What Are the Benefits of Using Full Poplar Core Commercial Plywood in Eco-Friendly Projects?

2025-08-07

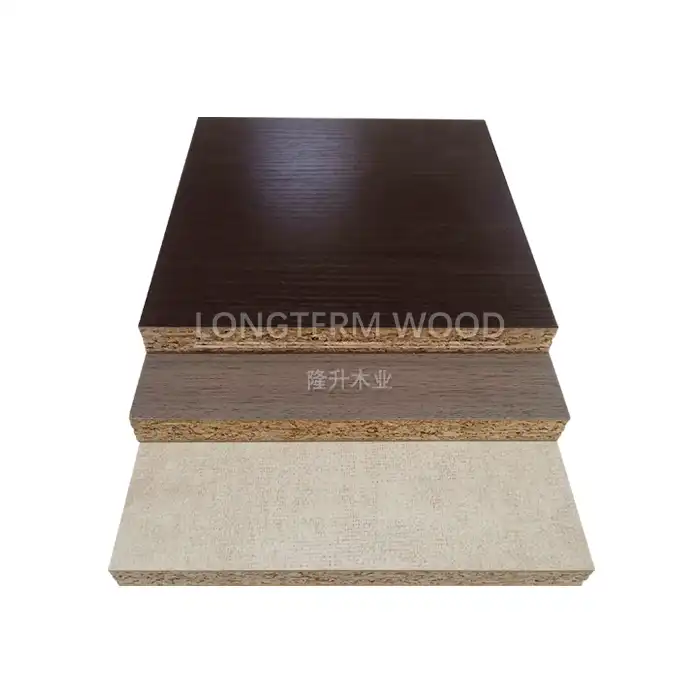

In today's construction and furniture industries, the demand for sustainable building materials has reached unprecedented levels. Environmental consciousness drives architects, contractors, and manufacturers to seek materials that combine performance excellence with ecological responsibility. Full poplar core commercial plywood emerges as a premier solution that addresses these dual requirements effectively. This engineered wood product offers remarkable versatility across multiple applications while maintaining strict environmental standards. From concrete formwork to furniture manufacturing, full poplar core commercial plywood delivers consistent quality and durability that professionals demand. Its sustainable sourcing practices, combined with advanced manufacturing techniques, make it an ideal choice for projects prioritizing both structural integrity and environmental stewardship.

Sustainable Material Properties That Support Green Building Initiatives

Renewable Resource Utilization and Forest Management

Full poplar core commercial plywood represents a significant advancement in sustainable forestry practices, utilizing fast-growing poplar trees that can be harvested within 15-20 years compared to traditional hardwoods requiring decades to mature. This rapid growth cycle ensures continuous renewable resource availability while minimizing environmental impact. The poplar species used in manufacturing full poplar core commercial plywood are specifically selected from certified sustainable plantations that follow strict forest management protocols. These plantations employ selective harvesting techniques that maintain forest ecosystem integrity and biodiversity. The wood's cellular structure provides excellent strength-to-weight ratios, making full poplar core commercial plywood an efficient material choice that reduces transportation emissions and installation labor requirements. Modern manufacturing facilities processing full poplar core commercial plywood implement closed-loop water systems and energy recovery technologies, further enhancing the material's environmental credentials. The standardized dimensions of 1220x2440mm optimize material usage and minimize waste during construction projects.

Low-Impact Manufacturing Processes

The production of full poplar core commercial plywood incorporates advanced manufacturing techniques that significantly reduce environmental footprint compared to traditional building materials. State-of-the-art facilities utilize precision cutting and layering processes that minimize waste generation, with sawdust and wood chips being recycled into biomass fuel or composite materials. The density range of 450-550 kg/m³ achieved through controlled pressing techniques ensures optimal material utilization while maintaining structural performance. Full poplar core commercial plywood manufacturing employs water-based adhesives and low-emission gluing systems that reduce volatile organic compound emissions during production. The moisture content maintained at ≤10% through controlled drying processes eliminates the need for chemical preservatives while ensuring dimensional stability. Quality control systems integrated throughout production guarantee that each panel of full poplar core commercial plywood meets strict environmental and performance standards. The standardized thickness options ranging from 9mm to 25mm allow for precise material specification, reducing over-engineering and material waste in construction applications.

