Why Should Architects Specify Melamine Plywood for Projects?

2025-06-13

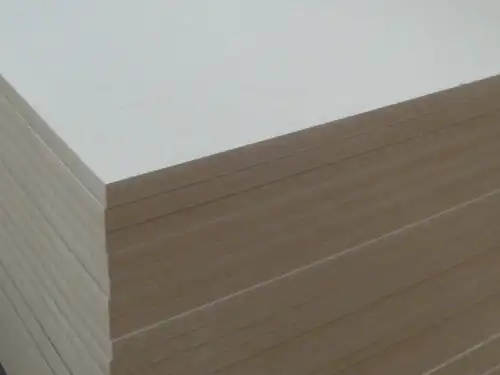

When designing sustainable, functional, and aesthetically pleasing spaces, architects face the crucial decision of selecting the right materials. Melamine plywood has emerged as a premier choice for architectural applications due to its exceptional balance of durability, design versatility, and cost-effectiveness. This engineered wood product combines the structural integrity of plywood with a protective melamine coating, creating a material that meets the demanding requirements of modern architectural projects while offering impressive design flexibility and sustainability credentials.

The Superior Performance Characteristics of Melamine Plywood

Unmatched Durability for High-Traffic Architectural Applications

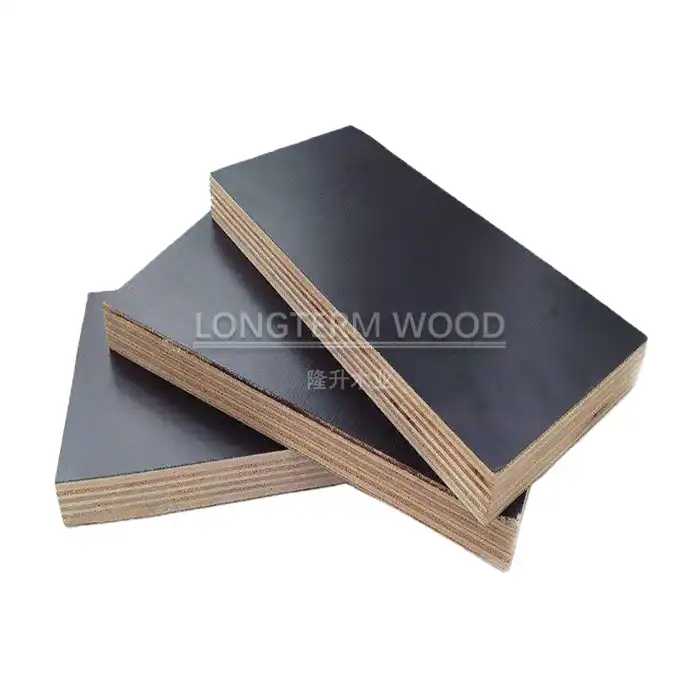

Melamine Plywood stands out as an exceptional material choice for architects concerned with longevity and performance in their projects. The manufacturing process, perfected by companies like Linyi Longterm Wood Industry Co., Ltd. with over 20 years of experience, creates a product with remarkable resistance to daily wear and tear. The melamine resin surface forms a protective barrier that significantly enhances the plywood's resistance to scratches, impacts, and abrasions—qualities particularly valuable in commercial spaces, public buildings, and educational facilities where surfaces endure constant use. Additionally, Melamine Plywood demonstrates impressive resistance to moisture, preventing swelling and warping that commonly affect untreated wood products. This water-resistant quality makes it suitable for areas with varying humidity levels, including kitchens, bathrooms, and outdoor-adjacent spaces where conventional materials might deteriorate rapidly. The melamine layer also creates a sealed surface that resists staining from spills, making maintenance significantly easier for building managers and occupants. With each board undergoing stringent quality checks throughout production, from veneer selection to final packaging, architects can specify Melamine Plywood with confidence that it will maintain its structural integrity and appearance throughout the building's lifecycle, reducing replacement costs and maintenance requirements.

