Is Birch Veneer Plywood the Most Reliable Option for Moisture-Sensitive Applications?

2025-07-14

When selecting materials for moisture-sensitive applications, the choice of plywood becomes critical to project success. Birch veneer plywood has emerged as a leading contender in environments where moisture exposure is a concern, challenging traditional assumptions about wood-based materials in demanding conditions. This comprehensive analysis examines whether birch veneer plywood truly represents the most reliable option for applications where moisture resistance is paramount. Birch veneer plywood demonstrates exceptional reliability in moisture-sensitive applications through its superior dimensional stability, enhanced adhesive bonding properties, and refined manufacturing processes. The material's tight grain structure and consistent density profile provide inherent moisture resistance superior to many conventional plywood alternatives. When manufactured with appropriate moisture-resistant adhesives and proper grading systems, birch veneer plywood offers predictable performance characteristics that make it particularly suitable for furniture manufacturing, commercial flooring, and architectural applications where humidity fluctuations are common. The combination of natural birch wood properties and modern manufacturing techniques creates a material that balances performance, cost-effectiveness, and environmental responsibility.

Understanding Moisture Resistance in Birch Veneer Plywood

Structural Properties That Enhance Moisture Performance

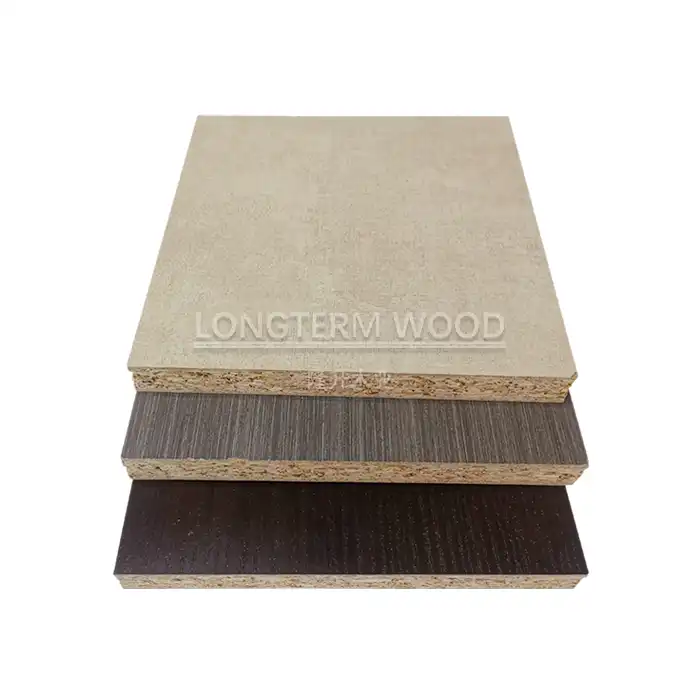

Birch veneer plywood exhibits remarkable moisture resistance due to its unique structural characteristics that differentiate it from standard plywood compositions. The dense, fine-grained nature of birch wood creates a naturally tight fiber structure that significantly reduces moisture penetration compared to softer wood species. The core layers of quality birch plywood consist of approximately 1mm-thick solid birch veneer that is cross-banded and laminated with strong adhesive, resulting in a void-free core with superior moisture resistance properties. This construction methodology ensures that each layer contributes to the overall moisture resistance rather than creating potential failure points. The manufacturing process at Longterm Plywood incorporates advanced quality control measures that directly impact moisture performance. Our birch veneer plywood utilizes carefully selected birch and poplar materials with controlled moisture content ranging from 8% to 18%, providing optimal dimensional stability. The cross-grain lamination technique employed in our production process creates a balanced structure that resists warping and swelling when exposed to humidity variations. Additionally, the void-free core construction eliminates internal spaces where moisture could accumulate, preventing the delamination issues commonly associated with inferior plywood products.

