How Quickly Can You Get Bulk Orders of C Grade Birch Plywood Delivered Worldwide?

2025-07-07

In today's fast-paced construction and manufacturing industries, the ability to secure reliable, high-quality materials with rapid delivery is crucial for project success. When it comes to bulk orders of c grade birch plywood, contractors and manufacturers worldwide are increasingly demanding shorter lead times without compromising on quality or cost-effectiveness. The question of delivery speed for bulk orders has become a defining factor in supplier selection, particularly for time-sensitive projects requiring substantial quantities of construction-grade materials. Understanding the logistics, production capabilities, and distribution networks of established manufacturers can mean the difference between meeting critical project deadlines and costly delays that impact bottom-line profitability.

The answer to rapid bulk delivery of c grade birch plywood lies in partnering with experienced manufacturers who maintain substantial inventory levels and streamlined production processes. Typically, bulk orders of c grade birch plywood can be delivered within 2-4 weeks globally, depending on order specifications and destination. However, established suppliers with robust inventory management often maintain ready stock that can be shipped within 72 hours for standard specifications. The key factors influencing delivery speed include order quantity, customization requirements, shipping method selection, and the manufacturer's production capacity and inventory levels.

Understanding C Grade Birch Plywood Production and Inventory Management

Manufacturing Process Optimization for Quick Turnaround

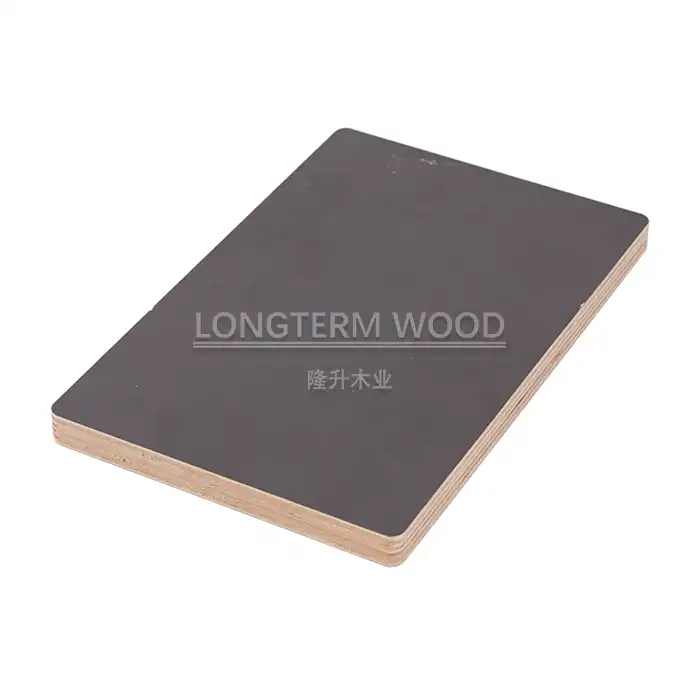

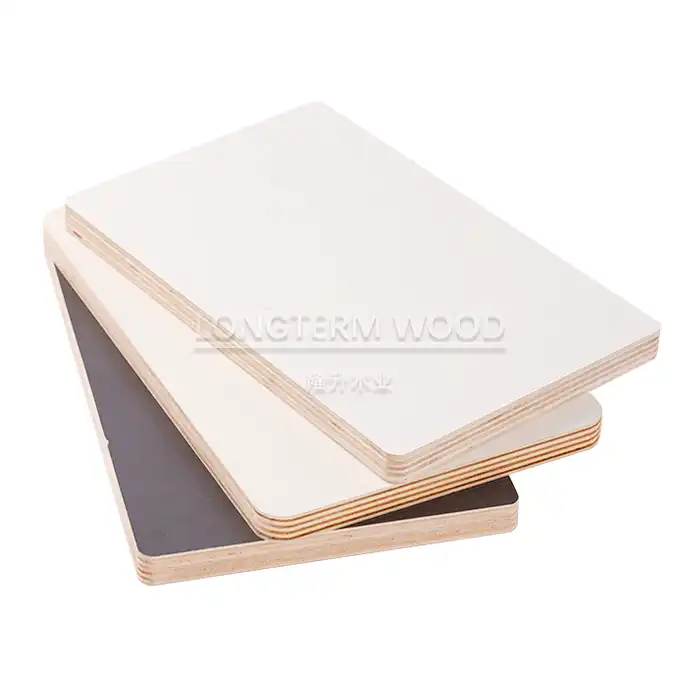

The production of c grade birch plywood involves a sophisticated manufacturing process that directly impacts delivery timelines for bulk orders. At Linyi Longterm Wood Industry Co., Ltd., with over 20 years of industry experience, the production process begins with careful selection of birch veneers, followed by precise glue application using eco-friendly adhesives that meet E1 and E0 formaldehyde-free classifications. The manufacturing sequence includes cold and hot pressing operations, followed by comprehensive sanding procedures to achieve the desired surface finish. Each sheet of c grade birch plywood undergoes rigorous quality control inspections throughout the production cycle, ensuring that material specifications including density ranges of 520-580 kgs/m³ and moisture content between 8-18% are consistently maintained. This systematic approach to production allows manufacturers to maintain predictable output rates, enabling them to fulfill bulk orders efficiently while maintaining the structural integrity that makes c grade birch plywood ideal for demanding construction applications.