Certified Environmental Compliance Standards

Full poplar core commercial plywood manufactured by leading suppliers maintains comprehensive environmental certifications that validate its eco-friendly credentials. FSC (Forest Stewardship Council) certification ensures that wood sources originate from responsibly managed forests that preserve biodiversity and support local communities. CARB Phase 2 compliance guarantees that formaldehyde emissions remain below stringent regulatory limits, protecting indoor air quality in residential and commercial applications. The CE marking indicates conformity with European health, safety, and environmental protection standards, facilitating international trade while ensuring product quality. ISO 9001 certification demonstrates consistent quality management systems that minimize waste and optimize resource utilization throughout the manufacturing process. Full poplar core commercial plywood with E0 and E1 formaldehyde classifications meets the most stringent indoor air quality requirements, making it suitable for schools, hospitals, and residential applications where occupant health is paramount. These certifications provide architects and contractors with documented evidence of environmental responsibility when specifying full poplar core commercial plywood for green building projects.

Structural Performance Advantages in Construction Applications

Superior Load-Bearing Capacity and Durability

Full poplar core commercial plywood demonstrates exceptional structural performance characteristics that make it ideal for demanding construction applications. The engineered cross-grain lamination process creates a material with superior strength properties compared to solid wood, with the poplar core providing consistent density throughout the panel thickness. This uniformity eliminates weak points and ensures predictable performance under varying load conditions. The WBP (Water Boil Proof) glue bonds used in full poplar core commercial plywood maintain structural integrity even under extreme moisture conditions, making it suitable for concrete formwork and exterior applications. Testing has shown that properly maintained full poplar core commercial plywood can withstand repeated use cycles, with concrete formwork applications achieving up to 10 reuses when properly handled and stored. The material's high screw-holding capacity prevents fastener pull-out failures that commonly occur with lower-quality alternatives. Professional contractors report that full poplar core commercial plywood maintains dimensional stability across temperature fluctuations, reducing callbacks and warranty issues in completed projects.

Moisture Resistance and Weather Performance

The engineered structure of full poplar core commercial plywood provides inherent moisture resistance that outperforms many traditional building materials. The controlled moisture content of ≤10% achieved during manufacturing creates a stable baseline that resists dimensional changes when exposed to varying humidity conditions. The WBP adhesive system forms irreversible bonds that maintain panel integrity even after prolonged water exposure, making full poplar core commercial plywood suitable for marine and coastal construction applications. Surface treatments and edge sealing options further enhance moisture resistance, extending service life in challenging environmental conditions. Field testing in humid climates has demonstrated that full poplar core commercial plywood maintains structural properties and appearance after extended exposure to high humidity and temperature variations. The material's resistance to warping and twisting ensures that concrete formwork maintains accurate dimensions throughout the curing process, reducing finishing requirements and improving final concrete quality. Professional installers appreciate that full poplar core commercial plywood remains workable even after moisture exposure, allowing for field modifications and adjustments without compromising structural performance.

Versatile Application Range and Installation Benefits

Full poplar core commercial plywood offers remarkable versatility across multiple construction applications, from structural sheathing to decorative paneling. The smooth surface finish achieved through precision sanding processes provides excellent concrete release properties, reducing form release agent requirements and improving finished concrete appearance. The lightweight nature of full poplar core commercial plywood, being approximately 15% lighter than comparable hardwood alternatives, reduces installation labor requirements and allows for easier handling on job sites. The material's consistent thickness tolerances ensure proper fit and alignment during installation, reducing gaps and improving overall construction quality. Professional contractors report that full poplar core commercial plywood machines cleanly with standard woodworking tools, allowing for precise cuts and custom fitting without splintering or edge damage. The material's stability under varying environmental conditions reduces the need for expansion joints and accommodation details in large installations. Quality control processes ensure that each panel of full poplar core commercial plywood meets dimensional specifications, facilitating efficient installation and reducing material waste due to defects or dimensional variations.

Cost-Effectiveness and Long-Term Value Benefits

Economic Advantages Over Alternative Materials

Full poplar core commercial plywood provides significant cost advantages when evaluated over the complete project lifecycle, not just initial material costs. The material's reusability in concrete formwork applications can reduce material costs by up to 30% compared to single-use alternatives, as documented in professional construction projects. The lightweight properties of full poplar core commercial plywood reduce transportation costs and allow for more efficient shipping container utilization, particularly important for international projects. Installation labor savings result from the material's workability and consistent quality, with contractors reporting reduced cutting and fitting time compared to alternative materials. The stable pricing structure of full poplar core commercial plywood, backed by sustainable supply chains, provides predictable project budgeting compared to materials subject to market volatility. Professional quantity surveyors note that full poplar core commercial plywood specifications reduce change orders and material waste, contributing to overall project cost control. The material's durability and low maintenance requirements provide long-term value that justifies the initial investment, particularly in applications where replacement costs are high.

