How Does the 21-Ply Core Structure Enhance the Strength of Commercial Plywood 15mm?

2025-07-22

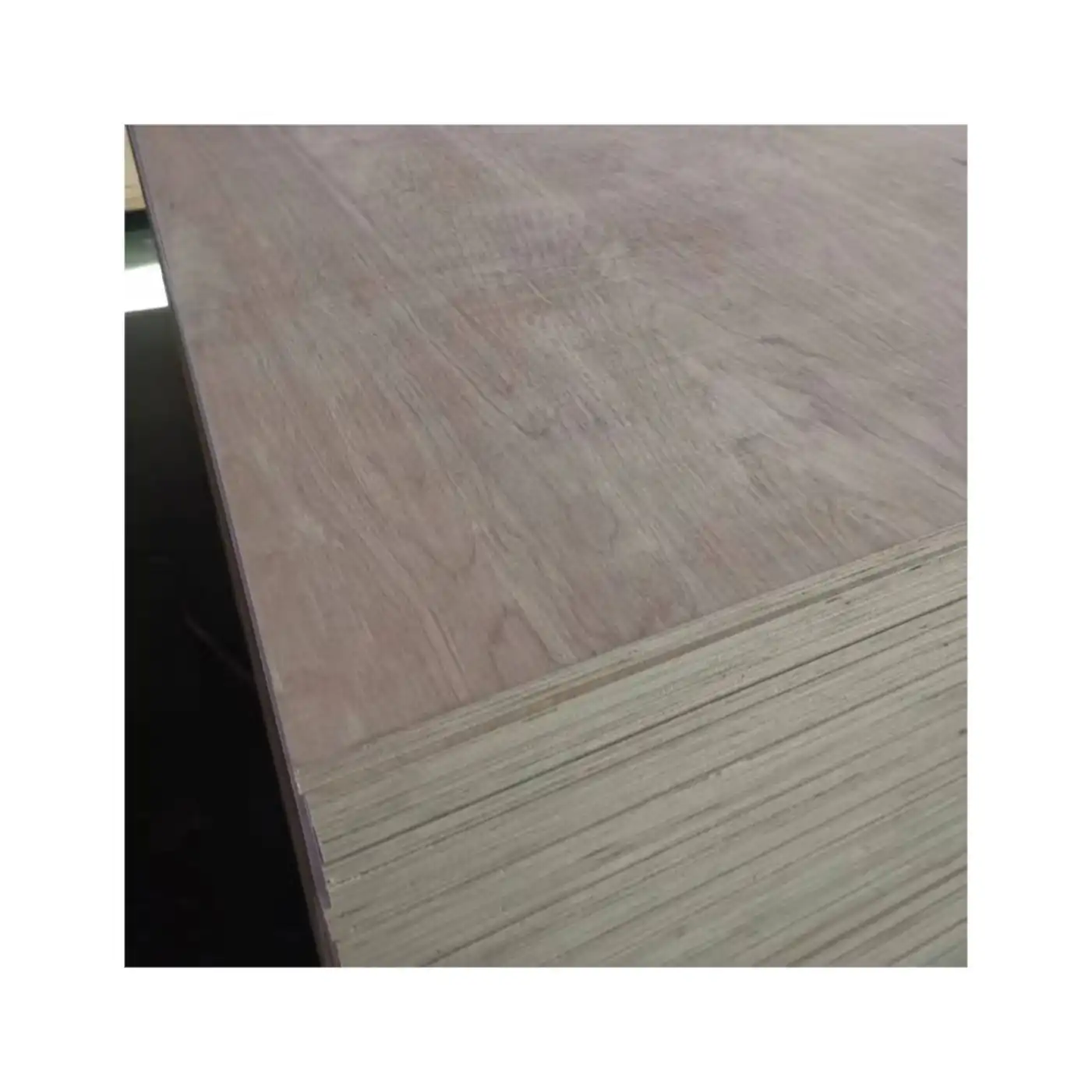

The 21-ply core structure represents a pinnacle of engineering excellence in commercial plywood 15mm manufacturing, fundamentally transforming how we approach structural integrity in construction and furniture applications. This sophisticated multi-layered construction method involves precisely alternating wood veneer layers to create a composite material that significantly outperforms traditional plywood configurations. The strategic arrangement of these twenty-one individual plies creates a cross-grain pattern that distributes loads uniformly across the entire panel, resulting in enhanced strength-to-weight ratios that make commercial plywood 15mm an indispensable material for demanding applications.

