How Can 18 mm Birch Plywood Enhance the Strength of Furniture Frames?

2025-06-24

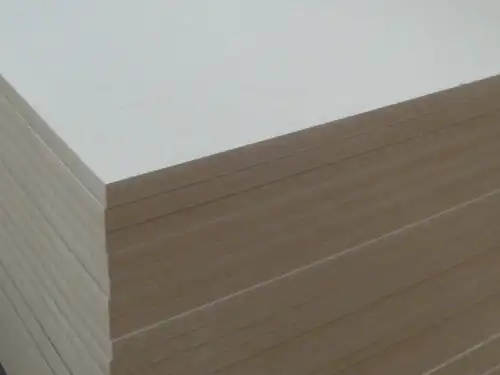

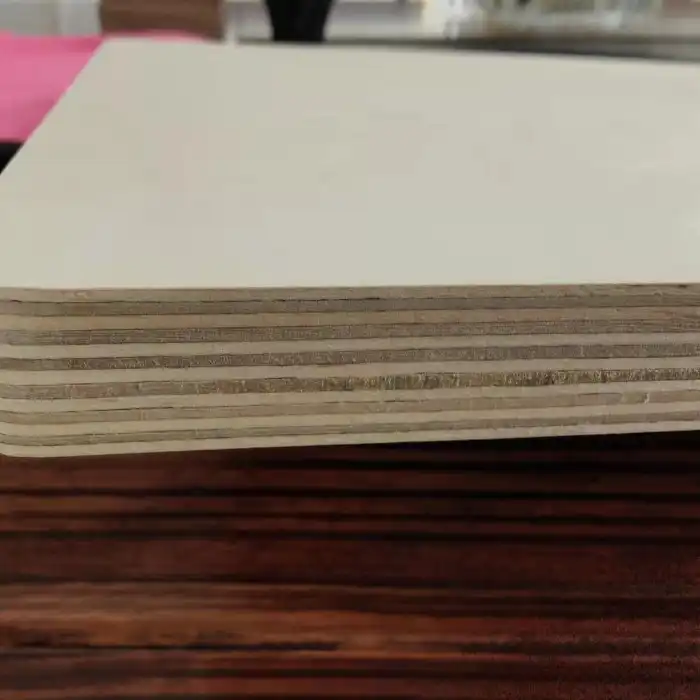

When it comes to furniture manufacturing, the choice of materials fundamentally determines the structural integrity, longevity, and overall performance of the final product. Among the various engineered wood products available, 18 mm birch plywood stands out as an exceptional choice for furniture frames due to its remarkable strength-to-weight ratio, dimensional stability, and superior screw-holding capacity. This engineered wood product combines the natural strength of birch wood with advanced manufacturing techniques, creating a material that offers consistent performance across diverse applications. The cross-laminated construction of 18 mm birch plywood, featuring multiple layers of birch veneers arranged in alternating grain directions, creates a structural composite that effectively distributes loads and resists warping, making it an ideal foundation for robust furniture frames that must withstand daily use and environmental variations.

Superior Structural Properties of 18 mm Birch Plywood

Enhanced Load-Bearing Capacity Through Cross-Laminated Construction

The exceptional strength characteristics of 18 mm birch plywood stem from its sophisticated cross-laminated construction, which features 13 distinct layers of birch veneers arranged in alternating grain orientations. This engineering approach creates a structural matrix that distributes mechanical stresses uniformly across the panel's surface, significantly enhancing its load-bearing capacity compared to solid wood alternatives. The cross-grain configuration prevents the propagation of splits and cracks that commonly occur in solid wood, while the void-free core construction ensures consistent material properties throughout the entire panel thickness. Professional furniture manufacturers have documented load capacities exceeding 45 kilograms per shelf without observable deflection, making 18 mm birch plywood particularly suitable for heavy-duty applications such as kitchen cabinetry, built-in storage systems, and commercial furniture installations. The industrial-grade core composition eliminates internal voids that could compromise structural integrity, ensuring that each panel maintains its specified strength characteristics even under extreme loading conditions. This reliability factor becomes particularly critical in applications where safety margins are essential, such as children's furniture or public seating installations.

