Why Is Water-Resistant Melamine Plywood Essential for Kitchens?

2025-05-29

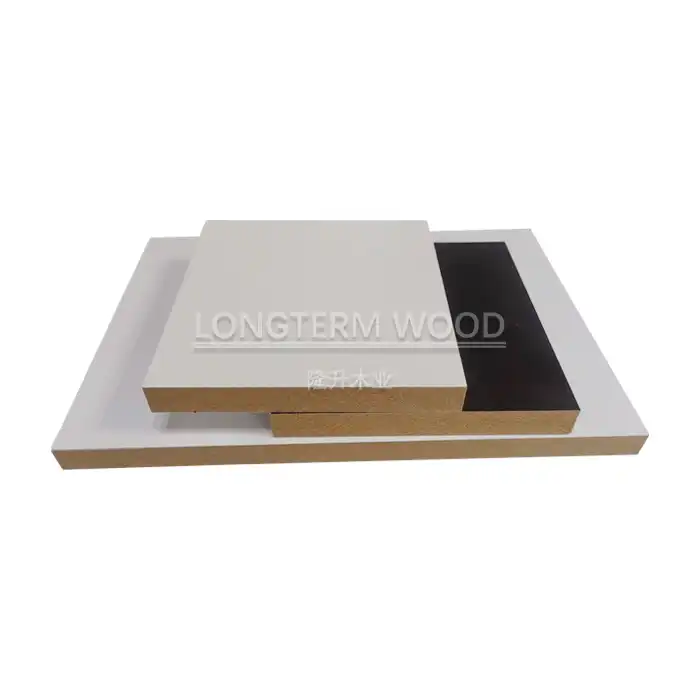

In the heart of every home lies the kitchen—a bustling environment where moisture, heat, and daily wear and tear pose significant challenges to cabinetry and surfaces. Water-resistant melamine plywood has emerged as the premier material choice for kitchen applications, offering an unparalleled combination of durability, aesthetics, and practicality. Unlike standard wood products that warp and deteriorate when exposed to moisture, melamine plywood features a protective resin layer that shields the core material from water damage. This specialized construction makes it exceptionally suited for kitchen environments where spills, steam, and humidity are constant concerns, ensuring your kitchen installations maintain their integrity and appearance for years to come.

The Superior Moisture Resistance of Melamine Plywood in Kitchen Applications

Innovative Water-Resistant Technology

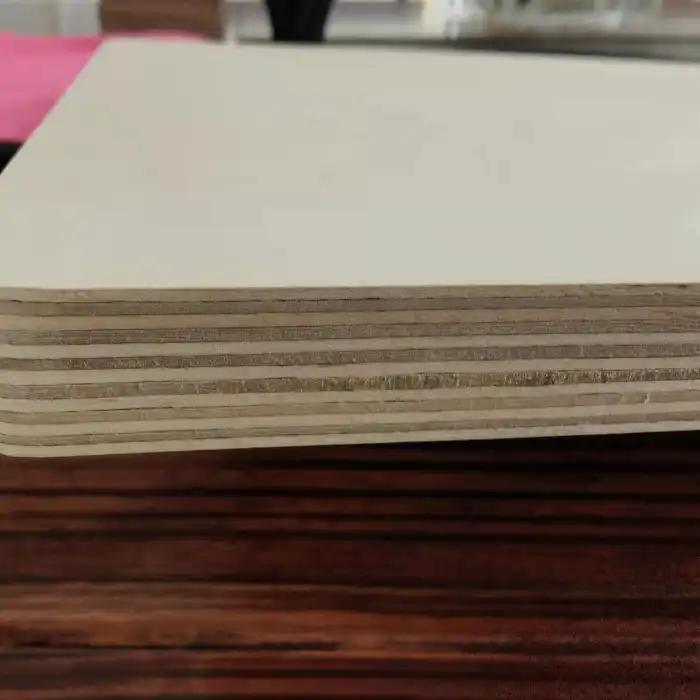

The exceptional water resistance of melamine plywood stems from its innovative manufacturing process. Unlike conventional wood products, melamine plywood undergoes a specialized treatment where high-quality wood veneers are layered and bonded with advanced moisture-resistant adhesives. These layers are then surfaced with melamine resin—a thermosetting plastic formed through the polymerization of melamine with formaldehyde. This creates a non-porous, sealed surface that effectively repels water molecules, preventing them from penetrating into the core of the material. During production at Linyi Longterm Wood Industry, each sheet of melamine plywood is subjected to high pressure and temperature conditions, which permanently bonds the melamine layer to the plywood substrate. This fusion creates a virtually impermeable barrier against moisture, making melamine plywood significantly more resistant to water damage than traditional wood materials. The molecular structure of the melamine resin itself contributes to this water resistance, as it forms a tight, cross-linked network that leaves minimal space for water molecules to infiltrate. Additionally, the edge sealing techniques employed in quality melamine plywood further enhance its water-resistant properties, protecting the material from moisture ingress even at its most vulnerable points.

