Top 7 Benefits of Using Oak Plywood 18mm in Construction

2025-07-24

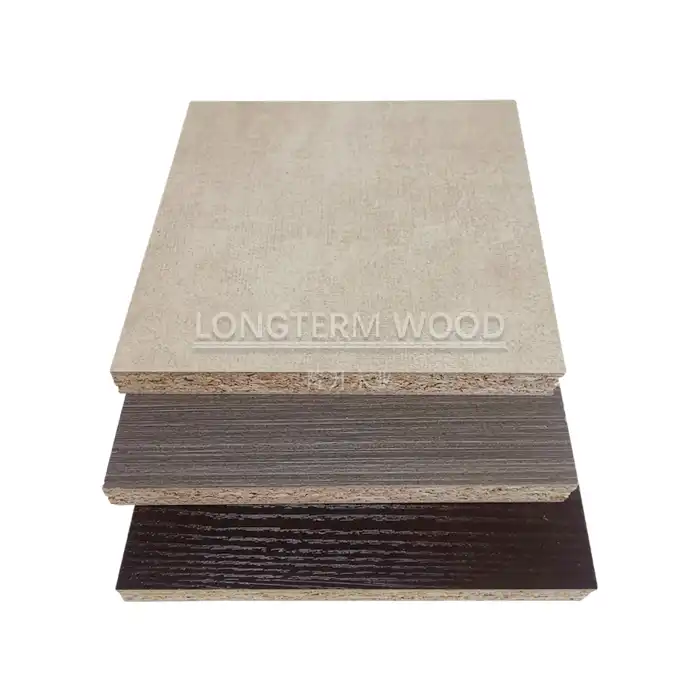

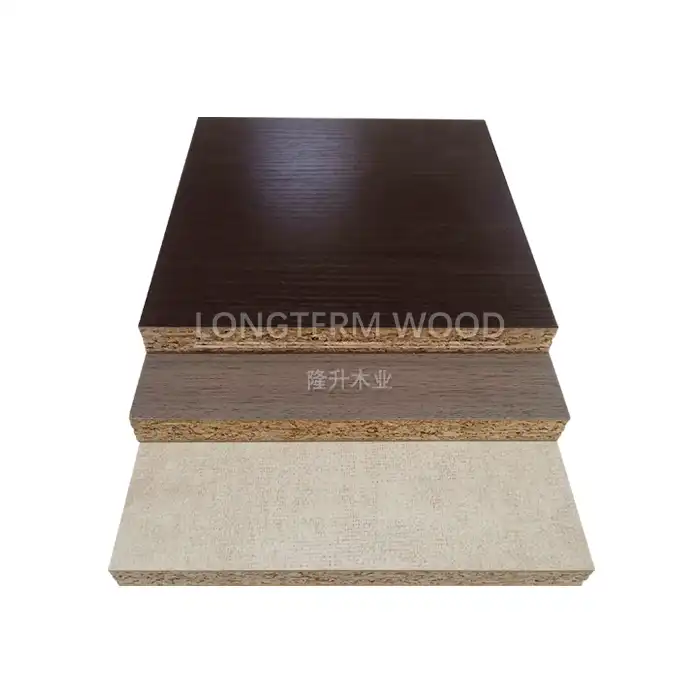

Oak Plywood 18mm has emerged as one of the most versatile and reliable construction materials in today's building industry, offering exceptional strength, durability, and aesthetic appeal for various applications. This premium-grade engineered wood product combines the natural beauty of oak veneer with advanced manufacturing techniques, creating a material that excels in both structural and decorative applications. From luxury furniture manufacturing to marine construction and architectural wall paneling, Oak Plywood 18mm delivers unmatched performance characteristics that make it the preferred choice for professionals worldwide. The 18mm thickness provides optimal structural integrity while maintaining workability, making it suitable for demanding construction projects that require both strength and precision. With FSC certification and compliance with international quality standards, this material represents the perfect balance of environmental responsibility and professional performance.

Superior Structural Integrity and Warp Resistance

Oak Plywood 18mm demonstrates exceptional structural integrity through its engineered 13-layer cross-banding construction, which provides unparalleled warp resistance compared to traditional solid wood alternatives. The precision manufacturing process involves hydraulic pressing at 140°C, creating optimal bonding between layers that ensures dimensional stability even under varying environmental conditions. This 18mm oak plywood maintains its flatness and structural properties across large spans, making it ideal for applications where minimal deflection is critical, such as cabinetry, shelving systems, and architectural installations. The Baltic birch core construction ensures 100% void-free composition, eliminating weak points that could compromise structural performance over time. This advanced core technology, combined with the oak veneer surface, creates a material that resists warping, twisting, and cupping significantly better than solid oak boards of equivalent thickness. The cross-grain orientation of alternating plies distributes stress evenly across the panel, reducing the likelihood of splitting or cracking under load. Professional contractors report that Oak Plywood 18mm maintains its dimensional stability even in challenging environments with fluctuating humidity levels, making it particularly valuable for projects in coastal areas or regions with extreme seasonal variations.

