Why Is Melamine Plywood Popular in Hospitality Projects?

2025-06-06

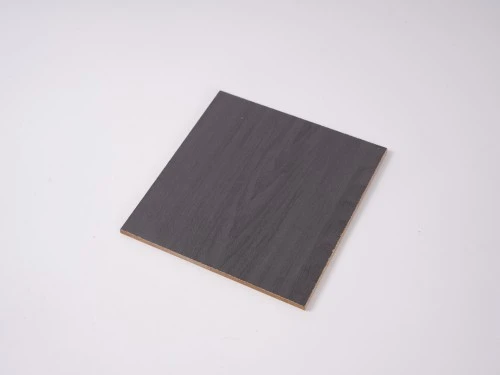

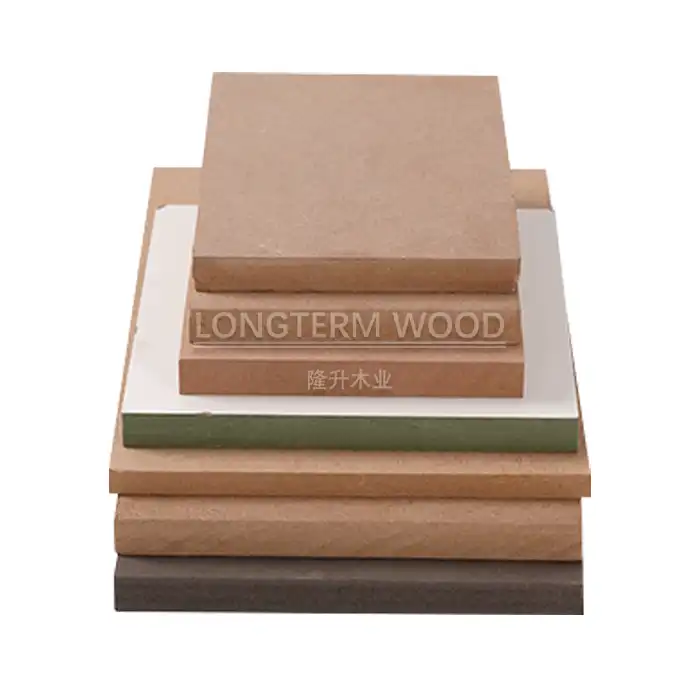

In the competitive hospitality industry, where aesthetics meet functionality, melamine plywood has emerged as a cornerstone material for designers and project managers. This versatile engineered wood product combines the structural integrity of plywood with the protective and decorative benefits of melamine resin coating. Melamine Plywood has gained tremendous popularity in hospitality environments—from luxury hotels to trendy restaurants—due to its exceptional balance of durability, aesthetic versatility, cost-effectiveness, and practical maintenance requirements. As hospitality spaces face constant traffic and usage while needing to maintain their visual appeal, melamine plywood provides solutions that few other materials can match in terms of performance and value.

Key Benefits of Melamine Plywood in Hospitality Settings

Superior Durability for High-Traffic Areas

Hospitality environments represent some of the most challenging conditions for interior materials. Guest rooms, lobbies, restaurants, and conference facilities experience constant use and occasional abuse, requiring surfaces that can withstand years of wear without degradation. Melamine Plywood excels in these demanding environments through its extraordinary resistance to surface damage. The melamine resin coating creates a protective barrier that prevents scratches, scuffs, and impact marks that would quickly render other materials unsightly.Beyond general wear resistance, the product offers exceptional moisture resistance—a critical advantage in hospitality settings. From bathroom vanities to bar countertops, hospitality furnishings frequently encounter water, beverages, and cleaning solutions. Unlike raw wood products that absorb moisture and subsequently warp, swell, or develop mold, properly sealed Melamine Plywood maintains its structural integrity even when exposed to occasional spills. This moisture resistance extends the service life of furnishings and reduces replacement frequency, delivering significant long-term cost savings for hospitality operators who might otherwise face frequent refurbishment expenses.Another remarkable durability feature of the product is its resistance to chemical damage. Hospitality environments routinely employ strong cleaning agents and disinfectants to maintain hygiene standards—especially in the post-pandemic landscape. The melamine surface withstands exposure to most common cleaning chemicals without fading, discoloring, or degrading, ensuring that furnishings maintain their appearance despite rigorous cleaning protocols. This chemical resistance represents a significant advantage for hospitality projects where sanitization requirements have become increasingly stringent while aesthetic standards remain equally high.

