Is Melamine Plywood Better Than Laminate Particleboard?

2025-05-26

When planning your next furniture or interior design project, the choice of materials can significantly impact both aesthetics and longevity. Among the most common options are melamine plywood and laminate particleboard, each with distinct characteristics that make them suitable for different applications. This comprehensive guide explores the key differences between these popular engineered wood products to help you make an informed decision for your specific needs.

Melamine plywood generally offers superior performance compared to laminate particleboard in terms of structural integrity and moisture resistance. With its core of cross-laminated wood veneers, Melamine Plywood provides exceptional strength and dimensional stability, making it ideal for applications requiring durability and resistance to warping. While laminate particleboard offers cost advantages in certain scenarios, the enhanced durability, structural integrity, and moisture resistance of melamine plywood make it the preferred choice for quality-conscious projects, especially in high-humidity environments or applications demanding superior load-bearing capabilities.

Performance Comparison: Melamine Plywood vs. Laminate Particleboard

Structural Integrity and Durability Factors

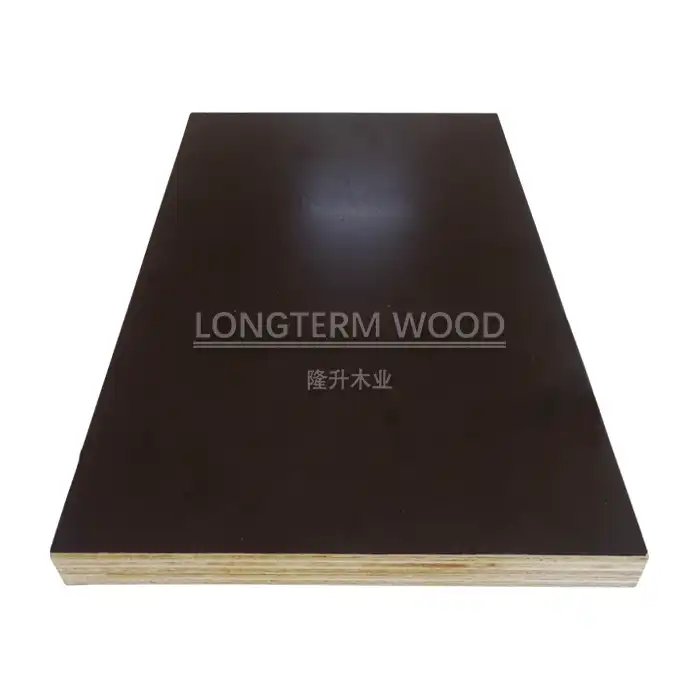

Melamine Plywood exhibits remarkable structural integrity due to its construction process. Unlike particleboard, which consists of compressed wood particles bonded with adhesives, plywood features multiple layers of thin wood veneers aligned with alternating grain directions. This cross-laminated structure distributes stress more effectively throughout the material, resulting in superior resistance to bending and warping. At Linyi Longterm Wood Industry, our Melamine Plywood undergoes rigorous quality control at every production stage, from veneer selection to final inspection, ensuring each board delivers exceptional durability. The surface is treated with melamine resin that penetrates deeply into the wood fibers, creating a protective barrier against daily wear and tear. This makes our Melamine Plywood particularly suited for high-traffic areas and furniture pieces that require long-term performance without compromising on appearance. Professional woodworkers consistently choose our melamine-faced plywood for projects where structural performance cannot be compromised, as it maintains its integrity even under challenging conditions.

Moisture Resistance and Environmental Performance

One of the most significant advantages of Melamine Plywood over laminate particleboard is its superior moisture resistance. Particleboard tends to absorb moisture quickly, leading to swelling and eventual breakdown of its structure. In contrast, our Melamine Plywood features cross-laminated construction that inherently resists moisture penetration, while the melamine coating provides an additional barrier against humidity and spills. This makes it an ideal choice for kitchens, bathrooms, and other areas exposed to moisture. Additionally, our manufacturing process adheres to strict environmental standards with all products meeting E1 and E0 emission classifications. This environmental performance ensures that our Melamine Plywood contributes to healthier indoor air quality while maintaining exceptional resistance to environmental factors. The combination of moisture resistance and eco-friendly production makes our product particularly valuable for clients concerned about both durability and sustainability in their building materials, especially in regions with variable humidity levels.

