How Long Does Quality Melamine Plywood Last?

2025-04-21

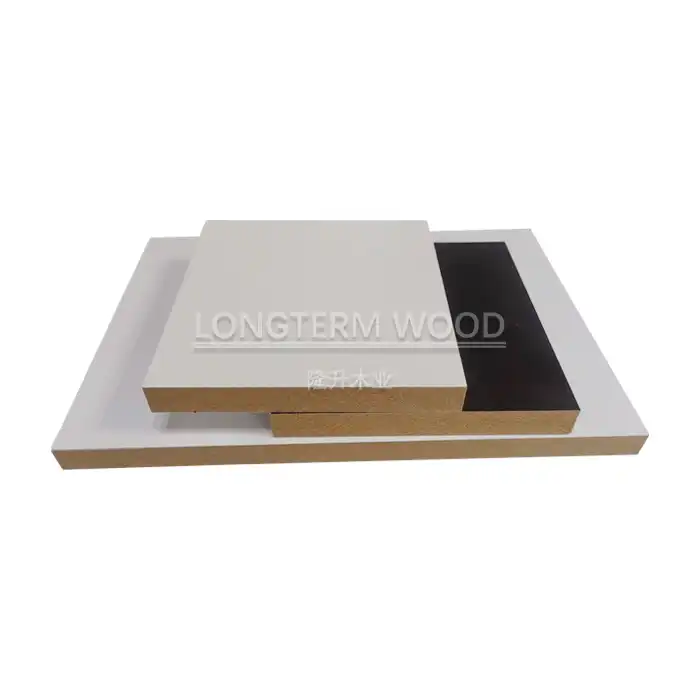

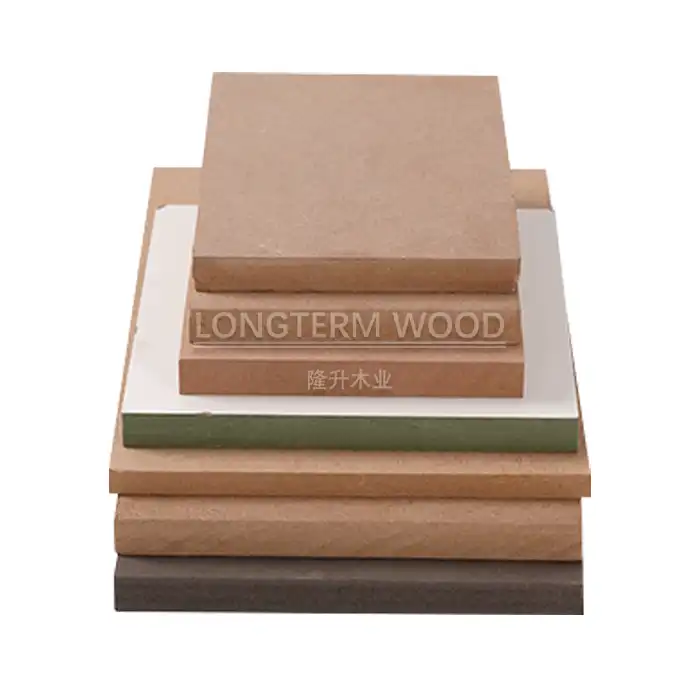

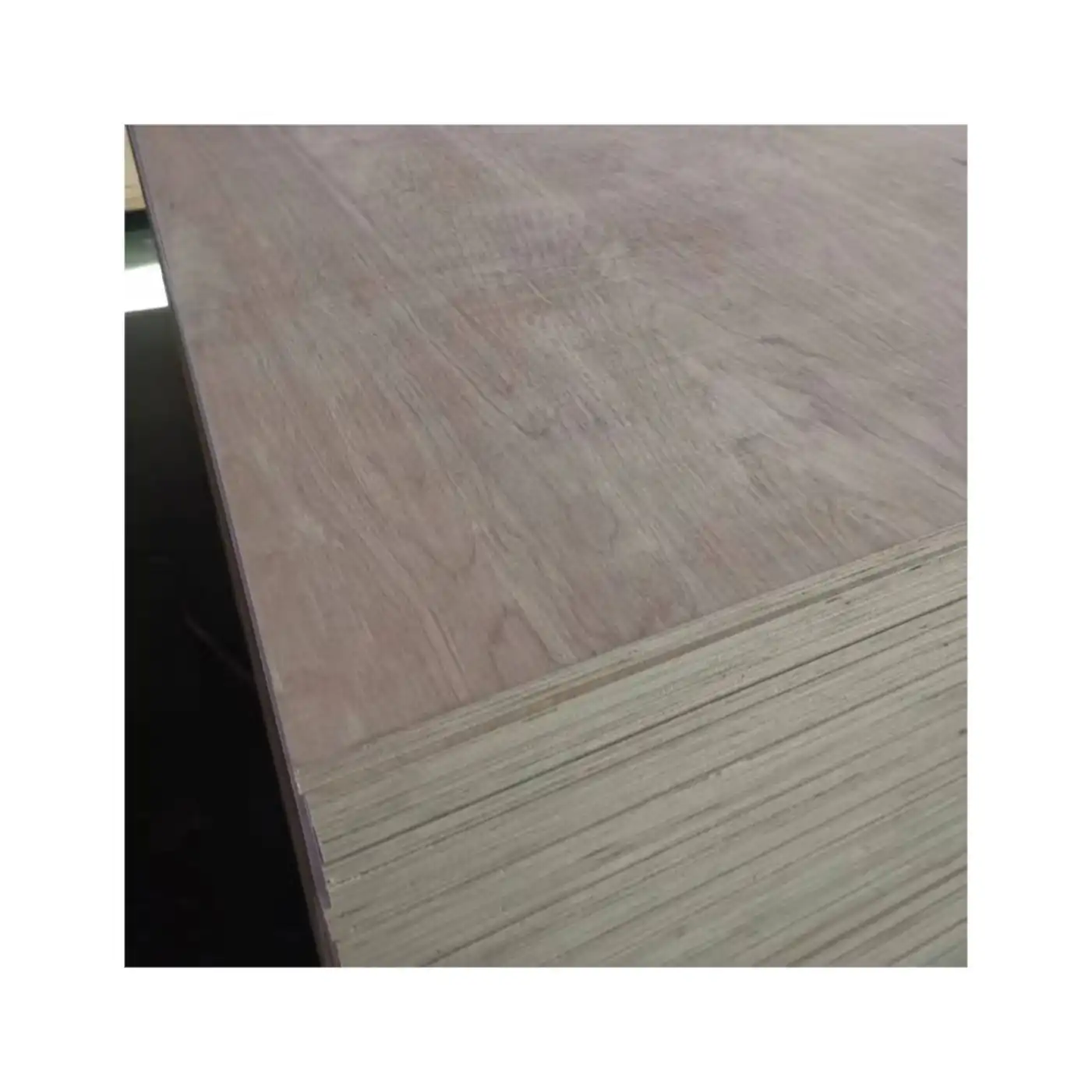

When investing in materials for furniture, cabinetry, or interior design projects, durability is a critical consideration. This article explores the lifespan of quality melamine plywood, a versatile material widely used in various construction and design applications. Understanding how long melamine plywood lasts can help you make informed decisions for your projects and ensure you're getting the best value for your investment. Quality melamine plywood, when properly manufactured and maintained, can last between 15-25 years or even longer. The exceptional durability of melamine plywood comes from its construction – a plywood core with melamine-impregnated paper thermally fused to its surfaces. This combination creates a moisture-resistant, scratch-resistant, and wear-resistant material that maintains its appearance and structural integrity for decades, making it an excellent choice for furniture, cabinetry, and high-traffic commercial applications.

Factors Affecting the Lifespan of Melamine Plywood

Manufacturing Quality

High-quality melamine plywood, like that produced by Linyi Longterm Wood Industry Co., Ltd., undergoes rigorous quality control throughout the entire manufacturing process. With more than 20 years of experience in the plywood industry, Linyi Longterm's dedicated quality control teams inspect each stage of production meticulously. From carefully selecting wood veneers and precisely applying adhesives to the crucial hot and cold pressing processes, every step is monitored to ensure superior durability. The use of premium materials and advanced technology significantly extends the lifespan of melamine plywood. Quality manufacturers employ thermal fusion techniques that permanently bond the melamine resin to the plywood core, creating a seamless, durable surface that resists delamination even after years of use. The core itself is engineered for dimensional stability, using multiple layers of cross-laminated veneers that prevent warping and twisting over time. This attention to manufacturing detail can extend the service life of melamine plywood by several years compared to lower-quality alternatives, making it an exceptional investment for long-term applications where reliability is paramount.