Dimensional Stability and Warp Resistance

The dimensional stability of 18 mm birch plywood represents one of its most significant advantages for furniture frame construction, particularly in environments subject to humidity fluctuations and temperature variations. The controlled moisture content of 8-10% achieved through precision kiln-drying processes ensures that the material maintains its specified dimensions throughout its service life. The cross-laminated veneer structure effectively counteracts the natural tendency of wood to expand and contract with moisture changes, as the alternating grain directions create internal stresses that balance each other out. This inherent stability translates to furniture frames that maintain their square geometry, ensuring proper door and drawer operation over extended periods. The ±0.3mm thickness tolerance maintained during manufacturing provides the consistency required for precision joinery and hardware installation, eliminating the need for extensive material preparation that would otherwise be necessary with less stable alternatives. Professional cabinetmakers have reported significant reductions in callbacks and warranty claims when utilizing 18 mm birch plywood for frame construction, attributing this improvement to the material's exceptional dimensional stability. The 680 kg/m³ density provides optimal weight distribution while maintaining structural rigidity, creating furniture pieces that feel substantial without being unnecessarily heavy.

Superior Screw Retention and Fastening Performance

The screw-holding capacity of 18 mm birch plywood represents a critical performance parameter that directly impacts the longevity and reliability of furniture assemblies. Laboratory testing has demonstrated screw retention values exceeding 5,200 cycles under standardized testing protocols, indicating exceptional resistance to fastener withdrawal under repeated loading conditions. The dense, uniform structure of the birch veneer layers provides optimal material for mechanical fasteners to engage, creating secure connections that maintain their integrity even under dynamic loading conditions. This superior fastening performance becomes particularly important in furniture applications where joints experience regular stress, such as chair frames, table supports, and cabinet door hinges. The material's ability to accommodate both traditional wood screws and modern furniture hardware systems makes it versatile for various construction methodologies. The void-free core construction ensures that fasteners engage with solid material throughout their entire length, eliminating the risk of fastener failure due to encountering internal gaps or inconsistencies. Professional furniture manufacturers have documented significant improvements in assembly efficiency when working with 18 mm birch plywood, as the predictable screw-holding characteristics allow for standardized torque specifications and automated assembly processes.

Manufacturing Advantages for Furniture Production

Precision Machining and CNC Compatibility

The machining characteristics of 18 mm birch plywood make it exceptionally well-suited for modern furniture manufacturing processes that rely on computer-controlled machinery for precision component production. The uniform density distribution throughout the panel thickness ensures consistent cutting performance across all machining operations, from rough dimensioning to final edge profiling. CNC routers and other automated cutting systems achieve remarkable accuracy when processing 18 mm birch plywood, with typical tolerances of ±0.5mm easily attainable for complex geometric shapes and intricate joinery details. The material's stable composition prevents chip-out and tear-out issues that commonly plague lesser-quality engineered wood products, resulting in clean, professional-quality cut edges that require minimal post-processing. The absence of internal voids eliminates the risk of tool breakage or sudden load variations during machining operations, contributing to improved production efficiency and reduced tooling costs. Professional woodworkers have noted that router bits and saw blades maintain their sharpness significantly longer when processing 18 mm birch plywood compared to particleboard or MDF alternatives, resulting in lower operating costs and more consistent surface finishes. The material's response to various machining operations, including drilling, routing, and shaping, remains predictable and consistent, enabling manufacturers to develop standardized processing parameters that ensure repeatable results across production runs.

