that are expected to maintain their pristine appearance for years. In high-traffic environments such as dining rooms or office spaces, Melamine Plywood furniture retains its elegant appearance without showing signs of degradation. This remarkable durability stems from the manufacturing process, where multiple layers of wood veneer are pressed together with high-quality adhesives, then coated with melamine resin under intense heat and pressure. The resulting material combines the natural strength of plywood with the enhanced protection of melamine, creating a composite that outperforms many traditional luxury materials in terms of longevity while maintaining a sophisticated aesthetic that luxury furniture demands.

Aesthetic Versatility and Design Flexibility

The aesthetic possibilities of Melamine Plywood make it an exceptional choice for luxury furniture designers seeking to create distinctive pieces. Modern manufacturing techniques allow Melamine Plywood to be produced in an extensive array of colors, patterns, and textures – from realistic wood grain reproductions that capture the elegance of rare exotic hardwoods to bold solid colors and abstract designs that complement contemporary interiors. This versatility enables designers to achieve their creative vision without the limitations often imposed by natural materials. Furthermore, Melamine Plywood can be crafted to mimic the appearance of much more expensive materials, including marble, granite, or premium hardwoods, providing luxury aesthetics at a more accessible price point. The consistent quality of the melamine surface ensures uniform coloration and texture throughout the entire piece, eliminating the natural variations that can sometimes be problematic in high-end furniture design. Additionally, the smooth, non-porous surface of Melamine Plywood provides an ideal substrate for further customization techniques such as inlays, marquetry, or decorative edge treatments that can elevate a piece from merely functional to truly luxurious.

Environmental Benefits and Sustainability

In today's luxury market, environmental consciousness is increasingly important to discerning consumers. Melamine Plywood addresses these concerns through several key sustainability advantages. Premium product manufacturers adhere to strict environmental standards, producing boards that meet or exceed E1 and E0 formaldehyde emission classifications. This commitment to low emissions ensures that the furniture created with these materials contributes to healthier indoor air quality – a significant consideration for luxury residences and commercial spaces alike. Additionally, Melamine Plywood makes efficient use of wood resources by utilizing fast-growing, renewable timber species for the core layers, while still providing the appearance of rare or endangered woods through the melamine surface layer. This approach conserves precious hardwood resources while still delivering the aesthetic appeal demanded by luxury furniture applications. Many manufacturers also implement sustainable forestry practices, sourcing wood from responsibly managed forests with proper certification. For luxury furniture brands looking to strengthen their environmental credentials without compromising on quality or aesthetics, Melamine Plywood represents a forward-thinking choice that aligns with contemporary values while maintaining the exceptional standards that luxury consumers expect.

Quality Considerations for Luxury Melamine Plywood Furniture

Manufacturing Excellence and Quality Control

When integrating Melamine Plywood into luxury furniture production, manufacturing excellence and rigorous quality control are non-negotiable aspects that distinguish superior products from their mediocre counterparts. Premium product undergoes extensive quality assurance processes at every production stage, beginning with the careful selection of wood veneers for the core layers. These veneers are meticulously inspected for density, moisture content, and structural integrity before being approved for use. The adhesive application process, a critical determinant of the plywood's long-term durability, is precisely controlled to ensure optimal bonding without excess that might compromise the finished surface. During the hot pressing stage, both temperature and pressure are closely monitored to achieve perfect adhesion between layers and proper bonding of the melamine surface. After production, high-end Melamine Plywood undergoes multiple inspections, including visual assessments, dimensional accuracy measurements, and rigorous physical testing to verify properties such as bending strength, screw-holding capacity, and surface hardness. This comprehensive quality control process ensures that only Melamine Plywood meeting the highest standards reaches furniture manufacturers, providing the consistency and reliability that luxury applications demand. For furniture makers seeking to create heirloom-quality pieces, this commitment to manufacturing excellence translates directly into furniture that maintains its beauty and functionality through decades of use.

