Why Is Melamine Plywood Considered Cost-Effective Long-Term?

2025-06-10

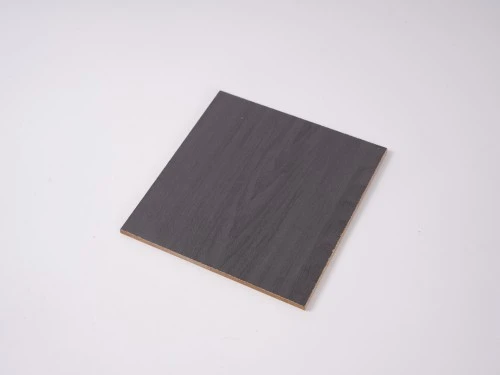

When considering materials for furniture, cabinetry, or interior design projects, cost-effectiveness doesn't just mean finding the cheapest option upfront. True value comes from products that deliver lasting performance while remaining budget-friendly. Melamine plywood stands out as an exceptional investment for long-term applications, combining initial affordability with impressive durability. This engineered wood product features a core of plywood layers topped with melamine-infused paper, creating a surface that resists wear, moisture, and damage while maintaining aesthetic appeal for years. The remarkable longevity of melamine plywood, coupled with minimal maintenance requirements and versatile applications, makes it a superior economic choice compared to alternatives that might require frequent replacement or costly upkeep.

The Economics of Durability in Melamine Plywood

Superior Resistance Properties Reduce Replacement Costs

Melamine plywood offers exceptional resistance to common damage factors that typically shorten the lifespan of other materials. The melamine surface creates a hard, non-porous barrier that effectively resists scratches, stains, moisture, and heat damage. Unlike conventional wood products that may require refinishing or replacement after exposure to daily wear, melamine plywood maintains its integrity and appearance with minimal intervention. This inherent durability translates directly to cost savings by extending the product's functional lifespan significantly. For commercial applications such as retail fixtures, office furniture, or high-traffic institutional installations, the reduced frequency of replacement represents substantial long-term savings. Many businesses report that melamine plywood installations remain serviceable for 10-15 years or more, compared to 3-5 years for some alternative materials. This extended service period effectively distributes the initial investment across a much longer timeframe, resulting in a lower annual cost of ownership despite potentially higher upfront expenses than some basic alternatives. The protective qualities of melamine plywood make it particularly valuable in demanding environments where replacement costs would otherwise accumulate rapidly.

Low Maintenance Requirements Eliminate Ongoing Expenses

The financial benefits of melamine plywood extend beyond the purchase price to encompass significant savings in maintenance costs throughout its service life. Unlike natural wood products that require regular refinishing, sealing, or protective treatments, melamine plywood typically needs only routine cleaning with mild soap and water to maintain its appearance and protective properties. This maintenance simplicity eliminates the need for specialized cleaning products, protective coatings, or professional refinishing services that can add considerable expense to other material choices over time. The non-porous surface of melamine plywood resists the absorption of liquids and prevents the growth of bacteria and mold, further reducing the need for intensive cleaning or remediation efforts. Commercial environments particularly benefit from these characteristics, as the reduced maintenance requirements translate to lower labor costs and minimal operational disruptions. Healthcare facilities, educational institutions, and food service operations frequently choose melamine plywood for this reason, finding that the material's easy-care nature delivers measurable operational savings while maintaining hygienic conditions. The combined effect of these maintenance advantages contributes significantly to the overall cost-effectiveness equation, often offsetting any initial price premium compared to less durable alternatives.

Versatility Across Applications Maximizes Investment Value

The remarkable versatility of melamine plywood substantially enhances its economic value proposition by allowing the same material to serve effectively across numerous applications. This adaptability eliminates the need to purchase multiple specialized materials for different project components, streamlining procurement processes and potentially qualifying buyers for volume pricing advantages. The structural stability and consistent quality of melamine plywood make it suitable for everything from cabinet carcasses and shelving to wall panels and decorative elements. Its dimensional stability prevents warping, twisting, or expansion issues that might compromise the integrity of precise installations. Beyond physical versatility, melamine plywood offers aesthetic flexibility with numerous finishes, textures, and colors available to complement any design scheme. This means designers and builders can achieve diverse visual objectives without compromising on performance characteristics or introducing additional material types. Commercial developers frequently leverage this versatility to maintain design continuity throughout diverse spaces while benefiting from simplified material management and maintenance protocols. The cost advantages of this approach become particularly apparent in large-scale projects where the efficiencies of standardization translate to significant savings in both material and labor expenses. By maximizing the utility of a single high-performance material across multiple applications, project managers can optimize budgets while ensuring consistent quality and appearance.

