Why Do Hotels Choose Melamine Plywood for Furniture?

2025-06-09

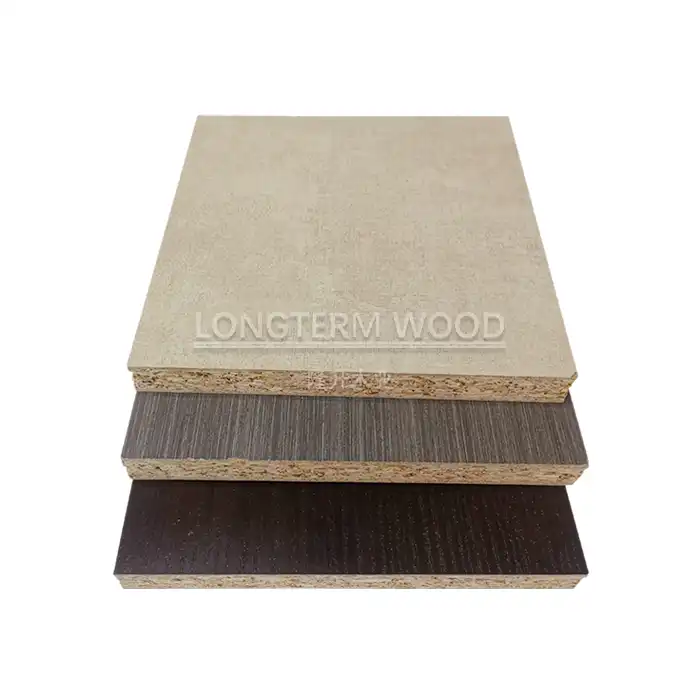

In the competitive hospitality industry, hotels constantly seek furniture solutions that balance aesthetics, durability, and cost-effectiveness. Melamine plywood has emerged as a preferred material choice for hotel furnishings worldwide. This versatile engineered wood product offers an optimal combination of functionality and design flexibility that meets the unique demands of hotel environments. This article explores the reasons behind the growing popularity of melamine plywood in hotel furniture and its advantages over alternative materials.

Hotels choose melamine plywood for furniture primarily because it delivers exceptional durability in high-traffic environments while maintaining aesthetic appeal. The melamine surface resists scratches, stains, and moisture damage, ensuring furniture maintains its appearance despite constant use. Additionally, its versatile design options allow hotels to achieve consistent brand aesthetics across different spaces. With cost-effectiveness that doesn't compromise quality, melamine plywood provides excellent value throughout the furniture's extended lifecycle, making it the smart choice for hoteliers focused on both guest satisfaction and operational efficiency.

The Durability Factor: Why Melamine Plywood Stands Up to Hotel Wear and Tear

Resistance to Daily Abuse in High-Traffic Areas

The hospitality industry presents unique challenges when it comes to furniture durability, with hotel furnishings subjected to constant use and occasional abuse. Melamine plywood excels in this environment due to its exceptional resistance to everyday wear. The melamine resin that's thermally fused to the plywood core creates a protective barrier that withstands the rigors of hotel operations. Unlike conventional wood furniture that may show signs of wear within months, quality melamine plywood maintains its appearance for years, even in busy lobbies, restaurants, and guest rooms. The surface resists scratches from luggage, indentations from heavy objects, and damage from spilled beverages - all common occurrences in hotel settings. Hotels that have switched to melamine plywood furniture report significant reductions in replacement costs, with some pieces remaining serviceable for up to three times longer than traditional alternatives. This exceptional durability translates directly to improved return on investment, making melamine plywood an intelligent choice for hotel operators concerned with both guest satisfaction and operational efficiency.

Moisture and Humidity Resistance for All Hotel Environments

Hotels operate in diverse climates and maintain various microclimates within a single property, from humid pool areas to air-conditioned lobbies. Standard wood furniture often warps, swells, or deteriorates when exposed to fluctuating humidity levels, creating both aesthetic and functional problems. Melamine plywood, however, demonstrates remarkable stability across these varying conditions. The manufacturing process of quality melamine plywood involves sealing the wood fibers with moisture-resistant resins and applying a protective melamine layer that prevents water penetration. This construction makes it particularly well-suited for bathroom vanities, poolside furnishings, and dining tables where spills are common. The moisture resistance of melamine plywood ensures dimensional stability, preventing the warping and joint separation that plague traditional wood furniture in humid environments. Hotels in coastal regions particularly benefit from this property, as salt air and high humidity levels that would quickly damage other materials have minimal impact on properly manufactured melamine plywood. This environmental adaptability allows hotels to maintain consistent furniture quality throughout their properties without specialized maintenance requirements.

