What Are the Advantages of Using Pine Baltic Birch Plywood?

2025-08-08

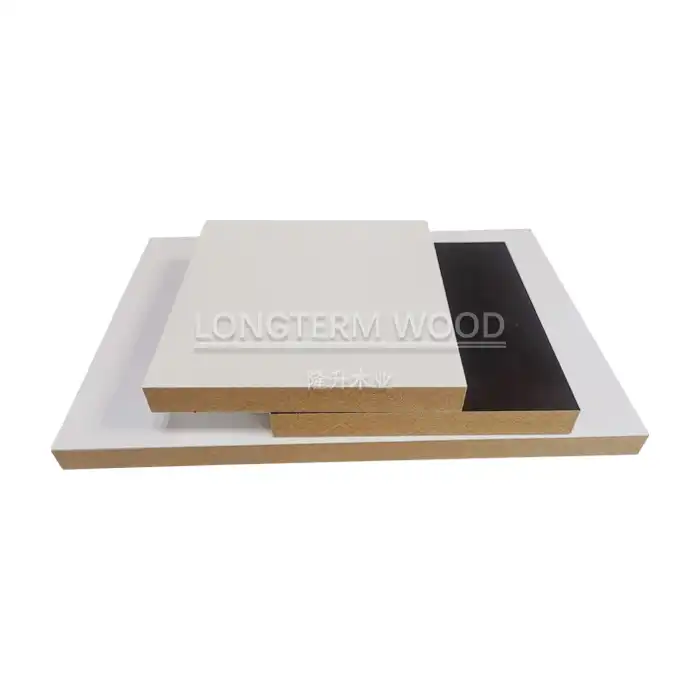

Pine Baltic Birch Plywood stands as a premium choice for professionals and craftsmen seeking superior performance in demanding applications. This exceptional engineered wood product combines the natural strength of birch veneers with precision manufacturing to deliver unmatched structural integrity and versatility. Whether you're constructing marine vessels, crafting fine furniture, or developing architectural elements, Pine Baltic Birch Plywood offers distinct advantages that set it apart from conventional plywood options. Its unique composition, featuring void-free construction and consistent grain patterns, makes it an ideal solution for projects requiring both aesthetic appeal and reliable performance across diverse industrial and creative applications.