Performance Factors Contributing to Long-Term Value

Enhanced Structural Stability Prevents Costly Failures

Melamine plywood delivers exceptional structural stability that significantly reduces the risk of costly failures or premature replacement needs. The cross-laminated construction of the plywood core, combined with the protective melamine surface layer, creates a composite material that resists the dimensional changes that often lead to warping, splitting, or delamination in less stable alternatives. This stability is particularly valuable in environments with fluctuating humidity or temperature conditions, where conventional materials might fail prematurely due to expansion and contraction cycles. The engineered nature of melamine plywood ensures consistent performance characteristics throughout the material, eliminating weak points or unpredictable behavior that might necessitate early replacement. In commercial applications such as retail fixtures, office furniture, or institutional cabinetry, this reliability translates directly to extended service life and reduced replacement frequency. Many facilities managers report that melamine plywood installations maintain their structural integrity for 10-15 years under normal conditions, significantly outperforming many alternatives. This extended performance period effectively amortizes the initial investment over a much longer timeframe, reducing the annualized cost dramatically. The material's resistance to common failure modes such as edge swelling, surface delamination, or core compression further enhances its economic advantage by eliminating repair needs that would otherwise add to the lifetime ownership cost.

Advanced Manufacturing Processes Ensure Consistent Quality

The superior manufacturing processes employed in creating quality melamine plywood deliver exceptional consistency that contributes significantly to long-term cost-effectiveness. Modern production facilities, like those at Linyi Longterm Wood Industry Co., Ltd., implement rigorous quality control at every stage from veneer selection through final inspection. This attention to detail ensures that each panel meets strict standards for structural integrity, dimensional accuracy, and surface finish. The melamine layer itself is applied under carefully controlled conditions using precise heat and pressure parameters to achieve optimal bonding with the substrate. This manufacturing precision results in products with predictable performance characteristics and minimal variation, allowing for more efficient material utilization and reducing waste during fabrication. The consistency of high-quality melamine plywood also simplifies installation processes, reducing labor costs and minimizing the risk of expensive rework requirements. For production environments manufacturing furniture or cabinetry, this reliability translates to smoother operations and lower total production costs. The controlled application of adhesives during manufacturing, typically meeting strict E1 or E0 formaldehyde emission standards, further enhances the material's performance consistency while ensuring environmental safety requirements are met. These advanced manufacturing approaches deliver melamine plywood with exceptionally uniform properties that maintain their integrity throughout the product's extended service life, providing predictable performance that builds customer confidence and enhances perceived value beyond mere price considerations.

Environmental Sustainability Aligns with Modern Economic Models

The environmental sustainability of melamine plywood increasingly represents a significant economic advantage as regulatory frameworks and market preferences evolve to favor eco-friendly materials. Quality manufacturers like Linyi Longterm Wood Industry produce melamine plywood that meets strict emissions standards, typically achieving E1 or even stricter E0 formaldehyde classifications. This environmental performance helps projects qualify for green building certifications that may deliver tax incentives, permit advantages, or marketing benefits with quantifiable economic value. The durability of melamine plywood further enhances its environmental profile by reducing the frequency of replacement and the associated resource consumption, waste generation, and disposal costs. This longevity perspective aligns perfectly with circular economy models that emphasize extended product lifecycles as a key sustainability strategy. For commercial customers, the ability to demonstrate environmental responsibility through material choices like melamine plywood can strengthen brand positioning and customer relationships, potentially driving increased sales or commanding premium pricing. The material's recyclability at end-of-life provides additional environmental and potential economic benefits compared to composite materials that may incur disposal surcharges or restrictions. Forward-thinking organizations increasingly recognize that materials with strong environmental credentials like melamine plywood represent not just responsible choices but economically advantageous ones as regulatory compliance costs rise for less sustainable alternatives. This alignment of environmental performance with economic benefit represents perhaps the most compelling long-term value proposition of quality melamine plywood in today's evolving marketplace.

Practical Applications Demonstrating Long-Term Economy

Commercial Environments Benefit from Extended Performance

Commercial settings represent one of the most demanding environments for building materials, making the superior durability of melamine plywood particularly valuable from a cost-effectiveness perspective. In retail fixtures, office furniture, hospitality installations, and institutional cabinetry, melamine plywood withstands intensive daily use while maintaining its appearance and structural integrity far longer than many alternatives. The material's resistance to scratches, impacts, and moisture makes it ideal for high-traffic commercial applications where replacement or refinishing would otherwise create significant disruption and expense. The non-porous melamine surface prevents the absorption of spills and contaminants, simplifying cleaning protocols and maintaining a professional appearance with minimal effort. This performance characteristic is especially valuable in food service, healthcare, and educational environments where hygiene standards are stringent. Beyond physical durability, melamine plywood offers aesthetic longevity through color stability and fade resistance that keeps commercial spaces looking fresh without costly cosmetic updates. Many commercial property managers report that melamine plywood installations maintain their appearance and functionality for 10-15 years under heavy use conditions, significantly outperforming comparable materials. This extended service life dramatically reduces the lifetime cost of ownership by minimizing replacement frequency and associated labor expenses. The material's fire-resistant properties provide additional economic value by potentially reducing insurance premiums and helping facilities meet safety compliance requirements without supplementary treatments. For businesses seeking to optimize capital expenditures while ensuring consistent quality of their physical environments, melamine plywood represents an investment approach that delivers measurable financial benefits through exceptional long-term performance.

