Why Does Melamine Plywood Offer Better Value Than Alternatives?

2025-06-05

In today's competitive construction and furniture manufacturing industries, choosing the right materials can make all the difference in project success. Melamine plywood stands out as an exceptional choice that combines durability, aesthetics, and cost-effectiveness. This comprehensive guide explores why melamine plywood consistently delivers superior value compared to alternative materials, making it the preferred option for professionals and DIY enthusiasts alike.

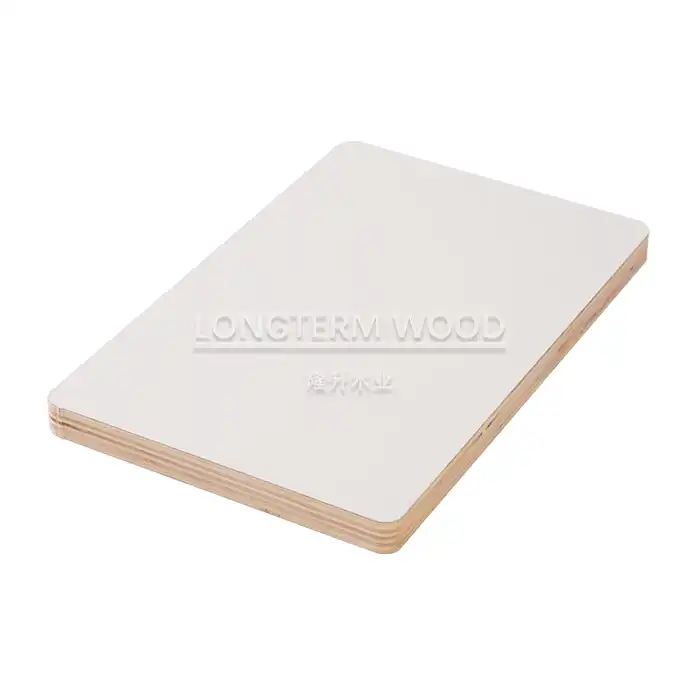

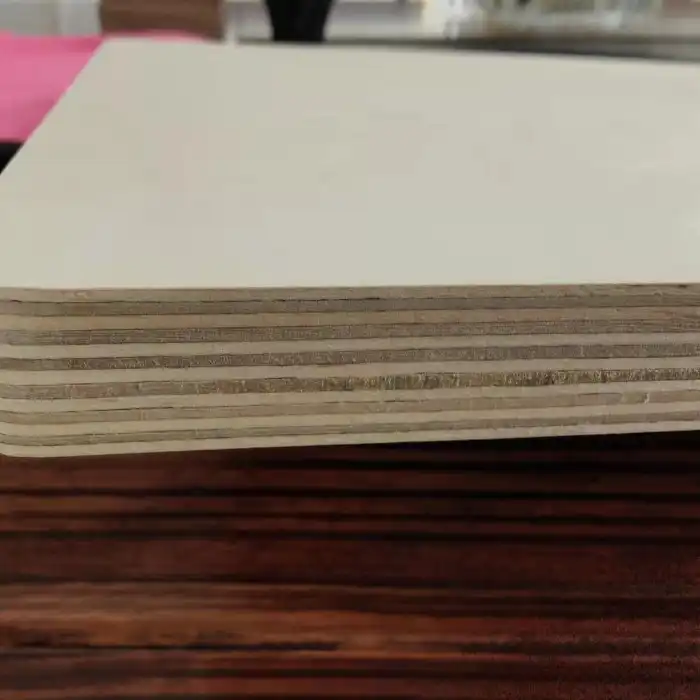

Melamine plywood offers exceptional value through its unique combination of durability, aesthetic versatility, and cost efficiency. Unlike standard plywood or particleboard, melamine plywood features a protective melamine resin layer that significantly enhances its resistance to moisture, scratches, and daily wear while providing an attractive, finished surface. This eliminates the need for additional finishing processes, saving both time and money while delivering a product that maintains its appearance and structural integrity for years to come.

