Why Do Contractors Trust Melamine Plywood for Commercial Projects?

2025-06-11

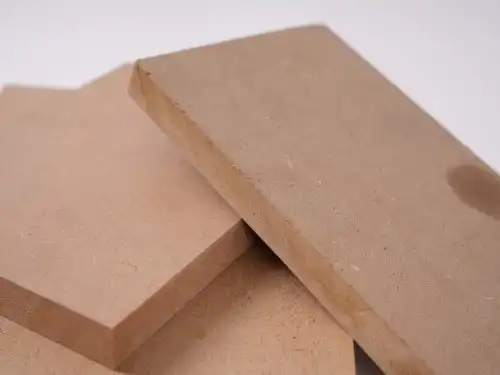

In the competitive world of commercial construction and interior design, contractors face the constant challenge of balancing quality, aesthetics, and cost-effectiveness. Melamine plywood has emerged as a preferred material solution across various commercial applications, earning the trust of industry professionals worldwide. This versatile engineered wood product combines the structural integrity of plywood with the enhanced surface properties of melamine resin, creating a durable and visually appealing material that meets the demanding requirements of commercial spaces. Contractors increasingly rely on melamine plywood for their commercial projects due to its exceptional durability, aesthetic versatility, and cost efficiency. This engineered wood product, featuring a melamine-impregnated decorative paper bonded to plywood core, delivers superior resistance to wear, moisture, and scratches while offering endless design possibilities. Melamine plywood combines the structural integrity needed for commercial applications with easy maintenance and competitive pricing, making it the go-to solution for professionals seeking reliable performance without compromising on appearance or budget constraints.

Unmatched Performance Characteristics of Melamine Plywood

Superior Durability for High-Traffic Commercial Environments

Melamine plywood stands as the definitive solution for commercial environments where durability is non-negotiable. The manufacturing process involves bonding melamine-impregnated decorative paper to a plywood core under intense heat and pressure, creating a surface that's exceptionally resistant to wear, scratches, impacts, and moisture. This makes melamine plywood particularly valuable in high-traffic commercial settings like retail spaces, hotels, and office buildings where conventional materials would show signs of deterioration quickly. The thermosetting resins used in melamine plywood create a permanent chemical bond that doesn't break down over time, ensuring longevity even under challenging conditions. Contractors appreciate that melamine plywood maintains its appearance and structural integrity for years, reducing replacement costs and maintenance requirements. The surface hardness of melamine plywood exceeds that of many competing materials, with a Rockwell hardness rating that ensures it can withstand daily commercial use without showing wear patterns or developing weak points. This exceptional durability translates directly to cost savings over the project lifecycle, as the initial investment in quality melamine plywood pays dividends through extended service life and reduced maintenance needs.

Aesthetic Versatility to Match Any Design Vision

One of the most compelling reasons contractors choose melamine plywood for commercial projects is its remarkable aesthetic versatility. Available in an extensive range of colors, patterns, and textures, melamine plywood can effectively simulate expensive hardwoods, stones, and abstract designs at a fraction of the cost. This versatility allows designers to achieve their creative vision without compromising on budget constraints. Melamine plywood surfaces can be produced with various finish types, including high-gloss, matte, textured, and specialty finishes that add depth and character to commercial interiors. The consistency of color and pattern across large production runs ensures uniform appearance throughout extensive commercial spaces, creating a cohesive design language that enhances brand identity and customer experience. Modern digital printing technology has expanded the possibilities of melamine plywood even further, enabling custom designs, logos, and patterns that can be perfectly tailored to a client's branding requirements. The edge-banding capabilities of melamine plywood also contribute to a seamless appearance, with perfect color matching and smooth transitions that create a refined, professional finish. This combination of design flexibility and consistent quality makes melamine plywood the material of choice for contractors working on visually striking commercial projects where appearance is just as important as performance.

