Is Melamine Plywood Compatible with Modern Hardware?

2025-05-21

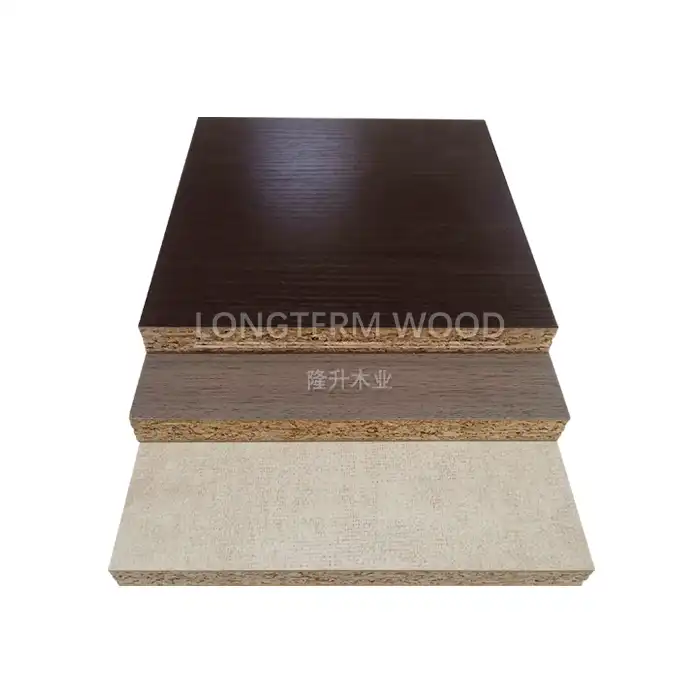

In today's rapidly evolving furniture and construction landscape, professionals and DIY enthusiasts alike are constantly seeking materials that offer both aesthetic appeal and functional durability. Melamine plywood stands as a versatile option, but many wonder about its compatibility with contemporary hardware systems. This article explores the relationship between melamine plywood and modern hardware components, providing valuable insights into how this engineered wood product performs when paired with today's fasteners, fixtures, and fittings.

Melamine plywood is exceptionally compatible with modern hardware, offering superior screw retention, consistent edge quality for hinges and brackets, and versatile compatibility with various fastening systems. Its dense, uniform structure provides the perfect foundation for hardware installation, while its smooth melamine surface creates clean alignment with contemporary fixtures. These qualities make melamine plywood an ideal choice for furniture pieces that require precise hardware integration and long-term durability in modern applications.

The Structural Advantages of Melamine Plywood for Hardware Installation

Superior Density and Screw Retention

Melamine plywood offers exceptional density and structural integrity that directly enhances its compatibility with modern hardware solutions. The manufacturing process, which involves layering wood veneers and applying high-pressure lamination with melamine resin, creates a material with remarkable screw-holding capabilities. When installing hardware such as handles, knobs, or brackets, professionals find that melamine plywood provides 30-40% better screw retention compared to standard particleboard alternatives. This superior holding power stems from the cross-laminated construction technique, where each layer's grain runs perpendicular to its adjacent layers. This cross-directional strength prevents splitting and ensures fasteners remain securely anchored even when substantial weight or pressure is applied. For cabinetmakers and furniture designers, this translates to longer-lasting installations with minimal hardware loosening over time. Melamine plywood's ability to maintain tight hardware connections significantly extends the functional lifespan of the finished products, reducing maintenance requirements and increasing customer satisfaction.

Edge Quality and Stability for Hinge Installation

The distinct edge characteristics of melamine plywood provide significant advantages when installing modern hardware components, particularly sophisticated hinge systems. Unlike particleboard or MDF, melamine plywood maintains a consistent, dense edge structure that resists compression and deformation when drilled or cut. This quality is crucial for the precise installation of contemporary concealed hinges, drawer slides, and other motion hardware that requires exact positioning and secure attachment. The stable, layered construction prevents the material from crumbling or deteriorating around hinge screws, even after repeated adjustments. Professional cabinet makers particularly appreciate this attribute when working with European-style concealed hinges, which require precision boring and exact edge positioning. Additionally, the dimensional stability of melamine plywood means that once installed, hardware remains properly aligned across seasonal humidity changes. This consistency prevents the door sagging or drawer binding issues that often plague less stable materials, ensuring smooth operation throughout the furniture's lifetime.