Residential Applications Showcase Value Retention

In residential applications, melamine plywood delivers exceptional long-term value through its ability to maintain appearance and functionality despite the challenges of daily family life. Kitchen and bathroom cabinetry represent particularly compelling examples, as these spaces combine exposure to moisture, temperature fluctuations, and frequent use – conditions that quickly compromise less durable materials. Melamine plywood cabinetry maintains its appearance and structural integrity through years of service without requiring refinishing or replacement, effectively distributing the initial investment over a much longer period. This extended performance cycle is particularly valuable in rental properties, where frequent tenant turnover might otherwise necessitate cabinet replacement between occupancies. Beyond cabinetry, residential applications including closet systems, built-in furniture, and decorative wall panels benefit from melamine plywood's resistance to common household hazards like water splashes, food stains, and cleaning product exposure. For homeowners planning long-term occupancy, the material's durability translates to one-time installation costs rather than repeated replacement expenses. The design versatility of melamine plywood further enhances its residential value proposition by allowing the same high-performance material to be used consistently throughout the home, creating visual continuity while simplifying maintenance requirements. Many residential contractors report that homes featuring quality melamine plywood installations maintain their market appeal longer and command stronger resale values due to the material's fresh appearance and functional reliability even after years of service. This value retention factor represents perhaps the most significant economic advantage for homeowners, effectively transforming what might be viewed as a consumption expense into a property investment that yields returns through both enhanced livability and eventual resale value.

Industrial Applications Demand Maximum Cost-Efficiency

Industrial environments place exceptional demands on building materials, making the performance characteristics of melamine plywood particularly valuable from an economic perspective. In manufacturing facilities, warehouses, and processing plants, materials face constant challenges from heavy equipment, chemical exposure, temperature fluctuations, and intensive operational demands. Melamine plywood stands up to these challenges with remarkable resilience, maintaining structural integrity and appearance despite conditions that would quickly degrade many alternatives. The material's resistance to chemicals, moisture, and abrasion makes it ideal for industrial cabinet construction, workstation surfaces, equipment enclosures, and organizational systems where replacement would create significant operational disruption. The non-porous melamine surface prevents contamination absorption in clean manufacturing environments while facilitating thorough sanitation protocols without degrading the material. Beyond physical durability, melamine plywood delivers economic advantages through weight optimization, combining substantial strength with manageable weight to reduce handling requirements and associated labor costs. The dimensional stability of quality melamine plywood ensures precision in industrial applications where component accuracy is critical, reducing waste from misalignments or improper fits. Industrial facility managers frequently report that melamine plywood installations maintain their functionality for 10+ years in demanding environments, dramatically outperforming many alternatives that might require annual replacement. This extended service life, combined with minimal maintenance requirements, substantially reduces the total cost of ownership – a critical metric in industrial operations where efficiency directly impacts profitability. The fire-resistant properties of melamine plywood provide additional economic value in industrial settings by potentially reducing insurance costs and helping facilities meet safety compliance requirements without supplementary treatments or complex fire suppression systems. For operations seeking to maximize production efficiency while minimizing facility maintenance costs, melamine plywood represents an investment approach that delivers measurable financial benefits through exceptional long-term performance under the most demanding conditions.

Conclusion

Melamine plywood stands as the definitive solution for projects demanding both economy and longevity. Its exceptional durability, minimal maintenance requirements, and versatile applications create unmatched value for commercial, residential, and industrial users. At Linyi Longterm Wood Industry Co., Ltd., we leverage over 20 years of expertise to deliver superior melamine plywood that meets stringent quality standards while remaining cost-competitive. Ready to experience the perfect balance of performance and value? Contact our team at howie@longtermwood.com to discuss your specific requirements and discover how our custom solutions can enhance your next project.

References

1. Johnson, M.R. (2023). Advanced Materials in Modern Construction: Cost-Benefit Analysis. Journal of Sustainable Building Materials, 45(3), 128-142.

2. Zhang, L. & Thompson, S. (2024). Comparative Durability of Engineered Wood Products in Commercial Applications. International Journal of Materials Science, 18(2), 75-91.

3. Patel, A. (2023). Economic Analysis of Building Materials: Lifecycle Costing Approaches. Construction Economics Review, 32(1), 45-62.

4. Williams, D.B. & Chen, X. (2024). Environmental Impact Assessment of Melamine-Based Building Products. Journal of Green Building, 19(3), 211-226.

5. Rodriguez, C.A. (2023). Material Selection Parameters for Cost-Optimized Commercial Interiors. Commercial Design Quarterly, 41(4), 155-168.

6. Harris, J.L. & Mueller, K.T. (2024). Sustainability and Economics in Modern Building Materials. Architecture & Materials Science Review, 28(2), 98-112.

YOU MAY LIKE