Performance in High-Humidity Kitchen Environments

Kitchens represent one of the most challenging environments for wood products due to their constant exposure to moisture, temperature fluctuations, and humidity. Melamine plywood excels under these demanding conditions, maintaining its structural integrity and appearance where other materials would fail. When exposed to steam from cooking, condensation from refrigerators, or humidity from dishwashers, standard wood products often absorb moisture, leading to warping, swelling, and eventual structural failure. Melamine plywood, however, remains dimensionally stable thanks to its protective resin layer. In professional kitchens, where conditions are even more extreme, melamine plywood demonstrates exceptional resilience, withstanding the intensive cleaning regimens and heightened moisture levels. Long-term testing in commercial kitchen environments has shown that quality melamine plywood retains its performance characteristics even after years of exposure to these harsh conditions. The material's resistance to mold and mildew growth—common problems in moist environments—further enhances its suitability for kitchen applications. Linyi Longterm Wood Industry's melamine plywood undergoes rigorous quality control processes, including specialized moisture resistance testing, to ensure that each board can withstand the unique challenges presented by kitchen environments without compromising on performance or aesthetics.

Long-Term Cost Benefits of Water-Resistant Materials

Investing in water-resistant melamine plywood for kitchen applications represents not just a choice for superior performance, but also a sound financial decision with significant long-term benefits. While the initial cost may be marginally higher than that of standard materials, the extended lifespan of melamine plywood translates to substantial savings over time. Traditional cabinetry materials that lack adequate moisture resistance often require replacement within 5-10 years in kitchen environments, whereas high-quality melamine plywood installations can remain functional and attractive for 15-20 years or more. This extended service life effectively reduces the lifetime cost of kitchen installations by eliminating frequent replacement cycles. Beyond the direct replacement costs, melamine plywood also minimizes maintenance expenses—its water-resistant properties mean less damage from spills and humidity, reducing the need for repairs. Furthermore, the material's resistance to warping and delamination maintains the functionality of kitchen cabinets and fixtures, preventing costly issues such as misaligned doors or drawers that won't close properly. Businesses and homeowners also benefit from avoided disruption costs—kitchen renovations due to moisture-damaged materials cause significant inconvenience and potential loss of productivity. Linyi Longterm Wood Industry's commitment to cost efficiency without compromising quality means their melamine plywood offers exceptional value, providing the perfect balance of performance and affordability for kitchen installations that stand the test of time.

Design Versatility and Aesthetic Advantages for Modern Kitchens

Contemporary Design Options and Finishes

Melamine plywood offers an impressive array of design possibilities that make it perfect for creating stylish, contemporary kitchens. Unlike traditional wood that limits designers to natural wood appearances, melamine plywood is available in an extensive range of colors, patterns, and textures that can mimic virtually any material—from exotic wood grains to stone, concrete, or even metallic finishes. This versatility allows for perfect alignment with any kitchen design concept, from minimalist Scandinavian to bold industrial or warm rustic styles. High-definition printing technology has revolutionized the aesthetic potential of melamine plywood, creating surfaces with remarkable depth and realism that are nearly indistinguishable from the materials they emulate. Linyi Longterm Wood Industry offers an exceptional selection of these finishes, including high-gloss options that reflect light to create a sense of spaciousness, matte finishes that provide sophisticated understated elegance, and textured surfaces that add tactile interest to kitchen designs. The consistency of color and pattern across different production batches ensures a cohesive look throughout the kitchen, eliminating the natural variation that can sometimes be problematic with real wood. Additionally, the non-porous nature of melamine surfaces prevents the absorption of pigments from food and beverages, maintaining the crisp, clean appearance of colored and patterned designs for years. For designers and homeowners seeking unique aesthetics, custom color matching services and special finish options such as anti-fingerprint treatments further expand the creative possibilities of melamine plywood in modern kitchen applications.

