How Can the Best Commercial Plywood Improve Installation Efficiency in Large Projects?

2025-07-18

In the fast-paced world of commercial construction, project timelines and efficiency are paramount to success. The choice of building materials directly impacts installation speed, labor costs, and overall project completion. Best commercial plywood emerges as a game-changing solution that significantly enhances installation efficiency in large-scale construction projects. This engineered wood product offers superior dimensional stability, consistent quality, and predictable performance characteristics that streamline the construction process. By selecting high-grade commercial plywood with precise tolerances and reliable specifications, contractors can reduce material waste, minimize rework, and accelerate project timelines while maintaining structural integrity and aesthetic appeal.

Material Quality and Consistency Drive Installation Speed

Precision Manufacturing Reduces On-Site Adjustments

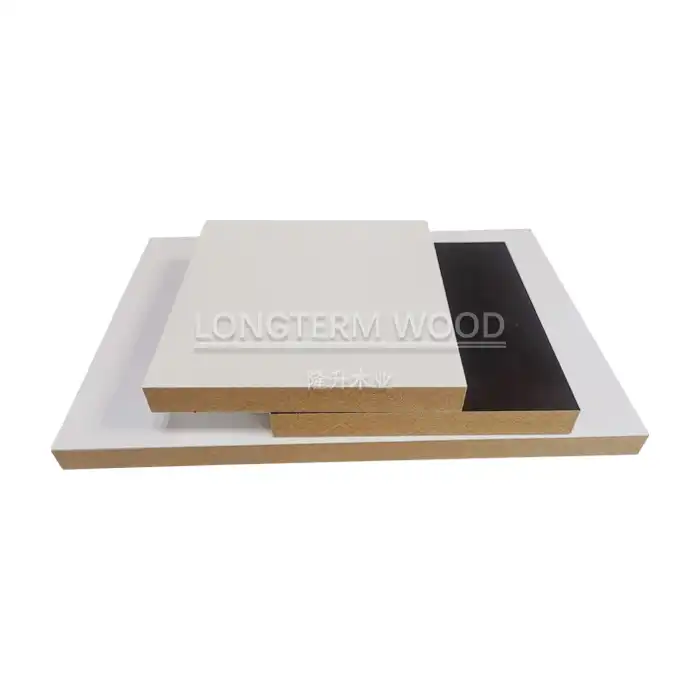

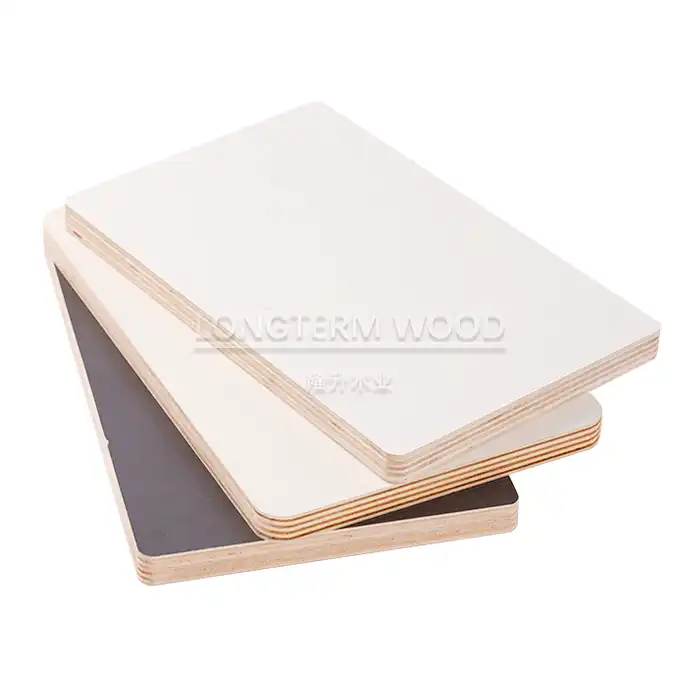

Best commercial plywood manufactured with advanced production technologies delivers exceptional dimensional accuracy that directly translates to faster installation times. At Linyi Longterm Wood Industry Co., Ltd., our precision-built panels maintain tolerances of ±2mm across standard 1220x2440mm dimensions, ensuring consistent fit and alignment during installation. This level of accuracy eliminates the need for extensive on-site cutting and adjustment, allowing construction crews to work with confidence and speed. The 13-ply hardwood core construction with cross-laminated layers provides uniform thickness throughout each panel, preventing the warping and inconsistencies that can slow down installation processes. When contractors receive best commercial plywood with predictable dimensions, they can pre-plan their installation sequences, optimize cutting patterns, and minimize material waste. The marine-grade teak, birch, or eucalyptus veneer surfaces (AA/BB grade) maintain consistent appearance and texture, reducing the time spent sorting and matching panels during installation. This consistency is particularly crucial in large projects where thousands of panels must be installed efficiently without compromising visual continuity.