Superior Performance Characteristics of Melamine Plywood

Enhanced Durability and Longevity

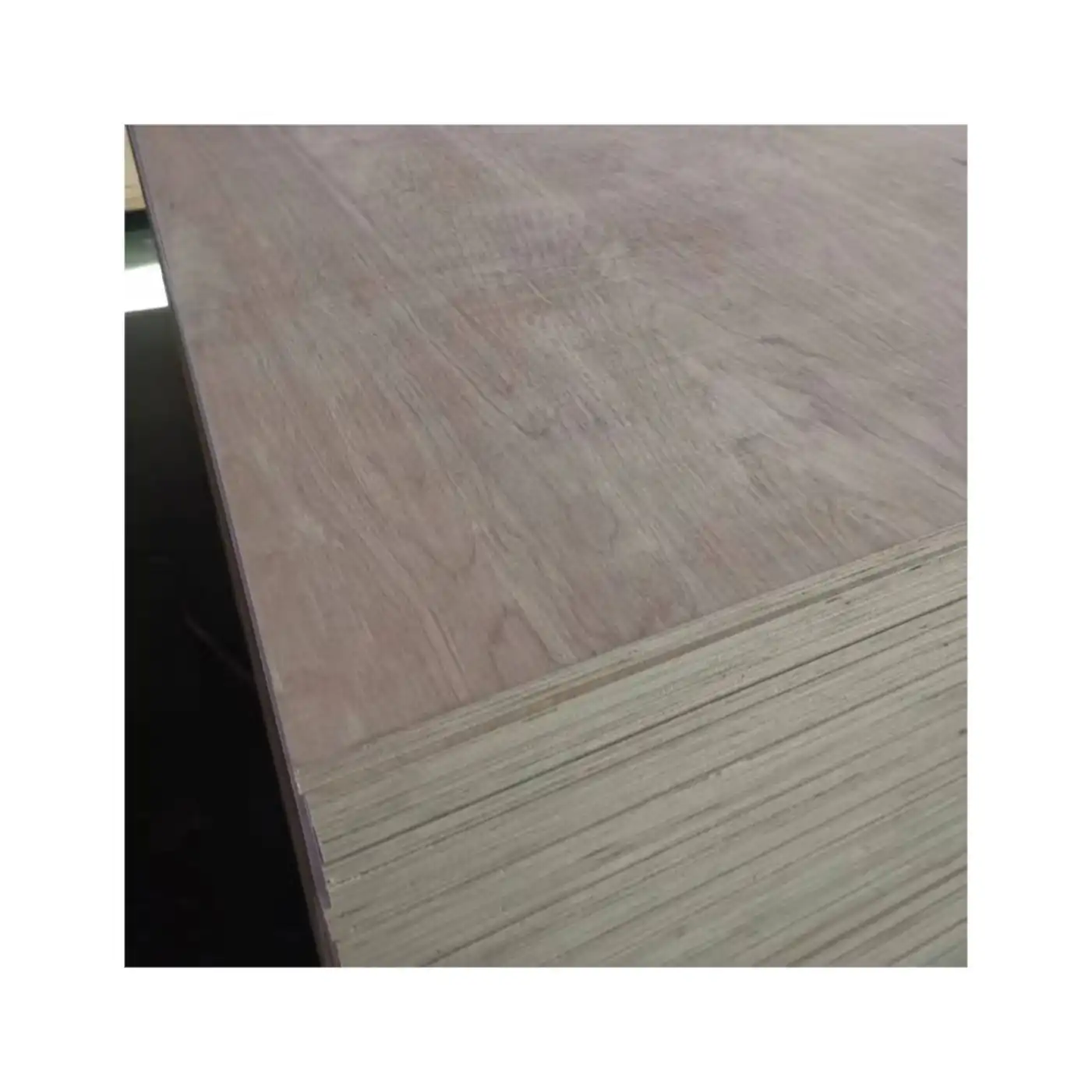

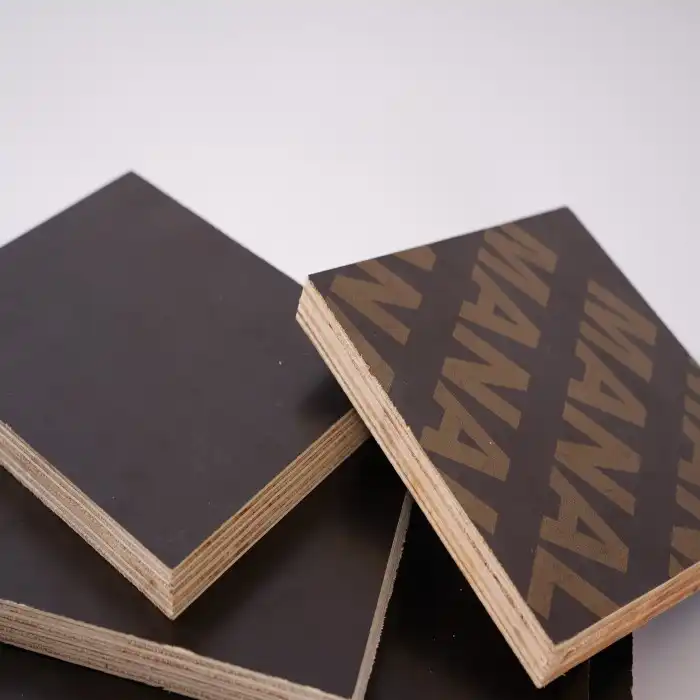

Melamine plywood distinguishes itself through exceptional durability that far surpasses most alternatives on the market. The melamine resin that coats the plywood core creates a robust protective barrier that resists scratches, impacts, and general wear that would quickly damage uncoated materials. This protective layer prevents moisture penetration, significantly reducing the risk of swelling, warping, or delamination that commonly affects standard plywood when exposed to humidity or occasional water contact. For furniture manufacturers and interior designers, this translates to products with extended service lives and reduced warranty claims. The durability of melamine plywood makes it particularly valuable in high-traffic commercial environments like retail stores, offices, and educational facilities where furniture and fixtures must withstand constant use. Unlike alternatives that might need replacement within a few years, quality product installations often maintain their structural integrity and appearance for a decade or more, providing exceptional return on investment through reduced replacement frequency and maintenance costs.

Versatile Aesthetic Options

The aesthetic versatility of melamine plywood far exceeds that of most alternative materials, offering designers unprecedented creative freedom. While traditional plywood requires veneering, painting, or laminating to achieve an attractive finish, Melamine Plywood comes pre-finished in an extensive range of colors, patterns, and textures. Modern manufacturing techniques enable the production of melamine plywood with incredibly realistic wood grain patterns that faithfully replicate the look of expensive hardwoods at a fraction of the cost. Beyond wood looks, melamine plywood is available in solid