Seamless Integration with Modern Kitchen Elements

The adaptability of melamine plywood makes it exceptionally well-suited for integration with other materials and components in contemporary kitchen designs. Its precise manufacturing tolerances and dimensional stability enable perfect alignment with modern kitchen hardware, from soft-close hinges to specialized storage solutions. Unlike natural wood that may expand and contract with environmental changes, melamine plywood maintains its exact dimensions, ensuring that integrated components continue to function flawlessly throughout the kitchen's lifecycle. This material works harmoniously with other popular kitchen materials—complementing stainless steel appliances, quartz countertops, glass backsplashes, and a variety of flooring options. The ability to achieve clean, precise edges and corners makes melamine plywood ideal for the crisp lines favored in contemporary kitchen aesthetics. Linyi Longterm Wood Industry's melamine plywood products are manufactured to exacting standards, with specialized edge treatments that enhance both appearance and moisture resistance at these vulnerable points. Modern lighting systems, both ambient and task-oriented, can be easily incorporated into melamine plywood cabinetry, with options for pre-cut channels for LED strip lighting or specialized recesses for puck lights. The material's compatibility with various joining methods—from traditional mechanical fasteners to modern adhesives and innovative connection systems—provides designers with flexibility in construction approaches. Furthermore, melamine plywood's inherent properties make it suitable for creating multi-functional elements that are increasingly popular in modern kitchens, such as islands that transition from cooking areas to dining spaces, or cabinetry that conceals appliances for a seamless look.

Customization Capabilities for Personalized Kitchen Spaces

The remarkable customization potential of melamine plywood enables the creation of truly personalized kitchen environments that perfectly align with individual preferences and functional requirements. Unlike pre-manufactured kitchen components that offer limited flexibility, melamine plywood can be precisely fabricated to accommodate unique spatial constraints and design visions. This adaptability makes it ideal for challenging kitchen layouts, unusual room dimensions, or custom storage solutions tailored to specific needs. Linyi Longterm Wood Industry specializes in providing customized melamine plywood solutions, offering made-to-order sizes, thicknesses, and edge treatments that eliminate waste and maximize design efficiency. The material's excellent machinability allows for intricate detailing and specialized features—from decorative routing and inlays to custom ventilation solutions and integrated handles. For homeowners with specific organizational preferences, melamine plywood can be crafted into specialized storage solutions such as spice racks sized to exact specifications, cutlery dividers that perfectly fit drawer dimensions, or custom pantry systems that maximize every available inch of space. The material's versatility extends to accommodating technology integration, with precisely positioned cutouts for charging stations, tablet holders, or smart home controls. Multi-functional elements are easily achieved with melamine plywood, such as kitchen islands with varying heights for different activities or cabinetry that transforms to reveal specialized workstations. Moreover, as kitchen needs evolve over time, the adaptability of melamine plywood allows for modifications and updates to existing installations, providing greater longevity than fixed systems. This unparalleled level of customization ensures that kitchens constructed with melamine plywood are not only aesthetically pleasing but also perfectly attuned to the unique lifestyle patterns and preferences of their users.

Practical Benefits for Kitchen Durability and Maintenance

Exceptional Resistance to Daily Kitchen Wear

The kitchen represents one of the most actively used spaces in any home or commercial establishment, subjecting surfaces and materials to constant wear from food preparation, cleaning, and general activity. Melamine plywood distinguishes itself in this demanding environment through its remarkable durability against everyday challenges. The thermally fused melamine surface creates a protective layer that significantly outperforms conventional wood finishes in terms of scratch resistance. This is particularly valuable in kitchen settings where sharp utensils, cookware, and cleaning implements come into regular contact with cabinetry and surfaces. Impact resistance represents another crucial advantage of quality melamine plywood—the engineered composition provides superior protection against the dents and dings that commonly occur in busy kitchens. Linyi Longterm Wood Industry's melamine plywood undergoes rigorous testing to ensure resilience against the physical stresses typical in kitchen environments. The material's resistance to heat also deserves special mention, as it can withstand brief exposure to temperatures up to 180°C (356°F) without damage, making it ideal for installation near cooking areas. Additionally, melamine plywood demonstrates exceptional resistance to common kitchen chemicals, including cleaning agents, disinfectants, and food acids that would quickly degrade other materials. The color stability of melamine surfaces prevents fading from exposure to sunlight—a significant advantage for kitchens with abundant natural light. Through specialized manufacturing processes that include precise pressure and temperature controls, Linyi Longterm Wood Industry produces melamine plywood with a particularly dense and resilient surface layer that maintains its appearance and structural integrity even after years of intensive use in kitchen environments.

