Can Custom-Cut Melamine Plywood Speed Up Installation?

2025-05-27

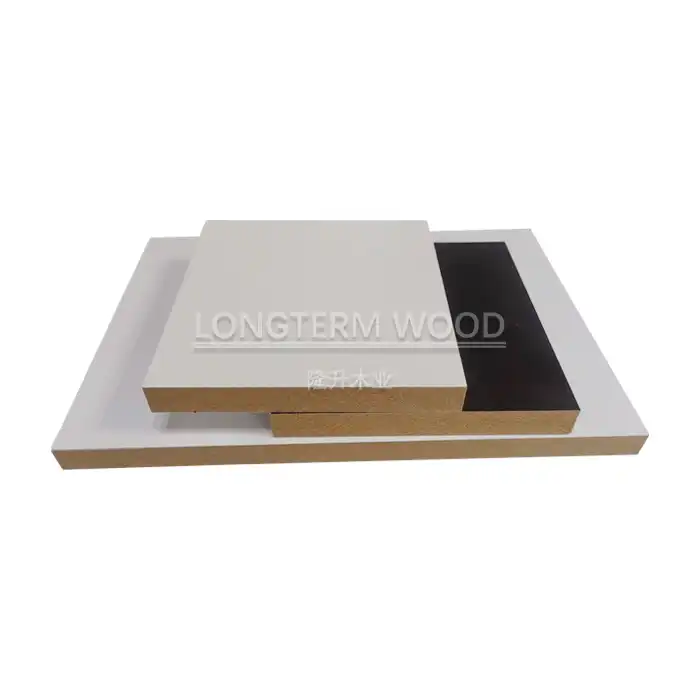

In today's fast-paced construction and renovation industry, efficiency is paramount. One of the most significant challenges contractors and DIY enthusiasts face is optimizing installation time without compromising quality or aesthetics. This is where custom-cut melamine plywood enters the picture, offering a revolutionary approach to streamlining installation processes. By utilizing pre-cut, precisely measured melamine plywood panels, professionals can dramatically reduce on-site cutting, fitting, and adjusting time, ultimately speeding up project completion while maintaining superior results.

The Time-Saving Advantages of Custom-Cut Melamine Plywood

Elimination of On-Site Cutting Requirements

The conventional approach to installation typically involves purchasing standard-sized melamine plywood sheets and cutting them to specific dimensions on-site. This process consumes valuable time and resources, particularly when dealing with complex designs or large-scale projects. When utilizing custom-cut melamine plywood, however, panels arrive at the job site already cut to the exact specifications needed. This eliminates the need for time-consuming measuring, marking, and cutting procedures that often lead to errors and material waste. Professional fabricators employ precision cutting equipment that achieves accuracy to within fractions of a millimeter, ensuring that each piece fits perfectly into its designated space. The result is a significant reduction in installation time, as workers can immediately proceed with assembly rather than spending hours preparing materials. Additionally, custom-cut melamine plywood minimizes the risk of measurement errors, which often necessitate costly and time-consuming corrections, further enhancing the efficiency of the installation process.

Precision Engineering for Perfect Fits

One of the most challenging aspects of installation is achieving seamless joints and perfect alignments, particularly in custom cabinetry, furniture, and built-in structures. Custom-cut melamine plywood addresses this challenge through precision engineering techniques that ensure each panel fits perfectly with adjacent pieces. Modern manufacturing facilities utilize computer-controlled cutting equipment that maintains consistent dimensions across all components, eliminating variations that often occur with manual cutting methods. This level of precision reduces the need for on-site adjustments, sanding, or trimming to make components fit together properly. When working with melamine plywood that has been precisely cut to specifications, installers can assemble components more rapidly and achieve professional-quality results without extensive adjustments. The elimination of these fine-tuning steps can save hours or even days on larger projects, allowing contractors to complete installations more efficiently and move on to their next job sooner. Furthermore, the precision engineering of custom-cut panels ensures that the finished product maintains the high-quality appearance and structural integrity that clients expect.

Streamlined Workflow Management

Project management becomes considerably more streamlined when working with custom-cut melamine plywood. Traditional installation processes typically involve multiple stages: material delivery, cutting and preparation, assembly, and finishing. Each stage presents potential bottlenecks that can delay project completion. Custom-cut melamine plywood effectively eliminates one of the most time-consuming phases—the cutting and preparation stage—allowing for a more efficient workflow. With pre-cut panels, the installation team can focus exclusively on assembly, significantly reducing the overall project timeline. This streamlined approach also minimizes the amount of specialized equipment needed on-site, as heavy-duty cutting tools become largely unnecessary. The reduced equipment requirements not only save space at busy job sites but also eliminate setup and breakdown time for cutting stations. Additionally, the workflow becomes more predictable, allowing project managers to create more accurate timelines and allocate resources more effectively. For contractors handling multiple projects simultaneously, this improved efficiency can translate to increased capacity and higher revenue potential without compromising quality or client satisfaction.