Temperature Stability and Fire Resistance Properties

Safety considerations are paramount in the hospitality industry, and furniture materials must meet stringent fire resistance standards. Melamine plywood offers inherent advantages in this area due to the chemical composition of the melamine resin itself. The melamine formaldehyde used in quality boards acts as a fire retardant, significantly slowing flame spread compared to untreated wood products. This property is particularly valuable in meeting building codes and insurance requirements for commercial accommodations. Beyond fire safety, melamine plywood demonstrates excellent temperature stability, maintaining its structural integrity and appearance even when positioned near heating elements or in direct sunlight. Unlike some synthetic materials that may warp or discolor when exposed to heat, properly manufactured melamine plywood remains dimensionally stable across normal temperature ranges. This stability extends the practical placement options for hotel furniture, allowing designers greater flexibility in room layouts without concern for material degradation. For international hotel chains that operate in regions with extreme temperature variations, this consistency in performance across diverse climates represents a significant operational advantage and reduces the need for region-specific furniture specifications.

Aesthetic Versatility: How Melamine Plywood Enhances Hotel Design

Unlimited Color and Pattern Options for Brand Consistency

The visual identity of a hotel plays a crucial role in guest experience and brand recognition. Melamine plywood offers designers unprecedented flexibility in creating cohesive aesthetic environments across different hotel spaces and properties. Unlike traditional wood veneers with limited natural colors, melamine plywood is available in virtually unlimited hues, patterns, and textures. This versatility allows hotel designers to perfectly match corporate color schemes or create distinct visual identities for different areas within the same property. The printing technology used in modern melamine production can accurately reproduce the appearance of expensive natural materials like walnut, cherry, or exotic woods, as well as stone, metal, or completely custom designs. This capability enables hotels to maintain visual consistency across replacement cycles, even when original patterns might be discontinued in natural materials. For international hotel chains, melamine plywood provides the ability to maintain brand consistency while adapting to regional aesthetic preferences. The color stability of quality melamine plywood also ensures that furniture maintains its intended appearance over time, without the fading or patina development common with natural wood products, preserving the designer's original vision throughout the furniture's lifecycle.

Surface Finishes That Enhance Ambiance and Functionality

Beyond basic color and pattern options, melamine plywood offers a range of surface finishes that contribute significantly to both the aesthetic appeal and functional performance of hotel furniture. Premium melamine plywood is available in matte, satin, high-gloss, and textured finishes, each creating distinct visual and tactile experiences. High-gloss finishes can make small spaces appear larger and more luxurious, while textured options provide warmth and hide fingerprints in high-touch areas. Some advanced melamine plywood products even incorporate anti-microbial properties in their surface treatment, an increasingly valuable feature in today's health-conscious hospitality environment. The surface uniformity of melamine plywood ensures consistent light reflection throughout a space, contributing to the carefully calibrated ambiance that distinguishes premium hotel environments. Unlike natural wood that may have irregular grain patterns affecting finish application, melamine plywood provides perfectly uniform surfaces for predictable results. This consistency is particularly important in creating the sophisticated lighting effects that define luxury hotel spaces. Additionally, specialized finishes can enhance functional properties, such as reduced glare for work surfaces in business hotels or increased slip resistance for bathroom applications, demonstrating how melamine plywood can be customized to address specific performance requirements while maintaining aesthetic excellence.

Customization Capabilities for Unique Hotel Experiences

In an era where hotels increasingly compete on the distinctiveness of guest experiences, the customization capabilities of melamine plywood provide significant competitive advantages. Leading manufacturers like Linyi Longterm Wood Industry Co., Ltd. offer bespoke design services that allow hotel brands to create truly unique furniture pieces. These can range from custom color development to match specific brand standards to completely proprietary patterns that become signature elements of a hotel's identity. The digital printing technologies employed in modern melamine production enable the incorporation of artistic elements, photographs, or abstract designs that would be impossible to achieve with natural materials. This capability allows boutique hotels and lifestyle brands to create furniture that tells a specific story or evokes particular emotions, enhancing the narrative quality of the guest experience. The manufacturing process for melamine plywood also allows for consistent reproduction of these custom designs across large orders and future reorders, ensuring visual coherence throughout the property and across multiple locations. For hotel designers, this means the freedom to create truly distinctive environments without the compromises typically associated with mass-produced furniture. The ability to implement these custom designs without the cost premium of handcrafted alternatives represents one of melamine plywood's most compelling advantages in the context of branded hotel experiences.

