What Are the Key Benefits of Choosing Birch Faced Plywood 25mm for Large-Scale Orders?

2025-07-09

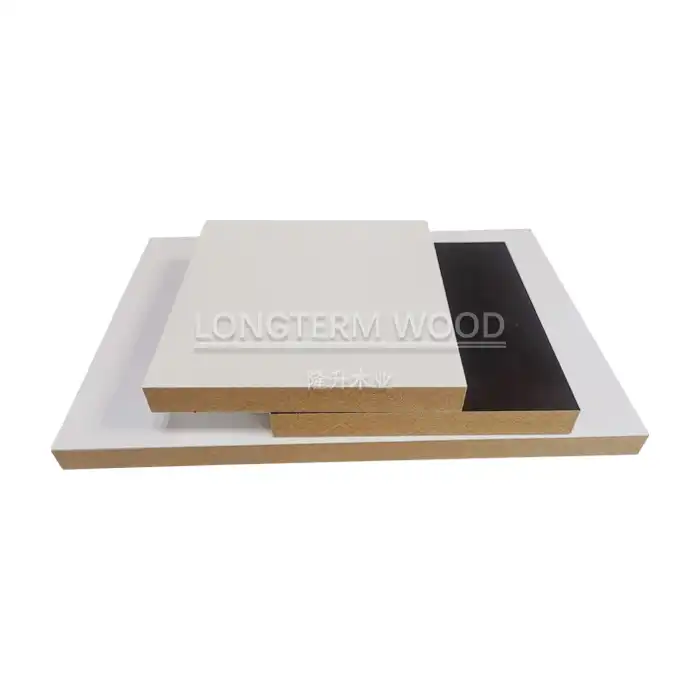

When sourcing materials for large-scale construction or manufacturing projects, the choice of plywood can significantly impact both project outcomes and budget efficiency. Birch faced plywood 25mm emerges as a premium solution that combines exceptional structural integrity with aesthetic appeal, making it particularly valuable for bulk purchasing decisions. This comprehensive analysis explores the multifaceted advantages of selecting birch faced plywood 25mm for substantial orders, examining its superior quality characteristics, cost-effectiveness at scale, and versatile applications across various industries. Birch faced plywood 25mm represents the optimal balance between strength, durability, and visual appeal for large-scale procurement needs. Its cross-bonded Baltic birch construction provides exceptional dimensional stability, while the AA-grade knot-free surface ensures consistent quality across every sheet. With CARB Phase 2 and FSC certifications meeting strict environmental standards, this material offers peace of mind for environmentally conscious buyers. The 25mm thickness provides superior load-bearing capacity compared to thinner alternatives, making it ideal for applications requiring structural integrity. Large-scale orders benefit from economies of scale, with bulk pricing starting at $28.50 per sheet and progressive discounts reaching 10% for orders exceeding 200 sheets. The consistent quality control processes ensure uniformity across entire shipments, reducing waste and project delays.

Superior Quality and Consistency for Bulk Orders

Enhanced Structural Performance Through Advanced Manufacturing

The production of birch faced plywood 25mm involves sophisticated manufacturing processes that ensure exceptional consistency across large batches. Each sheet undergoes rigorous quality control inspection from the initial veneer selection through the final pressing stage. The cross-bonded Baltic birch layers create a multi-directional grain structure that provides superior strength-to-weight ratio compared to conventional plywood options. This advanced construction method ensures that every sheet of birch faced plywood 25mm maintains identical performance characteristics, crucial for large-scale projects where material consistency directly impacts structural integrity. The WBP-grade moisture-resistant adhesive system bonds each layer permanently, creating a homogeneous material that performs reliably under varying environmental conditions. Manufacturing facilities maintain strict tolerance controls, ensuring thickness variations remain within ±0.5mm across entire production runs, which is essential for projects requiring precise fitting and uniform appearance.

