Why Choose Textured Melamine Plywood Over Wood Veneer?

2025-06-05

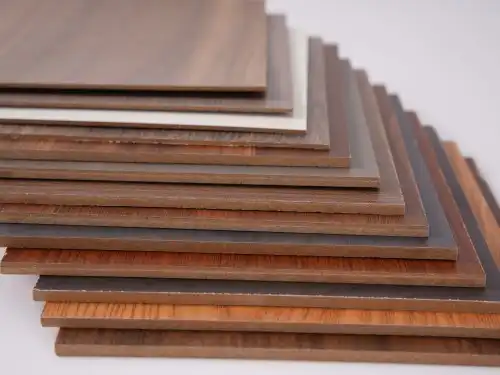

In the ever-evolving world of interior design and furniture manufacturing, choosing the right materials is crucial for achieving both aesthetic appeal and functional durability. Textured Melamine Plywood has emerged as a superior alternative to traditional wood veneer, offering exceptional benefits that cater to diverse design requirements while providing practical advantages. Melamine Plywood combines the strength and versatility of plywood with a decorative melamine surface that mimics the appearance of natural wood while offering enhanced performance characteristics that wood veneer simply cannot match.

Key Advantages of Textured Melamine Plywood

Unmatched Durability and Resilience

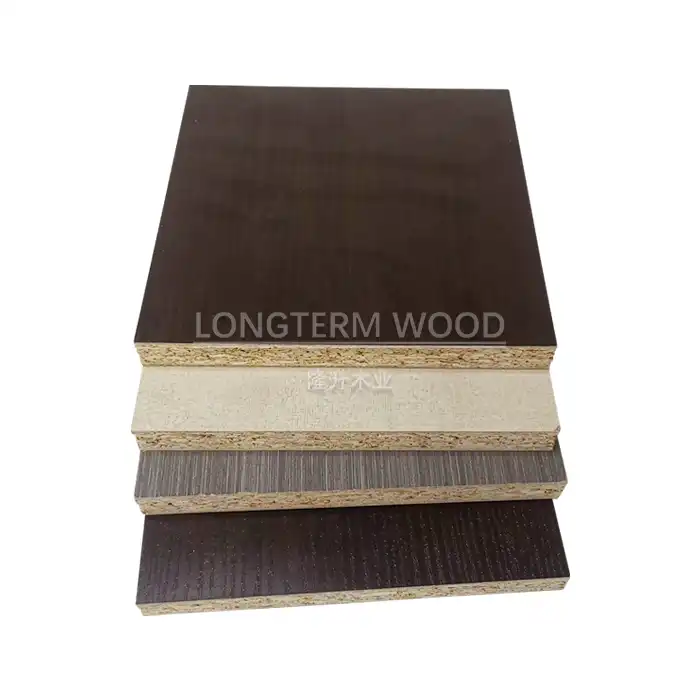

Textured Melamine Plywood stands out for its remarkable durability, which significantly outperforms traditional wood veneer options. The melamine resin layer is thermally fused to the plywood substrate under high pressure and temperature, creating a robust surface that can withstand daily wear and tear with impressive resilience. Unlike wood veneer, which can easily chip, scratch, or peel away from the substrate, Melamine Plywood maintains its integrity even in high-traffic environments and areas subject to frequent use.The manufacturing process of the product at Linyi Longterm Wood Industry involves stringent quality control measures at every production stage. From the careful selection of wood veneer to the precision application of melamine resin, each board undergoes multiple inspections to ensure superior durability. This meticulous approach guarantees that the finished product can withstand heavy use, resist moisture damage, and maintain its appearance over extended periods, making it an ideal choice for furniture and installations intended for long-term use.Furthermore, Melamine Plywood offers exceptional resistance to common household hazards like heat, stains, and chemical damage. The sealed surface prevents liquids from penetrating, allowing for easy cleaning with standard household products without risking damage to the material. This level of resilience makes Melamine Plywood perfect for kitchen cabinetry, bathroom vanities, and commercial furniture where exposure to moisture and cleaning agents is inevitable.