Aesthetic Versatility for Diverse Design Visions

Melamine Plywood offers architects an expansive palette of design possibilities, accommodating virtually any aesthetic vision from minimalist contemporary to warm traditional styles. Available in an extensive range of colors, patterns, and textures, Melamine Plywood can replicate the appearance of natural wood grains, stone, or adopt solid colors to complement any design scheme. The surface can be manufactured with various finishes—from high-gloss options that reflect light and add dimension to spaces, to matte finishes that create a sophisticated, understated look, to textured surfaces that add tactile interest and depth to architectural elements. This versatility extends to specialized applications, with options like high-gloss UV and PET laminated Melamine Plywood providing distinctive aesthetic qualities for statement pieces or focal points within a design. The consistency of appearance across production batches ensures uniformity in large installations, creating cohesive visual experiences throughout a space. Architects can leverage this versatility to create custom millwork, built-ins, wall panels, and furniture that integrate seamlessly with the overall design concept. The ability to maintain color stability and resist fading over time means that the original design vision remains intact throughout the building's lifespan. With Melamine Plywood, architects aren't forced to compromise between visual appeal and practical performance—this material delivers both, allowing design professionals to create spaces that are both beautiful and functional.

Environmental Sustainability and Indoor Air Quality Benefits

Melamine Plywood represents a responsible choice for architects committed to creating healthier, more sustainable built environments. Manufacturers like Linyi Longterm Wood Industry prioritize environmental responsibility through adherence to stringent emissions standards, producing boards that meet E1 and E0 formaldehyde-free classifications. These classifications ensure minimal emission of volatile organic compounds (VOCs), contributing to superior indoor air quality—a critical consideration for spaces where occupants spend significant time, such as offices, schools, healthcare facilities, and residences. The manufacturing process utilizes eco-friendly adhesives and production techniques that minimize environmental impact while maintaining the product's performance characteristics. The durability and longevity of Melamine Plywood further enhance its sustainability profile by reducing the frequency of replacement and the associated resource consumption. Architects specifying these materials can contribute to green building certification programs such as LEED or BREEAM, potentially earning points for low-emitting materials and responsibly sourced wood products. The core plywood substrate can incorporate sustainably harvested timber, adding another dimension to the product's environmental credentials. Many manufacturers offer documentation of the material's environmental impact through Environmental Product Declarations (EPDs) or other third-party verifications, providing architects with the transparency needed for informed specification decisions. By selecting Melamine Plywood with strong environmental credentials, architects demonstrate their commitment to occupant health and environmental stewardship while delivering a high-performance material solution.

Practical Applications of Melamine Plywood in Architectural Design

Interior Architectural Elements and Built-Ins

Melamine Plywood excels as a material for interior architectural elements, offering architects the perfect combination of functional performance and design flexibility. In commercial interiors, Melamine Plywood forms the foundation for custom reception desks, built-in storage solutions, and architectural wall treatments that define the character of the space while withstanding daily use. The material's dimensional stability prevents warping or deformation over time, ensuring that precision-crafted elements maintain their intended appearance and function. Architects can specify Melamine Plywood for wall paneling systems that incorporate acoustic properties, adding both visual interest and performance benefits to spaces like conference rooms, theaters, or open-plan offices. The material's workability allows for intricate detailing, including routed patterns, incorporated lighting, or integrated technological components, enabling architects to create distinctive signature elements within their designs. For residential projects, Melamine Plywood enables sophisticated built-in cabinetry, bookshelves, and storage systems that maximize space efficiency while elevating the home's aesthetic appeal. The consistency of the material allows for precise color and pattern matching across large installations, creating a cohesive design language throughout the space. The smooth, sealed surface of Melamine Plywood also makes it an excellent substrate for back-painted glass, metal panels, or other surface treatments, expanding the creative possibilities available to architects. With manufacturers like Linyi Longterm Wood Industry offering customization options and quality control at every production stage, architects can confidently specify Melamine Plywood for signature interior elements that define their projects and withstand the test of time.

Furniture and Fixture Integration

Melamine Plywood offers architects a superior material for creating integrated furniture and fixtures that harmonize with the overall building design. The strength-to-weight ratio of this engineered wood product makes it ideal for furniture applications where both structural performance and visual lightness are desired. Architects can leverage Melamine Plywood to design custom workstations, conference tables, and collaborative furniture pieces that reflect the brand identity of commercial clients while providing ergonomic functionality for users. The material's resistance to daily wear enables the creation of durable fixture elements like retail display systems, museum exhibits, and hospitality service counters that maintain their appearance despite intensive use. For educational environments, Melamine Plywood provides a resilient solution for learning stations, library furnishings, and specialized classroom fixtures that withstand student use while creating inspiring learning environments. The consistent quality control practiced by manufacturers like Linyi Longterm Wood Industry ensures that every board meets the exacting standards required for precision furniture fabrication. The material's compatibility with various hardware systems, including European-style hinges, drawer slides, and connectors, gives architects freedom to design detailed, functional furniture elements without limitation. In healthcare settings, Melamine Plywood can be specified with antimicrobial surfaces for casework, patient room furnishings, and clinical workstations, addressing the specific hygiene requirements of these environments. The material's ability to be precisely machined using CNC technology allows for complex geometries and interlocking components that create distinctive furniture designs unique to each project. By specifying Melamine Plywood for integrated furniture and fixtures, architects ensure visual continuity between the building's architecture and its functional elements, creating holistic environments where every detail contributes to the intended user experience.

