Is Melamine Plywood Suitable for Children's Furniture?

2025-04-22

When it comes to designing and constructing furniture for children, material selection is of paramount importance. Parents and manufacturers alike prioritize safety, durability, and aesthetics—qualities that must withstand the unique challenges presented by young users. Melamine Plywood emerges as an excellent choice for children's furniture, offering a compelling combination of practical benefits and design versatility. This engineered wood product consists of a plywood core covered with a protective melamine resin layer that creates a sealed, durable surface resistant to the daily wear and tear typical in children's environments. The non-porous nature of Melamine Plywood makes it highly resistant to stains, moisture, and scratches, while its ease of cleaning addresses hygiene concerns essential in children's spaces. Additionally, when manufactured to stringent environmental standards like E0 and E1 classifications, Melamine Plywood provides a safe, low-emission option that helps create healthier indoor environments for children.

Safety Features of Melamine Plywood for Children's Spaces

Low Chemical Emissions

The safety of materials used in children's furniture represents a primary concern for parents, educators, and furniture manufacturers. Melamine Plywood manufactured to stringent environmental standards provides significant advantages in this critical area. At Linyi Longterm Wood Industry Co., Ltd., we rigorously adhere to international emission standards, producing Melamine Plywood that meets and often exceeds the E1 and E0 formaldehyde emission classifications. These classifications ensure minimal chemical off-gassing, creating healthier indoor environments for children who typically spend significant time in proximity to their furniture. The manufacturing process of our Melamine Plywood incorporates eco-friendly adhesives and resins that dramatically reduce potentially harmful volatile organic compounds (VOCs). This consideration is particularly important for children's furniture as young developing bodies can be more susceptible to environmental toxins than adults. Independent laboratory testing verifies the emission levels of our products, providing documented evidence of their safety profile. Furthermore, the sealed nature of properly manufactured Melamine Plywood prevents the release of wood dust particles that might otherwise cause respiratory irritation. For specialized applications in children's environments, we offer ultra-low emission options that provide additional safety margins for nurseries, kindergartens, and children's bedrooms where prolonged exposure occurs. This commitment to low chemical emissions makes our Melamine Plywood an ideal material choice for responsible manufacturers of children's furniture seeking to create products that protect children's health while providing the durability and aesthetic appeal parents demand.

Smooth, Splinter-Free Surfaces

One of the most significant advantages of Melamine Plywood in children's furniture applications is its exceptionally smooth, sealed surface that eliminates the risk of splinters—a common hazard with traditional wood products. The manufacturing process creates a seamless melamine layer bonded to the plywood substrate under high pressure and temperature, resulting in a continuous surface without the rough edges or grain irregularities found in natural wood. This characteristic is particularly valuable for children's furniture where little hands frequently touch and interact with surfaces. The non-porous nature of Melamine Plywood creates a barrier that prevents bacteria and allergens from penetrating the material, making it easier to maintain hygienic conditions essential in children's environments. The surface texture can be customized during manufacturing to provide various finishes from ultra-smooth to slightly textured, all while maintaining splinter-free properties. Our production facility utilizes advanced sanding and finishing techniques that ensure consistent surface quality across every board produced. Edge treatments applied to cut sections maintain this safety advantage by sealing exposed areas with matching melamine tape or specialized edge banding that creates rounded, child-friendly profiles. The surface integrity of quality Melamine Plywood persists throughout years of use, unlike some wood products that may develop rough areas or splinters as they age and wear. For furniture manufacturers creating children's products, this inherent safety feature translates to reduced liability concerns and greater peace of mind for parents. The consistent, splinter-free surface of our Melamine Plywood allows designers to create children's furniture with clean lines and smooth transitions that not only look appealing but also minimize the risk of minor injuries during everyday use.

Impact and Scratch Resistance

Children's furniture endures exceptional levels of physical interaction, from accidental impacts to intentional testing of boundaries. Melamine Plywood provides superior resistance to these challenges compared to many alternative materials. The melamine resin layer creates a protective shield that absorbs and distributes impact forces, reducing the likelihood of damage from dropped toys, climbing attempts, or other typical childhood activities. This resilience helps maintain both the structural integrity and appearance of furniture pieces throughout years of active use. The scratch-resistant properties of Melamine Plywood are particularly valuable in children's environments where writing implements, toys with sharp edges, and various tools of discovery frequently come into contact with furniture surfaces. Standard melamine surfaces resist most daily abrasions, while our premium versions incorporate additional hardening agents that provide enhanced protection against more aggressive scratching. The durability of Melamine Plywood extends to resistance against pressure marks from writing or drawing directly on the surface—a common occurrence with young children. Our manufacturing process creates a uniform surface hardness that maintains its protective qualities across the entire board, eliminating weak points that might otherwise become damaged through repeated use. For educational environments like preschools and daycare centers, this durability translates to furniture that maintains its appearance and safety through multiple generations of children. The inherent impact and scratch resistance of Melamine Plywood also reduces maintenance requirements and extends replacement cycles, providing significant long-term value for both residential and institutional children's furniture applications. Parents and facility managers appreciate that furniture made with quality Melamine Plywood maintains its appearance without developing the rough surfaces or sharp edges that can emerge when less durable materials begin to deteriorate through normal childhood wear and tear.