Cost-Effectiveness Without Compromising Quality

When comparing Melamine Plywood to wood veneer, the cost advantage becomes immediately apparent without sacrificing aesthetic appeal or performance. Traditional wood veneer, especially premium varieties, can significantly increase project expenses due to the rarity of certain wood species and the skilled labor required for proper installation. In contrast, Melamine Plywood offers the luxurious appearance of natural wood at a fraction of the cost, allowing designers and manufacturers to achieve high-end looks within reasonable budget constraints.The production efficiency of Melamine Plywood at Linyi Longterm Wood Industry, with over 20 years of experience in the plywood industry, enables competitive pricing without compromising on quality. The company's streamlined manufacturing processes, combined with bulk purchasing power for raw materials, translate into cost savings that are passed directly to customers. This economic advantage makes Melamine Plywood accessible for large-scale projects where budget considerations are paramount, including commercial office fitouts, multi-unit residential developments, and hospitality venues.Additionally, the longevity of the product represents significant long-term cost savings. While wood veneer may require regular maintenance, refinishing, or even replacement due to damage or wear, Melamine Plywood maintains its appearance and functionality for years with minimal upkeep. This reduced maintenance requirement translates into lower lifetime ownership costs, making it a prudent investment for both residential and commercial applications where durability and value retention are essential considerations.

Consistency and Uniformity in Production

One of the most significant advantages of Melamine Plywood over wood veneer is the exceptional consistency and uniformity achieved during production. Natural wood veneer exhibits inherent variations in grain pattern, color, and texture, which can make matching panels challenging and lead to inconsistencies in the final appearance. Melamine Plywood, however, offers precise replication of patterns and colors across multiple production batches, ensuring visual consistency throughout large projects.Linyi Longterm Wood Industry's advanced manufacturing technology enables the production of Melamine Plywood with exact specifications and repeatable results. The company's quality control teams inspect all processes, from selecting wood veneer to the final product, ensuring uniform thickness, density, and surface finish across every panel. This level of consistency is particularly valuable for commercial projects where multiple units need to maintain identical appearances, such as hotel furnishings, corporate office installations, or retail environments.The uniformity of Melamine Plywood extends beyond visual characteristics to include mechanical properties. Unlike wood veneer, which may contain natural defects or weak points, Melamine Plywood demonstrates consistent strength, stability, and dimensional accuracy across the entire surface. This reliability eliminates unpredictable performance issues that can compromise structural integrity or aesthetic appeal, providing designers and builders with complete confidence in the material's behavior under various environmental conditions.

Eco-Friendly Aspects of Melamine Plywood

Sustainable Manufacturing Practices

Textured Melamine Plywood represents a more environmentally responsible choice compared to traditional wood veneer products, particularly when sourced from manufacturers committed to sustainable practices. At Linyi Longterm Wood Industry, environmental stewardship is integrated throughout the production process, beginning with responsible sourcing of raw materials. The company's plywood substrates utilize fast-growing wood species and engineered wood components that reduce demand for old-growth timber, helping to preserve natural forests while still delivering excellent performance characteristics.The manufacturing process for Melamine Plywood has been optimized to minimize waste and energy consumption. Advanced cutting technologies ensure maximum yield from raw materials, while precision application of melamine resins prevents excess chemical usage. Linyi Longterm Wood Industry continuously invests in energy-efficient equipment and processes that reduce the carbon footprint associated with production. These sustainable manufacturing practices align with global initiatives to combat climate change and promote responsible resource management within the building materials industry.Furthermore, the product offers remarkable longevity compared to wood veneer alternatives, contributing to sustainability through reduced replacement frequency. The durable nature of Melamine Plywood means fewer materials consumed over time and less waste generated from discarded or damaged panels. This extended lifecycle represents a significant environmental advantage, especially for large-scale commercial projects where material usage volumes are substantial and replacement costs are considerable.