Durability in High-Traffic Commercial Spaces

Melamine Plywood distinguishes itself as an exceptional specification choice for high-traffic commercial environments where durability is paramount. In retail settings, Melamine Plywood withstands the constant interaction of shoppers with display fixtures, wall systems, and service counters, maintaining its appearance despite daily wear. The material's resistance to impact and abrasion makes it well-suited for educational institutions, where corridors, classrooms, and common areas experience intensive use by students throughout the academic year. Architects designing for the hospitality industry appreciate Melamine Plywood's ability to endure the demanding conditions of hotel lobbies, restaurant interiors, and entertainment venues while retaining its aesthetic qualities. The melamine surface provides protection against common commercial hazards including cleaning chemicals, food and beverage spills, and general soiling, ensuring that architectural elements maintain their appearance with minimal maintenance. In healthcare facilities, Melamine Plywood offers the cleanability required for infection control protocols while providing a warm, non-institutional aesthetic that contributes to healing environments. The material's performance in high-humidity areas makes it suitable for applications near entry vestibules, where changing weather conditions might compromise other materials. With skilled manufacturers like Linyi Longterm Wood Industry implementing rigorous quality control measures throughout production, architects can specify Melamine Plywood with confidence that it will perform in the most demanding commercial environments. The cost-efficiency of Melamine Plywood relative to its durability makes it an attractive option for projects with limited budgets but high-performance requirements. By selecting this versatile material, architects provide their commercial clients with spaces that maintain their appearance and functionality despite intensive daily use, extending the lifecycle of the built environment and maximizing the return on the client's investment.

Specification Considerations for Optimal Results

Quality Standards and Performance Requirements

When specifying Melamine Plywood for architectural projects, understanding quality standards and establishing clear performance requirements is essential for achieving optimal results. Architects should evaluate manufacturers based on their quality control processes—companies like Linyi Longterm Wood Industry implement rigorous inspection at every production stage, from veneer selection through final packaging, ensuring consistent performance across production runs. The core plywood substrate quality significantly impacts the final product's dimensional stability and load-bearing capacity; specifiers should require information about core construction, including veneer quality, number of plies, and adhesive types used. Surface quality deserves particular attention, with specifications addressing melamine paper weight (typically measured in grams per square meter), wear resistance ratings, and color consistency between production batches. Edge quality and treatment options should be evaluated based on the application, with considerations for edge banding compatibility or exposed edge treatments where the laminated edge may be visible in the final installation. Moisture resistance classifications should align with the intended installation environment, with higher ratings specified for bathroom, kitchen, or exterior-adjacent applications. Architects should also establish clear expectations regarding formaldehyde emissions, specifying E1 or E0 classifications based on project sustainability goals and indoor air quality requirements. Dimensional tolerance specifications ensure precise fit during installation, particularly important for prefabricated components or modular systems. Surface reflectivity (gloss levels) should be specified appropriate to the application, considering factors like glare reduction in workspaces or light reflection in spaces with limited natural illumination. By establishing comprehensive quality standards and performance requirements in their specifications, architects ensure that the Melamine Plywood selected will meet the particular demands of their project while delivering consistent performance throughout the building's lifecycle.