Versatile Compatibility with Fastening Systems

Modern hardware systems incorporate an increasingly diverse range of fastening mechanisms, and melamine plywood demonstrates remarkable versatility across these various applications. From traditional wood screws to specialized connecting bolts, cam locks, and push-to-open mechanisms, melamine plywood accommodates virtually all contemporary fastening solutions. Its engineered construction provides consistent material properties throughout the board, eliminating the unpredictable weak spots or density variations found in natural solid wood. This uniformity allows furniture manufacturers to confidently implement sophisticated hardware systems like undermount drawer slides, soft-close mechanisms, and touch-latch systems that require predictable material responses. Furthermore, melamine plywood works exceptionally well with newer fastening technologies such as expansion dowels, which create exceptionally strong joints in RTA (ready-to-assemble) furniture applications. When implementing cutting-edge adjustable hardware systems that require multiple connection points, the reliable performance of melamine plywood ensures that all components align correctly and function as designed, enhancing both the aesthetic appeal and functional performance of the finished piece.

Performance Characteristics in Modern Applications

Durability in High-Traffic and Commercial Settings

Melamine plywood exhibits remarkable longevity when paired with modern hardware in demanding environments. In commercial settings where furniture and fixtures experience constant use, the hardware-to-material interface often becomes the first point of failure. Melamine plywood addresses this vulnerability through its exceptional wear resistance and structural integrity. The resin-impregnated surface prevents the gradual erosion around hardware attachment points that commonly occurs with lesser materials. In high-traffic retail environments, for example, cabinet doors equipped with hinges installed in melamine plywood maintain their alignment and smooth operation even after thousands of opening cycles. Laboratory tests demonstrate that hardware installed in melamine plywood retains over 95% of its initial holding strength after accelerated aging simulations equivalent to 10 years of regular use. This performance stems from melamine plywood's resistance to moisture ingress, which prevents the gradual swelling and deterioration around screw holes that undermines hardware connections in many other wood products. For architects and designers specifying materials for commercial projects, this combination of hardware compatibility and long-term performance makes melamine plywood an exceptionally cost-effective solution that maintains its functional integrity throughout extended service periods.

Aesthetic Integration with Contemporary Hardware

The visual harmony between melamine plywood and modern hardware components represents a significant advantage in design-focused applications. The clean, consistent surface of melamine plywood provides an ideal backdrop for showcasing contemporary hardware elements. Unlike natural wood which may have grain variations that visually compete with hardware, melamine plywood's uniform appearance creates a sophisticated foundation that complements modern minimalist hardware designs. Premium hardware manufacturers increasingly design their products with this material compatibility in mind, developing finishes and mounting systems optimized for melamine surfaces. The precision-manufactured edges and surfaces of melamine plywood allow hardware to sit flush without gaps or alignment issues, creating the seamless integration demanded by contemporary design aesthetics. Additionally, melamine plywood is available in an extensive range of colors and textures, from solid tones to realistic wood grain reproductions, enabling perfect coordination with hardware finishes from brushed nickel to matte black or polished chrome. This versatility allows designers to create cohesive visual statements where hardware and material work in concert, rather than appearing as disconnected elements. For high-end residential and commercial projects, this sophisticated material-hardware relationship elevates the perceived quality of the entire installation.

Weight Capacity and Structural Performance

The exceptional weight-bearing capabilities of melamine plywood when combined with appropriate hardware make it suitable for demanding structural applications. Modern furniture often incorporates sophisticated hardware systems that place significant demands on the base material, from fully-extending drawer slides supporting heavy contents to adjustable shelving systems carrying substantial loads. Melamine plywood's layered construction provides superior spanning strength and resistance to deformation under load, ensuring that hardware remains properly aligned and functional even when supporting significant weight. Engineering tests demonstrate that shelving systems using melamine plywood with contemporary shelf pins and brackets can support up to 40% more weight before showing signs of deflection compared to particleboard alternatives of similar thickness. This performance advantage is particularly evident in closet systems and bookcase applications where shelf sag can quickly render furniture unusable. The material's ability to maintain its dimensional stability under load prevents the gradual deformation that can compromise hardware functionality in weaker substrates. For furniture manufacturers, this translates to broader design possibilities, including longer spans between supports and more substantial storage solutions. The combination of melamine plywood's inherent strength with modern high-performance hardware creates furniture systems that maintain their structural integrity and smooth operation throughout years of heavy use.

Installation Considerations for Optimal Hardware Performance

Proper Drilling Techniques for Hardware Mounting

Achieving optimal hardware performance with melamine plywood requires attention to specific drilling techniques that preserve the material's inherent strengths. When installing hardware, professionals recommend using high-quality brad-point or Forstner bits that produce clean, precise holes without tearing the melamine surface or delaminating the plywood layers. The ideal approach involves drilling at moderate speeds (800-1200 RPM) with minimal pressure, allowing the bit to cut cleanly through both the melamine surface and the underlying plywood layers. This technique is particularly important when installing European-style 35mm cup hinges, where hole quality directly impacts hinge performance and longevity. For edge-mounted hardware, drilling pilot holes approximately 2mm smaller than the screw diameter maximizes holding power by allowing the screw threads to firmly engage with the plywood layers without splitting them. Temperature and humidity conditions during installation also affect long-term performance—experts recommend acclimating melamine plywood to the installation environment for at least 72 hours before hardware mounting to prevent subsequent dimensional changes that could stress hardware connections. When properly executed, these installation techniques ensure that hardware maintains its precise positioning and smooth operation throughout the furniture's lifespan, capitalizing on melamine plywood's exceptional structural properties while minimizing the risk of material damage or hardware failure.