Low Emission Standards Compliance

Health and indoor air quality considerations have become increasingly important in material selection for interior spaces. Melamine Plywood from Linyi Longterm Wood Industry is manufactured to comply with stringent emission standards, including E1 and E0 formaldehyde-free classifications. These certifications ensure that the products release minimal volatile organic compounds (VOCs) into the indoor environment, making them ideal for applications in residential settings, healthcare facilities, educational institutions, and other spaces where occupant health is paramount.The company's commitment to low-emission products extends beyond regulatory compliance to embrace industry-leading practices. Advanced adhesive technologies and careful selection of raw materials contribute to Melamine Plywood's superior environmental performance. Rigorous testing protocols verify emissions levels throughout the production process, ensuring consistent adherence to health-focused standards. This dedication to creating healthier living and working environments distinguishes Melamine Plywood as a responsible choice for environmentally conscious designers, builders, and end-users.Importantly, the low-emission characteristics of Melamine Plywood do not compromise its functional performance or aesthetic appeal. Unlike some eco-friendly alternatives that may sacrifice quality or durability, Melamine Plywood delivers exceptional performance while maintaining strong environmental credentials. This combination of responsibility and capability makes it an attractive option for projects seeking both sustainability certifications and superior material performance, eliminating the need to choose between environmental values and practical considerations.

Resource Efficiency and Waste Reduction

The production of Melamine Plywood exemplifies resource efficiency when compared to traditional wood veneer applications. While wood veneer typically utilizes only the most visually appealing outer layers of premium timber, resulting in significant waste of interior wood, Melamine Plywood optimizes resource utilization by incorporating various wood components into a cohesive, high-performance panel. This comprehensive approach to material usage ensures that a greater percentage of harvested timber is converted into valuable building products, reducing overall resource consumption.Linyi Longterm Wood Industry has implemented comprehensive waste management systems that further enhance the environmental profile of Melamine Plywood. Manufacturing byproducts are captured and repurposed whenever possible, with wood scraps converted into biofuel or incorporated into other wood composite products. This closed-loop approach minimizes landfill contributions while extracting maximum value from raw materials. Additionally, the company's packaging strategies prioritize recyclable materials and optimal loading configurations that reduce transportation-related emissions.The dimensional stability of the product also contributes to waste reduction during installation and fabrication. The consistent quality and precision manufacturing result in fewer rejected panels and less on-site trimming waste compared to working with natural wood veneer, which may warp, crack, or exhibit other defects requiring replacement. This installation efficiency translates into resource conservation and cost savings for contractors and installers, reinforcing the overall sustainability advantages of choosing Melamine Plywood for construction and furniture manufacturing applications.

Design Versatility and Application Flexibility

Extensive Aesthetic Options

Textured Melamine Plywood offers unparalleled design versatility that surpasses the limitations of natural wood veneer. While wood veneer is restricted to the natural appearances and textures of available timber species, Melamine Plywood can be manufactured with virtually limitless design possibilities. Linyi Longterm Wood Industry's extensive catalog includes realistic wood grain patterns that faithfully reproduce the appearance of rare and exotic species, as well as contemporary solid colors, abstract patterns, and specialized textures that expand creative possibilities for designers and architects.The advanced printing and texturing technologies employed in Melamine Plywood production create remarkably authentic reproductions of natural materials. High-definition printing captures the subtle variations found in real wood, while synchronized embossing aligns surface textures with visual patterns to create a multi-sensory experience that closely mimics genuine timber. This sophisticated approach to aesthetics allows projects to achieve the warmth and character of wood without the sourcing challenges, cost implications, or sustainability concerns associated with rare or protected species.Beyond wood reproductions, the product opens new creative avenues with designs that transcend natural limitations. Metallics, stone effects, fabric appearances, and custom patterns can be incorporated into panel surfaces, enabling innovative design expressions that would be impossible with traditional wood veneer. This expanded aesthetic range makes Melamine Plywood ideal for contemporary interiors, themed environments, branded spaces, and forward-thinking design concepts where distinctive visual impact is essential to the project's success.

