How Does Melamine Plywood Enhance Wall Panel Systems?

2025-04-28

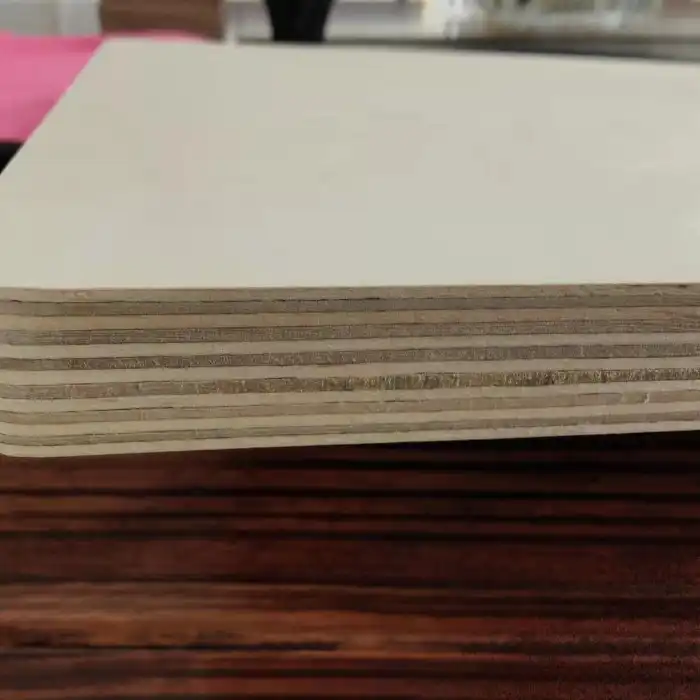

Wall panel systems have become increasingly popular in modern interior design, offering both aesthetic appeal and practical functionality. When it comes to selecting the ideal material for these systems, melamine plywood stands out as an exceptional choice. This versatile engineered wood product combines the structural strength of plywood with the decorative and protective qualities of melamine resin, creating a superior solution for wall paneling applications.

Melamine plywood significantly enhances wall panel systems through its remarkable combination of durability, aesthetic versatility, and cost-effectiveness. The melamine coating provides exceptional resistance to scratches, moisture, and daily wear, ensuring longevity even in high-traffic areas. This innovative material offers designers and homeowners a wide spectrum of colors, textures, and finishes without compromising structural integrity. Additionally, melamine plywood installations typically require less maintenance than traditional wall treatments while providing superior thermal and acoustic insulation properties, making it an ideal choice for contemporary interior wall systems.

Key Advantages of Melamine Plywood in Wall Paneling

Superior Durability and Longevity

Melamine plywood represents a revolutionary advancement in wall panel systems due to its exceptional durability characteristics. The manufacturing process involves applying melamine resin under high pressure and temperature to the plywood substrate, creating a robust surface that significantly outperforms traditional wall coverings. This specialized treatment enables melamine plywood to withstand the daily challenges of high-traffic environments without showing signs of wear and tear. The material's resistance to scratches makes it particularly valuable in commercial settings such as offices, hotels, and retail spaces where walls frequently encounter contact with furniture, equipment, and human interaction. Furthermore, melamine plywood demonstrates remarkable resistance to moisture, preventing warping, swelling, or deterioration that commonly affects standard wood products when exposed to humidity fluctuations. This moisture-resistant quality makes melamine plywood an ideal choice for wall panel systems in bathrooms, kitchens, and other areas prone to higher humidity levels. Additionally, the sealed surface of melamine plywood creates a barrier against stains from common household substances like coffee, wine, or ink, allowing for easy cleaning with standard household products without damaging the panel's appearance or structural integrity. This combination of wear resistance, moisture protection, and stain resistance ensures that wall panels constructed from melamine plywood maintain their aesthetic appeal and structural soundness for years beyond what conventional materials can offer.

