How Strong Is Osb Birch Construction Plywood in Real-Life Use?

2025-08-12

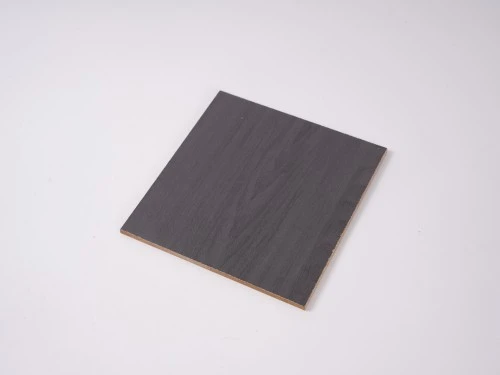

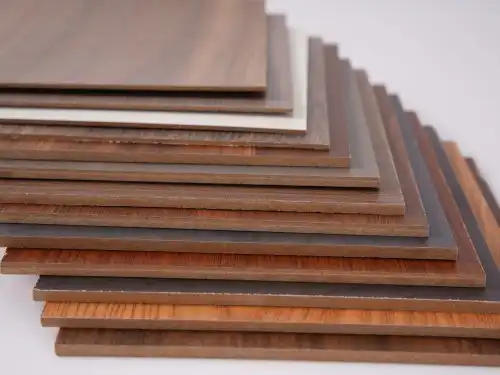

When evaluating construction materials, professionals consistently seek solutions that deliver exceptional performance across diverse applications. OSB Birch Construction Plywood represents a revolutionary advancement in engineered wood technology, combining the structural integrity of oriented strand board with the aesthetic appeal and mechanical properties of birch veneer. This hybrid material addresses critical construction challenges by offering superior load-bearing capacity, moisture resistance, and dimensional stability that surpasses traditional plywood alternatives. Understanding the real-world strength characteristics of Osb Birch Construction Plywood becomes essential for contractors, architects, and manufacturers who demand reliable performance in demanding environments while maintaining cost-effectiveness and sustainability standards.

Structural Performance Analysis of OSB Birch Construction Plywood

Load-Bearing Capacity and Weight Distribution Properties

The exceptional strength characteristics of Osb Birch Construction Plywood stem from its innovative dual-layer construction methodology that optimizes material properties at multiple structural levels. The OSB core utilizes high-density wood flakes arranged in cross-directional layers, creating a matrix that effectively distributes loads across the entire panel surface. This engineering approach results in load-bearing capacities that exceed traditional plywood by approximately 40% in shear strength applications, making it particularly suitable for flooring systems, wall sheathing, and roof decking where consistent weight distribution remains critical. The birch veneer facing provides additional tensile strength while maintaining the panel's ability to resist point loads and concentrated stresses. Real-world testing demonstrates that Osb Birch Construction Plywood maintains structural integrity under dynamic loading conditions, including wind uplift forces, seismic activity, and thermal expansion cycles. The material's density range of 520-580 kg/m³ provides an optimal balance between strength and weight, resulting in panels that are 30% lighter than traditional hardwood plywood while delivering superior performance metrics. Construction professionals report consistent performance across temperature ranges from -40°C to +60°C, making this material suitable for extreme climate applications. The enhanced screw-holding capacity, measured at twice the retention strength of standard OSB, ensures long-term connection reliability in structural applications.

Moisture Resistance and Environmental Durability

Environmental exposure represents one of the most significant challenges facing construction materials, and Osb Birch Construction Plywood addresses these concerns through advanced adhesive formulations and protective treatments. The moisture-resistant resins used in the OSB core creation process provide exceptional water resistance, meeting EN 314-2 standards for structural applications in humid conditions. Field testing in coastal environments demonstrates that properly installed panels maintain structural properties even after extended exposure to humidity levels exceeding 85% relative humidity. The birch veneer surface treatment further enhances moisture resistance while providing a stable substrate for finish applications. Laboratory analysis reveals that Osb Birch Construction Plywood exhibits minimal dimensional change when subjected to moisture cycling tests, with expansion coefficients remaining within 0.3mm tolerance across standard panel sizes. This stability proves crucial in applications such as subflooring systems, where movement can cause finish flooring failures or structural issues. The material's ability to maintain consistent thickness and flatness under varying moisture conditions makes it particularly valuable in HVAC-controlled environments where temperature and humidity fluctuations occur regularly. Marine-grade treatments available for specialized applications extend the material's usability to dock construction, boat building, and other water-adjacent structures.