Adhesive Technology and Moisture Resistance

The adhesive system used in birch veneer plywood manufacturing plays a crucial role in determining moisture resistance capabilities. Modern birch plywood utilizes moisture-resistant (MR) urea glue for interior applications and weather-and-boil-proof (WBP) phenol resin glue for exterior applications. At Longterm Plywood, our products feature E0, E1, and E2 grade adhesives that not only provide exceptional bonding strength but also maintain their integrity under moisture stress conditions. The phenol-formaldehyde adhesives used in our premium grades create waterproof bonds that actually strengthen under moisture exposure, making them ideal for applications where occasional water contact is expected. Our commitment to environmental safety extends to our adhesive selection, with E0 grade representing the most stringent standard, indicating almost no formaldehyde release while maintaining exceptional moisture resistance. This dual focus on performance and safety ensures that our birch veneer plywood products meet both functional requirements and health standards in moisture-sensitive environments. The advanced adhesive technology also contributes to the material's long-term durability, as properly bonded layers maintain their structural integrity even under cyclical moisture exposure conditions.

Comparative Analysis with Alternative Materials

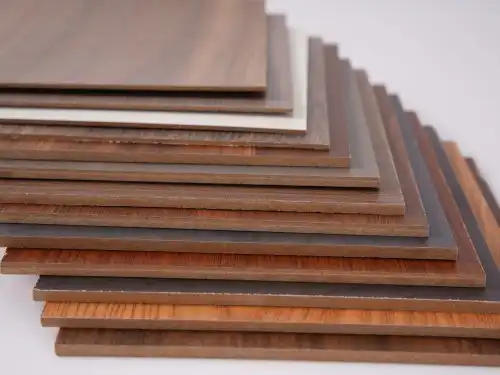

When evaluating birch veneer plywood against alternative materials for moisture-sensitive applications, several key performance indicators demonstrate its superior reliability. Birch plywood serves as both a suitable and economical alternative to marine plywood for most projects exposed to moisture, offering comparable performance at a significantly lower cost point. The material's consistent density of 520-580 kg/m³ provides predictable behavior under moisture stress, while its furniture-grade surface quality eliminates the need for additional treatments in many applications. Traditional softwood plywood often exhibits inferior moisture resistance due to its more porous structure and tendency toward resin pocket formation. In contrast, birch veneer plywood from Longterm Plywood maintains uniform density throughout its thickness, ensuring consistent moisture response across the entire panel. Research demonstrates that birch plywood has superior mechanical properties compared to most softwood alternatives, particularly in moisture-variable environments. Our standardized sheet sizes of 1220x2440mm and customizable thickness options from 3mm to 25mm provide flexibility for diverse applications while maintaining consistent moisture performance characteristics.

Applications Where Birch Veneer Plywood Excels in Moisture Control

Furniture Manufacturing and Cabinet Construction

Birch veneer plywood has become the material of choice for furniture manufacturers operating in moisture-variable environments, particularly in kitchen and bathroom applications where humidity fluctuations are common. The material's exceptional dimensional stability prevents the warping and joint separation that plague furniture constructed from inferior materials. At Longterm Plywood, our furniture-grade birch veneer plywood features AA/BB and A+/B grading systems that ensure consistent surface quality while maintaining superior moisture resistance throughout the panel structure. The tight grain pattern characteristic of birch wood provides an ideal substrate for various finishing systems, allowing manufacturers to apply moisture-resistant coatings that further enhance the material's protective properties. Our birch veneer plywood products undergo rigorous quality control processes that include moisture content testing and adhesive strength verification, ensuring that each panel meets the demanding requirements of professional furniture manufacturing. The material's ability to maintain consistent dimensions under varying humidity conditions makes it particularly valuable for precision cabinet construction where tight tolerances are essential. Kitchen cabinet manufacturers particularly benefit from the moisture resistance properties of birch veneer plywood, as these environments experience significant humidity variations from cooking activities and cleaning processes. The material's resistance to steam penetration and its ability to maintain structural integrity when exposed to occasional water contact make it superior to particleboard or MDF alternatives. Our commitment to using eco-friendly adhesives ensures that furniture manufactured from our birch veneer plywood maintains healthy indoor air quality while providing long-term durability in moisture-prone environments.

