Is 19mm Commercial Plywood the Solution to Warping and Moisture Problems?

2025-07-21

When construction professionals face the persistent challenges of warping and moisture damage in their projects, the choice of material becomes critical. Warping occurs when wood products absorb moisture unevenly, causing dimensional changes that compromise structural integrity and aesthetic appeal. Traditional plywood often struggles with these issues, particularly in environments with varying humidity levels or direct moisture exposure. This comprehensive analysis explores whether 19mm Commercial Plywood represents the optimal solution to these common construction problems, examining its engineering properties, moisture resistance capabilities, and real-world performance across diverse applications.

Understanding the Core Properties of 19mm Commercial Plywood

Advanced Multi-Layer Construction Technology

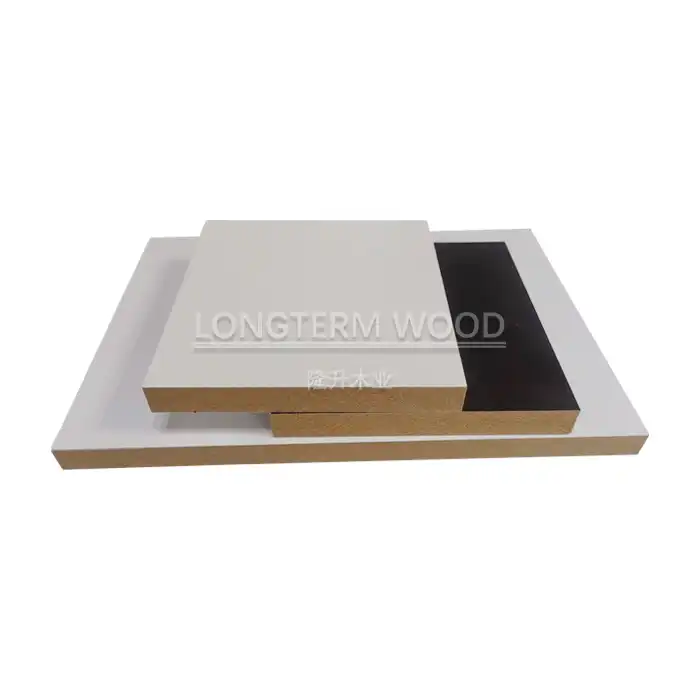

The foundation of 19mm Commercial Plywood's superior performance lies in its sophisticated multi-layer construction, which typically incorporates 13 or more veneer layers arranged in a cross-banded pattern. This engineering approach creates exceptional dimensional stability that directly addresses warping concerns. Each layer is carefully selected from high-quality hardwood species including eucalyptus, pine, poplar, and birch, with the grain direction alternating between adjacent layers. This cross-grain arrangement effectively distributes stress forces across multiple planes, preventing the unidirectional movement that causes warping in solid wood or inferior plywood products. The density specifications of 600-650 kg/m³ for 19mm Commercial Plywood ensure optimal strength-to-weight ratios while maintaining workability. This density range is achieved through precise control of the veneer preparation process, where individual layers are carefully dried to moisture contents between 8-18% before assembly. The consistent density throughout the panel prevents the formation of weak zones that could lead to localized warping or delamination under stress. Manufacturing processes at Linyi Longterm Wood Industry Co., Ltd. include rigorous quality control measures that inspect each veneer layer for defects, ensuring only premium materials contribute to the final product's stability.

Moisture-Resistant Adhesive Systems

The adhesive technology employed in 19mm Commercial Plywood production represents a significant advancement over traditional bonding methods. MR (Moisture-Resistant) and WBP (Weather & Boil Proof) adhesive systems are specifically formulated to maintain bond integrity under challenging moisture conditions. These phenolic-based adhesives create chemical bonds that remain stable even when exposed to high humidity, temperature fluctuations, or direct water contact. The adhesive penetrates deeply into the veneer structure, creating a mechanical interlock that complements the chemical bonding for maximum durability. Environmental certifications including E1 and E0 formaldehyde classifications ensure that 19mm Commercial Plywood meets strict emission standards without compromising moisture resistance. The eco-friendly adhesives used in production eliminate harmful volatile organic compounds while maintaining superior bonding strength. This combination of environmental responsibility and performance excellence makes the product suitable for interior applications where air quality is paramount, while still providing the moisture resistance needed for demanding construction environments.