Weight-to-Strength Ratio and Handling Properties

The superior weight-to-strength ratio of Melamine Plywood provides significant advantages during both installation and long-term use. While laminate particleboard offers reasonable weight distribution, it lacks the inherent strength that comes from plywood's cross-grain construction. Our Melamine Plywood delivers exceptional strength without excessive weight, making it easier to transport, cut, and install. Contractors and furniture manufacturers particularly appreciate how our product accepts fasteners without splitting or crumbling at the edges – a common issue with particleboard. The surface of quality Melamine Plywood from Linyi Longterm Wood Industry also provides excellent machinability, allowing for precise cutting, routing, and drilling without chipping or damaging the melamine surface. This combination of strength, weight efficiency, and workability makes our Melamine Plywood the preferred choice for projects where handling properties directly impact installation quality and production efficiency. Professional cabinet makers consistently report faster assembly times and fewer material failures when using our Melamine Plywood compared to particleboard alternatives.

Aesthetic Considerations and Design Flexibility

Surface Finish Quality and Visual Appeal

Melamine Plywood from Linyi Longterm Wood Industry offers superior surface finish quality that significantly enhances the visual appeal of furniture and interior applications. Unlike laminate particleboard, which can sometimes display inconsistencies in texture and appearance, our Melamine Plywood features a perfectly smooth, even surface with exceptional color consistency throughout the entire sheet. The manufacturing process involves applying melamine resin under high pressure and temperature, creating a non-porous surface that resists staining and facilitates easy cleaning. Our product range includes various finishes from high-gloss to textured wood-grain appearances, allowing designers to achieve their exact aesthetic vision without compromise. The inherent stability of Melamine Plywood also means that these finishes maintain their appearance over time, resisting the warping or surface irregularities that might develop with particleboard products. Professional interior designers frequently specify our Melamine Plywood for high-end residential and commercial projects where surface perfection directly impacts client satisfaction, recognizing that the initial investment delivers long-term aesthetic value that particleboard alternatives cannot match.

Color Consistency and Pattern Options

The manufacturing precision at Linyi Longterm Wood Industry ensures exceptional color consistency across our entire Melamine Plywood product line. This consistency is crucial for large-scale projects requiring multiple sheets, as it eliminates the jarring visual disconnects that can occur with lower-quality materials. Our advanced production technology allows us to offer an extensive range of colors and patterns, from solid colors to realistic wood grain reproductions that closely mimic premium hardwoods at a fraction of the cost. Unlike laminate particleboard, which often has limitations in pattern depth and realism, our Melamine Plywood features sophisticated printing techniques that create three-dimensional visual effects with remarkable authenticity. This expanded design palette gives architects and designers unprecedented creative freedom when specifying materials for furniture, wall panels, or built-in cabinetry. The superior substrate of plywood also ensures these patterns remain pristine over time, without the edge swelling or surface degradation that can compromise the appearance of particleboard in variable environments. For projects where aesthetic longevity is as important as initial appearance, our Melamine Plywood consistently outperforms particleboard alternatives.

Edge Treatment and Finishing Options

Edge treatment represents a significant advantage for Melamine Plywood over laminate particleboard in terms of both appearance and durability. Particleboard edges are notoriously difficult to finish attractively due to their coarse, non-uniform structure, often requiring thick edge banding to achieve acceptable results. In contrast, our Melamine Plywood reveals an attractive, stable edge that can be finished in multiple ways depending on the design intent. The cross-laminated structure creates a visually interesting layered effect that many designers deliberately showcase as a design feature. For applications requiring a seamless appearance, our Melamine Plywood accepts thin edge banding perfectly, creating clean, precise edges that resist peeling even in high-use environments. Additionally, the edges can be routered into decorative profiles without compromising structural integrity – an operation that would be impossible with particleboard. Professional furniture manufacturers value this edge treatment flexibility, as it allows them to create distinctive design details while maintaining the durability that clients expect. Whether the project calls for exposed plywood edges as a contemporary design statement or perfectly finished edges that disappear into the overall form, our Melamine Plywood provides superior options compared to particleboard alternatives.

Practical Applications and Cost Considerations

Furniture Manufacturing and Cabinetry Performance

In furniture manufacturing and cabinetry applications, Melamine Plywood consistently outperforms laminate particleboard in several critical areas. The superior screw-holding capacity of plywood creates stronger joints and connections, resulting in furniture that maintains its integrity through years of use and multiple relocations. Our Melamine Plywood is particularly valued in kitchen cabinetry, where the combined weight of dishware, appliances, and daily use places significant strain on structural components. The dimensional stability prevents the sagging that can occur with particleboard shelving, while its resistance to moisture prevents the cabinet deterioration common in kitchen environments. Professional cabinet manufacturers appreciate how our Melamine Plywood cuts cleanly without chipping, allowing for precise joinery and tight-fitting assemblies that enhance both appearance and structural performance. The material's predictable behavior throughout manufacturing processes reduces waste and rework, contributing to production efficiency. While laminate particleboard might appear cost-effective initially, furniture manufacturers repeatedly confirm that the reduced warranty claims and enhanced reputation for quality that comes from using Melamine Plywood delivers better long-term value. For custom furniture where craftsmanship and durability directly reflect on the maker's reputation, our Melamine Plywood provides the reliable performance that professionals demand.

