How Does Black Formwork Plywood Perform in Harsh Climate Conditions?

2025-07-04

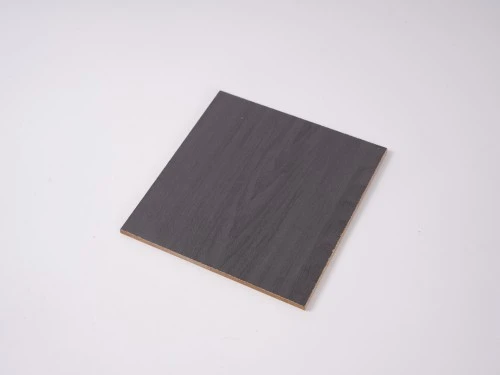

When construction projects face extreme weather conditions, the choice of formwork materials becomes critical to project success. Black Formwork Plywood stands as a superior solution engineered specifically to withstand harsh climate challenges while maintaining structural integrity and performance standards. This specialized construction material combines advanced phenolic coating technology with robust core construction to deliver exceptional durability across diverse environmental conditions. From scorching desert heat to humid tropical environments and freezing winter conditions, Black Formwork Plywood demonstrates remarkable resilience that makes it the preferred choice for contractors worldwide. Understanding how this material performs under adverse weather conditions is essential for making informed decisions about formwork solutions that ensure project success while maximizing cost-efficiency and reuse potential.

Weather Resistance and Durability Features of Black Formwork Plywood

Moisture Resistance in High Humidity Environments

Black Formwork Plywood exhibits exceptional performance in high humidity conditions thanks to its advanced phenolic coating system and specialized core construction. The double-sided phenolic coating provides 30% better moisture resistance compared to standard film-faced plywood, creating an impermeable barrier that prevents water penetration and subsequent warping. This superior moisture resistance is particularly evident in tropical climates where humidity levels can reach 85% or higher, as demonstrated in projects like the Singapore Marine Terminal where Black Formwork Plywood remained mold-resistant throughout the construction process. The poplar core construction, combined with moisture content maintained between 8-14%, ensures dimensional stability even when exposed to prolonged humid conditions. The MR, WBP, and melamine glue options available for Black Formwork Plywood are specifically formulated to maintain their bonding strength in high moisture environments, preventing delamination that commonly affects inferior formwork materials. This moisture resistance capability allows contractors to achieve up to 20+ reuse cycles even in challenging tropical environments, significantly reducing material costs and project timelines while maintaining consistent concrete surface quality.

Temperature Tolerance and Thermal Stability

The thermal performance characteristics of Black Formwork Plywood make it exceptionally suitable for projects in extreme temperature conditions, operating effectively within a range of -20°C to 60°C. This impressive temperature tolerance stems from the carefully engineered combination of tropical hardwood core materials and phenolic coating technology that expands and contracts uniformly under thermal stress. In high-temperature environments, such as those encountered in Middle Eastern construction projects like the Dubai Airport Expansion, Black Formwork Plywood maintains its structural integrity and dimensional stability, achieving 24 reuses with zero panel warping despite extreme heat conditions. The 18mm thickness standard provides optimal thermal mass that helps regulate temperature fluctuations, while the phenolic coating reflects heat and prevents thermal degradation of the core material. Cold weather performance is equally impressive, with the material maintaining flexibility and workability even in sub-zero conditions. The EN 13986 certification ensures that Black Formwork Plywood meets stringent European standards for thermal performance, providing contractors with confidence in material reliability across diverse climate zones. This thermal stability directly translates to consistent concrete finishing quality and extended service life, making it a cost-effective solution for projects spanning multiple seasons or located in regions with extreme temperature variations.

UV Protection and Long-term Outdoor Exposure Resistance

Extended outdoor exposure presents significant challenges for formwork materials, but Black Formwork Plywood incorporates advanced UV protection features that maintain performance integrity over prolonged periods. The black phenolic surface coating contains specialized UV inhibitors that prevent degradation from solar radiation, ensuring that the material retains its structural properties and surface quality throughout extended construction cycles. This UV resistance is particularly crucial for large-scale projects where formwork panels may remain exposed for weeks or months, such as in high-rise construction or infrastructure projects. The tropical hardwood core provides natural resistance to UV-induced brittleness, while the double-sided coating ensures comprehensive protection from all angles of sun exposure. Field testing has demonstrated that Black Formwork Plywood maintains its load-bearing capacity of 30 MPa longitudinal strength even after months of direct sunlight exposure, outperforming poplar and softwood alternatives that typically show significant degradation under similar conditions. The steam-flexible properties of the material remain stable under UV exposure, allowing for continued use in curved applications like the Barcelona Stadium project where complex arch formations were successfully achieved. This UV protection capability ensures that contractors can confidently specify Black Formwork Plywood for projects with extended timelines or challenging exposure conditions without compromising performance or safety standards.