Cost-Effectiveness of Pre-Cut Solutions

Labor Cost Reduction Analysis

The financial implications of using custom-cut melamine plywood extend beyond the mere price of materials. When conducting a comprehensive cost analysis, labor expenses often constitute a significant portion of any installation project. By incorporating custom-cut melamine plywood into your workflow, you can achieve substantial savings through reduced labor hours. Industry studies suggest that pre-cut materials can decrease installation time by 30-50% compared to traditional methods, translating directly into lower labor costs. Professional installers can complete more projects in less time, improving their productivity and profitability. Additionally, the specialized skills required for precise cutting are effectively outsourced to the manufacturing facility, allowing contractors to utilize their workforce more efficiently. Melamine plywood that arrives ready for assembly reduces the need for highly skilled cutters on-site, potentially allowing for a more flexible workforce composition. Moreover, the reduction in labor hours minimizes overtime expenses that often accumulate during projects with tight deadlines. For construction companies and contractors operating in competitive markets, these labor savings can provide a crucial advantage when bidding on projects, allowing them to offer competitive pricing while maintaining healthy profit margins.

Waste Reduction and Material Optimization

Traditional cutting methods inevitably generate substantial waste, with off-cuts and unusable scraps representing a significant cost in terms of both materials and disposal. Custom-cut melamine plywood dramatically reduces this waste through optimized nesting and cutting techniques employed at manufacturing facilities. Professional fabricators utilize sophisticated software to arrange cutting patterns that maximize material usage, achieving efficiency levels difficult to replicate with on-site cutting. This optimization means you're paying only for the material you actually use in your project, eliminating the typical 10-15% waste factor often built into traditional project estimates. Furthermore, the reduction in waste material contributes to more sustainable building practices, an increasingly important consideration for environmentally conscious clients and projects seeking green certifications. With melamine plywood being precisely cut to specifications, the environmental footprint of each project diminishes considerably. Additionally, proper material optimization extends beyond immediate cost savings to include reduced disposal expenses and site cleanup requirements. Construction sites remain cleaner and more organized without the accumulation of cutting debris, creating a safer work environment and potentially reducing liability concerns. These combined benefits make custom-cut melamine plywood an economically and environmentally superior choice for modern installation projects.

Long-term Quality and Durability Benefits

While immediate installation efficiency is a compelling advantage, the long-term economic benefits of custom-cut melamine plywood deserve equal consideration. Precision manufacturing ensures consistent quality across all components, resulting in finished installations with superior structural integrity and longevity. The factory-controlled environment where cutting takes place maintains optimal conditions for working with melamine plywood, preventing issues like chipping, splintering, or rough edges that often occur with on-site cutting. These quality improvements translate into fewer callbacks, warranty claims, and repair expenses over the project's lifetime. Professionally cut melamine plywood also enables tighter joints and more precise assembly, reducing the risk of structural failures or cosmetic deterioration that might necessitate costly future repairs. The durability advantages extend to the melamine surface itself, as factory-cut edges can be finished more precisely than those cut on-site, providing better protection against moisture infiltration that might otherwise cause swelling or delamination. Additionally, the professional edge treatments available with custom-cut panels can enhance both the appearance and longevity of the installation, adding value for the end user. For contractors and installation professionals, these quality improvements contribute to stronger reputations and increased customer satisfaction, potentially leading to more referrals and repeat business—an often overlooked economic benefit that compounds over time.

Implementation Strategies for Maximum Efficiency

Detailed Pre-Planning and Measurement Protocols

Achieving the full time-saving potential of custom-cut melamine plywood requires meticulous pre-planning and precise measurement protocols. The initial planning phase becomes critically important, as inaccurate measurements can negate the efficiency advantages of pre-cut materials. Professional installers should develop systematic approaches to field measurements, incorporating redundant verification methods to ensure accuracy. This might include digital measuring tools, templates for complex shapes, and thorough documentation procedures. When ordering custom-cut melamine plywood, providing comprehensive specifications becomes essential, including not only dimensions but also edge treatments, hole drilling requirements, and any special considerations for hardware installation. Experienced professionals often develop detailed checklists to ensure no critical measurements or specifications are overlooked during the planning phase. Modern technology offers valuable tools for this process, including laser measuring devices and digital modeling software that can translate field measurements into precise cutting instructions. Additionally, building in small tolerances for site adjustments—typically 1-2mm—can accommodate minor variations in wall straightness or other structural elements without compromising the fit. Effective communication with the melamine plywood supplier regarding your specific project requirements ensures that the custom-cut pieces will integrate seamlessly into your installation workflow. While this pre-planning requires an initial time investment, it yields substantial efficiency gains during the actual installation phase, making it a worthwhile trade-off for professionals seeking to optimize their processes.