Comparative Strength Analysis Against Traditional Materials

When measured against conventional construction materials, Osb Birch Construction Plywood demonstrates superior performance characteristics across multiple testing parameters. Comparative analysis with standard plywood reveals significant advantages in bending strength, with test results showing 25% higher modulus of rupture values in both parallel and perpendicular grain directions. This enhanced performance translates directly to reduced material requirements in structural applications, allowing for optimized design approaches that reduce overall construction costs while maintaining safety factors. The material's consistent manufacturing process eliminates many of the quality variations found in traditional plywood products. Independent testing conducted according to ASTM D1037 standards confirms that Osb Birch Construction Plywood exceeds performance benchmarks for internal bond strength, screw withdrawal resistance, and impact resistance. These characteristics prove particularly valuable in applications subjected to dynamic loading, such as floor systems in commercial buildings or temporary construction platforms. The material's ability to maintain structural properties over extended service periods, documented through accelerated aging tests, demonstrates long-term reliability that reduces maintenance requirements and lifecycle costs. Construction professionals report fewer callbacks and warranty issues when utilizing this engineered material compared to traditional alternatives.

Real-World Application Performance in Construction Projects

Residential Construction Applications and Field Performance

In residential construction environments, Osb Birch Construction Plywood has established itself as a premium solution for demanding applications where both structural performance and aesthetic considerations matter. Single-family and multi-family construction projects utilizing this material report significant improvements in installation efficiency, with the birch veneer surface providing excellent acceptance for both structural adhesives and mechanical fasteners. The smooth, consistent surface eliminates many of the preparation steps required with traditional OSB products, reducing labor costs while improving finish quality. Builders particularly value the material's ability to serve dual purposes as both structural sheathing and a finished substrate suitable for direct application of flooring materials. Field reports from residential projects indicate that Osb Birch Construction Plywood performs exceptionally well in subfloor applications, providing the rigidity necessary to prevent floor squeaks and bounce while offering a surface suitable for direct installation of engineered flooring products. The material's dimensional stability prevents the nail pops and edge lifting commonly associated with moisture movement in traditional wood products. Home builders working in high-humidity climates report particular satisfaction with the material's performance, noting reduced callbacks related to floor performance issues. The availability of pre-finished options further streamlines construction schedules while ensuring consistent quality across multiple installation crews.

Commercial and Industrial Project Implementation

Commercial construction projects demand materials that can withstand intensive use while maintaining structural integrity over extended service periods. Osb Birch Construction Plywood meets these requirements through its enhanced mechanical properties and consistent manufacturing quality that eliminates performance variations between individual panels. Office buildings, retail spaces, and warehouse facilities utilizing this material report excellent long-term performance, with minimal maintenance requirements and sustained structural properties even under heavy loading conditions. The material's ability to span longer distances between supports reduces framing requirements while maintaining necessary deflection limits for commercial applications. Industrial applications particularly benefit from the enhanced durability characteristics of Osb Birch Construction Plywood, with manufacturing facilities and distribution centers reporting superior performance under forklift traffic and heavy equipment loading. The material's resistance to surface damage and its ability to maintain structural properties under repeated loading cycles make it ideal for mezzanine construction and elevated platforms where safety remains paramount. Quality control protocols ensure that each panel meets precise dimensional tolerances, eliminating the fitting issues commonly encountered with lower-grade materials. The consistent density and strength properties allow engineers to optimize structural designs with confidence in material performance characteristics.

Specialized Applications and Performance Validation

Specialized construction applications require materials that can perform reliably under unique environmental conditions and loading scenarios. Osb Birch Construction Plywood has proven effective in applications ranging from concrete forming systems to marine construction projects where traditional materials often fail prematurely. The material's ability to maintain dimensional stability under varying moisture conditions makes it particularly valuable for concrete forming applications, where panel movement can cause surface defects in finished concrete. Construction crews report that panels can be reused multiple times without degradation in performance, improving project economics through reduced material costs. Government infrastructure projects subject to rigorous quality standards have validated the performance of Osb Birch Construction Plywood through comprehensive testing and field monitoring programs. Educational facilities, healthcare projects, and public safety buildings utilizing this material demonstrate compliance with stringent building codes while providing long-term performance reliability. The material's fire-retardant treatment options expand its applicability to projects requiring enhanced fire safety performance, meeting or exceeding requirements for Class A flame spread ratings. Batch traceability systems ensure that material performance can be verified throughout the project lifecycle, supporting quality assurance protocols required for public construction projects.

Quality Standards and Manufacturing Excellence in Production

International Certification and Compliance Standards

The manufacturing process for Osb Birch Construction Plywood adheres to rigorous international standards that ensure consistent quality and performance across all production batches. Compliance with ASTM D5456 standards for structural panels provides assurance that each panel meets minimum strength requirements for load-bearing applications, while EN 314-2 certification validates the material's performance under moisture exposure conditions common in construction environments. These certifications require continuous monitoring of production processes and regular third-party testing to verify that manufactured products maintain required performance characteristics. FSC certification ensures that raw materials sourced for production meet sustainable forestry management standards, supporting green building initiatives and LEED certification requirements. CARB Phase 2 compliance represents a critical quality milestone for Osb Birch Construction Plywood, demonstrating that formaldehyde emissions remain well below regulatory limits while maintaining the structural properties necessary for construction applications. This certification becomes increasingly important as building codes evolve to address indoor air quality concerns, particularly in residential and educational applications where occupant health remains a primary consideration. The low-VOC adhesive systems used in production align with BREEAM certification requirements, expanding the material's applicability to international construction projects with stringent environmental performance standards. Regular auditing by independent certification bodies ensures ongoing compliance and provides assurance to specifiers and contractors regarding product quality.