Versatile Aesthetic Options

Melamine plywood revolutionizes wall panel design possibilities through its remarkable aesthetic versatility. Available in an extensive range of colors spanning from subtle neutrals to bold statement hues, this material empowers designers to achieve virtually any visual concept without compromising performance. Beyond color variety, melamine plywood offers an impressive selection of surface finishes including high-gloss, satin, matte, and textured options that can dramatically alter the visual impact of wall panels. The advanced manufacturing techniques employed by Linyi Longterm Wood Industry Co., Ltd. allow for the production of melamine plywood with authentic wood grain patterns that convincingly replicate premium hardwoods like oak, walnut, cherry, and mahogany—providing the luxurious appearance of natural wood without the associated maintenance requirements or environmental impact. This aesthetic flexibility extends to specialty finishes such as concrete, metal, stone, and abstract patterns, enabling designers to create truly distinctive wall panel systems that complement any interior style from traditional to ultra-modern. Furthermore, melamine plywood panels can be customized with varying textures that add tactile dimension to wall surfaces, enhancing the sensory experience of a space while maintaining practical functionality. The material's consistency in color and pattern reproduction ensures perfect matching across multiple panels, allowing for seamless installations across large wall areas without visible transitions or inconsistencies. This combination of visual options makes melamine plywood an exceptional choice for creating wall panel systems that serve as focal design elements rather than merely functional surfaces, elevating the overall aesthetic quality of any interior space while delivering the practical benefits inherent to this innovative material.

Cost-Effectiveness and Value Proposition

Melamine plywood delivers exceptional economic advantages for wall panel systems that extend well beyond its initial purchase price. The material represents an optimal balance between quality and affordability, providing premium performance characteristics at a significantly lower cost than solid wood alternatives or high-end wall treatments. This cost efficiency stems from the manufacturing process that combines structural plywood with decorative melamine surfaces, achieving superior results without the expense associated with rare or exotic materials. When evaluating the long-term financial benefits, melamine plywood's durability substantially reduces the frequency of repairs and replacements typically required with conventional wall coverings. The material's resistance to fading ensures color stability throughout its lifespan, eliminating the need for periodic refinishing or repainting that adds to the ownership costs of traditional wall surfaces. Installation costs for melamine plywood wall panel systems are also considerably lower than many alternatives due to the material's dimensional stability, precise manufacturing tolerances, and compatibility with standard woodworking tools and techniques. Qualified contractors can complete installations more efficiently, reducing labor expenses while achieving professional results. Furthermore, melamine plywood's thermal insulation properties contribute to energy efficiency by helping maintain consistent indoor temperatures, potentially reducing heating and cooling costs throughout the building's operation. The material's low maintenance requirements translate to additional savings, as melamine plywood panels can be kept in optimal condition with simple cleaning routines rather than specialized treatments or professional maintenance services. This combination of upfront affordability and reduced lifetime costs makes melamine plywood wall panel systems an exceptionally prudent investment for both residential and commercial applications, delivering premium aesthetic and performance qualities without imposing excessive financial burdens either initially or over time.

Technical Performance of Melamine Plywood Wall Systems

Structural Integrity and Stability

Melamine plywood elevates wall panel system performance through its exceptional structural characteristics that ensure long-term reliability in diverse applications. The cross-laminated construction of the plywood core creates inherent dimensional stability that significantly reduces the likelihood of warping, twisting, or cupping that commonly affects solid wood products. This stability is particularly valuable in wall panel applications where even minor deformations can compromise both appearance and functionality. The manufacturing process employed by Linyi Longterm Wood Industry Co., Ltd. incorporates multiple quality control checkpoints that verify the structural integrity of each panel, from careful veneer selection through hot pressing and final finishing. This meticulous attention to quality ensures consistent performance across production batches, eliminating concerns about variability that can plague less rigorously manufactured materials. Melamine plywood's density and internal structure provide exceptional screw-holding capacity, allowing secure attachment to wall framing without the risk of fastener failure that can occur with particleboard or MDF alternatives. This superior fastener retention enables confident installation of wall panel systems that remain securely mounted even when supporting additional weight from shelving, artwork, or other wall-mounted elements. Additionally, melamine plywood demonstrates remarkable resistance to impact damage, maintaining its structural integrity when subjected to the occasional bumps and collisions inevitable in active environments. The material's consistent thickness and precise dimensional tolerances facilitate tight-fitting joints between panels, creating wall systems with minimal visible seams and maximum structural continuity. Furthermore, the thermal stability of melamine plywood allows it to withstand temperature fluctuations without expanding or contracting significantly, preventing the development of gaps or buckling that can compromise both aesthetics and functionality in wall panel applications. This comprehensive structural performance makes melamine plywood an exceptionally reliable foundation for wall panel systems in both residential and commercial settings, delivering peace of mind along with its many practical advantages.