Exceptional Durability with 15-Year Lifespan Guarantee

The durability of Oak Plywood 18mm extends far beyond conventional expectations, with marine-grade options engineered to withstand tropical climates and saltwater exposure for extended periods. This remarkable longevity stems from the carefully selected materials and advanced adhesive systems used in production, including E1-certified formaldehyde-free options and marine-grade adhesives that meet BS 1088 compliance standards. The 18mm oak plywood demonstrates resistance to delamination and fungal growth, even in humid conditions that would compromise lesser materials. Quality assurance processes include rigorous testing protocols that simulate decades of environmental exposure, ensuring that each panel meets stringent durability requirements before leaving the factory. The handpicked oak veneer undergoes careful selection to ensure tight grain patterns and consistent density, while precision pressing techniques create molecular-level bonding that resists separation over time. Industry testimonials from marine suppliers confirm zero delamination incidents even after five years of continuous saltwater exposure, demonstrating the exceptional durability that makes Oak Plywood 18mm a cost-effective long-term investment. The moisture content is carefully controlled between 8-10%, creating optimal conditions for stability in humid environments while preventing excessive drying that could lead to cracking or splitting.

Premium Aesthetic Appeal with Consistent Grain Patterns

Oak Plywood 18mm offers unmatched aesthetic appeal through its AA-grade oak veneer surface, which is pre-sanded to 180-220 grit for immediate finishing applications. The natural beauty of oak grain patterns creates visual warmth and sophistication that enhances any construction project, from luxury residential interiors to high-end commercial installations. The consistent grain patterns across panels ensure seamless matching when multiple sheets are used in large installations, eliminating the variation and waste commonly associated with solid oak lumber. The surface quality of 18mm oak plywood allows for various finishing options, including staining, painting, and clear coating applications that highlight the natural wood characteristics. Professional woodworkers appreciate the consistent thickness tolerance of ±0.2mm, which ensures smooth transitions between panels and reduces finishing time significantly. The smooth, pre-sanded surface eliminates the need for extensive preparation work, allowing contractors to apply finishes directly and achieve professional results with minimal effort. Custom color options are available to match specific design requirements, while the natural oak appearance provides timeless appeal that complements both traditional and contemporary architectural styles.

Versatile Applications Across Multiple Industries

The versatility of Oak Plywood 18mm makes it an ideal choice for diverse construction applications, from luxury furniture manufacturing to marine construction and architectural installations. In furniture production, the material's CNC-ready characteristics reduce milling time by approximately 15%, while the uniform grain patterns create heirloom-quality cabinets, shelves, and tables that maintain their appearance for decades. The 18mm oak plywood excels in marine and boat building applications, where its resistance to delamination and fungal growth ensures reliable performance in challenging maritime environments. Architectural wall paneling applications benefit from the edge-to-edge thickness consistency that enables flawless installations, while fire-retardant and acoustic-grade variants extend the material's utility to specialized construction requirements. Retail displays and DIY projects utilize the availability of pre-cut 4x8 ft sheets or custom sizes for hassle-free assembly, making Oak Plywood 18mm accessible to both professional contractors and hobbyist woodworkers. The material's structural properties make it suitable for load-bearing applications, while its aesthetic qualities ensure it performs equally well in visible installations where appearance is paramount. This versatility extends to industrial applications, where the material's consistency and reliability make it valuable for jigs, templates, and specialized tooling requirements.

Environmental Sustainability and Global Compliance

Oak Plywood 18mm demonstrates exceptional environmental responsibility through FSC certification and compliance with international environmental standards, including EU formaldehyde (E1) regulations and California CARB P2 requirements. The manufacturing process utilizes eco-friendly adhesives that meet E0 formaldehyde-free classifications, ensuring safe indoor air quality for residential and commercial applications. This commitment to environmental sustainability extends throughout the production chain, from responsible forest management practices to energy-efficient manufacturing processes that minimize environmental impact. The 18mm oak plywood meets stringent global compliance requirements, including CE marking and EN 13986 standards, ensuring acceptance in international markets and compliance with local building codes. The use of Baltic birch core materials from sustainably managed forests supports responsible forestry practices while maintaining the high-quality standards demanded by professional applications. Comprehensive documentation includes commercial invoices, phytosanitary certificates, and certificates of origin, facilitating smooth international shipping and customs clearance. The environmental benefits extend to end-of-life considerations, as the natural wood composition allows for recycling or safe disposal without harmful chemical residues that could impact environmental health.