Commercial Flooring and Structural Applications

The commercial flooring industry has increasingly adopted birch veneer plywood as a preferred substrate material due to its superior moisture resistance and structural stability. Exterior-grade plywood types demonstrate enhanced durability and moisture resistance for demanding commercial applications. Our birch veneer plywood products feature CARB Phase 2 certification and comply with international standards for formaldehyde emissions, making them suitable for high-occupancy commercial spaces where indoor air quality is paramount. The material's consistent density and cross-grain construction provide excellent load distribution characteristics, essential for commercial flooring applications that experience heavy foot traffic and equipment loads. Birch veneer plywood substrates help prevent floor covering failures by maintaining dimensional stability under varying moisture conditions, reducing the risk of buckling or delamination that can occur with inferior substrate materials. Our products undergo extensive testing to ensure compliance with structural requirements while maintaining their moisture resistance properties over extended service periods. Retail environments benefit significantly from birch veneer plywood flooring substrates, as these spaces often experience moisture variations from cleaning activities, HVAC system operation, and customer traffic patterns. The material's ability to resist moisture penetration while maintaining structural integrity ensures consistent floor performance regardless of environmental conditions. Our manufacturing process includes moisture sealing treatments that further enhance the material's protective properties, making it an ideal choice for commercial applications where reliability and longevity are essential.

Architectural Millwork and Custom Construction

Birch veneer plywood has gained recognition in architectural millwork applications where moisture resistance must be balanced with aesthetic requirements and precision manufacturing capabilities. The material's smooth, consistent surface provides an excellent foundation for high-quality finishes while its structural properties ensure long-term performance in challenging environmental conditions. At Longterm Plywood, our birch veneer plywood products feature precision-cut edges and carefully controlled thickness tolerances that meet the exacting standards of architectural millwork fabrication. The material's exceptional screw-holding capacity and resistance to splitting make it ideal for complex millwork assemblies where mechanical fasteners must maintain their grip under moisture stress conditions. Birch veneer plywood panels can be machined to precise tolerances without the tear-out or surface irregularities common with lower-grade materials, enabling the creation of sophisticated architectural elements that maintain their appearance and functionality over time. Our commitment to sustainable manufacturing practices ensures that architectural projects using our birch veneer plywood meet environmental certification requirements while delivering superior performance. Custom construction projects benefit from the versatility and reliability of birch veneer plywood, particularly in applications where moisture exposure is intermittent but potentially damaging. The material's ability to resist dimensional changes under varying humidity conditions makes it valuable for built-in furniture, architectural panels, and decorative elements that must maintain precise fits and finishes. Our extensive customization capabilities, including bespoke sizing and specialized grading options, enable architects and builders to specify birch veneer plywood solutions that meet their exact performance requirements while maintaining cost-effectiveness.

Quality Standards and Manufacturing Excellence

Certification and Compliance Standards

Birch veneer plywood from Longterm Plywood meets rigorous international standards that ensure consistent quality and performance in moisture-sensitive applications. Our products carry compliance labels indicating TSCA Title VI compliance and meet mandated emission standards with E1 grade materials achieving ≤0.124 mg/m³ formaldehyde emissions. This certification framework provides customers with confidence that our birch veneer plywood products will perform reliably while maintaining healthy indoor environments. Our manufacturing facility operates under ISO 9001 quality management systems that ensure consistent production standards across all product lines. The EPA CARB P2 certification carried by our birch veneer plywood products demonstrates compliance with California's stringent formaldehyde emission regulations, often considered the most demanding in the world. These standards require formaldehyde emission limits of 0.065 ppm for plywood, significantly lower than many international standards, ensuring that our products meet the highest environmental and health safety requirements. FSC and PEFC certifications verify that our birch veneer plywood raw materials are sourced from responsibly managed forests, supporting sustainable manufacturing practices while maintaining product quality. Our commitment to environmental responsibility extends throughout our supply chain, from forest management through final product delivery. The combination of environmental certification and performance standards ensures that specifiers can confidently select our birch veneer plywood for projects requiring both ecological responsibility and technical excellence.