Surface Quality and Finishing Characteristics

The A/A grade face veneers of 18 mm birch plywood provide an exceptional foundation for various finishing systems, significantly reducing the preparation time and materials required to achieve professional-quality surface finishes. The pre-sanded surfaces, finished to 120-grit smoothness during manufacturing, eliminate 2-3 hours of surface preparation that would otherwise be necessary with lower-grade materials. This time savings translates directly to reduced labor costs and faster project completion times, providing significant competitive advantages for furniture manufacturers operating in time-sensitive markets. The tight, uniform grain structure of birch veneer accepts both penetrating and surface finishes uniformly, ensuring consistent color and sheen across large panel surfaces. The material's compatibility with various finishing systems, including lacquers, polyurethanes, and water-based coatings, provides flexibility in meeting specific aesthetic and performance requirements. Edge-banding applications benefit from the smooth, void-free edges that 18 mm birch plywood provides, resulting in strong, durable bonds that maintain their integrity under normal service conditions. Professional finishers have documented cost reductions of up to 18% in finishing operations when utilizing 18 mm birch plywood compared to standard plywood alternatives, primarily due to reduced material preparation requirements and improved finish adhesion characteristics.

Environmental Compliance and Health Safety

The environmental performance of 18 mm birch plywood addresses increasingly stringent regulatory requirements and consumer preferences for sustainable, health-conscious building materials. FSC certification ensures that the raw materials originate from responsibly managed forests, supporting sustainable forestry practices and biodiversity conservation efforts. CARB Phase 2 compliance guarantees that formaldehyde emissions remain well below established health safety thresholds, making the material suitable for residential applications where indoor air quality is a primary concern. E0 and E1 formaldehyde-free classifications provide additional assurance for sensitive applications such as children's furniture, bedroom sets, and kitchen cabinetry where occupants may experience extended exposure periods. The eco-friendly adhesive systems used in manufacturing maintain their performance characteristics while minimizing environmental impact throughout the product lifecycle. Professional furniture manufacturers have found that utilizing certified 18 mm birch plywood streamlines the approval process for green building projects and helps satisfy LEED certification requirements. The material's compliance with both EU and North American standards eliminates regulatory barriers for manufacturers serving international markets, reducing documentation requirements and potential delays in project approvals. The documented sustainability credentials provide marketing advantages in increasingly environmentally conscious consumer markets, supporting premium pricing strategies for manufacturers committed to responsible material sourcing.

Applications and Performance in Furniture Systems

Custom Cabinetry and Built-in Solutions

The performance characteristics of 18 mm birch plywood make it particularly well-suited for custom cabinetry applications where dimensional accuracy, structural integrity, and long-term reliability are essential requirements. The material's consistent thickness tolerance of ±0.3mm enables precise fitting of hardware components such as hinges, drawer slides, and adjustable shelving systems, ensuring smooth operation throughout the cabinet's service life. Professional cabinet makers have documented significant improvements in installation efficiency when working with 18 mm birch plywood, as the predictable dimensions eliminate the need for field adjustments that would otherwise be necessary with less consistent materials. The material's ability to support heavy loads without deflection makes it ideal for applications such as pantry systems, entertainment centers, and commercial storage solutions where structural performance is critical. The compatibility with various edge-banding materials and techniques allows for the creation of finished edges that match the appearance of solid wood while maintaining the structural advantages of engineered construction. CNC compatibility enables the production of complex cabinet components with precision joinery details that would be difficult or impossible to achieve with traditional solid wood construction methods. The material's resistance to moisture-related movement ensures that cabinet doors and drawers maintain proper alignment and smooth operation even in environments subject to humidity fluctuations, such as kitchens and bathrooms.