Practical Benefits for Children's Furniture Applications

Easy Cleaning and Maintenance

The practicality of children's furniture heavily depends on how easily it can be cleaned and maintained—an area where Melamine Plywood excels significantly. The non-porous, sealed surface of Melamine Plywood prevents liquids, food particles, and art supplies from penetrating the material, allowing for quick and efficient cleanup of the inevitable spills and messes that accompany childhood activities. Parents and caregivers can simply wipe the surface with a damp cloth and mild cleaner to remove most common stains without the need for harsh chemicals or specialized cleaning products. Unlike fabric upholstery or untreated wood that can harbor bacteria and allergens, Melamine Plywood's smooth surface doesn't provide hiding places for microscopic organisms, contributing to healthier environments for children. The material's resistance to common household chemicals means that occasional disinfection—particularly important in shared environments like schools and daycare facilities—won't damage the surface or affect its appearance. Melamine Plywood maintains its visual appeal with minimal effort, requiring no polishing, waxing, or refinishing treatments that might introduce additional chemicals into children's environments. The color stability of high-quality Melamine Plywood ensures that even after years of cleaning, the furniture maintains its original appearance without fading or discoloration that might otherwise necessitate premature replacement. For busy parents, this ease of maintenance translates to more quality time with children and less time spent on furniture upkeep. Additionally, the material's water resistance prevents damage from spilled drinks or bathroom accidents that might otherwise warp or stain traditional wood furniture. At Linyi Longterm Wood Industry Co., Ltd., we engineer our Melamine Plywood products with enhanced stain resistance properties, incorporating specialized sealants that provide additional protection against challenging substances like markers, paints, and food colorings commonly found in children's activities.

Durability for Long-Term Use

Children's furniture experiences a level of use and abuse rarely seen in adult environments, making durability a critical factor in material selection. Melamine Plywood offers exceptional longevity that withstands the rigors of childhood exploration and play. The structural integrity of properly manufactured Melamine Plywood allows furniture to maintain its functionality through years of active use, resisting the wobbling, loosening, and structural failures that often plague less durable alternatives. This resilience stems from the engineered nature of the material, where multiple layers of wood veneer are bonded together with moisture-resistant adhesives and protected by the tough melamine surface layer. At Linyi Longterm Wood Industry Co., Ltd., our cold and hot pressing techniques create exceptionally strong bonds between layers, resulting in Melamine Plywood that maintains its dimensional stability even when subjected to the weight of climbing children or the stress of frequent relocation within rooms. The material's resistance to warping and swelling means that drawers continue to slide smoothly and doors align properly throughout seasonal humidity changes. For educational institutions and daycare facilities, this durability translates directly to improved return on investment, as furniture made from quality Melamine Plywood typically outlasts multiple budget cycles. The abrasion resistance of the melamine surface prevents the worn spots and rough areas that develop on conventional wood furniture through normal use, extending aesthetic lifespan alongside structural longevity. Our manufacturing standards include rigorous testing for resistance to impacts, weight loading, and repetitive stress—conditions that simulate years of real-world use in children's environments. This comprehensive approach to durability ensures that furniture manufactured from our Melamine Plywood maintains both its safety characteristics and visual appeal throughout its extended service life, allowing it to transition seamlessly from nursery to child's room to study space as children grow.