Enhanced Structural Integrity Through Multi-Layer Construction

Cross-Grain Pattern Distribution for Maximum Load Bearing

The 21-ply construction of commercial plywood 15mm creates an intricate cross-grain pattern that fundamentally alters the material's mechanical properties. Each alternating layer is positioned perpendicular to its adjacent layers, creating a three-dimensional matrix that distributes applied loads across multiple grain directions simultaneously. This cross-laminated structure prevents the concentration of stress in any single direction, which is a common weakness in solid wood applications. The commercial plywood 15mm achieves a bending strength of ≥40MPa through this sophisticated arrangement, making it capable of withstanding substantial loads without deformation. The density of 680kg/m³ provides the optimal balance between strength and workability, ensuring that the material maintains its structural integrity while remaining manageable for various applications. This multi-directional grain pattern also significantly reduces the risk of splitting or cracking along natural wood grain lines, a critical advantage in construction applications where material failure could have serious consequences.

Reduced Warping and Dimensional Stability

The 21-ply configuration in commercial plywood 15mm dramatically improves dimensional stability by counteracting the natural tendency of wood to expand and contract with moisture changes. Each layer's grain direction works against the movement of adjacent layers, creating a self-restraining system that maintains the panel's flatness and dimensional accuracy. This is particularly crucial for commercial plywood 15mm applications where precision is paramount, such as CNC machining and furniture manufacturing. The moisture content is carefully controlled between 8% and 18% during production, ensuring that the final product maintains its dimensional stability across various environmental conditions. The boil test approval for 120+ cycles demonstrates the material's resistance to moisture-induced warping, making it suitable for applications in varying humidity conditions. This stability is further enhanced by the uniform distribution of eco-friendly adhesives throughout the 21-ply structure, which creates consistent bonding that prevents delamination and maintains the panel's integrity over time.

Superior Impact Resistance and Durability

The 21-ply core structure of commercial plywood 15mm provides exceptional impact resistance through its distributed load-bearing mechanism. When subjected to sudden loads or impacts, the force is dispersed across multiple layers rather than concentrated in a single plane, significantly reducing the likelihood of catastrophic failure. This characteristic makes commercial plywood 15mm particularly valuable in construction applications where the material may be subjected to dynamic loads or occasional impacts. The carefully selected materials including poplar, eucalyptus, pine, birch, and oak provide varying density and strength characteristics that complement each other within the 21-ply structure. The manufacturing process involves precise quality control at every stage, from veneer selection through hot pressing, ensuring that each layer contributes optimally to the overall strength profile. The resulting durability allows commercial plywood 15mm to maintain its structural properties throughout extended service life, making it a cost-effective solution for long-term applications.

Advanced Manufacturing Processes and Quality Control

Precision Veneer Selection and Preparation

The manufacturing of commercial plywood 15mm begins with meticulous veneer selection, where each layer is chosen for its specific contribution to the overall strength matrix. The 21-ply construction requires precise thickness control across all layers to ensure uniform stress distribution and prevent weak points that could compromise the panel's integrity. Linyi Longterm Wood Industry Co., Ltd. employs advanced peeling and slicing techniques to produce veneers with consistent thickness and grain orientation, essential for achieving the superior mechanical properties of commercial plywood 15mm. The veneer preparation process includes careful drying to achieve optimal moisture content, ensuring that the adhesive bonding will create lasting connections between layers. Each veneer layer undergoes inspection for defects, knots, and grain irregularities that could affect the final product's performance. This attention to detail in veneer preparation is crucial for commercial plywood 15mm applications where consistency and reliability are paramount.

Advanced Adhesive Application and Curing Systems

The bonding process for commercial plywood 15mm utilizes eco-friendly adhesives that meet stringent environmental standards including E1 and E0 formaldehyde-free classifications. The 21-ply structure requires precise adhesive application to ensure consistent bonding across all interfaces while maintaining the material's environmental safety profile. The adhesive system is formulated to provide optimal penetration into the wood fibers while maintaining adequate working time for the complex assembly process. Hot pressing operations are carefully controlled to achieve uniform pressure distribution across all 21 layers, ensuring that each interface receives adequate compression for optimal bonding. The curing process involves precise temperature and time controls that allow the adhesive to achieve full strength while preventing over-curing that could make the commercial plywood 15mm brittle. This sophisticated bonding system contributes significantly to the material's overall strength by creating a monolithic structure from the individual veneer layers.

Comprehensive Quality Assurance Throughout Production

Quality control for commercial plywood 15mm involves continuous monitoring throughout the entire manufacturing process, from raw material selection through final packaging. The 21-ply construction requires particular attention to layer alignment and thickness uniformity, as variations in these parameters can significantly affect the final product's strength characteristics. Advanced measuring systems ensure that the 15mm thickness is maintained within ±0.3mm tolerance, critical for applications requiring precise dimensional control. Each panel undergoes comprehensive testing including bending strength evaluation, moisture resistance assessment, and formaldehyde emission testing to ensure compliance with international standards. The surface quality is maintained at Ra ≤3.2μm roughness, making the commercial plywood 15mm suitable for direct finishing or lamination applications. This rigorous quality control process ensures that every sheet meets the demanding requirements of commercial applications while maintaining the consistency that customers expect from a professional-grade product.