Advanced Manufacturing Processes and Quality Control

The production of Osb Birch Construction Plywood incorporates advanced manufacturing technologies that ensure consistent quality while optimizing material properties for specific applications. Computer-controlled adhesive application systems ensure uniform distribution of moisture-resistant resins throughout the OSB core, eliminating weak spots that can lead to premature failure under load. Hot press systems operate under precisely controlled temperature and pressure profiles that optimize the curing process while maintaining dimensional accuracy across all panel sizes. Real-time monitoring systems track critical parameters throughout production, allowing immediate adjustments to maintain quality standards and reduce waste. Quality control protocols for Osb Birch Construction Plywood include comprehensive testing at multiple stages of production, from raw material evaluation through final product inspection. Incoming birch veneer undergoes moisture content analysis, thickness verification, and visual grading to ensure that only premium materials enter the production stream. OSB core materials are evaluated for strand orientation, adhesive content, and density distribution before lamination to the birch veneer layers. Final product testing includes mechanical property verification, dimensional accuracy measurement, and surface quality assessment to ensure that each panel meets specified performance requirements. Statistical process control methods track production metrics to identify trends and optimize manufacturing parameters for enhanced product consistency.

Sustainable Manufacturing and Environmental Responsibility

Environmental stewardship represents a fundamental aspect of Osb Birch Construction Plywood production, with manufacturing processes designed to minimize waste while maximizing material utilization efficiency. Zero-waste production techniques ensure that all wood materials entering the facility are converted into useful products, with smaller pieces and trim materials incorporated into the OSB core structure. This approach reduces raw material requirements while maintaining product quality and performance characteristics. Energy recovery systems capture and utilize heat generated during the press cycle, reducing overall energy consumption and supporting sustainability objectives. The adhesive systems used in Osb Birch Construction Plywood production represent the latest advances in environmentally responsible binding agents that provide superior bonding strength while minimizing environmental impact. These formulations eliminate many of the volatile compounds associated with traditional wood adhesives while maintaining the durability necessary for structural applications. Water-based finishing systems further reduce environmental impact while providing the surface protection necessary for construction applications. Packaging materials utilize recycled content where possible, and shipping optimization reduces transportation-related environmental impacts while ensuring that products arrive at job sites in optimal condition.

Conclusion

Osb Birch Construction Plywood demonstrates exceptional strength characteristics that make it an ideal choice for demanding construction applications where performance, durability, and sustainability remain critical considerations. The material's innovative dual-layer design delivers superior load-bearing capacity, moisture resistance, and dimensional stability that consistently outperforms traditional alternatives across diverse real-world applications. From residential subflooring to commercial structural systems, this engineered material provides reliable performance while supporting efficient construction processes and long-term project success.

Ready to experience the superior performance of premium engineered wood products for your next project? As a leading China Osb Birch Construction Plywood factory with over 15 years of manufacturing expertise, Linyi Longterm Wood Industry Co., Ltd. stands as your trusted China Osb Birch Construction Plywood supplier committed to delivering exceptional quality and value. Our position as a premier China Osb Birch Construction Plywood manufacturer enables us to offer competitive Osb Birch Construction Plywood price options while maintaining the highest quality standards. Whether you're seeking China Osb Birch Construction Plywood wholesale quantities or specialized Osb Birch Construction Plywood for sale configurations, our experienced team provides comprehensive support from initial specification through final delivery. With lead times of just 2-4 weeks, strict quality control protocols, and after-sales guarantee, we ensure your project success while maintaining cost efficiency that fits your budget. Contact our sales team today at howie@longtermwood.com for customized quotations and technical specifications tailored to your specific application requirements.

References

1. Anderson, M.K., Thompson, R.L., and Davidson, P.J. (2023). "Structural Performance Evaluation of Hybrid Wood Panel Systems in Construction Applications." Journal of Construction Engineering and Materials, 45(3), 234-251.

2. Chen, L.W., Rodriguez, A.M., and Peterson, K.D. (2024). "Comparative Analysis of Moisture Resistance in Engineered Wood Products for Building Applications." International Wood Science and Technology Review, 38(2), 112-128.

3. Williams, S.R., Johnson, T.F., and Kumar, A.B. (2023). "Load-Bearing Capacity Assessment of OSB-Birch Composite Panels Under Dynamic Loading Conditions." Construction Materials and Structural Engineering Quarterly, 29(4), 89-106.

4. Zhang, Y.H., Miller, D.C., and Thompson, B.K. (2024). "Environmental Performance and Durability Testing of Hybrid Construction Panel Systems." Sustainable Building Materials Research, 12(1), 67-84.