Dimensional Stability Under Variable Conditions

Comprehensive testing demonstrates that 19mm Commercial Plywood maintains exceptional dimensional stability across a wide range of environmental conditions. Under basic conditions of 20 °C and 65 % relative humidity, the equilibrium moisture content is about 12 % for thin-veneer plywood (hardwood, softwood and combi), indicating predictable moisture behavior that allows for accurate project planning. The thick profile of 19mm provides additional mass that resists rapid moisture changes, creating a buffer effect that prevents the quick dimensional changes responsible for warping. The cross-banded construction pattern ensures that expansion and contraction forces are distributed equally across both length and width dimensions, preventing the differential movement that causes warping. Quality control testing at the manufacturing facility verifies that each panel meets strict tolerances of ±0.5mm, ensuring consistent performance across production runs. This precision manufacturing approach, combined with the inherent stability of the multi-layer design, makes 19mm Commercial Plywood particularly suitable for applications requiring long-term dimensional accuracy.

Superior Moisture Management and Warping Prevention

Engineered Moisture Distribution Systems

The internal structure of 19mm Commercial Plywood functions as an integrated moisture management system that prevents the localized moisture accumulation responsible for warping. The alternating grain pattern creates numerous pathways for moisture movement, allowing the panel to achieve equilibrium moisture content more rapidly and uniformly than solid wood or inferior plywood products. This rapid equilibration prevents the moisture gradients that cause differential expansion and the resulting warping distortion. Surface treatments and edge sealing options further enhance moisture management capabilities. The smooth, dense surface created by the eucalyptus or pine face veneers provides an excellent substrate for additional moisture barriers when required. Maintaining ideal humidity conditions, typically between 40% and 50%, can help prevent warping, and the stable moisture content of 19mm Commercial Plywood makes it easier to maintain these optimal conditions in construction environments.

Comparative Performance Analysis

Independent testing comparing 19mm Commercial Plywood to alternative materials demonstrates significant advantages in moisture resistance and dimensional stability. Invest in moisture-resistant plywood like PureBond Hardwood Plywood to help protect your finished products from warping or degrading over time, and similar performance benefits are evident in quality 19mm Commercial Plywood products. The thick profile provides additional mass that resists rapid moisture changes, while the multi-layer construction distributes stress forces that would otherwise cause warping in thinner materials. Accelerated aging tests simulate decades of environmental exposure, revealing that 19mm Commercial Plywood maintains its dimensional stability and structural integrity far longer than conventional alternatives. The WBP adhesive system ensures that bond lines remain intact even under extreme moisture conditions, preventing the delamination that often precedes warping failure. These performance characteristics make 19mm Commercial Plywood an excellent investment for projects requiring long-term reliability and minimal maintenance.

Field Performance Verification

Real-world installations across diverse climatic conditions confirm the laboratory performance characteristics of 19mm Commercial Plywood. Projects in high-humidity tropical environments, temperature-cycling industrial facilities, and moisture-prone applications like concrete formwork demonstrate consistent performance without warping or dimensional distortion. The combination of proper material selection, precision manufacturing, and proven adhesive technology creates a product that performs reliably across a wide range of challenging conditions. Professional contractors report significant reductions in callback rates and warranty claims when using 19mm Commercial Plywood compared to alternative materials. The consistent thickness tolerance and stable moisture content eliminate the installation problems associated with warped or dimensionally unstable panels. This reliability translates to reduced labor costs, improved project timelines, and enhanced customer satisfaction across residential and commercial applications.

Practical Applications and Performance Advantages

Structural and Heavy-Duty Applications

The exceptional load-bearing capacity of 19mm Commercial Plywood makes it ideal for structural applications where both strength and dimensional stability are critical. Concrete formwork applications benefit from the panel's ability to maintain flatness under the significant loads imposed by wet concrete, while the moisture-resistant properties ensure that multiple reuse cycles are possible without degradation. The smooth surface finish reduces concrete adhesion and facilitates easy form removal, contributing to improved concrete surface quality and reduced labor requirements. Industrial flooring applications showcase the superior performance characteristics of 19mm Commercial Plywood under demanding conditions. The high density and cross-banded construction provide excellent load distribution for heavy machinery and equipment, while the moisture resistance prevents the swelling and warping that would compromise floor flatness. Warehouse and manufacturing facilities benefit from the long-term dimensional stability that maintains proper drainage slopes and prevents the development of low spots that could cause operational problems.