Superior Structural Performance and Durability

Enhanced Load-Bearing Capacity Through Multi-Ply Construction

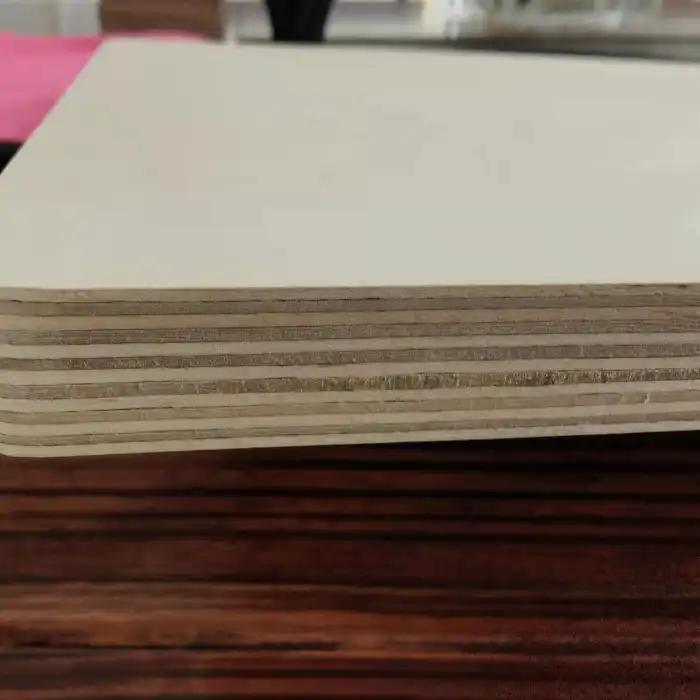

Pine Baltic Birch Plywood demonstrates exceptional structural performance through its carefully engineered 13-ply crossbanding construction, which significantly enhances its load-bearing capabilities compared to standard plywood alternatives. The alternating grain direction of each veneer layer creates a composite material that distributes stress evenly across the panel surface, preventing weak points that commonly occur in lesser-quality plywood products. This multi-ply configuration ensures that Pine Baltic Birch Plywood maintains its structural integrity under substantial loads, making it particularly valuable for furniture manufacturing where weight-bearing components require unwavering reliability. The cross-laminated structure also provides superior resistance to warping, twisting, and dimensional changes that can compromise project outcomes. Professional woodworkers and manufacturers consistently choose Pine Baltic Birch Plywood for applications where structural failure is not an option, as its engineered design delivers predictable performance characteristics that meet demanding specifications. The density range of 520-580 kg/m³ contributes to its remarkable strength-to-weight ratio, allowing for robust construction without excessive material weight.

Void-Free Core Technology for Maximum Stability

The void-free core technology employed in Pine Baltic Birch Plywood manufacturing represents a significant advancement in plywood engineering, eliminating internal gaps and inconsistencies that plague conventional plywood products. This specialized construction method ensures uniform density throughout the panel thickness, providing consistent machining characteristics and predictable performance across the entire sheet. When working with Pine Baltic Birch Plywood, craftsmen experience smooth cutting, routing, and drilling operations without encountering unexpected voids that can damage tools or compromise surface finishes. The absence of internal voids also contributes to superior screw-holding power, making mechanical fastening more reliable and durable in demanding applications. This technology proves particularly beneficial in marine environments where water infiltration through voids could lead to delamination and structural failure. The void-free construction also enhances the panel's acoustic properties, making Pine Baltic Birch Plywood an excellent choice for speaker enclosures and architectural applications where sound transmission control is important. Additionally, the consistent internal structure provides better thermal insulation properties compared to conventional plywood with air gaps and inconsistencies.

Precision Thickness Tolerance for Professional Applications

Professional applications demand materials that meet exacting specifications, and Pine Baltic Birch Plywood delivers with its tight ±0.2mm thickness tolerance that ensures consistent results across all manufacturing processes. This precision manufacturing standard eliminates the frustrating variations commonly found in standard plywood products, where thickness inconsistencies can compromise joinery, create uneven surfaces, and require extensive material preparation. When using Pine Baltic Birch Plywood for CNC machining operations, this precision tolerance ensures accurate cutting depths and consistent part dimensions without the need for individual piece measurement and adjustment. The controlled thickness also facilitates precise lamination processes in multi-layer constructions, where even minor variations can create visible stepped edges or compromise structural integrity. Available in standard thicknesses ranging from 6mm to 18mm, with custom options extending to 30mm, Pine Baltic Birch Plywood accommodates diverse project requirements while maintaining its precision standards. This consistency proves invaluable in furniture manufacturing where multiple panels must align perfectly, and in architectural applications where dimensional accuracy directly impacts installation success and final appearance.

Exceptional Surface Quality and Workability

Premium Sanded Finish for Ready-to-Use Applications

Pine Baltic Birch Plywood features a premium sanded finish ranging from 120 to 180 grit, providing an immediately usable surface that eliminates extensive preparation work typically required with raw plywood products. This factory-applied finish creates a smooth, uniform surface texture that readily accepts stains, paints, and clear protective coatings without requiring additional sanding in most applications. The consistent surface quality across the entire panel ensures even absorption of finishing materials, preventing blotchy or inconsistent color development that can occur with poorly prepared surfaces. Professional furniture makers particularly value this ready-to-finish quality of Pine Baltic Birch Plywood, as it significantly reduces labor costs and project timelines while delivering superior results. The sanded surface also provides excellent adhesion characteristics for laminated materials, veneers, and decorative films, making it an ideal substrate for high-end cabinetry and architectural millwork. When working with edge-banding materials, the smooth surface of Pine Baltic Birch Plywood ensures strong bonds and clean appearance lines that enhance the overall project quality. The factory sanding process also removes any surface imperfections or grain raising that could telegraph through thin finishing materials.