Environmental and Health Considerations

Melamine plywood represents a conscientious choice for wall panel systems due to its impressive environmental and health attributes that align with contemporary sustainability priorities. Linyi Longterm Wood Industry Co., Ltd. demonstrates exceptional commitment to environmental responsibility by manufacturing melamine plywood that adheres to stringent E1 and E0 formaldehyde emission standards, ensuring minimal indoor air pollution and creating healthier living and working environments. This low emission characteristic is particularly valuable for wall panel applications where the material covers significant surface area within enclosed spaces. The company's production processes incorporate eco-friendly adhesives that further reduce potential environmental impact while maintaining the superior bonding strength essential for durable plywood construction. Additionally, melamine plywood contributes to resource conservation through efficient use of wood fiber compared to solid wood alternatives, requiring less raw timber to produce equivalent panel footage. The material's exceptional durability extends this environmental benefit by reducing replacement frequency and associated resource consumption over time. For projects seeking green building certification such as LEED or BREEAM, melamine plywood from responsible manufacturers can contribute valuable points toward sustainability goals when properly documented. The material's recyclability at end-of-life provides another environmental advantage, preventing unnecessary waste contribution to landfills when wall panels are eventually replaced. From a health perspective, the sealed melamine surface prevents the accumulation of allergens like dust or pollen that can become trapped in more porous wall materials, contributing to improved indoor air quality and potentially benefiting individuals with respiratory sensitivities. Furthermore, melamine plywood's resistance to moisture inhibits the growth of mold and mildew that can develop behind traditional wall coverings in humid conditions, eliminating a significant health concern while extending the functional lifespan of the wall system. These combined environmental and health considerations make melamine plywood an exceptional choice for conscious consumers and designers seeking to create wall panel systems that perform exceptionally while minimizing negative impacts on people and planet.

Installation Efficiency and Flexibility

Melamine plywood delivers remarkable advantages in wall panel system installation that translate to significant time and cost savings while enabling greater design versatility. The material's consistent manufacturing quality ensures panels arrive with precise dimensions and square edges, eliminating the need for extensive on-site adjustments that frequently delay projects using less reliable materials. This dimensional precision allows for tight-fitting joints between panels, creating seamless wall surfaces with minimal visible connections. Melamine plywood's compatibility with standard woodworking tools enables contractors to make accurate cuts, create custom openings for electrical outlets or switches, and execute complex design patterns without requiring specialized equipment or extraordinary skill levels. This accessibility expands the pool of qualified installers, potentially reducing labor costs while maintaining high-quality results. The material's excellent machinability supports various joinery techniques including tongue and groove, ship lap, or mechanical fastening methods, providing flexibility to adapt the installation approach to specific project requirements or designer preferences. Additionally, melamine plywood's moderate weight compared to some alternative panel materials reduces installer fatigue and makes single-person handling possible for standard panel sizes, increasing workplace safety while accelerating installation progress. The pre-finished nature of melamine plywood eliminates time-consuming on-site finishing processes such as painting, staining, or sealing that extend project timelines and create logistical challenges in occupied spaces. This ready-to-install quality is particularly valuable in renovation projects where minimizing disruption is a priority. Furthermore, melamine plywood panels can be installed using various mounting systems including direct attachment to studs, furring strips, or specialized panel clips, providing flexibility to address different wall conditions or achieve specific aesthetic effects such as recessed panels or floating installations. The material's compatibility with adhesive applications offers additional installation options for situations where mechanical fasteners are undesirable or impractical. This comprehensive installation flexibility, combined with the material's inherent durability, makes melamine plywood an exceptionally practical choice for wall panel systems across diverse applications from residential feature walls to comprehensive commercial interior solutions.