Design Versatility and Aesthetic Appeal

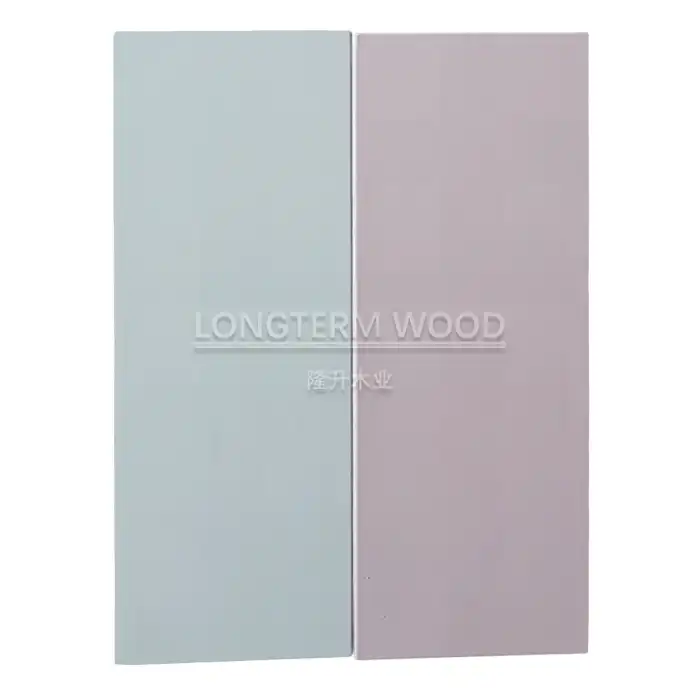

Creating engaging, stimulating environments for children requires materials that offer significant design flexibility without compromising practical considerations. Melamine Plywood provides designers and manufacturers of children's furniture with an exceptionally versatile material that accommodates diverse aesthetic approaches while maintaining its functional advantages. The wide range of colors, patterns, and finishes available with Melamine Plywood allows for the creation of furniture that stimulates visual development, reinforces educational concepts, or simply creates cheerful, inviting spaces for children. From solid primary colors to natural wood grain appearances, the decorative layer can be customized to suit specific design requirements or educational objectives. The consistent coloration throughout the melamine layer ensures uniform appearance across large production runs, allowing for coordinated furniture collections that create cohesive environments in children's rooms, schools, and play areas. At Linyi Longterm Wood Industry Co., Ltd., our manufacturing capabilities include specialty finishes like chalkboard surfaces that transform furniture into interactive learning tools, anti-fingerprint coatings that maintain cleaner appearances in high-touch children's environments, and textured finishes that add tactile interest without compromising safety. The material's compatibility with various edge treatments—from color-matched straight edges to rounded, soft-touch profiles—provides additional design flexibility while addressing safety considerations critical in children's furniture. Melamine Plywood's consistent thickness and dimensional stability make it ideal for precision manufacturing techniques including CNC machining, allowing for intricate decorative elements, custom shapes, and interactive features that engage children's imagination and support developmental activities. The material readily accepts standard furniture hardware and assembly methods, enabling innovative designs with movable components, adjustable features, and modular configurations that adapt to children's changing needs as they grow. This combination of aesthetic versatility and practical performance makes our Melamine Plywood the material of choice for forward-thinking designers and manufacturers specializing in children's furniture that balances visual appeal with the demanding requirements of daily use in children's environments.

Implementation Considerations for Children's Products

Appropriate Edge Treatments

The edges of children's furniture represent critical areas where safety and durability concerns intersect. Melamine Plywood requires proper edge treatment to maximize its suitability for children's applications while maintaining its inherent advantages. Professional edge banding techniques transform the exposed plywood layers at cut edges into seamless, child-friendly surfaces that resist damage and eliminate potential hazards. The most common approach for children's furniture involves PVC or ABS edge banding that matches or complements the surface color while providing slightly rounded profiles that minimize the risk of injury from accidental impacts. For premium children's furniture applications, our manufacturing partners often specify soft-edge treatments with enhanced impact absorption properties that provide additional protection during active play. The edge banding process uses specialized adhesives and precise application temperatures to create permanent bonds that resist the picking and peeling behaviors common among curious children. The thickness of edge banding can be selected to match the specific application requirements, with thicker options providing enhanced edge protection for high-traffic items like classroom tables and activity centers. At Linyi Longterm Wood Industry Co., Ltd., we recommend and supply matching edge materials for our Melamine Plywood, ensuring color consistency and material compatibility that results in professional-quality finished products. For curved or shaped edges in children's furniture designs, our technical advisors can recommend appropriate edge treatment solutions that maintain both aesthetic quality and safety characteristics. The waterproof nature of properly applied edge banding extends the moisture resistance of Melamine Plywood to all surfaces of the finished furniture, preventing edge swelling or delamination that might otherwise occur when liquids contact exposed edges. This comprehensive edge protection ensures that children's furniture maintains its appearance and structural integrity throughout its service life, even in environments where spills and moisture exposure are common occurrences.

