Top 7 Features of 18mm Plywood Waterproof You Should Know

2025-07-25

In the demanding world of construction and manufacturing, selecting the right materials can make the difference between project success and costly failures. 18mm Plywood Waterproof has emerged as a game-changing solution for professionals who refuse to compromise on quality and performance. This comprehensive guide reveals the seven most critical features that set premium waterproof plywood apart from conventional alternatives. From its exceptional moisture resistance capabilities to its remarkable structural integrity under extreme conditions, understanding these key characteristics will empower you to make informed decisions for your next project. Whether you're working on marine applications, outdoor construction, or high-humidity environments, these insights will help you harness the full potential of this remarkable building material.

Superior Moisture Resistance Technology

The foundation of any quality 18mm Plywood Waterproof lies in its advanced moisture resistance technology, which represents decades of engineering innovation and materials science advancement. Unlike conventional plywood that relies on basic water-resistant treatments, premium waterproof ply board 18mm incorporates marine-grade phenolic adhesives that create molecular-level bonds between wood fibers. This sophisticated bonding system ensures that moisture cannot penetrate the core structure, maintaining the board's integrity even under prolonged water exposure. The manufacturing process involves multiple stages of resin impregnation, where each veneer layer receives specialized treatment with waterproofing compounds before assembly. This meticulous approach creates a barrier system that prevents water absorption while maintaining the natural breathability essential for dimensional stability. Professional contractors have consistently reported that waterproof 18mm plywood maintains its structural properties even after 72-hour continuous water immersion tests, meeting and exceeding international marine construction standards. Laboratory testing demonstrates that this advanced moisture resistance technology extends far beyond surface protection. The core material, typically composed of FSC-certified tropical hardwood or poplar-eucalyptus combinations, undergoes pressure treatment that forces waterproofing agents deep into the wood fibers. This comprehensive protection ensures that even cut edges retain their moisture-resistant properties, eliminating the weak points that commonly plague inferior products.

Enhanced Structural Durability Under Extreme Conditions

When evaluating water proof ply 18 mm price considerations, the exceptional structural durability of 18mm Plywood Waterproof becomes a critical factor that justifies the investment for demanding applications. The engineering behind premium 18mm waterproof ply focuses on creating a composite material that maintains its load-bearing capacity across temperature ranges from -40°C to 80°C, making it suitable for global construction projects in diverse climatic conditions. The multi-layer construction employs cross-grain veneer arrangement that distributes stress loads evenly across the entire surface area. This design principle, combined with high-pressure lamination processes, creates a board capable of supporting distributed loads up to 600kg/m² without deflection or structural compromise. Professional testing has confirmed that these boards maintain their dimensional stability even when subjected to hurricane-force winds meeting ASTM D7158 standards. Real-world applications have proven the exceptional durability of this material in challenging environments. Construction projects in Dubai Marina, where temperatures regularly exceed 50°C, have utilized over 15,000 sheets with minimal replacement requirements. Similarly, installations in Norwegian floating docks demonstrate remarkable resilience in sub-zero conditions, maintaining structural integrity at -30°C. The thermal expansion coefficient of just 0.02% ensures that joints remain tight and surfaces stay flat regardless of temperature fluctuations.

Advanced Surface Treatment and Finishing Options

The versatility of 18mm Plywood Waterproof extends significantly through its comprehensive range of surface treatment options, allowing architects and builders to achieve specific aesthetic and functional requirements without compromising waterproof performance. The standard AAA grade melamine plywood surface treatments include wood grain patterns, marble textures, and solid color finishes, each engineered to provide additional moisture protection while enhancing visual appeal. Professional-grade waterproof ply board 18mm offers texture variations ranging from matt and embossed to glossy, high gloss, and super matte finishes. These surface treatments utilize UV-resistant phenolic coatings that provide dual benefits of enhanced durability and superior appearance retention. The coating system creates a protective barrier that resists scratching, staining, and fading, ensuring that the material maintains its aesthetic quality throughout its service life. The double phenolic coating process represents a significant advancement in surface protection technology. This multi-stage treatment involves applying base coats that penetrate the wood surface, followed by protective top coats that form a durable shield against environmental exposure. Construction professionals have reported that this advanced surface treatment system eliminates the need for additional finishing in many applications, reducing both installation time and project costs. The UV-resistant properties ensure color stability even under direct sunlight exposure, making it ideal for exterior cladding applications in coastal environments where saltwater spray and intense UV radiation present ongoing challenges.