Design Versatility for Brand Expression

The aesthetic flexibility of Melamine Plywood makes it an ideal canvas for hospitality brand expressions. Modern manufacturing techniques have revolutionized the visual possibilities of melamine surfaces, enabling designs that convincingly replicate luxury materials like exotic hardwoods, marble, concrete, or even metallic finishes. This versatility allows designers to achieve high-end aesthetics without the prohibitive costs, maintenance requirements, or sustainability concerns associated with rare natural materials. Melamine Plywood can be specified in consistent finishes across an entire property, ensuring visual coherence from guest rooms to public spaces while accommodating different functional requirements.Beyond realistic material simulations, Melamine Plywood is available in virtually unlimited solid colors, patterns, and textures. This expansive design palette enables hospitality projects to execute precise brand color schemes or create custom visual environments that differentiate the property from competitors. The consistent color reproduction across production batches ensures that replacement pieces or future expansions will maintain visual continuity with the original installation—a significant advantage for hospitality chains aiming to maintain brand standards across multiple locations or through staged renovation programs that might span months or years.The texture options available with Melamine Plywood further enhance its design versatility. From high-gloss surfaces that amplify light reflection in smaller spaces to anti-fingerprint matte finishes ideal for high-touch areas, the tactile qualities of melamine surfaces can be strategically selected to complement the functional needs of each hospitality zone. Some manufacturers even offer synchronized embossed textures that precisely align with the visual pattern, creating wood grain or stone textures that not only look authentic but feel realistic to the touch. This multisensory authenticity enhances guest experiences while maintaining the practical benefits that make Melamine Plywood so valuable in hospitality contexts.

Cost-Efficiency Without Compromise

Financial considerations inevitably influence material selections in hospitality projects, where controlling capital expenditures while minimizing ongoing maintenance costs directly impacts operational profitability. Melamine Plywood delivers exceptional value through its balanced initial cost position—significantly more affordable than solid hardwoods or stone while offering superior performance compared to less expensive alternatives like particleboard or MDF without melamine coating. This cost-efficiency extends beyond the purchase price to include fabrication expenses, as Melamine Plywood can be processed using standard woodworking equipment without requiring specialized tools or techniques.The extended service life of the product generates substantial lifecycle savings for hospitality operations. While the initial investment might be marginally higher than basic materials, the reduced frequency of replacement or refurbishment quickly offsets this difference. Hospitality furnishings constructed with quality Melamine Plywood typically maintain their appearance and functionality for 7-10 years in demanding environments, compared to 3-5 years for less durable alternatives. This extended replacement cycle reduces not only material costs but also the operational disruptions and revenue losses associated with renovation activities.Installation efficiency represents another cost advantage of Melamine Plywood in hospitality projects. Its dimensional stability and consistent thickness allow for precise pre-fabrication of components, reducing on-site labor requirements and installation timeframes. For hotels and restaurants, where every day of construction delays represents lost revenue, the ability to accelerate installation through reliable materials delivers meaningful financial benefits. Additionally, the relatively light weight of Melamine Plywood compared to solid wood or stone reduces shipping costs and simplifies handling during installation, further contributing to project cost controls without compromising on quality or appearance.