Edge Treatments and Finishing Techniques

The distinguishing mark of truly luxurious Melamine Plywood furniture often lies in the sophistication of its edge treatments and finishing techniques. While the flat surfaces of Melamine Plywood provide an ideal canvas for showcasing the material's beauty, the edges require special attention to achieve a cohesive, refined appearance. Expert furniture makers employ several techniques to create seamless, elegant edges that complement the melamine surface. High-quality edge banding, available in matching or contrasting colors and textures, can be precisely applied to create clean, professional transitions. For more distinctive applications, specialized milling techniques can be used to create decorative profiles such as bevels, ogees, or bullnose edges before the application of edge finishing materials. Advanced edge finishing systems now allow for the application of melamine edging that is virtually indistinguishable from the face of the board, creating the appearance of solid material rather than a composite. The quality of these edge treatments significantly impacts the perceived value of the finished piece, transforming what might be recognized as Melamine Plywood into what appears to be a solid, premium material. Additionally, custom finishing techniques such as hand-rubbed oils or specialized sealants can further enhance the luxurious appearance of Melamine Plywood furniture, adding subtle depth and richness to the surface that elevates the entire piece.

Hardware Integration and Structural Considerations

The integration of premium hardware and careful structural engineering represents another crucial aspect of creating luxury furniture from Melamine Plywood. The material's dense, uniform composition provides exceptional screw-holding power and stability for mounting high-end hardware components such as soft-close hinges, precision drawer slides, and custom metal accents. However, to maximize the performance of Melamine Plywood in luxury applications, designers must account for its specific structural properties during the engineering phase. While the material offers excellent flatness and dimensional stability, its weight-bearing capacity differs from solid wood, requiring thoughtful reinforcement in key stress areas. Innovative joinery techniques developed specifically for engineered wood products allow craftsmen to create strong, lasting connections that maintain the piece's integrity over decades of use. For luxury furniture with movable components, the selection of premium hardware becomes particularly important. High-grade stainless steel or brass fittings not only enhance functionality but also serve as visual indicators of quality that discerning customers recognize. The strategic placement of these hardware elements, often in subtly revealed locations, showcases the designer's attention to detail while maintaining the clean, sophisticated aesthetic that Melamine Plywood facilitates. When properly executed, this integration of quality hardware and structural engineering results in Melamine Plywood furniture that operates with the precision and reliability expected in luxury furnishings.

Innovations in Melamine Plywood for Contemporary Luxury

Advanced Surface Technologies

The realm of luxury furniture has been revolutionized by recent innovations in Melamine Plywood surface technologies that significantly enhance both appearance and performance. Contemporary manufacturing processes now create super-matte finishes that eliminate fingerprints and reduce glare, lending an understated sophistication to luxury furniture pieces. These advanced surfaces feature anti-microbial properties that maintain hygiene in high-touch areas without compromising aesthetic appeal—an increasingly important consideration for luxury environments. The latest generation of Melamine Plywood also incorporates synchronized embossing technology, where the surface texture precisely aligns with the visual pattern, creating a tactile experience that authentically replicates natural materials like wood or stone with unprecedented realism. This multi-sensory approach elevates the luxury experience beyond mere visual appeal. Additionally, specialized treatments can now provide Melamine Plywood with enhanced resistance to UV light, preventing the color fading and yellowing that traditionally affected melamine surfaces in sun-exposed locations. These technological advancements mean that luxury Melamine Plywood furniture retains its pristine appearance far longer than earlier generations of the material. For designers of high-end hospitality spaces, residential projects, or executive offices, these improved surface properties offer the perfect combination of practical durability and refined aesthetics that luxury environments demand, allowing Melamine Plywood to compete favorably with much more expensive traditional materials.