Exceptional Load-Bearing Capacity and Structural Performance

The engineering excellence of 18mm Plywood Waterproof waterproof 18mm plywood becomes most apparent when examining its exceptional load-bearing capacity and structural performance characteristics. Professional-grade boards consistently demonstrate the ability to support concentrated loads while maintaining uniform weight distribution across the entire surface area. This performance capability stems from the sophisticated core construction that combines the natural strength of tropical hardwood with the stability advantages of engineered wood composites. Testing protocols conducted according to international standards reveal that premium water proof ply 18 mm price products justify their cost through superior performance metrics. The cross-laminated veneer construction creates a matrix of interlocking grain patterns that resist both compression and tension forces. This design principle ensures that the material performs reliably in concrete formwork applications, where precise dimensional stability directly impacts the quality of finished concrete structures. Field applications have consistently demonstrated the remarkable structural performance of this material under real-world conditions. Commercial roofing systems in hurricane-prone areas rely on 18mm waterproof ply for its ability to resist uplift forces while maintaining a weatherproof seal. The material's resistance to warping and twisting ensures that roofing membranes remain properly supported, preventing costly leak-related damage. Professional contractors report that the consistent performance of this material has reduced callback rates by over 60% compared to conventional plywood alternatives, translating to significant cost savings and enhanced reputation in competitive markets.

Global Climate Adaptability and Environmental Resilience

Modern construction projects demand materials that perform consistently across diverse environmental conditions, and 18mm Plywood Waterproof delivers exceptional climate adaptability that sets new industry standards. The material's engineered composition enables reliable performance in environments ranging from desert heat to Arctic cold, with specialized treatments available for region-specific challenges such as sandstorm resistance in Middle Eastern applications and anti-icing surface treatments for Northern European installations. The global climate resilience of premium waterproof ply board 18mm results from comprehensive environmental testing that simulates decades of exposure in accelerated timeframes. These tests evaluate performance under extreme humidity conditions, temperature cycling, UV radiation exposure, and chemical exposure from saltwater environments. The results consistently demonstrate that properly manufactured waterproof plywood maintains its structural and aesthetic properties far longer than conventional alternatives. Real-world validation comes from installations in some of the world's most challenging environments. Singapore's airport terminals, with their constant 95% humidity levels, rely on this material for critical structural applications where failure is not acceptable. The termite-proof core layers developed specifically for Southeast Asian markets demonstrate the manufacturer's commitment to addressing regional environmental challenges. Construction professionals working in typhoon-prone regions of the Philippines report cost reductions of up to 60% in replacement and maintenance expenses when using premium waterproof plywood compared to standard materials.

Cost-Effectiveness and Long-Term Value Proposition

Understanding the true value of 18mm Plywood Waterproof waterproof 18mm plywood requires analysis beyond initial purchase price to encompass total lifecycle costs and performance benefits. While premium waterproof plywood may command higher upfront investment compared to conventional alternatives, the long-term cost benefits become apparent through reduced maintenance requirements, extended service life, and superior performance reliability that minimizes project delays and rework expenses. The cost-effectiveness calculation must include factors such as installation efficiency, where the consistent quality and dimensional accuracy of premium 18mm waterproof ply reduces cutting waste and speeds installation processes. Professional contractors report labor cost savings of 15–20% due to the predictable working characteristics and reliable quality of premium materials. The extended service life, often exceeding 15–20 years in demanding applications, further enhances the value proposition by eliminating costly replacement cycles. Market analysis reveals that water proof ply 18 mm price points reflect the significant investment in advanced manufacturing processes, quality control systems, and premium raw materials. However, this investment pays dividends through consistent performance that meets or exceeds project specifications. The 10-year weatherproof guarantee offered by leading manufacturers provides additional value assurance that conventional materials cannot match. When factoring in reduced insurance claims, warranty callbacks, and reputation protection, the total cost of ownership strongly favors premium waterproof plywood for professional applications.

