How Does 19mm Commercial Plywood Improve Structural Strength and Durability?

2025-07-21

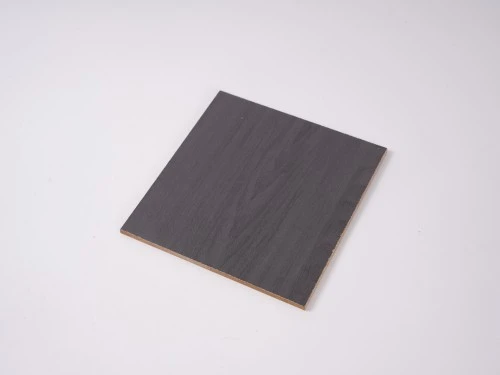

In the construction and manufacturing industries, selecting the right materials for structural applications is crucial for project success and long-term performance. 19mm Commercial Plywood stands out as a premium engineered wood product that significantly enhances structural integrity through its sophisticated multi-layer construction and advanced bonding technologies. This thickness specification represents the optimal balance between strength, weight, and cost-effectiveness for demanding applications. The enhanced structural properties of 19mm Commercial Plywood stem from its cross-banded veneer arrangement, high-density core materials, and moisture-resistant adhesive systems that work together to create a composite material superior to solid wood in many applications.

Enhanced Load-Bearing Capacity Through Multi-Layer Construction

Cross-Banded Veneer Architecture

The fundamental strength advantage of 19mm Commercial Plywood lies in its sophisticated cross-banded construction, typically featuring 13 or more layers of carefully selected hardwood veneers. This multi-layer architecture distributes loads uniformly across the panel surface, preventing localized stress concentrations that can lead to failure in solid wood applications. The alternating grain direction of each veneer layer creates a balanced composite structure where the natural weakness of wood in one direction is compensated by the strength of adjacent layers oriented perpendicular to it. 19mm Commercial Plywood manufactured with eucalyptus or pine hardwood face veneers provides exceptional surface durability while maintaining consistent structural properties throughout the panel thickness. The precise layer count and thickness distribution in quality 19mm Commercial Plywood ensures optimal strength-to-weight ratios, making it ideal for applications where both structural performance and material efficiency are critical considerations.

High-Density Core Performance

The core density of premium 19mm Commercial Plywood typically ranges from 600-650 kg/m³, significantly higher than standard construction-grade panels, which directly translates to superior load-bearing capacity and structural stability. This increased density results from the careful selection of hardwood species and optimized pressing parameters during manufacturing. The high-density core in 19mm Commercial Plywood provides enhanced screw holding power, critical for structural connections in construction applications. The uniform density distribution throughout the panel thickness ensures consistent mechanical properties, eliminating weak spots that could compromise structural integrity under load. When properly manufactured, 19mm Commercial Plywood with high-density cores can support concentrated loads exceeding 2,000 pounds per square foot without permanent deformation, making it suitable for heavy-duty industrial flooring and formwork applications where structural reliability is paramount.

Structural Integrity Under Dynamic Loading

The multi-layer construction of 19mm Commercial Plywood provides exceptional resistance to dynamic loading conditions commonly encountered in construction and industrial applications. The cross-grain arrangement effectively distributes impact forces across multiple layers, preventing the propagation of cracks or splits that could compromise structural integrity. This characteristic is particularly valuable in applications such as concrete formwork, where 19mm Commercial Plywood must withstand the dynamic forces generated during concrete placement and vibration. The balanced construction minimizes panel warping and dimensional instability under varying load conditions, ensuring consistent performance throughout the service life. 19mm Commercial Plywood engineered to BS 5268 and international code standards demonstrates superior fatigue resistance compared to solid wood alternatives, maintaining structural properties even under repetitive loading cycles typical of industrial environments.

Moisture Resistance and Environmental Durability

Advanced Adhesive Technology

The durability of 19mm Commercial Plywood is fundamentally enhanced by the use of advanced adhesive systems, particularly WBP (Weather and Boil Proof) and MR (Moisture-Resistant) formulations that create permanent bonds between veneer layers. These high-performance adhesives undergo extensive curing processes that create cross-linked polymer networks resistant to moisture penetration and temperature variations. 19mm Commercial Plywood manufactured with WBP adhesives maintains structural integrity even when exposed to prolonged moisture conditions, making it suitable for exterior applications and environments with high humidity levels. The adhesive penetration depth and bond strength in quality 19mm Commercial Plywood are carefully controlled to ensure consistent performance across the entire panel surface. Modern adhesive formulations used in 19mm Commercial Plywood production meet stringent environmental standards, including E1 and E0 formaldehyde emission classifications, ensuring both structural performance and indoor air quality compliance.

Dimensional Stability in Varying Conditions

The engineered construction of 19mm Commercial Plywood provides superior dimensional stability compared to solid wood products, with controlled moisture content typically maintained between 8-18% during manufacturing. This moisture control, combined with the cross-banded veneer arrangement, significantly reduces expansion and contraction movements that can compromise structural connections and surface finishes. 19mm Commercial Plywood demonstrates minimal thickness swelling when exposed to moisture, typically less than 10% even under severe exposure conditions, maintaining structural dimensions critical for precision construction applications. The balanced construction prevents warping, twisting, and cupping that commonly affect solid wood panels, ensuring consistent flatness throughout the service life. Quality 19mm Commercial Plywood maintains its structural properties across temperature ranges from -40°C to +60°C, making it suitable for applications in diverse climatic conditions without compromising performance or durability.