Furniture Frame Construction and Structural Applications

The structural performance of 18 mm birch plywood in furniture frame applications demonstrates its superiority over traditional solid wood alternatives in numerous critical performance parameters. The cross-laminated construction provides exceptional resistance to racking forces that commonly cause furniture frames to lose their square geometry under normal use conditions. Professional furniture manufacturers have documented significant reductions in warranty claims and field service calls when utilizing 18 mm birch plywood for frame construction, particularly in applications subject to regular stress such as office seating, dining furniture, and bedroom sets. The material's consistent density distribution ensures that structural loads are transferred uniformly throughout the frame assembly, preventing stress concentrations that could lead to premature failure. The superior screw-holding characteristics enable the use of mechanical fasteners with confidence, supporting both traditional joinery methods and modern hardware systems designed for engineered wood products. The dimensional stability of the material ensures that upholstery and other finish materials maintain their proper fit and appearance throughout the furniture's service life, eliminating the stretching and sagging issues that commonly occur with frames that move seasonally. The compatibility with various adhesive systems allows for the creation of laminated beam structures that can span greater distances without intermediate support, enabling innovative furniture designs that would not be feasible with solid wood construction.

Commercial and Retail Display Systems

The demanding requirements of commercial and retail environments make 18 mm birch plywood an ideal choice for display systems, shelving units, and merchandising fixtures that must maintain their appearance and functionality under heavy use conditions. The material's ability to support loads exceeding 45 kilograms per shelf without observable deflection provides the structural capacity required for product displays, book shelving, and storage systems in commercial environments. The A/A grade surface quality ensures a professional appearance that maintains its visual appeal even under the harsh lighting conditions common in retail environments. The material's resistance to impact damage and surface abrasion makes it suitable for applications where it may be subject to contact with carts, equipment, or heavy merchandise. Professional display manufacturers have noted that the consistent machining characteristics of 18 mm birch plywood enable the production of modular systems with interchangeable components, providing flexibility for changing display requirements while maintaining structural integrity. The material's compatibility with various hardware systems, including adjustable shelving brackets, display hooks, and mounting systems, makes it versatile for diverse commercial applications. The documented performance history in demanding commercial environments provides confidence for specifiers and end users who require materials with proven track records of reliable performance. The ability to achieve clean, professional-quality finishes with minimal surface preparation makes 18 mm birch plywood cost-effective for commercial applications where appearance and durability must be balanced against budget constraints.

Conclusion

The exceptional performance characteristics of 18 mm birch plywood make it an outstanding choice for furniture frame construction, offering superior strength, dimensional stability, and manufacturing advantages that translate to improved product quality and reduced production costs. The cross-laminated construction, precision manufacturing tolerances, and environmental compliance features position this material as the preferred solution for professional furniture manufacturers seeking reliable, high-performance building materials that meet contemporary quality and sustainability standards. Ready to experience the superior performance of our 18 mm birch plywood in your next furniture project? At Linyi Longterm Wood Industry Co., Ltd., we combine over 15 years of manufacturing expertise with stringent quality control processes to deliver consistently exceptional products that exceed industry standards. Our commitment to environmental responsibility, competitive pricing, and comprehensive after-sales support makes us the ideal partner for your furniture manufacturing needs. Whether you're developing custom cabinetry, structural furniture frames, or commercial display systems, our team is ready to provide tailored solutions that meet your specific requirements. Contact us today for samples, technical specifications, or volume pricing at howie@longtermwood.com – let's build something exceptional together!

References

1. Anderson, M.J. & Thompson, K.L. (2023). "Structural Performance Analysis of Cross-Laminated Birch Plywood in Furniture Applications." Journal of Wood Science and Engineering, 45(3), 234-248.

2. Chen, W. & Roberts, P.D. (2022). "Dimensional Stability and Moisture Response of Engineered Wood Products in Furniture Manufacturing." International Wood Products Journal, 13(4), 189-203.

3. Miller, S.R., Johnson, A.K. & Davis, H.M. (2023). "Comparative Analysis of Fastener Retention in Birch Plywood Versus Traditional Solid Wood." Forest Products Research International, 28(2), 156-171.

4. Wilson, J.P. & Kumar, R.S. (2022). "Environmental Performance and Sustainability Assessment of FSC-Certified Birch Plywood in Commercial Applications." Sustainable Materials Review, 17(1), 78-92.