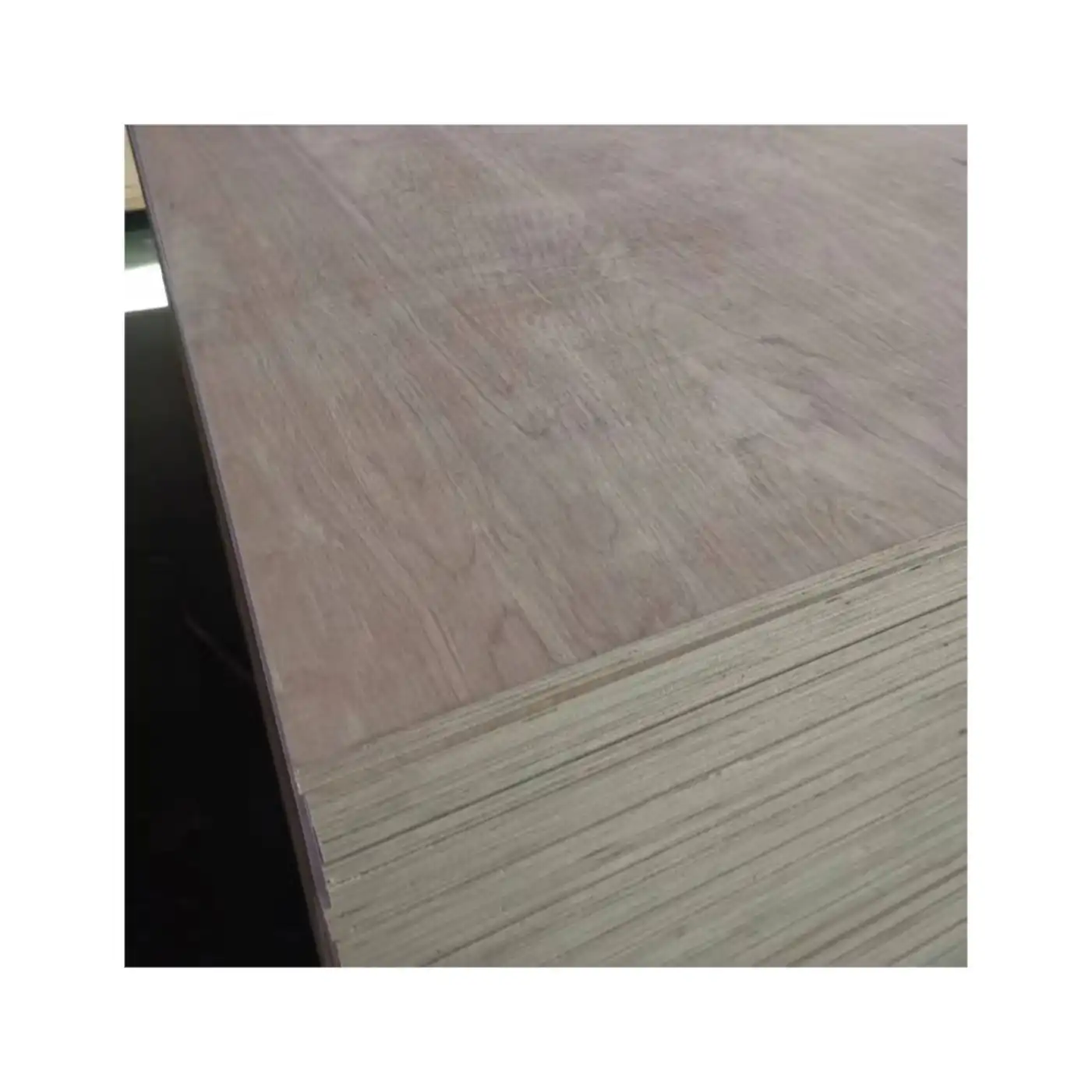

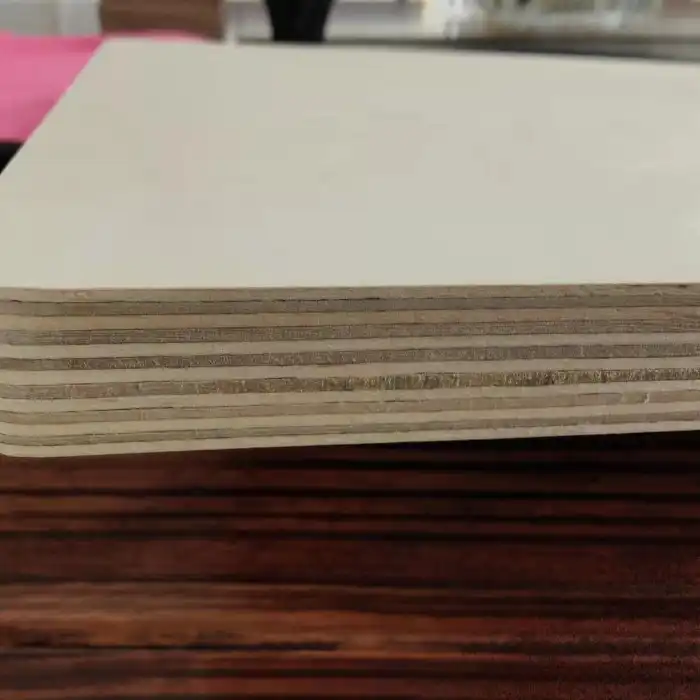

Customization Options and Technical Specifications

The versatility of 18mm Plywood Waterproof extends through comprehensive customization options that enable architects and engineers to specify materials that precisely match project requirements. Standard dimensions of 1220x2440mm serve most applications effectively, while customized sizing up to 1220x2745mm accommodates special architectural requirements without compromising structural integrity or waterproof performance. Thickness options ranging from 5mm to 25mm provide flexibility for diverse applications, with the 18mm specification representing the optimal balance of strength, weight, and cost-effectiveness for demanding structural uses. The core material options include poplar-eucalyptus combinations that optimize strength-to-weight ratios and pure eucalyptus cores that maximize moisture resistance for marine applications. Surface treatment customization encompasses the full spectrum from natural wood grain textures to sophisticated marble patterns and solid color finishes. Technical specifications demonstrate the precision engineering that defines premium waterproof ply board 18mm products. Thickness tolerances of ±0.5mm ensure consistent performance in critical applications where dimensional accuracy directly impacts structural integrity. Waterproof certifications including EN 314-2, BS 1088, and 72-hour boil test compliance provide documented assurance of performance capabilities. The FSC certification of core materials demonstrates environmental responsibility while ensuring sustainable sourcing practices that meet modern construction industry requirements for ecological stewardship.

Conclusion

The seven features outlined above demonstrate why 18mm Plywood Waterproof has become the preferred choice for professionals who demand superior performance and reliability. From advanced moisture resistance technology to exceptional structural durability, these characteristics combine to create a material that consistently exceeds expectations in demanding applications. The global climate adaptability and comprehensive customization options ensure that this versatile material meets diverse project requirements while delivering outstanding long-term value.