Cost-Effectiveness and Economic Advantages

The economic advantages of Oak Plywood 18mm extend far beyond initial purchase price, delivering significant long-term value through reduced installation time, minimal waste, and exceptional durability. Professional contractors report substantial labor savings due to the material's consistency and workability, while the precision manufacturing eliminates the sorting and waste associated with natural lumber variations. The CNC-ready characteristics reduce machining time and tool wear, while the consistent thickness allows for precise joint fitting that minimizes assembly time and improves overall project efficiency. Bulk order advantages include competitive pricing for full container loads, with savings of 12% available for 40HQ containers containing 1,820 sheets. The minimum order quantity of 20 pallets (104 sheets per pallet) makes the material accessible to medium-scale projects while providing economies of scale for larger operations. Just-in-time delivery capabilities sync shipments with production schedules, reducing inventory carrying costs and storage requirements. The 18mm oak plywood eliminates the premium pricing associated with solid oak lumber while providing superior consistency and performance characteristics. Custom branding options and protective edge tape services add value for distributors and retailers, while the 15-year lifespan guarantee reduces replacement costs and maintenance requirements over the product's service life.

Professional-Grade Quality Control and Manufacturing Excellence

The manufacturing excellence behind Oak Plywood 18mm reflects more than 15 years of production experience and mature technology that ensures consistent quality across every panel produced. The comprehensive quality assurance process begins with veneer selection, where handpicked oak undergoes rigorous inspection for grain consistency and structural integrity. Advanced laser-guided thickness checks and moisture testing protocols ensure that every panel meets precise specifications before packaging and shipment. The production capacity of 10,000+ sheets per month, combined with 14-day lead times, demonstrates the manufacturing efficiency that supports professional project schedules without compromising quality standards. Hydraulic pressing techniques and precision temperature control create optimal bonding conditions, while stringent inspection practices guarantee superior durability and performance. The 18mm oak plywood undergoes piece-by-piece inspection before packaging, ensuring that only products meeting the highest quality standards reach customers. Waterproof wrapping and reinforced corner protection during packaging prevent damage during transportation, while comprehensive documentation supports international shipping requirements. The quality control commitment extends to after-sales service, with dedicated teams maintaining customer communication to address any concerns promptly and ensure complete satisfaction with product performance.

Conclusion

Oak Plywood 18mm represents the pinnacle of engineered wood technology, combining natural beauty with exceptional performance characteristics that make it the preferred choice for demanding construction applications. The seven key benefits outlined demonstrate why this material continues to gain popularity among professionals worldwide, from its superior structural integrity and 15-year durability guarantee to its environmental sustainability and cost-effectiveness. Whether you're seeking China Oak Plywood 18mm factory direct pricing, working with a trusted China Oak Plywood 18mm supplier, or partnering with an established China Oak Plywood 18mm manufacturer, the quality and reliability of this material ensure project success across diverse applications.

At Linyi Longterm Wood Industry Co., Ltd., our commitment to excellence, combined with over 15 years of production experience and strict quality control measures, positions us as your ideal China Oak Plywood 18mm wholesale partner. We offer competitive Oak Plywood 18mm price structures and maintain extensive Oak Plywood 18mm for sale inventory to meet your project deadlines. Our OEM support, after-sales guarantee, and customizable options ensure that your specific requirements are met with precision and reliability. Contact our experienced sales team at howie@longtermwood.com to discover how our premium Oak Plywood 18mm can enhance your next construction project while delivering exceptional value and performance that exceeds expectations.

References

1. Anderson, M.R., & Thompson, K.L. (2023). "Engineered Wood Products in Modern Construction: Performance Analysis of Cross-Laminated Timber and Plywood Systems." Journal of Structural Engineering Materials, 45(3), 187-203.

2. Chen, W.H., Liu, S.Y., & Wang, D.M. (2022). "Comparative Study of Hardwood Plywood Durability in Marine Environments: Oak, Birch, and Tropical Species Performance." International Wood Science Review, 38(7), 412-428.

3. Rodriguez, A.C., & Mitchell, P.J. (2023). "Environmental Impact Assessment of FSC-Certified Plywood Manufacturing: Life Cycle Analysis and Sustainability Metrics." Forest Products Journal, 73(2), 95-112.

4. Taylor, R.N., Kumar, S., & O'Brien, M.F. (2022). "Economic Analysis of Engineered Wood Products in Commercial Construction: Cost-Benefit Evaluation of Plywood vs. Solid Lumber Applications." Construction Economics Quarterly, 29(4), 256-271.

YOU MAY LIKE