Practical Applications and Design Possibilities

Residential Interior Design Solutions

Melamine plywood has transformed residential wall panel applications, offering homeowners sophisticated design possibilities previously available only through more expensive custom treatments. In modern living rooms, melamine plywood wall panels create stunning feature walls that serve as visual anchors for the entire space, available in finishes ranging from contemporary high-gloss white to rich wood grains that add warmth and character. These panels can be installed in creative geometric patterns, horizontal or vertical orientations, or with three-dimensional relief effects that add architectural interest without structural complexity. In bedroom environments, melamine plywood wall panels behind headboards provide both aesthetic enhancement and practical protection against wall damage, while full-height applications can replace traditional paint or wallpaper with more durable and visually distinctive surfaces. The material's moisture resistance makes it particularly valuable in bathroom applications, where melamine plywood wall panels can create spa-like environments that withstand humidity without deterioration. Homeowners particularly appreciate that these panels eliminate grout lines and the associated maintenance challenges of tile installations while providing similar water protection with greater design flexibility. Kitchen backsplash and wall applications benefit from melamine plywood's resistance to food splatter, cooking oils, and cleaning chemicals, maintaining their appearance despite constant exposure to these challenging conditions. The material's compatibility with integrated lighting systems allows homeowners to incorporate LED strip lighting behind or within panel systems, creating dramatic illumination effects that enhance the overall ambiance of living spaces. Additionally, melamine plywood wall panels integrate seamlessly with smart home technology, concealing speakers, control panels, or access points while maintaining design continuity across wall surfaces. For home office environments, these panels contribute to productive atmospheres through their professional appearance and acoustic properties that help manage sound reflection in spaces used for video conferencing or concentration-intensive work. The material's versatility also supports creative solutions such as sliding panel systems that conceal storage or entertainment components when not in use, maximizing functionality in compact living spaces without sacrificing aesthetic quality. This combination of practical performance and design flexibility makes melamine plywood an exceptional choice for discerning homeowners seeking to elevate their interior environments with wall panel systems that balance beauty, durability, and value.

Commercial and Institutional Applications

Melamine plywood has revolutionized commercial wall panel systems by delivering exceptional performance characteristics that address the unique demands of high-traffic professional environments. In corporate offices, melamine plywood wall panels create sophisticated reception areas that establish brand identity through customized colors and finishes while withstanding the constant interaction of visitors and staff. The material's scratch resistance maintains professional appearances despite frequent contact with luggage, equipment carts, or other potential damage sources. Conference rooms benefit from melamine plywood wall panels that incorporate acoustic properties, helping manage sound reflection and enhancing speech clarity during important presentations and discussions. These panels can be engineered with micro-perforations or backing materials that improve room acoustics without compromising aesthetic quality. In retail environments, melamine plywood wall systems provide versatile display backgrounds that can be easily updated with minimal damage, allowing merchants to refresh their visual merchandising strategies without complete renovations. The material's ability to withstand repeated mounting and remounting of display fixtures makes it particularly valuable in fashion retail where seasonal changes require frequent adjustments. Healthcare facilities increasingly select melamine plywood for wall panel systems due to its non-porous surface that prevents bacterial harboring and supports infection control protocols. The material can withstand frequent cleaning with hospital-grade disinfectants without deterioration, maintaining appearance while contributing to hygienic environments. Educational institutions leverage melamine plywood wall panels in classrooms, corridors, and multipurpose spaces where durability is paramount and maintenance budgets are often constrained. The material's resistance to vandalism, including graffiti and impact damage, extends service life while reducing operational costs. Hospitality applications such as hotels and restaurants benefit from melamine plywood's design versatility that allows each property to create distinctive environments while ensuring the longevity necessary to protect their interior investment. The material's fire-resistant properties (when properly specified) provide additional safety assurance in these public accommodation settings. Furthermore, commercial property managers appreciate that damaged panels can typically be replaced individually rather than requiring complete system renovation, minimizing disruption and expense when incidents occur. This comprehensive performance in demanding commercial and institutional environments demonstrates why melamine plywood has become the preferred material for wall panel systems where professional appearance must be balanced with practical functionality and long-term value.