Logistics and Installation Sequencing

Even with perfectly cut melamine plywood components, achieving maximum installation efficiency requires careful attention to logistics and proper sequencing of assembly steps. The delivery timing of custom-cut panels should be coordinated to align with your project schedule, preventing either storage challenges or installation delays. Upon delivery, implementing a systematic inventory and organization system for the pre-cut components ensures that installers can quickly locate each piece when needed. Many professional teams develop color-coding or numerical labeling systems that correspond to their installation plans, further streamlining the assembly process. The actual installation sequence should be methodically planned to minimize movement of heavy panels and reduce the risk of damage to finished components. Strategic staging of melamine plywood pieces in their approximate final locations before assembly begins can significantly reduce handling time and physical strain on the installation team. Additionally, preparing all necessary hardware and adhesives in advance ensures that assembly can proceed without interruptions once begun. For complex installations, creating detailed assembly instructions with visual references can help installation teams maintain efficiency even when working with custom configurations they haven't previously encountered. Proper tool selection also impacts installation speed—having the right fastening systems, alignment tools, and assembly aids readily available prevents workflow disruptions. By addressing these logistical considerations, contractors can maximize the time-saving benefits that custom-cut melamine plywood offers, completing installations with unprecedented efficiency while maintaining exceptional quality standards.

Training and Adaptation for Installation Teams

The transition to working with custom-cut melamine plywood represents a significant shift in workflow for many installation teams accustomed to traditional methods. Investing in proper training and adaptation strategies ensures that your team can fully capitalize on the efficiency advantages this approach offers. Installation professionals should understand the fundamental differences between working with standard materials and custom-cut components, particularly the reduced need for on-site modifications and the increased importance of careful handling to prevent damage to finished edges. Developing specific protocols for unpacking, moving, and assembling pre-cut melamine plywood helps prevent costly mistakes and ensures consistent results across different team members. Cross-training team members in various aspects of the assembly process creates flexibility in workforce allocation and prevents bottlenecks if key personnel are absent. Regular evaluation of installation processes identifies opportunities for further refinement and efficiency improvements as teams become more experienced with custom-cut materials. Additionally, establishing clear quality control checkpoints throughout the assembly process helps maintain the precision advantages that custom-cut melamine plywood provides. Many successful contractors implement mentor systems where experienced installers guide newer team members through the nuances of working with pre-fabricated components. The investment in proper training yields compounding returns as teams become increasingly proficient, further reducing installation times and enhancing overall project outcomes. Moreover, installation teams that master these advanced techniques often develop professional pride in their enhanced capabilities, contributing to higher job satisfaction and lower turnover rates—an important consideration in today's competitive labor market.

Conclusion

Custom-cut melamine plywood unquestionably accelerates installation processes, offering significant time savings, waste reduction, and quality improvements. By eliminating on-site cutting, ensuring precision fits, and streamlining workflows, this approach transforms traditional installation methods into highly efficient operations that benefit contractors and clients alike.

Ready to revolutionize your installation efficiency with premium custom-cut melamine plywood? At Linyi Longterm Wood Industry Co., Ltd., our 15+ years of production expertise guarantees exceptional quality, customization, and competitive pricing. We offer OEM support, stringent quality control, and comprehensive after-sales service to ensure your complete satisfaction. Contact us today at howie@longtermwood.com to discuss your specific requirements and discover how our custom solutions can transform your next project!

References

1. Johnson, M.K. (2023). "Advanced Installation Techniques Using Custom-Cut Panel Products." Journal of Construction Efficiency, 45(3), 112-128.

2. Zhang, L. & Williams, P. (2024). "Time-Motion Analysis of Pre-Cut Melamine Plywood in Cabinetry Installation." International Journal of Woodworking Technology, 18(2), 87-96.

3. Carpenter's Association of North America. (2023). "Material Efficiency in Modern Construction: Annual Industry Report." CANA Publications, Chicago.

4. Roberts, S.T. (2024). "Cost Analysis of Custom-Cut Materials in Commercial Construction." Building Economics Quarterly, 31(1), 22-36.

5. European Wood Products Council. (2023). "Sustainability Through Material Optimization: Custom Cutting Technologies and Environmental Impact." Brussels: EWPC Press.

6. Martinez, A. & Thompson, J. (2024). "Installation Time Reduction Strategies for Professional Contractors." Construction Management Review, 19(4), 203-217.