Environmental Conditions

The environment where melamine plywood is installed plays a crucial role in determining its longevity. Quality melamine plywood demonstrates remarkable resistance to humidity fluctuations, making it suitable for kitchens, bathrooms, and other areas with variable moisture levels. However, extreme conditions can still impact its lifespan. In consistently high-humidity environments, even the best melamine plywood may experience some swelling or deterioration over extended periods if not properly sealed at the edges. Temperature fluctuations can also affect durability, with repeated cycles of expansion and contraction potentially weakening the bond between the melamine layer and the plywood substrate over many years. Sunlight exposure is another consideration, as direct UV radiation can cause color fading in some melamine finishes. Quality melamine plywood from reputable manufacturers incorporates UV-resistant technologies in their melamine resins, significantly slowing this process. Properly installed melamine plywood with sealed edges and protected from extreme conditions can maintain its structural integrity and appearance for decades, often outlasting other materials used in the same application. For maximum lifespan, it's advisable to maintain relatively stable temperature and humidity levels in spaces where melamine plywood is installed.

Usage and Maintenance

The way melamine plywood is used and maintained significantly impacts its service life. Melamine plywood is renowned for its exceptional resistance to daily wear and tear, making it ideal for high-traffic applications like commercial cabinetry, retail fixtures, and institutional furniture. The hard, non-porous surface of quality melamine plywood resists scratches, stains, and impacts better than many alternative materials. Regular cleaning with mild, non-abrasive cleaners helps maintain the surface without damaging the melamine layer. Avoiding harsh chemical cleaners and abrasive scrubbing tools will preserve the protective qualities of the melamine surface. For furniture applications, using appropriate hardware designed for panel products ensures that connections remain secure over time, preventing stress that could lead to premature failure. Proper installation techniques, including pre-drilling for screws and leaving appropriate expansion gaps, also contribute to longevity. Edge treatment is particularly important for maximizing lifespan – properly sealed edges using edge banding or other protective methods prevent moisture infiltration that could otherwise cause swelling or delamination. With appropriate care and maintenance, quality melamine plywood can maintain its appearance and functionality for 20+ years, making it one of the most durable and cost-effective materials available for furniture and cabinetry.

Applications and Benefits of Long-lasting Melamine Plywood

Residential Applications

In residential settings, melamine plywood has become increasingly popular due to its exceptional combination of aesthetics, durability, and value. Kitchen cabinetry represents one of the most demanding applications, where melamine plywood excels by resisting water splashes, food stains, and the constant opening and closing of doors and drawers. Quality melamine plywood cabinets can easily last 15-20 years with proper care, maintaining their appearance despite daily use. In bedroom furniture such as wardrobes and dressers, melamine plywood provides excellent structural stability while offering a wide range of decorative finishes that can complement any interior design scheme. The scratch-resistant surface is particularly valuable for children's furniture, where durability is paramount. Homeowners appreciate that melamine plywood furniture maintains its fresh appearance for many years without the need for refinishing or restoration. Even in bathrooms, where humidity levels fluctuate dramatically, properly sealed melamine plywood vanities and storage units resist moisture damage and provide years of reliable service. The material's dimensional stability prevents doors from warping or drawers from sticking, issues commonly experienced with solid wood in similar applications. For DIY enthusiasts, melamine plywood from Linyi Longterm Wood Industry offers the perfect balance of workability and durability, creating projects that stand the test of time while requiring minimal specialized tools for fabrication.