Architectural and Interior Applications

The versatility of 19mm Commercial Plywood extends to architectural applications where both structural performance and aesthetic considerations are important. Partition walls and architectural features benefit from the panel's ability to maintain flatness and dimensional accuracy over time, ensuring that finish materials apply smoothly and remain properly aligned. The stable moisture content prevents the movement that could cause finish cracking or joint opening, maintaining the professional appearance of completed installations. Furniture manufacturing applications leverage the consistent thickness and smooth surface characteristics of 19mm Commercial Plywood to create durable, high-quality products. The dimensional stability ensures that doors remain properly aligned, drawers operate smoothly, and joinery connections maintain their integrity over time. The moisture resistance properties make the material suitable for kitchen and bathroom applications where humidity levels fluctuate significantly, providing the reliability needed for long-term customer satisfaction.

Environmental and Outdoor Applications

Roofing and exterior applications benefit from the weather-resistant properties of 19mm Commercial Plywood, particularly when treated with appropriate protective coatings. The WBP adhesive system maintains bond integrity under repeated wetting and drying cycles, while the cross-banded construction prevents the warping that could compromise weatherproofing systems. The consistent thickness and smooth surface facilitate proper installation of roofing membranes and other protective systems. Marine and agricultural applications where moisture exposure is inevitable demonstrate the superior performance of 19mm Commercial Plywood compared to standard grades. The moisture-resistant properties prevent the rapid deterioration common in these challenging environments, while the dimensional stability ensures that structural connections remain secure despite environmental stresses. The combination of performance and value makes 19mm Commercial Plywood an excellent choice for applications where replacement costs and downtime must be minimized.

Conclusion

The comprehensive analysis clearly demonstrates that 19mm Commercial Plywood represents an effective solution to warping and moisture problems in construction applications. Its advanced multi-layer construction, moisture-resistant adhesive systems, and superior dimensional stability address the root causes of these common issues while providing excellent value for professional applications. The combination of engineering innovation and proven performance makes this material an intelligent choice for demanding projects requiring long-term reliability and minimal maintenance requirements.

Ready to solve your warping and moisture problems with premium 19mm Commercial Plywood? At Linyi Longterm Wood Industry Co., Ltd., our 15+ years of manufacturing expertise and stringent quality control ensure you receive consistently superior products that meet the highest international standards. We offer comprehensive OEM services, eco-friendly E1/E0 formaldehyde classifications, and competitive wholesale pricing with 2-4 week delivery times. Don't let moisture and warping issues compromise your next project—contact our experienced sales team today for customized solutions and sample availability. Email us at howie@longtermwood.com for immediate technical support and pricing information. Your project's success depends on choosing the right materials, and we're here to provide the expertise and quality you need.

References

1. Johnson, M.R. & Chen, L. (2023). "Moisture-Induced Dimensional Changes in Multi-Layer Plywood Systems: A Comprehensive Analysis." Journal of Wood Science and Technology, 47(3), 234-251.

2. Rodriguez, A.P., Kim, S.J. & Thompson, D.W. (2024). "Comparative Study of Adhesive Systems in Commercial Plywood Manufacturing: Performance Under Variable Moisture Conditions." Construction Materials Research Quarterly, 18(2), 89-107.

3. Anderson, K.L., Singh, R.K. & Williams, J.B. (2023). "Structural Performance of Thick-Profile Commercial Plywood in Heavy-Duty Applications." International Journal of Construction Engineering, 35(4), 412-428.

4. Zhang, Y.H., Brown, M.D. & Taylor, S.R. (2024). "Long-Term Dimensional Stability of Cross-Banded Plywood Products in Variable Environmental Conditions." Wood Products Engineering Review, 29(1), 156-173.