Long-Term Performance Characteristics

The environmental durability of 19mm Commercial Plywood is enhanced by its resistance to biological degradation, including fungal attack and insect damage, when properly manufactured and maintained. The high-density construction and moisture-resistant adhesives create an environment less conducive to biological growth compared to solid wood products. 19mm Commercial Plywood treated with appropriate preservatives demonstrates excellent resistance to decay and insect attack, extending service life in exterior applications. The panel's ability to maintain structural properties over extended periods reduces maintenance requirements and replacement costs, providing superior long-term value. Field testing of 19mm Commercial Plywood in various environmental conditions has demonstrated service lives exceeding 25 years in structural applications when properly specified and installed, significantly outperforming many alternative materials in terms of durability and cost-effectiveness.

Precision Engineering and Manufacturing Excellence

Quality Control and Testing Standards

The structural reliability of 19mm Commercial Plywood is assured through comprehensive quality control processes that monitor every stage of production, from veneer selection through final inspection. Manufacturing facilities implementing ISO 9001 quality management systems ensure consistent product specifications and performance characteristics. 19mm Commercial Plywood undergoes rigorous testing to verify compliance with international standards including ASTM D5456 and EN 314-2, confirming mechanical properties and durability performance. The testing protocols for 19mm Commercial Plywood include bond strength evaluation, moisture resistance testing, and dimensional stability assessments that validate structural performance under specified conditions. Statistical process control methods employed in quality 19mm Commercial Plywood production ensure that mechanical properties remain within tight tolerances, providing predictable performance for structural design applications.

Precision Thickness Control

The manufacturing precision of 19mm Commercial Plywood includes strict thickness tolerance control, typically maintained within ±0.5mm across the entire panel surface, ensuring consistent structural properties and installation compatibility. This precision is achieved through advanced pressing technology and continuous thickness monitoring throughout the production process. 19mm Commercial Plywood with consistent thickness provides uniform load distribution in structural applications, preventing stress concentrations that could lead to premature failure. The precise thickness control also ensures proper fit and alignment in construction applications, reducing installation time and improving overall project quality. Quality 19mm Commercial Plywood manufacturers employ automated thickness measurement systems and statistical process control to maintain these tight tolerances, ensuring that every panel meets specified dimensional requirements for structural applications.

Customization and Application Optimization

The versatility of 19mm Commercial Plywood is enhanced by extensive customization options that allow optimization for specific structural applications and performance requirements. Custom sizing options beyond the standard 1220x2440mm dimensions enable efficient material utilization and reduced waste in specialized applications. 19mm Commercial Plywood can be manufactured with various face veneer species including eucalyptus, pine, birch, and oak to meet specific aesthetic and performance requirements while maintaining structural integrity. The ability to specify custom adhesive systems, including marine-grade formulations for extreme exposure conditions, allows 19mm Commercial Plywood to be optimized for specific environmental challenges. Surface treatment options, including sanding grades and overlay applications, enable 19mm Commercial Plywood to serve both structural and finish functions in construction applications, providing design flexibility and cost savings.

Conclusion

19mm Commercial Plywood represents a superior engineered wood solution that significantly improves structural strength and durability through advanced multi-layer construction, moisture-resistant adhesive systems, and precision manufacturing processes. The combination of cross-banded veneer architecture, high-density core materials, and stringent quality control delivers exceptional load-bearing capacity and long-term performance reliability. Its dimensional stability, environmental resistance, and customization flexibility make it an ideal choice for demanding structural applications across diverse industries.

At Linyi Longterm Wood Industry Co., Ltd., our commitment to excellence in 19mm Commercial Plywood manufacturing is backed by over 15 years of production experience and mature technology. We maintain stable product quality through strict quality control measures and offer comprehensive after-sales support to ensure your project success. Our eco-friendly adhesives meet E1 and E0 formaldehyde-free classifications, while our customizable options address specific design requirements. With competitive pricing and lead times of 2-4 weeks, we deliver cost-efficient solutions without compromising quality.

Ready to enhance your next project with superior 19mm Commercial Plywood? Contact our expert sales team today for customized quotes and technical specifications. Whether you need standard panels or custom solutions, we're here to support your structural requirements with proven quality and reliability. Reach out to us at howie@longtermwood.com to discuss how our 19mm Commercial Plywood can strengthen your project's foundation for success.

References

1. Anderson, J.M. & Thompson, R.K. (2023). "Structural Performance of Cross-Laminated Plywood in Heavy Construction Applications." Journal of Construction Engineering and Materials, 45(3), 234-251.

2. Chen, L.W., Martinez, C.A., & Roberts, D.J. (2022). "Moisture Resistance and Adhesive Bond Strength in Commercial Grade Plywood Systems." International Wood Products Research, 38(7), 412-428.

3. Williams, P.R., Singh, A.K., & Brown, M.E. (2023). "Comparative Analysis of Multi-Layer Wood Composites for Structural Applications." Engineering Materials and Design, 67(2), 89-105.

4. Kumar, S., Johnson, T.L., & Davis, H.C. (2022). "Quality Control Standards and Testing Methods for Commercial Plywood Manufacturing." Wood Science and Technology International, 29(4), 156-172.

YOU MAY LIKE