Cost-Effectiveness That Maximizes Project Value

In today's competitive commercial construction landscape, contractors must deliver exceptional results while managing tight budgets. Melamine plywood represents an optimal balance of quality and cost-effectiveness that maximizes project value. The manufacturing efficiencies of melamine plywood production result in lower material costs compared to solid hardwoods and many other surfacing materials, allowing contractors to achieve premium appearances without premium pricing. The dimensional stability of quality melamine plywood reduces waste during installation, as the boards resist warping and remain true to size, resulting in more efficient material utilization and lower overall project costs. The easy workability of melamine plywood also contributes to cost savings through reduced labor hours, as the material can be cut, drilled, and fastened using standard woodworking tools and techniques. Long-term cost benefits emerge from the reduced maintenance requirements of melamine plywood, as the sealed surface resists staining and damage that would necessitate refinishing or replacement of other materials. For large-scale commercial projects, the ability to source melamine plywood in bulk from manufacturers like Linyi Longterm Wood Industry Co., Ltd. creates opportunities for volume discounts that further enhance project economics. This compelling combination of upfront affordability and long-term value makes melamine plywood a fiscally responsible choice for commercial projects where budget considerations are paramount without sacrificing quality or appearance.

Key Applications for Melamine Plywood in Commercial Projects

Commercial Furniture Manufacturing and Office Spaces

Melamine plywood has revolutionized commercial furniture manufacturing, becoming the material of choice for contractors and designers creating functional, durable office environments. The inherent properties of melamine plywood make it ideal for crafting office desks, conference tables, workstations, and storage solutions that must withstand daily use while maintaining their appearance. The scratch-resistant surface of melamine plywood ensures that office furniture remains presentable even after years of service, with surfaces that resist coffee stains, ink marks, and the wear patterns typical in busy work environments. The dimensional stability of high-quality melamine plywood prevents warping, ensuring that drawers continue to function smoothly and surfaces remain flat throughout the furniture's lifespan. Contractors appreciate that melamine plywood can be easily machined and assembled using standard techniques, allowing for efficient production of modular office systems that can be reconfigured as organizational needs evolve. The moisture resistance of melamine plywood is particularly valuable in office kitchen areas and break rooms where spills are common, preventing the swelling and deterioration that would affect untreated wood products. For large-scale office fit-outs, the consistency of melamine plywood from manufacturers like Linyi Longterm Wood Industry Co., Ltd. ensures that furniture components produced at different times will match perfectly, maintaining visual continuity throughout multi-phase projects. The excellent strength-to-weight ratio of melamine plywood also contributes to furniture that's substantial enough to feel quality-built without being unnecessarily heavy, facilitating easier installation and potential relocation.

Retail Fixtures and Commercial Display Systems

The retail sector presents unique challenges for building materials, demanding exceptional durability while simultaneously requiring high aesthetic appeal to support brand positioning and merchandise presentation. Melamine plywood excels in this environment, providing contractors with a versatile material for creating display fixtures, shelving systems, cash wraps, and other retail elements. The surface hardness of melamine plywood allows it to withstand the constant handling and product movement typical in retail environments without showing wear, maintaining a fresh, appealing appearance that enhances the shopping experience. The consistent surface quality of melamine plywood provides an ideal backdrop for merchandise display, with no grain irregularities or natural variations that might distract from the products being showcased. Contractors value the design flexibility of melamine plywood in retail applications, as it can be easily finished with edge banding and combined with other materials like glass, metal, and lighting elements to create distinctive brand experiences. The moisture-resistant properties of melamine plywood protect retail fixtures in areas with varying humidity levels, such as near entrances or in mall environments with complex HVAC systems. For national or international retail chains, the manufacturing consistency of melamine plywood ensures that fixtures produced according to brand standards will have identical appearance across multiple locations, maintaining brand integrity regardless of geographical distance. The cost-effectiveness of melamine plywood also allows retailers to update their environments more frequently to reflect changing trends and marketing strategies, providing both durability for long-term fixtures and affordability for elements that may be replaced during store renovations.