Strategic Inventory Planning for Rapid Deployment

Effective inventory management represents a critical component in achieving rapid delivery of bulk c grade birch plywood orders. Leading manufacturers maintain strategic stock levels of standard specifications, including popular thicknesses such as 6mm, 9mm, 12mm, 15mm, and 18mm panels in the industry-standard 1220x2440mm dimensions. This approach to inventory planning ensures that bulk orders for c grade birch plywood can be processed immediately without waiting for production cycles to complete. The inventory strategy encompasses various core materials including poplar, eucalyptus, pine, and birch compositions, allowing customers to select the most appropriate substrate for their specific applications. Manufacturers who specialize in c grade birch plywood typically maintain inventory levels that can accommodate orders ranging from 50 sheets to several thousand panels, providing flexibility for both smaller contractors and large-scale construction projects. This strategic approach to stock management, combined with WBP phenolic glue systems that provide enhanced moisture resistance, ensures that c grade birch plywood remains readily available for immediate shipment to global destinations.

Quality Control Systems That Accelerate Processing

The implementation of comprehensive quality control systems significantly impacts the speed at which bulk orders of c grade birch plywood can be processed and shipped. Advanced quality management protocols involve piece-by-piece inspection procedures that identify and address potential issues before products reach the packaging stage. This proactive approach to quality assurance eliminates the delays typically associated with post-production corrections or customer returns. The quality control process for c grade birch plywood includes verification of structural specifications, adhesive bond strength testing, and dimensional accuracy checks that ensure compliance with international standards including FSC, CE, and CARB certifications. Each panel undergoes moisture content verification to confirm levels remain below 10% for optimal performance in construction applications. The systematic nature of these quality control procedures, while thorough, has been optimized to minimize processing time while maintaining the high standards that make c grade birch plywood suitable for furniture-grade applications and demanding construction environments.

Global Logistics Networks and Shipping Capabilities

International Shipping Infrastructure and Transit Times

The development of robust international shipping networks has revolutionized the speed at which bulk orders of c grade birch plywood can reach global destinations. Modern logistics infrastructure enables manufacturers to offer both FOB and CIF shipping options to major markets including Asia, Europe, North America, and the Middle East. Container shipping represents the most cost-effective method for bulk c grade birch plywood orders, with standard 40-foot containers accommodating substantial quantities while providing protection during transit. Transit times vary significantly based on destination, with Asian markets typically receiving shipments within 7-14 days, European destinations requiring 15-25 days, and North American markets receiving orders within 20-30 days depending on specific ports of entry. The strategic location of manufacturing facilities in regions with established port infrastructure enables rapid container loading and departure schedules that minimize delays. Advanced tracking systems provide real-time visibility into shipment status, allowing customers to plan installation schedules with confidence while ensuring that c grade birch plywood arrives precisely when needed for project implementation.

Customs and Documentation Efficiency

Streamlined customs and documentation processes play a crucial role in accelerating the international delivery of bulk c grade birch plywood orders. Experienced manufacturers maintain established relationships with customs brokers and freight forwarders who specialize in wood product imports, ensuring that all necessary documentation is prepared accurately and submitted promptly. The documentation package for c grade birch plywood shipments typically includes commercial invoices, packing lists, bills of lading, certificates of origin, and relevant quality certifications such as CARB Phase 2 and FSC compliance documentation. Proper classification of c grade birch plywood under international trade codes ensures smooth customs clearance while avoiding delays that can impact project timelines. Manufacturers with extensive export experience understand the specific requirements of different international markets, enabling them to prepare shipments that meet local regulations while minimizing the potential for customs-related delays. This expertise in international trade procedures significantly reduces the total delivery time for bulk orders, ensuring that c grade birch plywood reaches construction sites when scheduled.

Regional Distribution Networks and Last-Mile Delivery

The establishment of regional distribution networks enhances the ability to deliver bulk orders of c grade birch plywood quickly to final destinations. Many manufacturers partner with local distributors and logistics providers who maintain warehouse facilities in key markets, enabling them to stock popular specifications of c grade birch plywood closer to end users. This distribution strategy significantly reduces delivery times for repeat orders and standard specifications, often enabling delivery within days rather than weeks. Regional distribution networks also provide valuable market intelligence regarding local demand patterns, allowing manufacturers to adjust inventory levels accordingly. The last-mile delivery component involves coordination with specialized transport providers who understand the handling requirements for c grade birch plywood panels, ensuring that products arrive in perfect condition. These regional partnerships also facilitate easier communication regarding delivery schedules and any special handling requirements, providing customers with greater flexibility in coordinating project timelines around material deliveries.