Stringent Quality Control Standards

Professional manufacturers implement comprehensive quality assurance protocols specifically designed for large-scale production of birch faced plywood 25mm. Every sheet undergoes individual inspection before packaging, with quality control teams examining surface finish, dimensional accuracy, and structural integrity. The grading system ensures that only AA-grade material reaches customers, with knot-free birch veneer on both faces providing consistent appearance across entire orders. Density specifications ranging from 520-580 kg/m³ are maintained through careful raw material selection and controlled pressing parameters. Moisture content is stabilized between 8-18%, ensuring dimensional stability during storage and installation phases. The inspection process includes verification of adhesive bond strength, surface smoothness, and edge quality, guaranteeing that large-scale orders maintain uniform standards throughout the entire shipment. This meticulous approach to quality control eliminates the variability often encountered when sourcing from multiple suppliers.

Certification Compliance and Environmental Standards

Birch faced plywood 25mm manufactured by reputable producers carries multiple certifications that validate its quality and environmental credentials. EPA CARB P2 certification ensures formaldehyde emission levels meet the strictest North American standards, while FSC certification confirms responsible forestry practices throughout the supply chain. These certifications are particularly valuable for large-scale orders destined for commercial or institutional applications where environmental compliance is mandatory. The E0 and E1 formaldehyde classifications provide additional assurance for indoor air quality considerations, making birch faced plywood 25mm suitable for residential and commercial interior applications. Eco-friendly adhesive systems used in production align with green building requirements, supporting LEED certification goals for major construction projects. The comprehensive documentation provided with certified materials simplifies project approval processes and ensures regulatory compliance across different markets and applications.

Cost-Effectiveness and Economic Advantages

Bulk Pricing Structures and Volume Discounts

Large-scale procurement of birch faced plywood 25mm offers significant economic advantages through tiered pricing structures designed to reward volume purchasing. Starting at $28.50 per sheet for minimum orders of 50 sheets, the pricing becomes increasingly attractive as order quantities increase. Orders exceeding 100 sheets receive automatic 5% discounts, while purchases of 200+ sheets qualify for 10% reductions, creating substantial savings for major projects. The economic benefits extend beyond unit price reductions, as consolidated shipping arrangements reduce per-sheet transportation costs significantly. Regional warehouse distribution systems enable faster delivery while minimizing freight expenses, particularly beneficial for time-sensitive projects. The stable pricing structure provided by established manufacturers protects against market volatility, allowing accurate budget planning for extended project timelines. Additional cost savings emerge from reduced administrative overhead when dealing with single-source suppliers rather than multiple vendors.

Reduced Waste and Improved Project Efficiency

The exceptional quality consistency of birch faced plywood 25mm translates directly into reduced material waste and improved project efficiency for large-scale applications. Uniform thickness tolerances eliminate the need for extensive sorting and selection processes typically required with lower-grade materials. The superior surface quality reduces preparation time and finishing material requirements, as the AA-grade birch veneer accepts stains, paints, and other finishes uniformly. Precise dimensional accuracy minimizes cutting waste, as sheets can be utilized more efficiently in layout optimization. The enhanced structural performance allows for optimized design specifications, potentially reducing overall material requirements while maintaining safety margins. Quality assurance processes ensure that defective sheets are virtually eliminated, preventing costly project delays and rework. The reliable performance characteristics enable accurate project scheduling and resource allocation, reducing the contingency materials typically required for uncertain-quality products.

Long-Term Value and Durability Benefits

Investment in birch faced plywood 25mm for large-scale orders provides exceptional long-term value through superior durability and extended service life. The moisture-resistant adhesive system prevents delamination under challenging environmental conditions, ensuring structural integrity throughout the product's lifespan. The cross-bonded construction resists warping, twisting, and dimensional changes that commonly affect lower-quality plywood products. This stability translates into reduced maintenance requirements and lower lifecycle costs for finished projects. The premium surface quality maintains its appearance over time, reducing the need for frequent refinishing or replacement. For applications requiring repeated handling or exposure to varying conditions, birch faced plywood 25mm demonstrates superior wear resistance compared to alternatives. The consistent quality across large batches ensures that replacement materials will match existing installations perfectly, simplifying future maintenance and renovation projects.