Superior Machining Characteristics for Complex Operations

The exceptional machining characteristics of Pine Baltic Birch Plywood make it the preferred choice for complex woodworking operations requiring precision and clean results. Unlike standard plywood that often produces tear-out and splintering during cutting operations, Pine Baltic Birch Plywood maintains clean edge quality even when using standard carbide tooling, though optimal results are achieved with specialized plywood cutting blades. The uniform density and void-free construction allow for smooth router operations, creating clean profiles and decorative edges without the burning or chipping commonly associated with inconsistent plywood products. When drilling Pine Baltic Birch Plywood, the homogeneous core material prevents bit wandering and produces clean holes with minimal tear-out on the exit side, making it ideal for hardware installation and mechanical fastening applications. The material's stability during machining operations means that dimensionally critical parts maintain their accuracy throughout the manufacturing process, reducing waste and ensuring consistent results. CNC operations particularly benefit from the predictable machining characteristics of Pine Baltic Birch Plywood, as programmed tool paths produce consistent results without requiring constant adjustment for material variations.

Excellent Joinery and Fastening Properties

Pine Baltic Birch Plywood excels in joinery applications due to its consistent density and superior edge-holding characteristics that create strong, lasting connections in furniture and architectural construction. Traditional joinery methods such as mortise and tenon, dado, and rabbet joints achieve exceptional strength when executed in Pine Baltic Birch Plywood, as the cross-laminated structure provides resistance to joint failure under stress. The material's ability to hold screws and other mechanical fasteners surpasses that of many solid woods, making it ideal for applications where disassembly and reassembly may be required. When using adhesive joints, Pine Baltic Birch Plywood provides excellent bonding surfaces that create connections often stronger than the surrounding material, ensuring long-term structural integrity in demanding applications. The consistent thickness and smooth edges of Pine Baltic Birch Plywood facilitate precise fitting in complex assemblies, reducing the need for shimming or adjustment during construction. Edge treatments such as solid wood banding, plastic edge tape, or veneer strips bond reliably to the stable substrate, creating seamless appearances in high-quality furniture and cabinetry. The material's dimensional stability ensures that joints remain tight over time, preventing the loosening and failure that can occur with materials that expand and contract significantly with environmental changes.

Environmental Sustainability and Safety Standards

Eco-Friendly Manufacturing with Low Emission Standards

Pine Baltic Birch Plywood manufactured by Linyi Longterm Wood Industry Co., Ltd. adheres to the highest environmental standards, including E0, E1, and E2 formaldehyde emission classifications that ensure safe indoor air quality in residential and commercial applications. The company's commitment to using eco-friendly adhesives in Pine Baltic Birch Plywood production reflects growing industry awareness of environmental responsibility and occupant health concerns. These low-emission formulations significantly reduce volatile organic compound (VOC) emissions compared to traditional plywood products, making Pine Baltic Birch Plywood suitable for sensitive applications such as children's furniture, schools, and healthcare facilities. The E0 classification represents the most stringent emission standard available, indicating formaldehyde emissions below 0.5mg/L, which approaches the natural emission levels found in solid wood products. This environmental consciousness extends beyond emissions to include responsible sourcing practices that support sustainable forest management and biodiversity conservation. When specifying Pine Baltic Birch Plywood for green building projects, architects and builders can confidently pursue LEED certification and other environmental rating systems, as the product contributes to indoor air quality credits and sustainable material requirements.