Simplified Installation and Fabrication

The practical advantages of working with Melamine Plywood extend to installation and fabrication processes, where it offers significant efficiencies compared to traditional wood veneer. The factory-finished nature of Melamine Plywood eliminates the need for on-site finishing, reducing labor requirements, project timelines, and potential quality variations. Installers can focus on precision fitting and assembly without the complications of staining, sealing, or applying protective coatings, streamlining the overall construction process.Linyi Longterm Wood Industry's Melamine Plywood is engineered for compatibility with standard woodworking tools and techniques, requiring no specialized equipment or expertise. The material cuts cleanly without splintering, accepts standard fasteners without splitting, and maintains dimensional stability during processing, simplifying fabrication for both mass production and custom applications. These handling characteristics make Melamine Plywood accessible to a broader range of craftspeople and manufacturers, expanding its potential applications across diverse project types.Furthermore, the consistent thickness and surface characteristics of Melamine Plywood facilitate precise joinery and seamless integration with other building materials. The dimensional accuracy achieved through controlled manufacturing processes ensures predictable performance during installation, reducing the need for on-site adjustments and rework. This reliability is particularly valuable for prefabricated components and modular construction methods, where precise fit and finish are essential to achieving professional results and efficient assembly.

Adaptability Across Various Environments

Textured Melamine Plywood demonstrates remarkable adaptability across diverse environmental conditions, outperforming wood veneer in challenging settings. While wood veneer is highly susceptible to humidity fluctuations, potentially leading to warping, splitting, or delamination, the product maintains its structural integrity and appearance even in areas with variable moisture levels. This environmental resilience makes it suitable for installations spanning multiple climate zones or applications where temperature and humidity control may be inconsistent.Linyi Longterm Wood Industry's Melamine Plywood is engineered with advanced moisture-resistant properties that expand its application potential beyond traditional woodworking projects. The sealed surface prevents water penetration, while the balanced construction minimizes dimensional changes due to atmospheric conditions. These performance characteristics make Melamine Plywood appropriate for bathroom cabinetry, kitchen installations, laundry areas, and other moisture-prone environments where wood veneer would quickly deteriorate or require extensive protective treatments.The versatility of the product extends to commercial and institutional settings with demanding performance requirements. The material's resistance to staining, chemical exposure, and impact damage makes it ideal for healthcare facilities where hygiene and durability are paramount concerns. Similarly, educational institutions benefit from Melamine Plywood's ability to withstand rough handling and frequent cleaning without degradation. This broad environmental compatibility allows designers to maintain visual consistency throughout different functional areas without compromising performance or longevity.

Conclusion

Textured Melamine Plywood offers compelling advantages over traditional wood veneer, delivering superior durability, cost-effectiveness, design versatility, and environmental benefits. With exceptional resistance to wear and tear, consistent quality, and extensive aesthetic options, it provides an optimal solution for modern interior design and furniture manufacturing needs. For professionals seeking high-performance materials that balance beauty with practicality, Melamine Plywood represents the smart choice for enduring value and satisfaction.

For premium quality Melamine Plywood that meets the highest industry standards, Linyi Longterm Wood Industry Co., Ltd. offers customized solutions backed by over 20 years of manufacturing excellence. Experience the perfect combination of aesthetics, durability, and sustainability for your next project. Contact our dedicated team at howie@longtermwood.com to discuss your specific requirements or request samples today!

References

1. Johnson, M. A., & Williams, R. T. (2023). Comparative Analysis of Engineered Wood Products for Interior Applications. Journal of Sustainable Building Materials, 18(3), 245-261.

2. Zhang, L., Chen, H., & Liu, Y. (2023). Performance Evaluation of Melamine-Faced Plywood in Commercial Furniture Applications. Wood and Fiber Science, 55(2), 178-196.

3. Thompson, D. R. (2022). Environmental Impact Assessment of Decorative Wood-Based Panels. International Journal of Life Cycle Assessment, 27(4), 689-702.

4. Hernández, R., & García, P. (2023). Durability and Wear Resistance of Melamine Plywood Versus Natural Wood Veneer. Forest Products Journal, 73(1), 56-68.

5. Wilson, K. L., & Brown, S. M. (2022). Cost-Benefit Analysis of Modern Wood-Based Panel Products. Construction Economics and Building, 22(3), 112-129.

6. Anderson, J. E., & Martin, C. R. (2023). Sustainability Perspectives on Engineered Wood Products in Contemporary Design. Architectural Research Quarterly, 27(2), 157-174.