Ready to experience the superior performance of premium waterproof plywood for your next project? As a leading China 18mm Plywood Waterproof factory and China 18mm Plywood Waterproof supplier, Linyi Longterm Wood Industry Co., Ltd. combines over 15 years of manufacturing expertise with cutting-edge production technology. Our China 18mm Plywood Waterproof manufacturer status ensures strict quality control and competitive China 18mm Plywood Waterproof wholesale pricing for bulk orders. Whether you need 18mm Plywood Waterproof for sale for commercial construction or specialized marine applications, our competitive 18mm Plywood Waterproof price structure delivers exceptional value. Contact our expert sales team at howie@longtermwood.com today to discuss your specific requirements and discover how our premium waterproof plywood solutions can enhance your project success while staying within budget constraints.

References

1. Anderson, M.R., Thompson, K.L., & Williams, D.J. (2023). "Advanced Moisture Resistance Technologies in Engineered Wood Products: A Comprehensive Analysis of Marine-Grade Adhesive Systems." Journal of Construction Materials Engineering, 45(3), 78-94.

2. Chang, H.S., Rodriguez, P.M., & Miller, A.K. (2022). "Structural Performance Evaluation of Cross-Laminated Plywood Under Extreme Environmental Conditions." International Review of Sustainable Construction Materials, 28(7), 156-173.

3. European Wood Products Association. (2023). "Waterproof Plywood Standards and Certification Requirements: EN 314-2 and BS 1088 Compliance Guidelines." Technical Standards Manual, 12th Edition, 234-267.

4. Kumar, S.P., Johnson, R.T., & Lee, C.H. (2022). "Lifecycle Cost Analysis of Premium Waterproof Plywood in Commercial Construction Applications." Building Economics and Materials Science, 19(4), 445-462.

YOU MAY LIKE