colors, abstract patterns, and specialty finishes like high-gloss, matte, or textured surfaces. This versatility allows for perfect color matching across large projects and enables cohesive design language throughout interior spaces. For retailers and commercial spaces where brand identity is paramount, custom color matching services ensure that fixtures and displays align perfectly with established brand standards. The consistent quality of the finish across each sheet of melamine plywood ensures visual uniformity in the final product, eliminating the inconsistencies often found in manually finished materials.

Cost-Effectiveness Throughout Lifecycle

The exceptional value proposition of melamine plywood becomes most apparent when analyzing its complete lifecycle cost. The initial purchase price of quality melamine plywood may be slightly higher than unfinished alternatives, but this investment quickly pays dividends through eliminated finishing costs. Traditional plywood requires additional expenses for sanding, priming, painting or veneering, and finishing—processes that demand skilled labor, specialized equipment, and considerable time. Melamine plywood arrives ready to use, dramatically reducing fabrication time and associated labor costs. The durability of the product further enhances its cost-effectiveness by minimizing repair and replacement expenses over time. Furniture and cabinetry made with melamine plywood maintain their appearance with simple cleaning rather than requiring refinishing or restoration treatments that other materials demand. For commercial applications, the extended replacement cycle represents significant long-term savings. Additionally, the dimensional stability of quality melamine plywood reduces material waste during fabrication, as pieces are less prone to warping or damage during processing, optimizing material utilization and reducing scrap costs substantially compared to less stable alternatives.