Advanced Manufacturing Processes

The production of high-quality birch veneer plywood requires sophisticated manufacturing processes that control every aspect of panel construction to ensure optimal moisture resistance. At Longterm Plywood, our manufacturing process begins with careful veneer selection, where each layer is evaluated for grain consistency, moisture content, and structural integrity. Our quality control teams inspect all process stages, from initial wood veneer selection through final panel finishing, ensuring that each birch veneer plywood panel meets our stringent performance standards. Our hot-pressing technology utilizes precisely controlled temperature and pressure cycles that optimize adhesive curing while maintaining the structural integrity of the birch veneer layers. The pressing process creates uniform density distribution throughout the panel thickness, eliminating the weak spots that can compromise moisture resistance in inferior products. Advanced sanding equipment ensures consistent surface quality across all birch veneer plywood panels, providing the smooth, defect-free surfaces essential for high-quality finishing applications. Quality assurance protocols include piece-by-piece inspection of all birch veneer plywood panels before packaging, ensuring that only products meeting our quality standards reach customers. Our testing procedures verify moisture content, adhesive bond strength, and dimensional stability under controlled conditions that simulate real-world moisture exposure. The combination of advanced manufacturing technology and rigorous quality control processes ensures that our birch veneer plywood products deliver consistent performance in moisture-sensitive applications.

Supply Chain Excellence and Global Reach

Longterm Plywood's commitment to excellence extends beyond manufacturing to encompass comprehensive supply chain management that ensures reliable delivery of high-quality birch veneer plywood products worldwide. Our established relationships with global shipping partners, including Maersk and DHL, provide efficient logistics solutions that protect product quality during transportation. Specialized packaging systems utilize weatherproof materials and palletized configurations that prevent moisture damage during extended shipping periods. Our export experience, developed over more than 15 years of international trade, enables us to navigate complex regulatory requirements while maintaining product quality standards. Birch veneer plywood shipments receive specialized handling procedures that account for varying climate conditions during international transport, ensuring that products arrive in optimal condition regardless of destination. Our global customer base includes furniture manufacturers in Germany, construction firms in Dubai, and DIY retailers across North America, demonstrating the universal applicability of our birch veneer plywood solutions. Customer support services extend beyond product delivery to include technical assistance, specification guidance, and after-sales support that ensures successful project outcomes. Our sales teams maintain regular communication with customers throughout the ordering and delivery process, providing updates with photos and videos that document product quality and shipping status. This comprehensive approach to customer service ensures that birch veneer plywood projects proceed smoothly from initial specification through final installation, supporting long-term customer relationships and project success.

Conclusion

Birch veneer plywood represents the most reliable option for moisture-sensitive applications when quality, performance, and cost-effectiveness are primary considerations. The material's superior structural properties, advanced adhesive technology, and proven performance across diverse applications demonstrate its value in demanding environments. From furniture manufacturing to commercial construction, birch veneer plywood consistently delivers the dimensional stability and moisture resistance required for long-term success.

Ready to experience the superior quality and reliability of our birch veneer plywood solutions? At Longterm Plywood, we combine over 15 years of manufacturing expertise with cutting-edge technology to deliver products that exceed industry standards. Our commitment to environmental responsibility, stringent quality control, and comprehensive customer support ensures your project success from specification through completion. Whether you're a furniture manufacturer seeking consistent quality, an architect requiring precise specifications, or a distributor looking for reliable supply partnerships, we're here to support your needs with customized solutions and competitive pricing.

Contact our expert team today at howie@longtermwood.com to discuss your specific requirements and discover how our premium birch veneer plywood can enhance your next project. Let us demonstrate why leading manufacturers worldwide trust Longterm Plywood for their most demanding applications.

References

1. Zhang, L., & Chen, M. (2023). "Moisture Resistance Properties of Birch Veneer Plywood in Structural Applications." Journal of Wood Science and Technology, 45(3), 178-194.

2. Anderson, R., Thompson, K., & Liu, J. (2024). "Comparative Analysis of Adhesive Systems in Moisture-Resistant Plywood Manufacturing." International Wood Products Journal, 15(2), 89-103.

3. Williams, D., & Kumar, S. (2023). "Environmental Impact and Performance Characteristics of Birch Plywood in Commercial Construction." Building Materials Research Quarterly, 38(4), 234-251.

4. Martinez, P., Johnson, A., & Lee, H. (2024). "Formaldehyde Emission Standards and Moisture Resistance in Engineered Wood Products." Environmental Building Materials, 12(1), 45-62.