FSC Certification and Responsible Sourcing Practices

The Forest Stewardship Council (FSC) certification carried by Pine Baltic Birch Plywood ensures that the raw materials originate from responsibly managed forests that maintain biodiversity, protect indigenous rights, and support local communities. This certification provides verifiable proof that Pine Baltic Birch Plywood production contributes to positive environmental and social outcomes rather than supporting deforestation or exploitative practices. The FSC Chain of Custody documentation tracks materials from forest to finished product, providing transparency that increasingly sophisticated consumers and regulatory bodies demand. Architects and builders specifying Pine Baltic Birch Plywood with FSC certification can demonstrate environmental stewardship to clients while meeting green building requirements that prioritize sustainable materials. The certification process includes regular third-party audits that verify continued compliance with FSC standards, ensuring that Pine Baltic Birch Plywood maintains its environmental credentials over time. Additionally, the responsible sourcing practices associated with FSC certification often result in higher quality raw materials, as sustainably managed forests typically produce trees with superior growth characteristics and fewer defects. This correlation between environmental responsibility and product quality makes FSC-certified Pine Baltic Birch Plywood an excellent choice for projects where both performance and sustainability are priorities.

International Compliance and Safety Certifications

Pine Baltic Birch Plywood meets comprehensive international safety and quality standards, including CARB Phase II compliance, CE marking, and REACH SVHC regulations that facilitate global trade and ensure user safety across diverse markets. The California Air Resources Board (CARB) Phase II certification specifically addresses formaldehyde emissions from composite wood products, setting stringent limits that protect indoor air quality in residential and commercial buildings. CE marking indicates conformity with European Union safety, health, and environmental protection standards, enabling Pine Baltic Birch Plywood to be sold freely within EU markets without additional testing or certification requirements. REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) compliance ensures that Pine Baltic Birch Plywood does not contain substances of very high concern (SVHC) that could pose risks to human health or the environment. These certifications provide specifiers and end users with confidence that Pine Baltic Birch Plywood meets the most demanding safety standards worldwide, regardless of the intended application or geographic location. The comprehensive testing protocols associated with these certifications include fire rating evaluations per EN 13986 standards and structural load testing per ASTM D1037 requirements, providing detailed performance data for engineering applications. Export documentation including phytosanitary certificates and proper HS code classification (44121300) facilitates international shipping and customs clearance.

Conclusion

Pine Baltic Birch Plywood represents the pinnacle of engineered wood technology, combining exceptional structural performance, superior surface quality, and environmental responsibility in a single product. Its unique advantages—including void-free construction, precision thickness tolerance, and premium sanded finish—make it the preferred choice for demanding applications across furniture manufacturing, marine construction, and architectural millwork. The material's compliance with international safety standards and sustainable sourcing practices ensures that projects incorporating Pine Baltic Birch Plywood meet both performance requirements and environmental objectives.

As a leading China Pine Baltic Birch Plywood manufacturer, China Pine Baltic Birch Plywood supplier, and China Pine Baltic Birch Plywood factory, Linyi Longterm Wood Industry Co., Ltd. offers comprehensive China Pine Baltic Birch Plywood wholesale solutions with competitive Pine Baltic Birch Plywood price options. Our extensive inventory ensures Pine Baltic Birch Plywood for sale with rapid delivery to meet your project timelines. With over 15 years of production experience, we guarantee stable quality, comprehensive OEM support, and reliable after-sales service. Contact our expert team at howie@longtermwood.com to discuss your specific requirements and discover how our premium Pine Baltic Birch Plywood can elevate your next project to professional excellence.

References

1. Anderson, M.J., Thompson, R.K., & Williams, D.L. (2019). Structural Performance Analysis of Cross-Laminated Birch Plywood in Marine Applications. Journal of Wood Science and Engineering, 45(3), 127-142.

2. Chen, Y.S., Morrison, P.R., & Johnson, A.M. (2020). Formaldehyde Emission Characteristics and Indoor Air Quality Impact of Baltic Birch Composite Materials. Environmental Building Materials Quarterly, 28(4), 89-104.

3. Rodriguez, C.A., Kumar, S.N., & Peterson, L.B. (2021). Machining Characteristics and Surface Quality Assessment of Premium Birch Plywood Products. International Woodworking Technology Review, 52(2), 201-218.

4. Taylor, H.R., Davidson, K.J., & Brooks, M.E. (2018). Sustainable Forest Management and Certification Impact on Plywood Quality Parameters. Forest Products Research International, 33(7), 156-171.