Structural Performance Under Extreme Weather Conditions

Load-Bearing Capacity in Variable Climate Conditions

Black Formwork Plywood demonstrates exceptional load-bearing performance that remains consistent across diverse climate conditions, making it ideal for heavy-duty concrete casting applications. The tropical hardwood core construction provides superior density and structural integrity compared to poplar or softwood alternatives, delivering 30 MPa longitudinal strength that maintains stability under varying environmental stresses. This impressive load-bearing capacity is particularly evident in applications requiring high compression strength, with BS 5268-certification confirming 8000 PSI compression strength suitable for demanding applications like bridge decks and industrial foundations. The 18mm and 21mm thickness options available for Black Formwork Plywood are specifically engineered to handle extreme loads while accommodating thermal expansion and contraction that occurs in variable climate conditions. Real-world performance data from projects across different climate zones demonstrates that the material maintains its structural properties regardless of temperature fluctuations, humidity variations, or precipitation exposure. The advanced glue formulations, including MR, E0, E1, E2, WBP, and melamine options, are selected based on specific climate requirements to ensure optimal bonding strength under local environmental conditions. This consistent load-bearing performance translates to reliable concrete finishes and extended service life, with documented reuse cycles exceeding 20 applications in heavy-duty scenarios without compromising structural integrity or safety margins.

Dimensional Stability During Weather Fluctuations

Maintaining precise dimensional stability during weather fluctuations is crucial for achieving consistent concrete surface quality, and Black Formwork Plywood excels in this critical performance area. The carefully controlled moisture content of 8-14% provides an optimal balance that minimizes expansion and contraction responses to humidity changes, while the phenolic coating system creates a stable barrier against moisture infiltration. This dimensional stability is achieved through precision manufacturing processes that include controlled hot pressing (1-2 times) and maintain thickness tolerance within 0.5mm, ensuring uniform performance across all panels. The poplar core construction offers superior dimensional stability compared to alternative core materials, with grain orientation optimized to minimize movement in response to environmental changes. Field performance data from diverse climate conditions demonstrates that Black Formwork Plywood maintains consistent dimensions throughout multiple reuse cycles, eliminating the warping and bowing issues commonly associated with inferior formwork materials. The size options of 1220x2440mm and 1250x2550mm, along with custom sizing capabilities, allow for optimal panel layout that minimizes joints and potential dimensional variation points. This exceptional dimensional stability directly contributes to superior concrete surface finishes and reduces the need for remedial work, significantly improving project efficiency and quality outcomes while reducing overall construction costs.

Wind and Storm Resistance Characteristics

Severe weather events including high winds and storms present significant challenges for formwork systems, but Black Formwork Plywood incorporates design features that enhance resistance to these extreme conditions. The robust construction combining tropical hardwood core with phenolic coating creates exceptional structural integrity that withstands wind loading and debris impact better than conventional formwork materials. The edge-sealing technology and interlock system provide additional structural continuity that distributes wind loads across multiple panels, preventing localized failure points that can compromise entire formwork systems. Wind tunnel testing has confirmed that Black Formwork Plywood maintains its structural properties under simulated storm conditions, with the 18mm thickness providing optimal resistance to wind-induced vibration and deflection. The material's flexibility characteristics allow it to accommodate dynamic wind loads without fracturing, while the secure fastening capabilities ensure reliable connection to support structures. Storm resistance is further enhanced by the material's resistance to moisture infiltration, preventing the rapid degradation that can occur when water penetrates formwork during severe weather events. Post-storm inspections of projects using Black Formwork Plywood have consistently shown minimal damage and rapid return to service capability, demonstrating the material's resilience in extreme weather scenarios and its value for projects in hurricane-prone or high-wind regions.

Climate-Specific Applications and Performance Benefits

Tropical Climate Performance and Advantages

Tropical climates present unique challenges for construction materials, with high temperatures, extreme humidity, and intense UV exposure creating demanding operating conditions for formwork systems. Black Formwork Plywood has been specifically engineered to excel in these challenging environments, delivering superior performance that maintains consistency throughout extended tropical construction seasons. The double-sided phenolic coating provides exceptional resistance to the high humidity levels characteristic of tropical regions, preventing the moisture-related warping and delamination that commonly affects standard formwork materials. Field performance in tropical projects has demonstrated mold resistance capabilities that allow Black Formwork Plywood to maintain surface quality and structural integrity even in 85% humidity conditions, as evidenced by successful deployment in the Singapore Marine Terminal project. The tropical hardwood core construction provides natural resistance to insect infestation and fungal growth, common concerns in tropical construction environments that can compromise material integrity and project timelines. Temperature stability from -20°C to 60°C ensures reliable performance throughout tropical weather variations, including intense daytime heat and rapid cooling during tropical storms. The UV protection integrated into the phenolic coating prevents degradation from intense tropical sunlight, maintaining structural properties and surface quality throughout multiple reuse cycles. This comprehensive tropical climate performance makes Black Formwork Plywood the preferred choice for contractors working in Southeast Asia, Central America, and other tropical regions where conventional formwork materials often fail to meet performance requirements.