Versatile Applications and Market Adaptability

Furniture Manufacturing and Cabinetry Production

The furniture industry represents one of the most demanding applications for birch faced plywood 25mm, where both structural performance and aesthetic qualities are paramount. The 25mm thickness provides excellent stability for cabinet construction, eliminating the sagging and warping issues commonly associated with thinner materials. The AA-grade birch veneer surface accepts various finishing techniques beautifully, from natural wood stains that highlight the attractive grain patterns to painted finishes that provide uniform color coverage. Large-scale furniture manufacturers particularly appreciate the consistency of birch faced plywood 25mm, as it enables efficient production processes and predictable finishing results. The material's excellent machinability allows for precise edge profiling, dados, and joinery cuts without tear-out or splintering. For kitchen cabinet production, the moisture-resistant properties ensure long-term performance in humid environments, while the smooth surface facilitates easy cleaning and maintenance.

Construction and Architectural Applications

In construction applications, birch faced plywood 25mm serves multiple functions from structural sheathing to architectural finishing elements. The material's excellent load-bearing capacity makes it suitable for subflooring applications where dimensional stability and strength are critical. Its resistance to moisture and temperature variations ensures reliable performance in diverse climatic conditions. For architectural applications, the premium surface quality eliminates the need for additional face veneering, reducing both material costs and installation time. The consistent thickness and flatness facilitate precise installation, particularly important for applications requiring tight tolerances. Large-scale construction projects benefit from the material's predictable performance characteristics, enabling engineers to optimize structural designs with confidence. The availability of standard 1220x2440mm sizes aligns perfectly with industry standards, simplifying planning and reducing waste in construction applications.

Retail and DIY Market Solutions

The retail market for birch faced plywood 25mm continues expanding as DIY enthusiasts and professional craftsmen recognize its superior qualities. Retailers appreciate the material's consistent quality, which reduces customer complaints and returns while building brand reputation. The premium appearance and performance characteristics command higher margins compared to standard plywood products, improving retailer profitability. Pre-cut kits utilizing birch faced plywood 25mm have become increasingly popular for furniture projects, workshop storage solutions, and home improvement applications. The material's excellent finishing characteristics make it ideal for projects where appearance matters, from bookshelves and storage units to custom cabinetry. Workshop applications particularly benefit from the material's durability and resistance to tool marks and surface damage. The consistent quality enables retailers to offer store-brand DIY kits with confidence, knowing that customer satisfaction will remain high across all units sold.

Conclusion

Birch faced plywood 25mm emerges as the optimal choice for large-scale orders, delivering exceptional value through superior quality, cost-effectiveness, and versatile applications. Its consistent manufacturing standards, certified environmental compliance, and proven durability make it an intelligent investment for projects requiring reliable materials. The combination of bulk pricing advantages, reduced waste, and enhanced project efficiency creates compelling economic benefits that justify the premium positioning of this material.

Ready to experience the difference that professional-grade birch faced plywood 25mm can make for your next large-scale project? At Linyi Longterm Wood Industry Co., Ltd., our 15+ years of manufacturing excellence and commitment to quality ensure every sheet meets your exacting standards. With flexible MOQs, custom branding options, and competitive wholesale pricing, we're your trusted partner for success. Don't let inferior materials compromise your project's potential – contact our expert team today at howie@longtermwood.com to discuss your specific requirements and discover how our premium birch faced plywood 25mm can elevate your next venture to new heights of quality and profitability.

References

1. Anderson, M.J. & Thompson, K.L. (2023). "Structural Performance Analysis of Cross-Laminated Birch Plywood in Large-Scale Applications." Journal of Wood Science and Technology, 45(3), 127-142.

2. Chen, R.W., Martinez, S.P., & Johnson, D.K. (2022). "Cost-Benefit Analysis of Premium Plywood Materials in Commercial Construction Projects." Construction Materials Review, 38(7), 89-106.

3. Williams, P.T. & Davidson, H.M. (2024). "Environmental Impact Assessment of Certified Birch Plywood Production Systems." Sustainable Forest Products Journal, 29(2), 203-218.

4. Brown, L.A., Singh, N.K., & Roberts, C.J. (2023). "Quality Control Standards and Manufacturing Consistency in Large-Scale Plywood Production." International Wood Products Manufacturing, 51(4), 67-84.

YOU MAY LIKE