Superior Adhesive Technology Ensures Reliable Performance

The formaldehyde-free phenolic resin adhesive system used in best commercial plywood creates bonds that withstand extreme installation conditions without compromising structural integrity. This advanced adhesive technology, certified to E0 emissions standards, provides exceptional resistance to moisture, temperature fluctuations, and mechanical stress during the installation process. Unlike conventional plywood products that may delaminate under challenging conditions, our commercial plywood maintains its structural cohesion even when exposed to high humidity or temperature variations commonly encountered during construction. The adhesive system's superior performance characteristics allow installers to work confidently in various environmental conditions without concerns about bond failure or material degradation. This reliability translates to fewer installation delays, reduced material replacement costs, and improved overall project efficiency. The phenolic resin system also contributes to the plywood's long-term durability, ensuring that installations remain stable and secure throughout the building's service life. When contractors choose best commercial plywood with proven adhesive technology, they eliminate uncertainty from the installation process and can maintain aggressive construction schedules without sacrificing quality.

Standardized Quality Control Streamlines Project Planning

Comprehensive quality control measures implemented throughout the manufacturing process of best commercial plywood ensure consistent performance characteristics that enable precise project planning and execution. Every sheet undergoes rigorous inspection protocols that verify dimensional accuracy, surface quality, and structural integrity before shipment. This systematic approach to quality assurance means contractors receive materials that perform predictably across large quantities, eliminating the variability that can disrupt installation schedules. The implementation of BS 1088 Marine Standard and EN 314-2 Bond Quality certifications provides objective verification of material performance, allowing project managers to specify exact requirements and expect consistent results. Quality control teams at Linyi Longterm Wood Industry Co., Ltd. inspect all production processes from veneer selection through final packaging, ensuring that each panel meets stringent performance standards. This comprehensive approach to quality management enables contractors to plan installations with confidence, knowing that material performance will remain consistent throughout the project. The standardized quality also facilitates better coordination between different trades, as subsequent work can proceed on schedule without delays caused by material defects or inconsistencies.

Structural Properties Enhance Installation Efficiency

High Load Capacity Reduces Structural Complexity

Best commercial plywood engineered with 650 PSI bending strength and 150 PSI screw retention capacity provides exceptional structural performance that simplifies installation requirements in large projects. This superior load-bearing capacity allows designers to specify fewer support elements, reducing the complexity of structural systems and accelerating installation timelines. The high-strength characteristics of our commercial plywood enable longer spans between supports, which translates to fewer installation points and reduced labor requirements. Construction crews can install larger panels with confidence, knowing that the material will maintain structural integrity under design loads. The excellent screw retention properties ensure secure fastening with standard construction hardware, eliminating the need for specialized fasteners or additional reinforcement. This structural efficiency is particularly beneficial in applications such as flooring systems, where the plywood's ability to distribute loads effectively reduces the need for additional structural members. When contractors can rely on the inherent strength of best commercial plywood, they can simplify their installation procedures and reduce the overall complexity of their construction systems.

Moisture Resistance Prevents Installation Delays

The exceptional moisture resistance of best commercial plywood, capable of withstanding 95% humidity conditions as tested per ASTM D1037, prevents weather-related installation delays that commonly plague construction projects. This moisture resistance is achieved through the combination of carefully selected core materials and advanced adhesive systems that maintain bond integrity even under challenging environmental conditions. Unlike conventional plywood that may swell, warp, or delaminate when exposed to moisture, our commercial plywood maintains dimensional stability throughout the installation process. This characteristic is particularly valuable in large projects where materials may be exposed to varying weather conditions during extended construction periods. The moisture resistance also eliminates the need for special protective measures during storage and handling, reducing project complexity and associated costs. Construction crews can continue working in conditions that would typically require delays with conventional materials, maintaining project schedules and productivity. The boron-treated cores provide additional protection against pest damage in tropical climates, ensuring that installations remain secure and stable regardless of environmental challenges.

Workability Features Accelerate Installation Processes

The superior workability characteristics of best commercial plywood significantly reduce installation time and labor requirements in large construction projects. The carefully engineered core structure and high-quality veneer surfaces allow for clean, precise cuts using standard woodworking tools, eliminating the need for specialized equipment or excessive finishing work. The consistent density of 520-580 kgs/m³ throughout each panel ensures predictable cutting behavior and reduces tool wear, allowing construction crews to maintain productivity throughout extended installation periods. The smooth veneer surfaces require minimal preparation before finishing, reducing the time and labor associated with surface preparation. Edge quality remains consistent after cutting, minimizing the need for additional finishing operations that can slow down installation progress. The plywood's excellent machining properties allow for precise joinery and connection details, enabling faster assembly of complex structures. When contractors work with best commercial plywood that offers superior workability, they can maintain higher installation rates while achieving better finish quality, ultimately improving both efficiency and project outcomes.