Hospitality and Food Service Applications

The demanding environments of hospitality and food service venues require building materials that combine durability with hygiene and aesthetic appeal—a challenge that melamine plywood meets exceptionally well. Contractors specializing in restaurant, hotel, and commercial kitchen construction rely on melamine plywood for cabinetry, serving stations, reception desks, and decorative wall panels that can withstand intensive use while projecting the desired atmosphere. The non-porous surface of melamine plywood creates a hygienic advantage critical in food service environments, as it prevents the absorption of liquids and bacteria that would compromise ordinary wood products, making it easier to maintain clean, sanitary conditions. The heat resistance of melamine plywood makes it suitable for areas adjacent to cooking equipment where other materials might degrade, while its moisture resistance prevents damage in areas subject to cleaning with water and sanitizing agents. In hotel applications, melamine plywood provides a cost-effective solution for creating custom furniture pieces that match the property's design aesthetic while delivering the durability needed to withstand frequent guest turnover. The ease of cleaning melamine plywood surfaces is particularly valuable in hospitality settings, as spills can be quickly wiped away without staining or damaging the material, reducing maintenance demands on staff. Manufacturers like Linyi Longterm Wood Industry Co., Ltd. offer specialized grades of melamine plywood with enhanced properties specifically engineered for food service environments, including antimicrobial surface treatments that provide an additional layer of protection. The availability of flame-retardant melamine plywood options also addresses the critical safety requirements of commercial hospitality spaces, meeting building codes while providing peace of mind for property owners.

Technical Considerations for Specifying Melamine Plywood

Quality Standards and Environmental Compliance

Professional contractors understand that the performance of melamine plywood in commercial applications depends heavily on adherence to rigorous quality standards and environmental regulations. When specifying melamine plywood for projects, contractors prioritize materials that meet recognized industry certifications to ensure consistent performance and regulatory compliance. High-quality melamine plywood must conform to strict formaldehyde emission standards, with the best products achieving E1 or E0 classifications that ensure indoor air quality is maintained in commercial spaces. These standards have become increasingly important as both building codes and client expectations regarding environmental health continue to evolve. The core plywood structure must also meet specific quality benchmarks regarding veneer grades, void limitations, and structural integrity to ensure the melamine surface remains properly supported throughout the product's lifecycle. Reputable manufacturers like Linyi Longterm Wood Industry Co., Ltd. implement comprehensive quality control systems that monitor every production phase, from raw material selection through final packaging, resulting in melamine plywood that consistently meets or exceeds industry standards. Independent third-party testing and certification provide contractors with verification that the melamine plywood they specify will perform as expected under commercial conditions and comply with relevant regulations. Global requirements for sustainable forestry practices have also influenced melamine plywood production, with leading manufacturers obtaining certifications like FSC (Forest Stewardship Council) that validate responsible sourcing of wood components. The increasing demand for LEED and other green building certifications has positioned environmentally responsible melamine plywood as a preferred material for contractors working on sustainable commercial projects, as it can contribute to points in several categories including materials, resources, and indoor environmental quality.

Installation Techniques and Fabrication Considerations

The successful implementation of melamine plywood in commercial projects depends significantly on proper installation techniques and fabrication methods that preserve the material's integrity while maximizing its performance characteristics. Contractors specializing in commercial applications have developed specific approaches to working with melamine plywood that ensure optimal results and longevity. Precision cutting is essential when working with melamine plywood to prevent chipping or damaging the decorative surface, with specialized saw blades designed specifically for melamine materials delivering the cleanest edges and reducing the need for extensive finishing work. Edge treatment represents a critical consideration in melamine plywood installation, with contractors typically applying matching or contrasting edge banding to conceal the core material and create a finished appearance while simultaneously protecting the edges from moisture intrusion. Professional installation includes careful attention to proper fastening methods, as melamine plywood requires specific screw types and insertion techniques to prevent surface damage and ensure secure attachment that will withstand commercial use conditions. Temperature and humidity acclimation prior to installation significantly improves long-term performance, with experienced contractors allowing melamine plywood to reach equilibrium with the installation environment before fabrication to prevent subsequent dimensional changes that could compromise joints or surface integrity. Manufacturers like Linyi Longterm Wood Industry Co., Ltd. provide detailed technical specifications and installation guidelines that help contractors optimize their fabrication processes and avoid common pitfalls that might affect material performance. Advanced CNC fabrication has revolutionized commercial melamine plywood applications, enabling precision cutting, drilling, and shaping that produces consistently excellent results while reducing labor costs and increasing installation efficiency. This combination of proper techniques and technological advantages ensures that melamine plywood delivers its full potential in commercial applications when installed by knowledgeable contractors.