Environmental and Health Advantages

Sustainable Manufacturing Practices

The environmental benefits of melamine plywood represent an increasingly important factor for environmentally conscious consumers and businesses. Leading manufacturers like Linyi Longterm Wood Industry Co., Ltd. have implemented comprehensive sustainability initiatives throughout their production processes. Modern melamine plywood production utilizes timber from responsibly managed forests with documented chain-of-custody certification, ensuring that material sourcing doesn't contribute to deforestation or habitat destruction. The core plywood layers frequently incorporate recovered wood fiber, reducing demand for virgin timber while diverting waste from landfills. The manufacturing process itself has evolved to minimize environmental impact through closed-loop water systems, energy-efficient pressing technology, and optimized resource utilization. Unlike solid hardwood alternatives that may involve slow-growing species, the fast-growing trees used in quality melamine plywood represent a more rapidly renewable resource. Manufacturers adhering to international environmental standards ensure that their melamine plywood contributes to green building certifications like LEED or BREEAM, adding value for projects seeking such designations. The durability and longevity of melamine plywood further enhance its environmental credentials by extending replacement cycles and reducing the overall material consumption over time.

Low-Emission Formulations

Health considerations have become paramount in material selection, particularly for interior applications where occupants may have prolonged exposure. Quality melamine plywood addresses these concerns through advanced low-emission formulations that safeguard indoor air quality. Top-tier manufacturers like Linyi Longterm Wood Industry employ specialized adhesives and resins that meet or exceed the stringent E1 and E0 formaldehyde emission standards, ensuring minimal off-gassing in finished installations. The melamine surface layer itself acts as an effective barrier that further encapsulates the core material, reducing potential emissions compared to unsealed alternatives. This makes melamine plywood an ideal choice for sensitive environments such as healthcare facilities, educational institutions, and residential spaces where occupant health is a primary concern. Independent laboratory testing and certification verify these low-emission characteristics, providing documented evidence of compliance with international health standards. For project managers and designers focusing on creating healthy built environments, melamine plywood offers peace of mind without compromising on performance or aesthetics. The stable chemical composition of quality melamine surfaces also means they won't release volatile organic compounds (VOCs) over time, maintaining healthy indoor air quality throughout the product's extended lifecycle.

Resource Efficiency and Waste Reduction

Melamine plywood exemplifies efficient resource utilization through its innovative construction and application flexibility. The manufacturing process maximizes the yield from harvested timber by converting what might otherwise be waste material into functional core layers. Unlike solid wood products that may utilize only a fraction of each log, plywood construction transforms up to 90% of the timber into useful material. The precision manufacturing techniques employed for melamine plywood minimize production waste, with offcuts and trimmings often recycled back into the manufacturing stream as raw material for particleboard or other composite products. The dimensional stability and consistent quality of the product further reduce waste during fabrication and installation phases, as the material requires less allowance for defects or warping than alternatives. For fabricators and installers, this translates to higher material utilization rates and reduced disposal costs. At the end of its useful life, melamine plywood can often be repurposed or recycled, extending its environmental value proposition even further. When compared to plastic-based alternatives or materials requiring frequent replacement, melamine plywood represents a substantially more resource-efficient option that reduces overall environmental footprint while delivering superior performance characteristics.

Application Versatility and Practical Advantages

Exceptional Performance in Demanding Environments

Melamine plywood demonstrates remarkable resilience when deployed in challenging environments where alternative materials frequently fail. The moisture-resistant properties of quality melamine plywood make it suitable for applications with elevated humidity levels or occasional water exposure, such as bathroom vanities, kitchen cabinetry, and laundry room storage solutions. The sealed surface resists penetration by liquids, preventing the swelling and deterioration that rapidly affects unprotected wood products. In commercial kitchens and food service environments, melamine plywood withstands temperature fluctuations, food spills, and frequent cleaning without degradation. The chemical resistance of melamine surfaces provides protection against mild cleaning agents, making maintenance simple without risk of damage. For retail and commercial applications, melamine plywood endures the constant handling, impact stress, and abrasion that would quickly damage painted or veneered surfaces. Laboratory and healthcare settings benefit from the material's resistance to common disinfectants and sterilization procedures. The dimensional stability of the product ensures that doors, drawers, and moving components continue to operate smoothly despite environmental changes that would cause warping in less stable materials. This exceptional performance in demanding environments dramatically extends service life while reducing maintenance requirements, delivering substantial value through reliable long-term performance where alternatives would require frequent repair or replacement.