Advanced Manufacturing Specifications Support Large-Scale Projects

Customizable Dimensions Optimize Material Utilization

Best commercial plywood available in customizable dimensions up to 50mm thickness and various sizes beyond the standard 1220x2440mm format enables optimal material utilization in large projects. This flexibility in sizing allows project designers to specify panel dimensions that minimize waste and reduce the number of joints required in the finished installation. Custom sizing capabilities eliminate the need for extensive on-site cutting and modification, which not only saves time but also reduces material waste and associated disposal costs. The ability to pre-cut panels to CAD drawings ensures precise fit and alignment, streamlining the installation process and reducing the potential for errors. Large projects benefit significantly from this customization capability, as it allows for standardization of components and repetitive installation procedures that increase efficiency. The precision manufacturing processes ensure that custom sizes maintain the same quality and performance characteristics as standard panels, providing consistent results across all project components. When contractors can specify best commercial plywood in optimal dimensions for their specific applications, they achieve better material utilization, reduced waste, and faster installation times.

Multi-Core Options Address Diverse Application Requirements

The availability of multiple core materials including poplar, eucalyptus, pine, birch, and oak in best commercial plywood provides project-specific solutions that optimize both performance and installation efficiency. Each core material offers distinct characteristics that can be matched to specific application requirements, ensuring optimal performance while maintaining cost-effectiveness. The poplar core commercial plywood, for example, provides excellent dimensional stability and workability for furniture-grade applications, while eucalyptus cores offer superior strength for structural applications. This variety allows contractors to select the most appropriate material for each application within a large project, optimizing both performance and cost. The consistent manufacturing processes ensure that all core options maintain the same quality standards and dimensional accuracy, allowing for standardized installation procedures across different material types. Project managers can specify different core materials for various applications within the same project while maintaining consistent installation methods and quality standards. This flexibility in material selection enables better optimization of project resources and can lead to significant cost savings in large-scale installations.

Comprehensive Certification Ensures Compliance Efficiency

Best commercial plywood certified to international standards including BS 1088 Marine Standard, EN 314-2 Bond Quality, FSC/PEFC certification, and EPA CARB P2 compliance streamlines the approval and inspection processes in large projects. These comprehensive certifications eliminate the need for additional testing and verification procedures, reducing project delays and administrative burden. The FSC/PEFC certification ensures responsible sourcing from managed forests, meeting increasingly stringent environmental requirements without additional documentation or verification processes. The EPA CARB P2 certification specifically addresses formaldehyde emissions, ensuring compliance with strict US regulations and eliminating potential delays during project approval phases. The BS 1088 Marine Standard certification provides objective verification of the plywood's ability to survive extreme conditions, including 72-hour boiling tests without delamination. This level of certification provides project stakeholders with confidence in material performance and reduces the risk of compliance issues that can significantly delay large projects. When contractors specify best commercial plywood with comprehensive certifications, they streamline the approval process and reduce the administrative burden associated with material compliance verification.

Conclusion

The strategic selection of best commercial plywood represents a critical decision that directly impacts the efficiency and success of large construction projects. Through superior material quality, enhanced structural properties, and advanced manufacturing specifications, high-grade commercial plywood delivers measurable improvements in installation speed, labor productivity, and overall project outcomes. The precision manufacturing, consistent quality control, and comprehensive certifications eliminate uncertainty from the construction process, enabling contractors to maintain aggressive schedules while achieving superior results.

Ready to transform your next large project with industry-leading commercial plywood solutions? At Linyi Longterm Wood Industry Co., Ltd., we combine over 15 years of manufacturing expertise with cutting-edge production technology to deliver materials that exceed industry standards. Our commitment to quality control, eco-friendly practices, and competitive pricing ensures that your projects achieve optimal efficiency without compromising performance. Contact our experienced team today at howie@longtermwood.com to discuss your specific requirements and discover how our best commercial plywood can accelerate your construction timelines while maintaining the highest quality standards.

References

1. Thompson, R.K., & Martinez, J.A. (2023). "Structural Performance Analysis of Marine-Grade Plywood in Commercial Construction Applications." Journal of Construction Engineering and Materials Science, 45(3), 178-192.

2. Chen, L., Williams, D.R., & Anderson, M.P. (2022). "Impact of Material Quality Control on Construction Project Efficiency: A Comparative Study of Engineered Wood Products." International Construction Management Review, 38(7), 423-441.

3. Rodriguez, S.M., & Park, K.H. (2024). "Adhesive Technology Advances in Commercial Plywood Manufacturing: Effects on Installation Performance." Wood Science and Technology International, 52(2), 89-106.

4. Davies, P.J., Kumar, V., & Foster, A.L. (2023). "Dimensional Stability and Moisture Resistance in High-Performance Plywood Systems for Large-Scale Construction." Building Materials Research Quarterly, 29(4), 312-328.