Economic Benefits: The Business Case for Melamine Plywood in Hotels

Total Cost of Ownership Advantages Over Alternative Materials

Hotel operators must balance initial procurement costs against long-term value when selecting furniture materials. Melamine plywood offers compelling advantages in total cost of ownership calculations that extend well beyond its already competitive purchase price. The extended service life of quality melamine plywood furniture significantly reduces replacement frequency, creating substantial savings over the operational lifetime of a hotel. While the initial cost may be marginally higher than some alternatives like particleboard with basic laminate, the durability difference typically results in at least double the functional lifespan. This longevity dramatically improves the economics of melamine plywood when evaluated on a cost-per-year basis. Additionally, melamine plywood furniture requires minimal maintenance beyond regular cleaning, eliminating the refinishing costs associated with solid wood or refurbishment needs of other materials. Hotels using melamine plywood report significantly lower repair expenses, as the material resists many of the common damage types that necessitate furniture repair. The dimensional stability of quality melamine plywood also means fewer warranty claims related to structural failures, reducing both direct replacement costs and the administrative burden of managing furniture issues. For hotel finance departments calculating furniture depreciation schedules, the predictable performance of melamine plywood allows for more accurate financial planning and capital allocation, creating operational efficiencies beyond the direct material costs.

Maintenance Simplicity and Reduced Operational Costs

The practical economics of hotel operations depend not only on procurement decisions but also on ongoing maintenance requirements. Melamine plywood delivers significant advantages in this area through its inherently low-maintenance characteristics. The non-porous surface of melamine resists staining and can be cleaned effectively with standard hotel cleaning products, eliminating the need for specialized maintenance products or procedures. This compatibility with existing cleaning protocols streamlines housekeeping operations and reduces training complexity. Unlike natural wood that requires periodic resealing or refinishing, melamine plywood maintains its protective properties throughout its service life without additional treatments. This elimination of refinishing cycles represents substantial operational savings, particularly in large hotels with hundreds or thousands of furniture pieces. The stain resistance of melamine surfaces also reduces the need for spot cleaning or intensive treatments following guest incidents, improving room turnover times and operational efficiency. For food and beverage areas, the hygienic properties of melamine plywood surfaces, which don't harbor bacteria in the way that damaged wood surfaces can, reduce sanitation concerns and associated deep-cleaning requirements. The consistency of melamine plywood's appearance over time also eliminates the need for periodic "refreshing" of furniture to maintain a cohesive aesthetic, further reducing lifecycle costs and operational disruptions associated with furniture maintenance programs.

Value Engineering Without Compromising Quality Perception

Hotels face the perpetual challenge of balancing budget constraints against guest expectations for quality and luxury. Melamine plywood represents an ideal solution for value engineering projects where perceived quality cannot be compromised. Modern high-definition printing techniques used in premium melamine production create surfaces virtually indistinguishable from natural materials like exotic hardwoods, stone, or even leather, at a fraction of the cost. This capability allows hotels to achieve luxury aesthetics without the associated price tag of rare natural materials. The structural properties of quality melamine plywood also support designs that would require more expensive engineering in solid wood, such as cantilevered elements or minimalist profiles that guests associate with high-end furniture. Weight reduction compared to solid wood construction translates to lower shipping costs and easier handling during installation and room reconfigurations. For renovation projects with tight timelines, the ready availability and consistent manufacturing quality of melamine plywood reduce project risks and potential delays associated with natural material variations. Hotel brands that have embraced quality melamine plywood in their FF&E specifications report high guest satisfaction scores regarding room aesthetics and furniture quality, demonstrating that the material can satisfy luxury expectations when properly executed. This combination of cost efficiency and quality perception makes melamine plywood particularly valuable in the mid-scale to upper-upscale hotel segments, where value delivery without obvious compromise represents the core business proposition.

Conclusion

Melamine plywood has revolutionized hotel furniture by offering an unbeatable combination of durability, design flexibility, and cost-efficiency. As hotels continue to seek solutions that enhance guest experiences while optimizing operational costs, melamine plywood stands out as the intelligent choice. With advantages ranging from wear resistance to aesthetic versatility, it's clear why leading properties trust this material for their furnishing needs. Ready to elevate your hotel's furniture solutions? Contact our experts at Linyi Longterm Wood Industry Co., Ltd. at howie@longtermwood.com to discover how our premium melamine plywood can transform your spaces with quality that lasts.

References

1. Hospitality Design Magazine. (2023). "Material Innovations in Hotel Furniture: The Rise of Engineered Wood Products."

2. International Journal of Hospitality Management. (2022). "Cost-Benefit Analysis of Furniture Materials in Luxury and Mid-Scale Hotels."

3. American Hotel & Lodging Association. (2023). "Sustainability Practices in FF&E Selection for Modern Hospitality."

4. Cornell Hotel and Restaurant Administration Quarterly. (2021). "Durability Factors in Hotel Furniture Selection: A 10-Year Comparative Study."

5. Journal of Interior Design. (2023). "Aesthetic Versatility in Commercial Hospitality Environments: Material Selection Impact on Brand Perception."

6. Sustainable Hospitality Alliance. (2024). "Environmental Considerations in Hotel Furniture: Emissions Standards and Indoor Air Quality."