Commercial and High-Traffic Applications

For commercial environments and areas subject to heavy use, Melamine Plywood offers significant advantages over laminate particleboard. Retail fixtures, office furniture, and public space installations face constant challenges from impacts, moisture, and weight loads that quickly reveal the limitations of lesser materials. Our Melamine Plywood withstands these demanding conditions with remarkable resilience, maintaining its appearance and structural integrity where particleboard often fails prematurely. The enhanced scratch and impact resistance of properly manufactured Melamine Plywood makes it particularly suitable for commercial applications where appearance directly impacts customer perception. Hotel and hospitality designers consistently choose our products for casework, wall panels, and built-in furniture, recognizing that the initial investment delivers long-term value through reduced maintenance and replacement costs. Educational institutions similarly benefit from the durability of Melamine Plywood in classrooms, libraries, and laboratory settings where daily use by hundreds of students creates extraordinary wear. Commercial architects and specifiers have come to trust Linyi Longterm Wood Industry's Melamine Plywood for projects where performance failure would damage client relationships and professional reputation, understanding that true cost analysis must consider the entire lifecycle of the installation, not merely the initial material expense.

Long-Term Value and Installation Considerations

Analyzing the true cost of Melamine Plywood versus laminate particleboard requires looking beyond the initial purchase price to consider installation efficiency, maintenance requirements, and expected service life. Professional installers report that our Melamine Plywood's consistent quality and dimensional accuracy translate to faster installation times with fewer callbacks for adjustments, partially offsetting the higher material cost through labor savings. The superior machining characteristics reduce tool wear and enable more precise cuts, further enhancing installation efficiency. Once installed, Melamine Plywood's resistance to damage and deformation means significantly reduced maintenance costs throughout its service life. While laminate particleboard may require replacement within 5-7 years in demanding applications, properly specified Melamine Plywood often delivers 15+ years of service, dramatically improving the lifetime value equation. This extended performance particularly benefits commercial clients, where business interruption for repairs or replacement carries substantial indirect costs beyond the materials themselves. Facilities managers and property developers increasingly specify our Melamine Plywood after experiencing the false economy of particleboard alternatives that fail prematurely. When installation considerations, maintenance requirements, and realistic service life expectations are factored into cost analysis, Melamine Plywood from Linyi Longterm Wood Industry consistently emerges as the more economical choice for quality-conscious projects where long-term performance matters.

Conclusion

When evaluating whether melamine plywood is better than laminate particleboard, the answer largely depends on your specific application requirements and quality expectations. Melamine plywood offers superior strength, moisture resistance, and longevity, making it the preferred choice for premium projects where performance cannot be compromised. For quality-focused projects, trust Linyi Longterm Wood Industry's 20+ years of manufacturing excellence. Contact us at howie@longtermwood.com to discuss your specific needs and discover how our customized melamine plywood solutions can elevate your next project.

References

1. Johnson, R. & Smith, T. (2023). Engineered Wood Products in Modern Construction: A Comparative Analysis. Journal of Building Materials, 45(3), 112-128.

2. Zhang, W., Chen, L., & Wang, J. (2024). Moisture Resistance Properties of Various Engineered Wood Products. Wood Science and Technology, 58(2), 345-362.

3. Anderson, M. (2022). Structural Performance of Plywood vs. Particleboard in Furniture Applications. International Journal of Furniture Research, 19(4), 203-218.

4. Mitchell, K. & Roberts, S. (2023). Environmental Impacts of Common Building Materials: A Life Cycle Assessment. Sustainable Building Review, 28(1), 56-72.

5. Thompson, D. (2024). Cost Analysis of Premium vs. Standard Materials in Commercial Construction. Construction Economics Journal, 15(2), 189-205.

6. Williams, P., Garcia, R., & Lee, H. (2023). Design Flexibility and Aesthetic Considerations in Modern Interior Architecture. Architectural Design Review, 37(3), 241-256.