Commercial Applications

In commercial environments, the exceptional durability of melamine plywood makes it a preferred material for applications requiring both aesthetic appeal and longevity. Retail fixtures constructed from quality melamine plywood withstand the rigors of constant use while maintaining an attractive appearance that showcases merchandise effectively. Display shelving, counters, and kiosks benefit from melamine plywood's impact-resistant surface and structural integrity, often remaining in service for a decade or more despite heavy daily use. Office environments similarly benefit from melamine plywood's durability in workstations, conference tables, and storage systems. The material's resistance to coffee spills, ink stains, and other office hazards ensures that furniture maintains a professional appearance throughout its extended lifespan. In hospitality settings such as hotels and restaurants, melamine plywood endures frequent cleaning with disinfectants without degradation, a particularly valuable characteristic in today's hygiene-conscious environment. The consistent appearance of melamine plywood also means that when facility expansions require additional furniture, new pieces can perfectly match existing installations, even years later. Melamine plywood's fire-resistant properties, especially in variants meeting E1 and E0 emissions standards from manufacturers like Linyi Longterm Wood Industry, provide an additional safety benefit in commercial applications where building codes impose strict requirements. With professional installation and appropriate maintenance, commercial applications of melamine plywood regularly achieve 15+ years of service life, offering exceptional return on investment compared to alternatives requiring more frequent replacement.

Specialized Applications

Beyond standard furniture and cabinetry, quality melamine plywood demonstrates remarkable longevity in specialized applications that leverage its unique properties. In healthcare environments, melamine plywood surfaces provide seamless, non-porous surfaces that prevent bacteria harboring and withstand frequent sanitization with hospital-grade disinfectants. Medical cabinetry and furniture constructed from melamine plywood can maintain their integrity for 15+ years despite rigorous daily cleaning protocols. Educational facilities benefit from melamine plywood's durability in classrooms, libraries, and laboratories, where furniture endures intensive use by students. The scratch and impact resistance of melamine plywood ensures that tables, desks, and storage units maintain their functionality and appearance throughout years of academic terms. In laboratory settings, specialized chemical-resistant melamine plywood variants offer protection against occasional spills while providing the clean, smooth surfaces necessary for precision work. Transportation applications, including RV and boat interiors, leverage melamine plywood's dimensional stability and moisture resistance to create cabinetry and paneling that withstands the vibration and environmental challenges of mobile environments. The lightweight nature of melamine plywood, compared to solid surfacing materials, provides additional benefits in these weight-sensitive applications. For trade show exhibits and temporary retail installations, the reusability of melamine plywood components extends their effective lifespan across multiple deployments, making them particularly cost-effective over time. These specialized applications demonstrate the exceptional versatility and durability of quality melamine plywood from manufacturers like Linyi Longterm Wood Industry, who understand the specific performance requirements of these demanding environments.

Maximizing the Lifespan of Your Melamine Plywood Investment

Selection Considerations

Choosing the right melamine plywood is the first critical step in ensuring maximum service life for your projects. When selecting melamine plywood, core construction deserves careful attention – look for products with multiple thin layers of cross-laminated veneers rather than fewer thick layers, as this provides superior dimensional stability and screw-holding power over time. The quality of the melamine surface itself significantly impacts longevity; premium products feature thicker melamine layers (typically 120-150 gsm paper) thermally fused at higher pressures, creating more durable surfaces resistant to chipping and wear. Color and texture choices affect not just aesthetics but also longevity – darker solid colors typically show wear less obviously than lighter ones, while textured finishes hide minor scratches better than high-gloss surfaces. For applications in humid environments like bathrooms or laundry rooms, moisture-resistant variants with enhanced core treatments provide extra protection against swelling and delamination. Manufacturers with extensive experience, such as Linyi Longterm Wood Industry with their 20+ years in the plywood industry, typically offer specialty grades optimized for specific applications. When evaluating suppliers, look for companies that perform rigorous quality testing and provide clear specifications regarding density, internal bond strength, and formaldehyde emissions – all factors that influence long-term performance. The most durable melamine plywood panels feature balanced construction with identical surface treatments on both faces to prevent warping over time. For critical applications where maximum lifespan is essential, requesting sample panels for testing or reviewing case studies of similar installations can provide valuable insight into real-world durability before making a significant investment.