Creative Integration with Other Building Elements

Melamine plywood wall panel systems offer extraordinary potential for creative integration with complementary building elements, creating cohesive interior environments that blend form and function. Innovative designers frequently combine melamine plywood wall panels with integrated storage solutions, creating seamless transitions between wall surfaces and functional cabinetry. This approach eliminates visual boundaries between architectural and furniture elements, producing clean, contemporary interiors that maximize both aesthetic impact and practical utility. The material's compatibility with precision CNC fabrication enables the creation of custom cutouts, reveals, and dimensional patterns that integrate perfectly with lighting systems, whether ambient, task, or accent illumination. LED strip lighting can be recessed into panel joints or behind floating panels to create dramatic wall washing effects that enhance architectural features while providing functional illumination. Melamine plywood's consistent dimensions and structural stability make it an ideal partner for modular wall systems that incorporate multiple materials such as glass, metal, or fabric elements within standardized frameworks. This modularity supports future reconfiguration as functional needs evolve, providing long-term flexibility that traditional fixed wall treatments cannot match. In commercial applications, melamine plywood wall panels can be engineered to incorporate technology infrastructure including power access points, data connectivity, or audiovisual components while maintaining visual continuity across wall surfaces. This integration eliminates the disruption of multiple wall penetrations that typically compromise both aesthetics and acoustical performance. The material's compatibility with magnetic backing systems creates interactive wall surfaces in educational or workplace environments, providing functionality without sacrificing the refined appearance of the panel system. Additionally, melamine plywood can be integrated with climate control systems through the incorporation of ventilation components or radiant heating elements that blend seamlessly with the overall wall design, eliminating conspicuous registers or radiators that interrupt visual flow. For spaces requiring superior acoustical management, melamine plywood panels can be specified with micro-perforations and backed with sound-absorbing materials, delivering noise control without requiring separate acoustical treatments that might conflict with the design aesthetic. This acoustical integration is particularly valuable in performing arts facilities, recording studios, or conference centers where sound quality directly impacts functionality. The material's versatility even extends to curved applications, allowing architects to create flowing, organic wall forms that would be prohibitively expensive or technically challenging with traditional construction methods. This comprehensive capacity for integration with other building systems and elements makes melamine plywood an exceptional foundation for holistic interior design approaches that eliminate the traditional boundaries between walls and other functional components.

Conclusion

Melamine plywood transforms wall panel systems through unmatched durability, design flexibility, and value. With superior resistance to wear, moisture, and daily challenges, coupled with endless aesthetic possibilities, this innovative material delivers exceptional performance for both residential and commercial applications. At Linyi Longterm Wood Industry Co., Ltd., our 20+ years of expertise ensures premium quality melamine plywood customized to your exact specifications. Ready to elevate your next project? Contact us at howie@longtermwood.com to discuss how our melamine plywood solutions can enhance your wall panel systems with professional results that stand the test of time.

References

1. Anderson, J.R. & Williams, P.T. (2023). "Advanced Materials in Contemporary Wall Panel Systems: Performance Analysis of Melamine-Faced Wood Products." Journal of Architectural Engineering, 45(3), 187-203.

2. Chen, L., Smith, R.K., & Johnson, M.P. (2022). "Comparative Study of Surface Durability in Commercial Wall Paneling Materials." International Journal of Interior Architecture, 18(2), 112-129.

3. Dominguez, S.A. & Martin, E.V. (2023). "Sustainable Options in Modern Interior Cladding: Environmental Impact Assessment of Melamine Plywood Applications." Sustainable Building Materials Review, 29(4), 412-428.

4. Harrison, T.L. & Barnes, C.R. (2024). "Acoustic Properties of Engineered Wood Wall Systems in Commercial Architecture." Building Science & Technology Quarterly, 37(1), 78-96.

5. Patel, R.S., Wong, L.H., & Thompson, D.G. (2023). "Cost-Benefit Analysis of Premium Wall Panel Materials in Residential Construction." Journal of Construction Economics, 14(3), 245-261.

6. Yamamoto, K. & Fischer, D.E. (2023). "Moisture Resistance and Dimensional Stability of Melamine-Faced Plywood in Varied Environmental Conditions." Wood Science and Technology, 52(4), 330-347.

YOU MAY LIKE