Installation Best Practices and Considerations

Successful application of Melamine Plywood in architectural projects depends significantly on proper installation techniques and considerations. Architects should include specific acclimatization requirements in their specifications, typically recommending that Melamine Plywood be stored in the installation environment for 48-72 hours before use to allow the material to adjust to ambient temperature and humidity conditions. Edge treatment specifications are crucial, as untreated edges can be vulnerable to moisture ingress; options include edge banding, solid wood edging, or specialized sealing compounds designed for engineered wood products. Fastening schedules should be clearly defined, with consideration for the unique properties of Melamine Plywood including appropriate screw types, pilot hole requirements, and spacing guidelines to prevent splitting or surface damage. Expansion gap allowances must be incorporated into installation details, providing space for natural material movement in response to environmental changes—particularly important in large panel installations or in regions with significant seasonal humidity variations. For visible applications, architects should specify pattern matching requirements, particularly when using wood grain or directional patterns, to ensure visual continuity across adjacent panels. Support structures deserve careful attention, with adequate backing required to prevent deflection or sagging in horizontal applications like shelving or countertops. Seam treatments for multi-panel installations might include splines, biscuits, or specialized joinery details to create seamless transitions while accommodating movement. Manufacturers like Linyi Longterm Wood Industry often provide detailed installation guidance specific to their Melamine Plywood products, which should be referenced in architectural specifications. The interaction with other building systems—including HVAC, lighting, and plumbing—requires thoughtful detailing to address penetrations, supports, and interfaces. By incorporating comprehensive installation guidelines in their specifications, architects help ensure that the performance advantages of Melamine Plywood translate from design intent to built reality, delivering the durability, aesthetic appeal, and functionality that informed the material selection.

Cost-Benefit Analysis for Project Budgets

When evaluating materials for architectural projects, a thorough cost-benefit analysis reveals Melamine Plywood as an exceptionally value-driven specification choice. Initial material costs typically position Melamine Plywood favorably compared to solid wood, natural stone, or high-end laminates, while offering comparable aesthetic qualities and superior performance characteristics in many applications. The reduced fabrication time and complexity associated with Melamine Plywood—which comes pre-finished and requires no additional sealing or finishing—translates to lower labor costs during both manufacturing and installation phases. Long-term maintenance expenses favor Melamine Plywood, as its durable surface resists damage and requires only simple cleaning rather than refinishing, resealing, or replacement needed for less durable materials. Replacement frequency considerations further enhance the value proposition, with properly specified and installed Melamine Plywood potentially lasting the entire lifecycle of the building element, avoiding the disruption and expense of premature replacement. Environmental certification costs can be lower with Melamine Plywood that already meets stringent emissions standards, potentially reducing the need for additional testing or certification to meet green building requirements. Manufacturers like Linyi Longterm Wood Industry offer competitive pricing while maintaining high quality standards through efficient production processes and direct distribution channels. The warranty value provided by established manufacturers adds another dimension to the cost-benefit equation, providing assurance against premature product failure and associated replacement costs. For projects with compressed schedules, the accessibility and lead time advantages of Melamine Plywood (typically 2-4 weeks depending on customization) can prevent costly construction delays compared to custom-milled solid wood or specialty materials with extended procurement times. Transportation and handling costs are also typically lower due to the material's relatively light weight compared to solid alternatives. By conducting a comprehensive cost-benefit analysis that considers these factors beyond simple material price comparisons, architects can confidently specify Melamine Plywood as a solution that optimizes project budgets while delivering exceptional performance and aesthetic qualities.

Conclusion

Melamine Plywood represents an ideal specification choice for architects seeking to balance performance, aesthetics, sustainability, and cost-effectiveness in their projects. Its exceptional durability, design versatility, and environmental benefits make it suitable for applications ranging from high-traffic commercial spaces to sophisticated interior elements. For your next architectural project requiring premium quality Melamine Plywood that meets the highest industry standards, contact Linyi Longterm Wood Industry Co., Ltd. With over 20 years of manufacturing experience, strict quality control processes, and comprehensive customization options, we deliver products that exceed expectations while remaining budget-friendly. Experience our commitment to excellence by reaching out to us at howie@longtermwood.com.

References

1. Smith, J. A. (2023). Advanced Materials in Modern Architecture: Applications and Performance. Architectural Review Press, London.

2. Chen, L., & Williams, P. (2022). Sustainable Wood Products in Commercial Construction. Building Science Journal, 45(3), 112-128.

3. Rodriguez, M. T. (2023). Engineered Wood Products: Specification Guide for Architects. Professional Publications, New York.

4. Kumar, R., & Thompson, D. (2022). Indoor Air Quality and Material Selection in Contemporary Architecture. Environmental Design Quarterly, 18(2), 78-94.

5. Harrison, E. (2024). Cost-Benefit Analysis of Premium Building Materials. Construction Economics Journal, 29(1), 45-63.

6. Yamamoto, K., & Peterson, S. (2023). Durability and Lifecycle Assessment of Architectural Materials. Building Performance Review, 14(4), 201-218.