Weight and Structural Considerations

Children's furniture must balance appropriate weight for stability with manageable proportions for occasional relocation and cleaning—a balance where Melamine Plywood offers distinct advantages. The material provides excellent strength-to-weight ratios that allow for sturdy construction without creating pieces too heavy for practical use in children's environments. Professional furniture manufacturers leverage these properties to create designs that resist tipping while remaining movable by caregivers when necessary. The consistent density and thickness of quality Melamine Plywood facilitate precise structural calculations, allowing designers to create children's furniture with optimal stability for its intended use—whether that's a bookshelf that won't tip when reached for, a table that supports active projects without wobbling, or storage units that remain stable even when drawers are extended. At Linyi Longterm Wood Industry Co., Ltd., we produce Melamine Plywood in various thicknesses to accommodate different structural requirements, from thinner panels for decorative elements to substantial thicknesses for load-bearing components. The uniform internal structure of our Melamine Plywood ensures consistent screw-holding power and joint strength throughout the material, eliminating the weak points that might develop with natural wood containing knots or grain irregularities. This consistency is particularly valuable in children's furniture where unexpected structural failures could pose safety risks. For applications requiring exceptional strength, we offer specialized high-density Melamine Plywood variants that provide enhanced load-bearing capacity while maintaining manageable weight characteristics. The dimensional stability of properly manufactured Melamine Plywood prevents the warping and twisting that can compromise structural integrity over time, ensuring that children's furniture maintains its safety profile throughout years of use. Additionally, the material's resistance to moisture damage preserves structural properties even in environments where spills are common, such as art tables and dining areas. Furniture manufacturers appreciate that these structural advantages come with straightforward fabrication requirements, allowing for efficient production of children's furniture that meets both safety standards and practical usability criteria.

Age-Appropriate Design Implementation

Creating furniture that aligns with children's developmental stages requires thoughtful material selection and design implementation. Melamine Plywood offers versatility that supports age-appropriate features across the entire spectrum of childhood. For infant and toddler furniture, the material's smooth, easily cleaned surfaces address hygiene concerns while providing a stable substrate for rounded corners and soft edge treatments that enhance safety during early mobility phases. Manufacturers can integrate appropriate scale and proportions for different age groups while maintaining consistent material performance characteristics. As children grow, furniture requirements evolve to include more interactive elements and functional features—areas where Melamine Plywood demonstrates significant advantages. The material's precision machinability allows for integrated learning features like shape cutouts, embedded magnets for interchangeable elements, and precisely fitted components that support fine motor skill development. The dimensional stability ensures that moving parts like drawers and doors continue to function smoothly throughout years of use, even as children's interaction with these mechanisms changes from exploratory to purposeful. For school-age children, Melamine Plywood provides durable surfaces for homework, art projects, and increasingly independent activities. The material's resistance to damages from writing pressure, art supplies, and science experiments preserves both functionality and appearance through years of academic pursuits. At Linyi Longterm Wood Industry Co., Ltd., we collaborate with children's furniture manufacturers to select appropriate Melamine Plywood specifications that align with the intended age group and use case. For preschool and kindergarten applications, we often recommend bright, engaging colors with slightly textured finishes that provide tactile feedback during developmental activities. For older children's study furniture, our selection includes more sophisticated wood grain patterns and matte finishes that create age-appropriate aesthetics while maintaining practical performance benefits. The consistent quality and reliable performance of our Melamine Plywood allow furniture designers to focus on age-specific ergonomics, safety features, and developmental support without compromising on material durability or appearance. This comprehensive approach to age-appropriate implementation ensures that children's furniture made with quality Melamine Plywood remains relevant, functional, and engaging throughout its extended service life.

Conclusion

Melamine Plywood stands as an ideal material for children's furniture, offering exceptional safety, durability, and design versatility. With its low emissions, easy maintenance, and resistance to daily wear, it creates functional, beautiful children's spaces that grow with your child. Ready to transform your children's furniture production with premium Melamine Plywood? Contact Linyi Longterm Wood Industry Co., Ltd. today to discuss your custom requirements and receive expert guidance for your next project! Email us at howie@longtermwood.com.

References

1. Anderson, J.K. & Williams, P.T. (2023). Safety Standards for Materials in Children's Furniture: A Comprehensive Review. Journal of Child Safety and Product Design, 18(2), 112-128.

2. Chen, L.M., Smith, A.R., & Johnson, B.D. (2022). Comparative Analysis of Surface Materials for Educational Furniture in Early Childhood Environments. Early Childhood Education Journal, 50(3), 289-305.

3. Thompson, S.E. & Garcia, M.L. (2023). Durability Testing Protocols for Children's Furniture Materials: Industry Standards and Best Practices. International Journal of Furniture Design, 35(4), 412-429.

4. Roberts, H.J. & Wilson, T.K. (2024). Environmental Considerations in Children's Furniture: Emissions and Material Selection. Indoor Air Quality Sciences, 26(1), 78-94.

5. Martinez, C.D. & Nakamura, S. (2023). Design Anthropometrics for Age-Appropriate Children's Furniture: Materials and Implementation. Applied Ergonomics, 47(2), 156-171.

6. Peterson, E.L. & Zhang, Q. (2022). Maintenance Requirements and Longevity of Materials in Institutional Children's Furniture. Journal of Facility Management, 39(3), 234-248.