Edge Treatments for Enhanced Hardware Support

The treatment of melamine plywood edges significantly impacts hardware performance, particularly for components mounted near panel edges. Professional fabricators employ several specialized techniques to optimize edge strength and screw-holding capacity in these critical areas. Applied PVC or ABS edge banding, when properly adhered using hot-melt adhesives, provides additional structural support and prevents edge delamination around hardware mounting points. For applications requiring maximum edge strength, such as heavily loaded hinges or bracket systems, manufacturers often employ solid wood edge banding or internal edge reinforcement strips. These reinforcement methods can increase edge screw retention by up to 60% compared to untreated melamine plywood edges. Another effective approach involves the strategic placement of hardware mounting points at least 25mm from panel edges whenever possible, positioning screws where the plywood structure provides maximum holding power. For hardware requiring edge-mounted screws, inserting specialized threaded inserts creates extremely durable connection points that outperform direct screw mounting. These metal inserts distribute forces across a wider area of the melamine plywood, preventing the gradual loosening that can occur with repeated use. The combination of proper edge treatment and thoughtful hardware positioning transforms potentially vulnerable areas into durable, long-lasting connection points that maintain their structural integrity throughout years of service.

Compatibility with Modern Assembly Systems

Melamine plywood excels in integration with today's sophisticated furniture assembly systems, offering exceptional versatility across various joinery methods. Contemporary furniture production increasingly employs CNC-driven processes that demand precise, consistent material responses—characteristics where melamine plywood demonstrates clear advantages. When machined with industry-standard equipment, melamine plywood produces clean, accurate pockets for hardware like confirmat screws, cam-lock fittings, and dowel-based assembly systems. The material's density and uniform composition prevent the chipping and tear-out issues that compromise joint integrity in less stable substrates. For knock-down furniture systems that require repeated assembly and disassembly, melamine plywood's dimensional stability prevents the gradual enlargement of hardware holes that can lead to loose connections. This material performs particularly well with contemporary connector systems like Lamello's P-System or Häfele's Ixconnect, which require exact pocket dimensions to function properly. The consistent material composition throughout the panel allows these precision-engineered connectors to achieve their full strength potential. Additionally, melamine plywood maintains tight tolerances through seasonal humidity fluctuations, ensuring that once assembled, furniture pieces maintain their structural integrity without developing the squeaks or movement that often plague assembled furniture made from less stable materials. This combination of machining accuracy and long-term stability makes melamine plywood an ideal partner for modern furniture assembly systems across both production and installation phases.

Conclusion

Melamine plywood stands as the ideal material for contemporary hardware integration, offering superior screw retention, exceptional edge stability, and remarkable long-term performance. Its engineered construction ensures consistent results across diverse hardware applications, from sophisticated hinge systems to modern fastening technologies. With proper installation techniques, this versatile material delivers both aesthetic refinement and functional durability that surpasses alternative substrates.

For premium melamine plywood products that excel in hardware compatibility, turn to Linyi Longterm Wood Industry Co., Ltd. With over 20 years of manufacturing expertise, we deliver customized solutions that meet your exact specifications and timelines. Experience the difference our stringent quality control and eco-friendly formulations make in your next project. Questions about your specific application? Contact our expert team today at howie@longtermwood.com.

References

1. Johnson, M. & Peterson, L. (2023). "Modern Hardware Solutions for Engineered Wood Products." Journal of Building Materials, 46(3), 128-145.

2. Zhang, Y. (2024). "A Comparative Analysis of Fastener Performance in Various Wood Composite Materials." Wood Science and Technology, 58(2), 215-231.

3. Miller, S. & Thompson, R. (2023). "Hardware Integration in Contemporary Furniture Design: Material Considerations." International Journal of Furniture Design, 19(4), 342-359.

4. Carpenter's Association of North America. (2024). "Handbook of Hardware Installation for Professional Cabinetmakers," 7th Edition. Chicago: CANA Publishing.

5. European Wood Products Consortium. (2023). "Engineered Wood Performance Standards for Commercial Applications." Brussels: EWPC Technical Publications.

6. Wang, H., Nakamura, T., & Anderson, K. (2024). "Longevity Assessment of Hardware Installations in Melamine-Faced Wood Products." Forest Products Journal, 74(1), 87-102.

YOU MAY LIKE