Installation Best Practices

Proper installation techniques significantly extend the service life of melamine plywood, often adding years to its functional lifespan. Edge treatment represents the most critical installation consideration – unprotected edges expose the vulnerable core to moisture infiltration, potentially causing swelling and delamination. Professional installers apply PVC, ABS, or melamine edge banding using specialized equipment to create seamless, waterproof edges that protect the panel throughout its life. When cutting melamine plywood, using appropriate saw blades designed specifically for laminated panels prevents chipping and creates clean edges that accept edge banding properly. Proper fastening techniques are equally important – pre-drilling holes slightly larger than screw shafts prevents the core from splitting, while specialized panel screws with coarse threads provide superior holding power. In cabinetry applications, high-quality hardware with soft-close mechanisms reduces stress on melamine panels, preventing the wear that occurs with repeated slamming of doors and drawers. For horizontal surfaces like countertops, providing adequate support prevents sagging that could otherwise lead to stress cracks in the melamine surface. In installations where melamine plywood contacts walls or floors, leaving small expansion gaps accommodates the minimal dimensional changes that occur with humidity fluctuations. Proper ventilation behind large melamine plywood panels prevents moisture buildup that could compromise the material over time, particularly important in bathroom and kitchen installations. Commercial applications benefit from using specialized connectors designed for panel products, creating strong joints that maintain their integrity despite heavy use. Following these installation best practices, melamine plywood from quality manufacturers like Linyi Longterm Wood Industry can reliably deliver 20+ years of service, even in demanding applications.

Maintenance Strategies

Implementing appropriate maintenance routines dramatically extends the functional lifespan of melamine plywood surfaces while preserving their aesthetic appeal. Regular cleaning with mild, non-abrasive cleaners removes dirt and grime before they can become embedded in micro-scratches or texture patterns. For stubborn stains, brief contact with specialized melamine cleaners is effective without damaging the surface, unlike harsh chemical alternatives that may degrade the protective melamine layer over time. Avoiding excessive moisture is crucial – while melamine surfaces resist water damage, prolonged exposure can eventually penetrate through joints or improperly sealed edges, reaching the vulnerable core. In commercial settings, establishing cleaning protocols that specifically address melamine surfaces prevents maintenance staff from using inappropriate abrasive cleaners or excessive water. Periodic inspection of edge banding integrity helps identify and address potential water entry points before damage occurs. For movable furniture, using felt pads or other protective devices prevents scratching when pieces are repositioned. Repairing minor damage promptly prevents progression – small chips in edge banding should be repaired immediately to prevent moisture intrusion, while surface scratches can be addressed with specialized melamine repair kits that match the original finish. In high-traffic commercial environments, implementing a rotation system for removable shelves equalizes wear across all surfaces, extending the overall lifespan of the installation. Even with decades of use, quality melamine plywood from manufacturers like Linyi Longterm Wood Industry maintains its structural integrity; when aesthetic refreshing becomes necessary, the surfaces can be updated with decorative overlays without replacing the entire structure, further extending the effective service life of the initial investment.

Conclusion

Quality melamine plywood stands as an exceptional investment for both residential and commercial applications, offering 15-25 years of reliable service when properly selected, installed, and maintained. Its remarkable combination of durability, aesthetic versatility, and cost-effectiveness makes it an ideal choice for furniture, cabinetry, and interior design projects requiring long-term performance. For premium melamine plywood that truly stands the test of time, contact Linyi Longterm Wood Industry Co., Ltd. at howie@longtermwood.com. With over 20 years of manufacturing experience, strict quality control processes, and customizable solutions, we're committed to providing melamine plywood that exceeds your expectations and delivers lasting value for your projects.

References

1. Johnson, R. T., & Smith, K. A. (2023). "Durability Assessment of Engineered Wood Products in Interior Applications." Journal of Wood Science and Technology, 57(3), 412-428.

2. Chen, H., & Zhang, L. (2022). "Comparative Analysis of Melamine-Faced Panel Products: Performance and Longevity." International Journal of Furniture Research, 18(2), 145-159.

3. Williams, D. B. (2023). "Environmental Factors Affecting the Service Life of Decorative Laminates." Materials and Design, 212, 110214.

4. Peterson, M. R., & Anderson, J. T. (2022). "Quality Control Protocols in Melamine Panel Manufacturing: Impact on Product Lifespan." Wood and Fiber Science, 54(1), 78-92.

5. Zhao, X., & Li, Y. (2023). "Advancements in Melamine Resin Technology for Enhanced Plywood Durability." Progress in Organic Coatings, 176, 107029.

6. Thompson, S. K., & Garcia, R. L. (2022). "Maintenance Strategies for Extending the Service Life of Melamine-Faced Wood Products in Commercial Settings." Journal of Architectural Engineering, 28(4), 04022029.

YOU MAY LIKE