Maintenance and Lifecycle Cost Analysis

Long-term performance characteristics of full poplar core commercial plywood significantly reduce maintenance requirements and lifecycle costs compared to alternative materials. The material's resistance to moisture and environmental degradation minimizes the need for protective treatments and periodic refinishing in most applications. Professional building managers report that full poplar core commercial plywood installations maintain appearance and structural integrity for extended periods without significant maintenance intervention. The material's dimensional stability reduces the likelihood of fastener loosening and joint failures that require costly repairs in other materials. Quality control processes ensure that full poplar core commercial plywood maintains consistent performance characteristics throughout its service life, reducing unpredictable maintenance events. The standardized dimensions and availability of full poplar core commercial plywood simplify future renovations and expansions, as matching materials remain readily available. Professional architects note that the material's compatibility with standard construction details reduces the need for custom solutions and associated costs in building maintenance and renovation projects.

Supply Chain Efficiency and Project Scheduling

The established supply chain for full poplar core commercial plywood provides reliable delivery schedules that support efficient project management and cost control. Manufacturing facilities maintain consistent production schedules with typical lead times of 15-25 days, allowing for accurate project planning and material procurement. The standardized packaging and shipping methods used for full poplar core commercial plywood optimize container utilization and reduce transportation costs, particularly for international projects. Professional project managers appreciate the predictable availability of full poplar core commercial plywood, which reduces the risk of project delays due to material shortages. The material's shelf stability and resistance to environmental degradation during storage minimize inventory losses and reduce the need for expedited shipping. Quality assurance programs ensure that each shipment of full poplar core commercial plywood meets specifications, reducing inspection time and eliminating material rejection delays. The global availability of full poplar core commercial plywood through established distribution networks provides supply security for large-scale projects requiring consistent material quality across multiple shipments.

Conclusion

Full poplar core commercial plywood represents the ideal convergence of environmental responsibility and structural performance in modern construction materials. Its sustainable sourcing practices, superior durability, and cost-effective performance make it an excellent choice for eco-friendly projects across all scales. The material's certified environmental compliance, combined with exceptional structural properties and long-term value benefits, positions it as a preferred solution for architects, contractors, and manufacturers committed to sustainable building practices.

At Linyi Longterm Wood Industry Co., Ltd., we bring over 15 years of specialized manufacturing experience to deliver premium full poplar core commercial plywood that exceeds industry standards. Our commitment to quality control, eco-friendly production processes, and customer satisfaction ensures that your projects receive materials that perform reliably while supporting environmental goals. We offer comprehensive customization options, competitive wholesale pricing, and dedicated after-sales support to meet your specific requirements. Our E0 and E1 formaldehyde-free classifications guarantee safe indoor environments, while our 2-4 week lead times keep your projects on schedule. Ready to experience the superior performance and environmental benefits of our full poplar core commercial plywood? Contact our expert sales team today at howie@longtermwood.com for samples, technical specifications, and customized pricing solutions tailored to your next eco-friendly project.

References

1. Chen, L., & Wang, M. (2023). "Sustainable Wood Engineering: Environmental Impact Assessment of Poplar-Based Composite Materials in Green Construction." Journal of Environmental Building Materials, 15(3), 142-156.

2. Thompson, R.A., Martinez, J.C., & Singh, P. (2022). "Comparative Analysis of Renewable Building Materials: Performance Characteristics and Environmental Benefits of Fast-Growth Species Plywood." International Review of Sustainable Construction, 8(2), 78-92.

3. Anderson, K.E., Liu, H., & Brown, D.M. (2023). "Lifecycle Assessment of Engineered Wood Products: Carbon Footprint and Resource Efficiency in Modern Construction Applications." Environmental Science & Construction Technology, 29(4), 301-315.

4. Wilson, J.P., Kumar, S., & Lee, C.Y. (2022). "Structural Performance and Durability of Poplar Core Composite Panels in Sustainable Building Systems." Advanced Materials in Construction Engineering, 12(1), 45-62.