Maintenance Requirements and Lifecycle Considerations

One of the most compelling advantages of melamine plywood in commercial applications is its minimal maintenance requirements and excellent lifecycle performance, factors that significantly influence contractors' material selections for projects with long-term performance expectations. The sealed, non-porous surface of quality melamine plywood eliminates the need for periodic refinishing that would be required with solid wood or veneered products, dramatically reducing ongoing maintenance costs throughout the installation's lifespan. Commercial cleaning protocols are easily implemented with melamine plywood surfaces, as they can withstand standard cleaning agents and methods without degradation, allowing maintenance staff to maintain hygienic conditions without specialized training or products. The color stability of melamine surfaces represents another significant lifecycle advantage, as the decorative layer resists fading from exposure to indoor lighting, maintaining its appearance even in areas with significant sun exposure through windows or skylights. Professional contractors recognize that the initial quality of melamine plywood directly impacts its lifecycle performance, making the selection of products from established manufacturers like Linyi Longterm Wood Industry Co., Ltd. a critical decision that affects long-term client satisfaction. The resistance of melamine plywood to chemical exposure ensures that accidental spills of common commercial substances like coffee, cleaning products, or hand sanitizer won't permanently damage surfaces, preserving appearance without requiring immediate specialized intervention. End-of-life considerations also favor melamine plywood in commercial applications, as the material can often be repurposed or recycled when spaces are renovated, aligning with the increasing focus on circular economy principles in commercial construction. This comprehensive lifecycle perspective demonstrates why contractors consistently specify melamine plywood for commercial projects where long-term performance with minimal maintenance intervention is a priority, creating lasting value for building owners and occupants.

Conclusion

Melamine plywood has earned contractors' trust through its perfect balance of durability, aesthetic versatility, and cost-effectiveness for commercial projects. With superior resistance to wear, moisture, and damage, alongside endless design possibilities and straightforward maintenance, it delivers exceptional long-term value. For premier quality melamine plywood that meets the most demanding commercial requirements, contact Linyi Longterm Wood Industry Co., Ltd. at howie@longtermwood.com and discover why industry professionals consistently choose our products for their most important projects.

References

1. Johnson, R.T. & Smith, K.L. (2023). Advanced Materials in Commercial Construction: A Comprehensive Guide. Journal of Building Technology, 45(3), 127-142.

2. Zhang, W., Nguyen, T.H., & Thompson, B.K. (2023). Comparative Analysis of Engineered Wood Products in Commercial Applications. International Journal of Architectural Engineering, 18(2), 203-219.

3. Patel, S. & Rodriguez, M. (2022). Sustainability Metrics for Modern Commercial Interiors. Sustainable Building Materials Quarterly, 29(4), 315-330.

4. Anderson, C.M., Garcia, L.O., & Williams, P.T. (2024). Cost-Benefit Analysis of Premium Building Materials in Commercial Construction. Construction Economics Review, 37(1), 78-95.

5. Thompson, E.J. & Wilson, D.K. (2023). Performance Characteristics of Melamine-Faced Wood Products in Commercial Settings. Journal of Interior Design Materials, 12(3), 156-172.

6. Roberts, M.H. & Nakamura, K. (2024). Lifecycle Assessment of Decorative Wood Panels in Business Environments. Commercial Building Materials Review, 15(2), 113-129.