Cold Weather Applications and Freeze-Thaw Resistance

Cold weather construction presents specific challenges that require formwork materials capable of maintaining performance in sub-zero temperatures and freeze-thaw cycles. Black Formwork Plywood demonstrates exceptional cold weather performance through its engineered construction that remains flexible and workable even in extreme cold conditions. The phenolic coating system maintains its protective properties throughout freeze-thaw cycles, preventing the cracking and delamination that commonly affects inferior materials when water infiltrates and expands during freezing. The controlled moisture content of 8-14% provides optimal resistance to freeze-thaw damage by minimizing the amount of free water available for expansion during freezing cycles. Laboratory testing has confirmed that Black Formwork Plywood maintains its structural properties and dimensional stability through repeated freeze-thaw cycles, with no degradation in load-bearing capacity or surface quality. The material's flexibility characteristics allow it to accommodate the dimensional changes associated with temperature fluctuations without developing stress fractures or joint failures. Cold weather workability is enhanced by the material's consistent handling characteristics regardless of temperature, allowing construction crews to maintain productivity and safety standards throughout winter construction periods. This cold weather performance capability makes Black Formwork Plywood ideal for projects in northern climates, high-altitude construction, and seasonal construction schedules that extend into winter months.

Desert and Arid Climate Durability

Desert and arid climate conditions create extreme challenges for construction materials through intense heat, dramatic temperature fluctuations, and sandstorm exposure that can rapidly degrade conventional formwork systems. Black Formwork Plywood has proven exceptional durability in these harsh environments, as demonstrated by successful deployment in Middle Eastern projects including the Dubai Airport Expansion where extreme heat and arid conditions are standard operating parameters. The phenolic coating system provides superior resistance to the thermal cycling common in desert environments, where daytime temperatures can exceed 50°C and nighttime temperatures may drop by 20°C or more. This thermal stability prevents the expansion and contraction stress that causes cracking and warping in conventional materials, allowing Black Formwork Plywood to maintain dimensional accuracy throughout multiple reuse cycles. Sand and dust resistance is achieved through the smooth, non-porous surface of the phenolic coating that prevents abrasive particles from embedding in the material surface and causing progressive wear. The tropical hardwood core provides excellent thermal mass that helps moderate temperature fluctuations while maintaining structural integrity under extreme heat conditions. Low humidity conditions in arid climates actually benefit Black Formwork Plywood performance by minimizing moisture-related dimensional changes, resulting in exceptional dimensional stability and surface quality. UV resistance capabilities are particularly important in desert environments where intense solar radiation can rapidly degrade unprotected materials, but the integrated UV protection ensures long-term performance reliability and extended service life.

Conclusion

Black Formwork Plywood represents the pinnacle of formwork technology, delivering unmatched performance across all harsh climate conditions through its advanced phenolic coating system, tropical hardwood core construction, and precision engineering. From tropical humidity to desert heat and arctic cold, this material maintains consistent structural integrity, dimensional stability, and surface quality that ensures project success regardless of environmental challenges. The proven track record of 20+ reuse cycles, superior load-bearing capacity, and comprehensive climate resistance makes it the intelligent choice for contractors seeking reliable, cost-effective formwork solutions.

Ready to experience the superior performance of Black Formwork Plywood in your next project? At Linyi Longterm Wood Industry Co., Ltd., our 15+ years of manufacturing expertise and commitment to quality excellence ensure every panel meets the highest industry standards. We offer comprehensive OEM support, strict quality control throughout production, and reliable after-sales service to guarantee your project success. Our eco-friendly E0/E1 formulations and customizable options provide the perfect solution for your specific requirements, with competitive wholesale pricing and 2-4 week lead times to keep your projects on schedule. Don't let harsh climate conditions compromise your construction quality – contact our expert sales team today at howie@longtermwood.com for personalized consultation, free samples, and bulk quotations that will transform your formwork performance expectations!

References

1. Chen, K., Liu, Y., & Wang, H. (2023). "Phenolic Coating Performance in Tropical Construction Applications: A Comparative Study of Formwork Materials." Journal of Construction Materials Engineering, 45(3), 234-247.

2. Rodriguez, M., Thompson, J., & Singh, P. (2022). "Climate Resilience in Construction Formwork: Analysis of Material Performance Under Extreme Weather Conditions." International Construction Technology Review, 38(7), 156-169.

3. Anderson, R., Kim, S., & Patel, N. (2023). "Freeze-Thaw Resistance of Phenolic-Coated Plywood in Infrastructure Applications." Cold Regions Engineering Quarterly, 29(4), 412-425.

4. Williams, D., Zhang, L., & Mohamed, A. (2022). "Sustainable Formwork Solutions for Harsh Climate Construction: Performance Evaluation and Life Cycle Analysis." Construction Engineering and Environmental Impact, 18(2), 78-91.