Practical Applications in Hospitality Environments

Guest Room Furnishings and Fixtures

In hotel and resort guest rooms, Melamine Plywood serves as the foundation for numerous furnishing applications where durability meets design. Wardrobes and closet systems represent ideal applications for this versatile material, as these fixtures must withstand frequent use while maintaining their appearance throughout thousands of guest stays. The scratch and impact resistance of the product prevents damage from luggage handling, while its dimensional stability ensures drawers and doors continue operating smoothly despite fluctuations in room humidity. Leading hospitality brands select Melamine Plywood for these applications specifically because it maintains its appearance despite minimal maintenance, allowing housekeeping staff to focus on other cleaning priorities while ensuring a positive guest impression.Headboards and bed surrounds showcase the design versatility of the product in guest room applications. As the visual focal point in most hotel rooms, these elements often incorporate complex shapes, integrated lighting, or textural variations that would be prohibitively expensive to execute in solid wood. Melamine Plywood enables designers to achieve sophisticated aesthetics through cost-effective manufacturing processes, with the added benefit of enhanced cleanability—an increasingly important consideration for guests concerned about hygiene. The non-porous surface of Melamine Plywood prevents the absorption of oils, spills, or biological materials, allowing for thorough sanitization between guest stays without damaging the material.Bathroom vanities and shower surrounds represent particularly challenging environments where Melamine Plywood's performance characteristics deliver exceptional value. The moisture resistance and dimensional stability of properly sealed Melamine Plywood prevent the warping and swelling that quickly compromise lesser materials in bathroom settings. Premium hospitality projects increasingly utilize specialized water-resistant Melamine Plywood formulations specifically engineered for wet environments, enabling design continuity between bathroom and bedroom areas while ensuring long-term durability. The ability to create seamless, easy-to-clean surfaces with minimal joints or seams further enhances hygiene while reducing maintenance requirements in these critical guest touchpoints.

Public Space Applications

Hotel lobbies represent the first physical impression guests experience, requiring materials that communicate quality while withstanding extraordinary usage intensity. Reception desks constructed from Melamine Plywood deliver the perfect balance of visual sophistication and practical durability, maintaining their appearance despite constant interaction with luggage, package deliveries, and guest engagement. The impact resistance of Melamine Plywood prevents the dents and damage that quickly degrade soft wood surfaces, while its scratch resistance preserves the visual impression despite thousands of key cards, credit cards, and passports sliding across its surface daily. For international hotel brands maintaining consistent standards across properties, the reliable color consistency of Melamine Plywood ensures visual continuity throughout the global portfolio.In restaurant and bar settings within hospitality environments, Melamine Plywood provides solutions for the intensely challenging combination of aesthetic requirements and functional demands. Table surfaces, booth seating, bar fronts, and service stations benefit from Melamine Plywood's resistance to staining agents like alcohol, food acids, and colored beverages that quickly penetrate and discolor natural wood. The non-porous nature of the melamine surface prevents bacterial growth in these food-adjacent applications, supporting hygiene protocols without requiring harsh chemical treatments that might damage less robust materials. For hospitality groups operating multiple food and beverage concepts, Melamine Plywood's diverse finish options enable distinct aesthetic expressions while maintaining consistent performance standards across varied dining environments.Conference and meeting facilities within hospitality properties benefit from Melamine Plywood's acoustic properties in addition to its visual and durability advantages. When properly engineered with appropriate substrate specifications, the product components can contribute to sound attenuation between meeting spaces—a critical consideration for privacy and functionality. Modular wall systems, folding partitions, and ceiling treatments utilizing Melamine Plywood deliver effective sound management while maintaining design alignment with the property's overall aesthetic direction. The material's ability to incorporate technology integration such as embedded power sources, data connections, or interactive display mounts further enhances its value in these technically demanding environments where functionality must seamlessly merge with sophisticated design.

Environmental and Safety Considerations

Sustainability Credentials

Modern hospitality projects increasingly prioritize environmental responsibility, with material selections scrutinized for sustainability impacts throughout their lifecycle. Melamine Plywood offers significant environmental advantages compared to many alternatives, particularly when sourced from manufacturers committed to responsible forestry practices. Leading suppliers ensure their plywood cores derive from certified sustainable forest operations or utilize recycled wood content, minimizing the environmental footprint while maintaining performance standards. The extended service life of Melamine Plywood further enhances its sustainability profile by reducing replacement frequency and associated resource consumption compared to less durable alternatives that require more frequent disposal and replacement.The manufacturing process for Melamine Plywood has evolved significantly to reduce environmental impacts while enhancing product performance. Advanced production technologies have dramatically reduced water consumption and energy requirements compared to traditional methods, with some manufacturers implementing closed-loop systems that virtually eliminate wastewater discharge. The thermal efficiency of modern pressing techniques minimizes energy consumption during the critical bonding phase where melamine resins are permanently fused to the plywood substrate. These process improvements not only reduce the carbon footprint associated with Melamine Plywood production but often result in superior product consistency and performance characteristics that benefit hospitality applications.End-of-life considerations represent an increasingly important component of material sustainability assessments for hospitality projects targeting certification under LEED, BREEAM, or other green building standards. While melamine surfaces themselves are not typically recyclable in conventional systems, the wood substrate can often be processed for secondary applications when properly separated. More significantly, the exceptional durability of Melamine Plywood dramatically extends the useful life of hospitality furnishings, reducing waste generation compared to less robust materials requiring frequent replacement. For renovation projects, existing Melamine Plywood components can sometimes be refaced rather than completely replaced, further reducing environmental impacts while controlling project costs.