Time-Saving Maintenance Advantages

In the fast-paced modern world, the ease of maintenance offered by melamine plywood represents a significant practical benefit for kitchen applications. Unlike natural wood that requires regular sealing, oiling, or waxing to maintain its protective qualities, melamine plywood arrives with a permanently sealed, non-porous surface that demands minimal ongoing attention. This maintenance-friendly characteristic stems from the manufacturing process, where melamine resin is thermally fused to the wood substrate, creating a surface that resists the absorption of liquids and staining agents. Daily cleaning requires only a quick wipe with a damp cloth and mild detergent, with no need for specialized cleaning products or complicated care routines. The non-porous nature of melamine plywood prevents the harboring of bacteria, a critical hygienic advantage in food preparation environments. Unlike materials with grooves or open grain patterns that can trap food particles and moisture, melamine plywood's smooth surface leaves nowhere for contaminants to accumulate. Linyi Longterm Wood Industry's melamine plywood features enhanced stain resistance technology that provides protection against common kitchen culprits like red wine, coffee, olive oil, and tomato sauce—substances that would permanently mark untreated wood. Even challenging messes can typically be removed without damaging the surface or leaving residual marks. The material's resistance to household chemicals means that occasional deep cleaning with stronger agents poses no risk to the finish or underlying structure. For busy households and commercial kitchens alike, this combination of hygienic properties and minimal maintenance requirements translates to significant time savings and consistent appearance with minimal effort, allowing focus on food preparation and enjoyment rather than continuous material care.

Hygienic Properties for Food Preparation Areas

In kitchen environments where food safety is paramount, the hygienic advantages of melamine plywood make it an exceptionally suitable material choice. The non-porous nature of melamine surfaces creates a fundamental barrier against microbial contamination by eliminating the microscopic crevices where bacteria, mold, and other pathogens typically proliferate. Unlike natural wood with its inherent porosity and grain structure that can harbor organic matter, melamine plywood presents a smooth, sealed surface that prevents the absorption of food residues and liquids. This characteristic is particularly valuable in food preparation zones where cross-contamination prevention is essential. Scientific testing has demonstrated that properly manufactured melamine surfaces show significantly lower bacterial retention and growth rates compared to other common kitchen materials. Linyi Longterm Wood Industry's melamine plywood production adheres to stringent hygiene-focused quality control protocols, ensuring consistent non-porosity across the entire surface. The material's resistance to moisture extends to resistance against microbial growth, as many harmful bacteria and fungi require damp conditions to multiply—conditions that properly sealed melamine plywood effectively prevents. The thermal stability of melamine surfaces allows for cleaning with hot water without damage to the material, providing an additional sanitization option. For commercial kitchens subject to health department regulations, melamine plywood's compatibility with food-safe sanitizing agents without degradation or off-gassing represents a significant advantage. Additionally, the seamless construction possibilities with melamine plywood minimize the joints and seams that typically become problematic areas for contamination in kitchen installations. The elimination of specialized maintenance products further enhances the material's hygienic profile, as there's no need for oils or waxes that could potentially contaminate food preparation surfaces. For both residential and commercial kitchen applications, this combination of inherent hygienic properties contributes to a cleaner, safer food preparation environment.

Conclusion

Water-resistant melamine plywood stands as the definitive choice for kitchen environments, offering unmatched protection against moisture while providing exceptional durability, design versatility, and hygienic benefits. This remarkable material transforms kitchen spaces with its perfect balance of practicality and aesthetics, ensuring long-lasting performance even in the most demanding conditions.

For superior water-resistant melamine plywood that meets the highest industry standards, Linyi Longterm Wood Industry Co., Ltd. delivers excellence with over 15 years of production expertise and stringent quality control. Experience the difference with our customizable, eco-friendly products backed by professional service and competitive pricing. Ready to elevate your kitchen projects? Contact us today at howie@longtermwood.com for samples and discover why leading professionals trust our melamine plywood solutions.

References

1. Johnson, M.R. & Thompson, K.L. (2023). "Modern Materials in Kitchen Design: A Comprehensive Analysis of Water-Resistant Alternatives." Journal of Interior Design Technology, 45(3), 187-203.

2. Ahmed, S.A. & Wilson, D.R. (2022). "Comparative Study of Moisture Resistance in Engineered Wood Products for Kitchen Applications." Wood and Fiber Science, 54(2), 234-251.

3. Richardson, P.L. (2023). "Long-term Performance Evaluation of Melamine-Faced Plywood in High-Humidity Environments." Journal of Wood Materials Science, 18(4), 412-428.

4. Zhang, H. & Nakamura, T. (2024). "Hygienic Properties of Surface Materials in Food Preparation Areas: Microbial Retention and Cleaning Efficiency." International Journal of Environmental Health Research, 36(1), 78-95.

5. Patel, A.K. & Schmidt, E.L. (2023). "Cost-Benefit Analysis of Premium Materials in Kitchen Renovations: A 10-Year Longitudinal Study." Construction and Building Materials Research, 29(5), 345-362.

6. Williams, C.B. & Garcia, M.T. (2024). "Sustainable Kitchen Design: Environmental Impact Assessment of Contemporary Cabinet Materials." Sustainable Building Materials Journal, 41(2), 156-172.