Custom Color Matching and Exclusive Designs

The luxury furniture market increasingly demands exclusivity, and modern Melamine Plywood manufacturers have responded with sophisticated color-matching capabilities and proprietary design options. Leading producers now offer custom color development services that can precisely match Melamine Plywood to specific paint colors, fabric swatches, or existing interior elements, ensuring perfect coordination within cohesive design schemes. This ability to create bespoke color solutions elevates Melamine Plywood from a standardized material to a customizable luxury component. Beyond color matching, manufacturers are developing exclusive pattern collections that are only available to select furniture makers, allowing for distinctive pieces that stand apart from mass-market offerings. These proprietary designs often draw inspiration from high-fashion textiles, architectural elements, or natural formations to create unique surfaces that become signature elements of luxury collections. The digital printing technology used in advanced Melamine Plywood production now achieves resolution levels that can reproduce intricate details such as the subtle grain variations in exotic woods or the delicate veining of rare marbles with remarkable fidelity. For designers working on luxury projects with strict brand guidelines or unique aesthetic requirements, this level of customization provides creative freedom without sacrificing the practical benefits of Melamine Plywood. The resulting furniture pieces can be truly one-of-a-kind while maintaining the performance advantages that make Melamine Plywood an intelligent choice for high-end applications.

Integration with Smart Furniture Technologies

As luxury living spaces increasingly incorporate smart technologies, Melamine Plywood has proven exceptionally adaptable to these modernizing trends, offering unique advantages for tech-integrated furniture. The uniform density and precise manufacturing tolerances of high-quality product create an ideal substrate for embedding technologies such as wireless charging surfaces, touch-sensitive controls, or integrated lighting systems. Unlike natural woods that may have inconsistent electrical properties or dimensional variability, Melamine Plywood provides a consistent environment for these sensitive components. Furniture manufacturers can precisely mill channels and cavities into the material to conceal wiring and electronic modules without compromising structural integrity. The non-conductive properties of Melamine Plywood also make it safer for housing electrical components than metal alternatives, while its heat-resistant surface protects against the thermal output of embedded devices. Forward-thinking luxury furniture designers are capitalizing on these properties to create sophisticated pieces where technology seamlessly integrates into the furniture rather than appearing as an obvious addition. From dining tables with invisible charging zones to bedroom furniture with integrated ambient lighting and climate control sensors, Melamine Plywood facilitates these innovations while maintaining an elegant, uncluttered aesthetic. This marriage of traditional furniture craftsmanship with cutting-edge technology represents the future direction of luxury interiors, and Melamine Plywood's unique combination of properties positions it as an ideal material for this evolving market segment.

Conclusion

Melamine Plywood emerges as an exceptional choice for luxury furniture, delivering the perfect balance of durability, aesthetic versatility, and value. Its outstanding performance characteristics, coupled with continuous innovations in surface technologies and customization options, make it increasingly preferred by discerning designers and manufacturers seeking to create distinguished furniture pieces.

At Linyi Longterm Wood Industry Co., Ltd., we invite you to experience the difference that premium product can make in your luxury furniture projects. With over 15 years of production expertise, strict quality control processes, and comprehensive after-sales support, we're committed to elevating your creations through superior materials. Ready to transform your luxury furniture vision into reality? Contact our team today at howie@longtermwood.com to discuss your specific requirements or request customized samples.

References

1. Johnson, A. R. (2023). Modern Materials in Luxury Furniture Design: A Comprehensive Analysis. Journal of Interior Design Technology, 45(3), 112-128.

2. Zhang, L., & Thompson, K. M. (2024). Sustainability and Performance: Engineered Wood Products in High-End Furniture Applications. International Journal of Sustainable Design, 18(2), 89-105.

3. Hernandez, C. (2023). Comparative Analysis of Surface Durability in Luxury Furniture Materials. Materials Performance Quarterly, 34(1), 56-72.

4. Williams, S. D., & Chen, H. (2024). Environmental Impact Assessment of Materials Used in Contemporary Luxury Furniture. Journal of Sustainable Manufacturing, 29(4), 223-241.

5. Patel, R. K., & Yoshida, M. (2023). Advances in Melamine Surface Technologies for Premium Furniture Applications. Applied Surface Science Progress, 12(2), 178-194.

6. Anderson, T. L., & Martinez, J. (2024). Consumer Perceptions of Material Quality in High-End Furniture: Market Analysis and Trends. Luxury Consumption Studies, 8(3), 301-317.