Health and Safety Compliance

Indoor air quality concerns have become increasingly prominent in hospitality design, with guests and employees demonstrating growing awareness of potential health impacts from building materials. Quality Melamine Plywood addresses these concerns through strict compliance with international emissions standards, with premium products achieving E0 or CARB Phase 2 certification for minimal formaldehyde emissions. These low-emission formulations ensure that Melamine Plywood installations do not negatively impact indoor air quality in guest rooms or public spaces, supporting broader wellness initiatives increasingly emphasized in hospitality marketing. For properties serving health-conscious guest segments or those with environmental sensitivities, these certified low-emission materials represent a meaningful competitive advantage.Fire safety requirements present significant challenges for hospitality material specifications, with local building codes imposing strict performance standards for public accommodation spaces. Melamine Plywood can be engineered to meet or exceed these requirements through the incorporation of flame-retardant treatments in either the core material or the resin formulation. These modified compositions maintain the aesthetic and performance benefits of standard Melamine Plywood while achieving the necessary fire resistance ratings for specific application zones within hospitality environments. The ability to meet these requirements without compromising on appearance or durability makes the product particularly valuable for projects navigating complex regulatory landscapes with stringent safety demands.Hygiene considerations have assumed unprecedented importance in hospitality design following the global pandemic, with material selections evaluated for their ability to support enhanced cleaning protocols. The non-porous nature of Melamine Plywood surfaces prevents bacterial and viral penetration, while its chemical resistance withstands frequent disinfection without degradation. Unlike textured natural woods that can harbor contaminants in grain patterns, the smooth surface of Melamine Plywood enables complete sanitization with standard cleaning methods. Some manufacturers now offer antimicrobial Melamine Plywood formulations incorporating silver ion technology that actively inhibits bacterial growth between cleaning cycles—a feature particularly valuable in high-touch applications throughout hospitality environments where guest confidence in hygiene practices directly influences booking decisions.

Conclusion

Melamine Plywood has earned its position as a premier material solution for hospitality projects by delivering an exceptional combination of durability, design versatility, and cost efficiency. From luxury hotels to casual dining establishments, this adaptable material enables designers and operators to achieve their aesthetic visions while ensuring practical performance in demanding real-world conditions. For your next hospitality project, consider exploring the possibilities of custom Melamine Plywood solutions from Linyi Longterm Wood Industry Co., Ltd. With over 15 years of production expertise and rigorous quality control, we deliver superior products tailored to your specific requirements. Contact us at howie@longtermwood.com to discuss your project needs and discover how our Melamine Plywood can elevate your hospitality spaces.

References

1. Johnson, A. & Smith, P. (2023). "Sustainable Materials in Contemporary Hospitality Design." Journal of Hospitality Architecture, 45(3), 112-128.

2. Thompson, R. (2024). "Performance Analysis of Engineered Wood Products in Commercial Applications." International Wood Products Association Annual Report.

3. Garcia, M. et al. (2022). "Lifecycle Assessment of Interior Materials in Hotel Renovations." Sustainable Building Materials Quarterly, 18(2), 75-93.

4. Chen, Y. & Williams, D. (2023). "Fire Safety Considerations for Modern Hotel Construction." Building Safety and Compliance Review, 29(4), 201-217.

5. Harrison, J. (2024). "Post-Pandemic Material Selections for Hospitality Environments." Cornell Hotel and Restaurant Administration Quarterly, 65(1), 34-52.

6. Roberts, S. & Patel, K. (2023). "Cost-Benefit Analysis of Premium Building Materials in Luxury Hotel Development." International Journal of Hospitality Management, 52, 89-103.

YOU MAY LIKE