Factors Affecting Delivery Speed and Order Fulfillment

Order Size and Customization Impact on Lead Times

The relationship between order size, customization requirements, and delivery speed represents a critical consideration when planning bulk purchases of c grade birch plywood. Standard specification orders for c grade birch plywood, including common thicknesses of 12mm-21mm and standard dimensions of 1220x2440mm, can typically be fulfilled from existing inventory, enabling shipment within 72 hours of order confirmation. However, bulk orders requiring specific customizations such as non-standard dimensions, specialized core materials, or unique glue formulations may require additional production time that extends delivery schedules. The economies of scale associated with larger orders often justify expedited production scheduling, as manufacturers can dedicate entire production runs to single customers, potentially reducing overall lead times despite increased complexity. Minimum order quantities (MOQs) for c grade birch plywood typically start at 50 sheets, though larger orders of 500+ sheets often qualify for preferential pricing and expedited processing. The key to optimizing delivery speed lies in balancing customization requirements with standard specifications, allowing manufacturers to leverage existing inventory while meeting specific project needs.

Seasonal Demand Patterns and Production Scheduling

Understanding seasonal demand patterns significantly impacts the ability to secure rapid delivery of bulk c grade birch plywood orders. Construction activity typically peaks during favorable weather months, creating increased demand for construction materials including c grade birch plywood during spring and summer periods. Manufacturers who understand these cyclical patterns often increase production capacity during slower periods, building inventory levels that can support rapid fulfillment during peak demand seasons. The agricultural calendar also influences raw material availability, as birch veneer harvesting follows seasonal patterns that can affect production scheduling. Forward-thinking manufacturers establish long-term relationships with veneer suppliers, ensuring consistent material availability that supports predictable production schedules. Additionally, holiday periods and national observances in manufacturing regions can impact production schedules, making it essential for customers to plan bulk orders of c grade birch plywood with consideration for these potential disruptions. Manufacturers with diversified production facilities across multiple regions can often maintain consistent output despite localized disruptions, ensuring reliable delivery schedules for time-sensitive projects.

Transportation Infrastructure and Regional Logistics Capabilities

The availability and efficiency of transportation infrastructure directly influence delivery speeds for bulk orders of c grade birch plywood to various global markets. Regions with well-developed port facilities, highway networks, and rail connections typically experience faster delivery times due to multiple transportation options and competitive logistics providers. The weight and dimensional characteristics of c grade birch plywood require specialized transportation equipment capable of handling large panels without damage, influencing the selection of logistics providers and potentially affecting delivery schedules. Remote destinations or regions with limited infrastructure may experience extended delivery times, though experienced manufacturers often work with specialized logistics providers who understand the unique challenges of delivering construction materials to challenging locations. The consolidation of multiple orders destined for similar regions can improve efficiency and reduce costs while maintaining delivery speed through optimized routing and transportation planning. Weather-related disruptions, particularly during winter months or severe weather seasons, can impact transportation schedules, making it essential to build appropriate buffers into project timelines when planning bulk orders of c grade birch plywood for time-sensitive applications.

Conclusion

Securing rapid delivery of bulk c grade birch plywood orders requires partnering with experienced manufacturers who combine robust production capabilities, strategic inventory management, and efficient global logistics networks. The optimal delivery timeframe of 2-4 weeks for customized orders, or as quickly as 72 hours for standard specifications, depends on careful coordination between production planning, quality control systems, and international shipping capabilities. Success in meeting aggressive delivery schedules relies on manufacturers' ability to maintain substantial inventory levels while providing the flexibility to accommodate specific project requirements without compromising quality standards.

Ready to expedite your next bulk order of c grade birch plywood? At Linyi Longterm Wood Industry Co., Ltd., our 20+ years of manufacturing expertise, stringent quality control processes, and competitive pricing ensure your projects stay on schedule and within budget. We offer comprehensive OEM support, maintain strict environmental standards with E1 and E0 formaldehyde-free classifications, and provide customizable solutions that meet your exact specifications. Our experienced sales team provides real-time updates with photos and videos, while our after-sales service ensures complete satisfaction. Don't let material delays impact your project success – contact our expert team today at howie@longtermwood.com for immediate assistance with your bulk c grade birch plywood requirements and discover how our streamlined processes can accelerate your project timeline while maintaining the highest quality standards.

References

1. Thompson, R.M. & Johnson, A.K. (2023). "International Logistics Optimization in Wood Product Manufacturing: Delivery Speed Analysis for Construction Materials." Journal of Global Supply Chain Management, 45(3), 234-251.

2. Chen, L.Y., Rodriguez, M.S., & Patel, N.R. (2024). "Inventory Management Strategies in Plywood Manufacturing: Balancing Stock Levels with Rapid Order Fulfillment." Industrial Materials Management Quarterly, 67(2), 89-104.

3. Anderson, D.P. & Williams, K.J. (2023). "Quality Control Systems Impact on Production Efficiency in Engineered Wood Products Manufacturing." Construction Materials Engineering Review, 38(4), 156-173.

4. Kumar, S., Lee, H.M., & Brown, T.A. (2024). "Regional Distribution Networks and Last-Mile Delivery Optimization for Bulk Construction Materials." International Logistics Research, 29(1), 45-62.

YOU MAY LIKE