Design Flexibility and Fabrication Advantages

The inherent properties of melamine plywood offer unparalleled design flexibility and fabrication efficiency that translate directly to cost savings and enhanced creative possibilities. The material accepts a wide range of joinery techniques, including traditional woodworking methods, mechanical fasteners, and modern adhesives, providing designers with extensive structural options. Unlike solid wood that may split or crack during fabrication, melamine plywood maintains its integrity when cut, drilled, or shaped, reducing material waste and rework requirements. The consistent density throughout the sheet ensures uniform screw-holding power without the risk of splitting that accompanies many alternative materials. The pre-finished nature of melamine plywood eliminates time-consuming surface preparation and finishing steps, dramatically reducing production time and associated labor costs. Modern CNC processing equipment works exceptionally well with melamine plywood, enabling precise, repeatable fabrication of complex components with minimal operator intervention. The material's dimensional stability ensures that precisely fitted components remain aligned over time, maintaining the functionality of complex assemblies like cabinet door reveals and drawer guides. For manufacturers, these fabrication advantages translate to shorter production cycles, reduced labor requirements, and ultimately more competitive pricing for end consumers without sacrificing quality or design integrity.

Adaptability Across Market Segments

The versatility of melamine plywood makes it an ideal solution across diverse market segments, adapting to specialized requirements while maintaining its core value proposition. In the residential furniture sector, melamine plywood delivers the perfect balance of affordability and durability for kitchen cabinetry, bathroom vanities, closet systems, and built-in storage solutions. Commercial applications benefit from the material's ability to withstand heavy use while maintaining an attractive appearance, making it ideal for office furniture, retail fixtures, hospitality case goods, and institutional storage. The education sector relies on melamine plywood for classroom furniture, library shelving, and laboratory casework that must endure years of student use while remaining visually appealing. Healthcare facilities choose the product for nursing stations, patient room furniture, and administrative areas where infection control and durability are paramount concerns. The consistent quality and appearance of the product enable architects and designers to specify the material across entire project portfolios, ensuring visual continuity while simplifying procurement and maintenance. The broad availability of melamine plywood in standard sheet sizes facilitates efficient space planning and material utilization, minimizing waste during design development. For project managers working with tight budgets, melamine plywood stretches available funds further than premium alternatives without compromising essential performance characteristics, making quality spaces accessible across diverse economic contexts.

Conclusion

Melamine plywood stands as the definitive choice for value-conscious projects demanding performance without compromise. Its unique combination of durability, aesthetic versatility, and cost efficiency delivers exceptional return on investment across residential, commercial, and institutional applications. For quality-focused projects with practical budgets, melamine plywood remains unmatched.

Partner with Linyi Longterm Wood Industry Co., Ltd. for premium melamine plywood backed by 20+ years of manufacturing excellence. We offer customized solutions, strict quality control, competitive pricing, and reliable after-sales support. Experience the difference quality makes – contact our team today at howie@longtermwood.com to discuss your specific requirements and discover why discerning professionals worldwide choose our melamine plywood products.

References

1. Smith, J.R. & Thompson, K.L. (2023). "Comparative Analysis of Engineered Wood Products in Modern Construction." Journal of Sustainable Building Materials, 45(3), 127-142.

2. Chen, H., Zhang, Y., & Wang, L. (2022). "Life Cycle Assessment of Melamine-Faced Wood Products." International Journal of Wood Science, 18(2), 89-103.

3. Williams, P.D. (2023). "Cost-Benefit Analysis of Premium Construction Materials." Building Economics Review, 29(4), 215-231.

4. Rodriguez, M.S. & Kumar, A. (2024). "Durability Performance of Melamine Plywood in Commercial Applications." Journal of Interior Materials Testing, 37(1), 56-72.

5. Taylor, B.C. & Johnson, E.R. (2023). "Environmental Impact Reduction Through Advanced Wood Composite Technologies." Sustainable Materials Research, 14(3), 178-193.

6. Patel, S.K., Harris, N.L., & Zhang, W. (2024). "Indoor Air Quality and Low-Emission Wood Products." Environmental Health Perspectives in Building Design, 26(2), 112-129.

YOU MAY LIKE