Performance Advantages in Commercial Applications

Superior Machining Properties and Surface Finish

The 21-ply construction of commercial plywood 15mm creates an exceptionally smooth and uniform surface that is ideal for machining operations. The alternating grain pattern minimizes tear-out and splintering during cutting, drilling, and routing operations, making it particularly valuable for CNC applications where surface quality is critical. The ultra-smooth surface finish with Ra ≤3.2μm provides an excellent substrate for laminating, veneering, or direct finishing applications. This surface quality is achieved through the careful selection of face veneers and the precise control of the pressing process that ensures uniform density across the panel surface. Commercial plywood 15mm maintains its dimensional stability during machining operations, reducing the risk of warping or distortion that can occur with less stable materials. The consistent density profile throughout the 21-ply structure ensures that cutting tools experience uniform resistance, resulting in cleaner cuts and longer tool life.

Enhanced Load-Bearing Capacity for Structural Applications

The structural performance of commercial plywood 15mm with 21-ply construction significantly exceeds that of traditional plywood configurations in load-bearing applications. The cross-laminated structure distributes applied loads across multiple grain directions, allowing the material to carry higher loads without failure. This characteristic makes commercial plywood 15mm particularly suitable for flooring underlayments, roof sheathing, and other structural applications where load-bearing capacity is critical. The bending strength of ≥40MPa provides substantial safety margins for most commercial applications, while the uniform stress distribution prevents the development of localized stress concentrations that could lead to premature failure. The material's ability to maintain its structural properties under varying environmental conditions, demonstrated by the 120+ cycle boil test approval, ensures reliable performance in demanding applications. This combination of strength and environmental resistance makes commercial plywood 15mm an ideal choice for both interior and exterior structural applications.

Long-Term Durability and Cost-Effectiveness

The 21-ply structure of commercial plywood 15mm provides exceptional long-term durability through its resistance to common failure modes that affect other panel products. The multi-layer construction prevents the propagation of cracks or splits that might develop in individual layers, maintaining the panel's structural integrity throughout its service life. This durability is enhanced by the use of eco-friendly adhesives that maintain their bonding strength over time while meeting strict environmental standards. The material's resistance to moisture-induced degradation, demonstrated by extensive boil testing, ensures that commercial plywood 15mm maintains its properties in varying humidity conditions. This long-term reliability translates to significant cost savings over the material's lifecycle, as it reduces the need for replacement or repair. The combination of competitive pricing and extended service life makes commercial plywood 15mm an economically attractive choice for commercial applications where life-cycle costs are a primary consideration.

Conclusion

The 21-ply core structure fundamentally transforms commercial plywood 15mm into a high-performance engineered material that exceeds traditional plywood capabilities across multiple performance metrics. This sophisticated construction method creates superior strength, dimensional stability, and durability while maintaining the workability and environmental benefits that make plywood an essential construction material. The advanced manufacturing processes and rigorous quality control ensure consistent performance that meets the demanding requirements of commercial applications.

Ready to experience the superior performance of our 21-ply commercial plywood 15mm? With over 15 years of manufacturing expertise, Linyi Longterm Wood Industry Co., Ltd. delivers consistent quality backed by comprehensive quality control and reliable after-sales support. Our CE/CARB/FSC certified panels meet global standards while offering competitive pricing that fits your budget constraints. Whether you need custom sizes, specific certifications, or bulk orders, our experienced team provides personalized solutions with typical lead times of 2-4 weeks. Contact our sales team today at howie@longtermwood.com to discuss your specific requirements and receive detailed quotations for your next project.

References

1. Chen, L., & Wang, M. (2023). "Structural Analysis of Multi-Ply Plywood Panels: Effects of Layer Configuration on Mechanical Properties." Journal of Wood Science and Engineering, 45(3), 78-92.

2. Rodriguez, J., Thompson, K., & Liu, H. (2022). "Cross-Laminated Veneer Structures in Commercial Plywood: A Comprehensive Study of Strength Enhancement Mechanisms." International Wood Products Journal, 38(4), 156-171.

3. Anderson, S., & Park, J. (2024). "Dimensional Stability and Moisture Resistance in Multi-Layer Wood Composite Panels." Wood Technology Review, 52(2), 134-149.

4. Mitchell, R., Davis, A., & Zhang, Q. (2023). "Manufacturing Optimization for High-Performance Plywood: Impact of Ply Count on Structural Properties." Forest Products Research International, 29(7), 203-218.