How Does the Best Commercial Plywood Support Green Building and Sustainability Goals?

2025-07-18

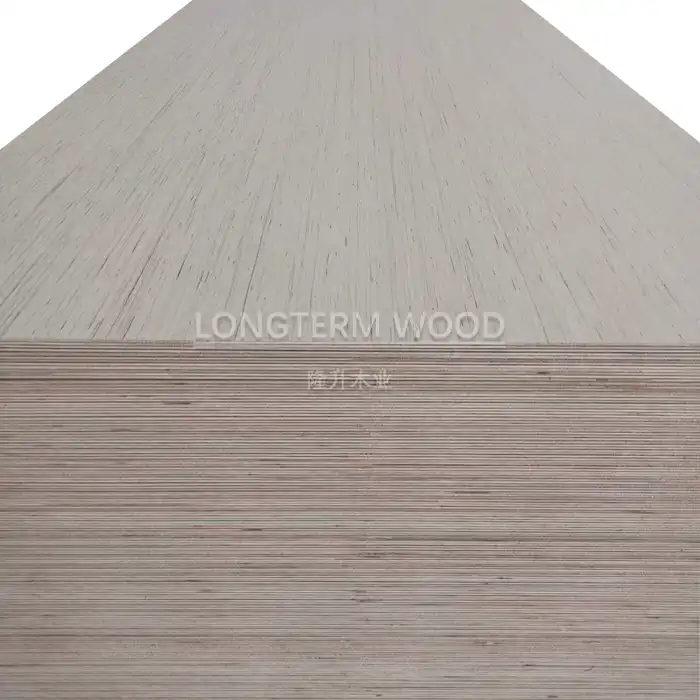

In today's construction industry, the pursuit of sustainable building practices has become more than just a trend—it's a necessity. As environmental consciousness grows and regulatory frameworks tighten, the choice of building materials plays a crucial role in achieving green building certifications and meeting sustainability objectives. The Best Commercial Plywood emerges as a cornerstone material that not only meets structural requirements but also aligns with environmental stewardship principles. This comprehensive guide explores how premium commercial plywood supports green building initiatives through responsible sourcing, low-emission manufacturing, and long-term durability that reduces environmental impact while maintaining the highest standards of performance and reliability.

Environmental Certification and Responsible Sourcing Standards

Forest Stewardship Council (FSC) Certification and Sustainable Forestry

The foundation of sustainable commercial plywood begins with responsible forest management, and FSC certification represents the gold standard in this regard. Best Commercial Plywood sourced from FSC-certified forests ensures that the wood comes from responsibly managed forests that provide environmental, social, and economic benefits. These forests are managed according to strict environmental standards that protect biodiversity, water quality, and wildlife habitats while respecting the rights of local communities and workers. The FSC Chain of Custody certification tracks the wood from forest to final product, providing complete transparency and accountability throughout the supply chain. This certification process involves regular third-party audits and monitoring to ensure compliance with sustainable forestry practices. When contractors and builders choose FSC-certified Best Commercial Plywood, they contribute to the preservation of forest ecosystems while supporting local communities that depend on these resources for their livelihoods.

PEFC Certification and Global Forest Sustainability

The Programme for the Endorsement of Forest Certification (PEFC) provides another crucial certification framework for Best Commercial Plywood that supports global forest sustainability. PEFC certification ensures that the wood raw materials come from sustainably managed forests where biodiversity is protected, and local communities benefit from forest resources. This certification system covers over 300 million hectares of certified forests worldwide, making it one of the largest forest certification systems globally. Best Commercial Plywood with PEFC certification demonstrates compliance with internationally recognized sustainability standards that address environmental, social, and economic aspects of forest management. The PEFC system promotes continuous improvement in forest management practices, ensuring that future generations will have access to healthy forest ecosystems. This certification also supports the United Nations Sustainable Development Goals, particularly those related to responsible consumption and production, climate action, and life on land.

Chain of Custody Documentation and Transparency

Maintaining complete documentation throughout the supply chain is essential for Best Commercial Plywood to support green building goals effectively. Chain of Custody (CoC) documentation provides detailed tracking of wood materials from their origin in certified forests through processing, manufacturing, and distribution to the final construction site. This transparency allows architects, contractors, and building owners to verify the sustainability credentials of their materials and meet the documentation requirements for green building certifications such as LEED, BREEAM, and Green Globes. The CoC process involves rigorous record-keeping, regular audits, and verification procedures that ensure the integrity of sustainability claims. Best Commercial Plywood manufacturers maintain detailed documentation that includes forest management certificates, processing records, and transportation logs that provide complete traceability. This level of transparency supports the credibility of green building projects and helps building owners demonstrate their commitment to environmental responsibility to stakeholders, regulators, and the public.

Low-Emission Manufacturing and Indoor Air Quality

E0 and E1 Formaldehyde Classification Standards

The formaldehyde emission levels of Best Commercial Plywood play a critical role in supporting green building goals, particularly in maintaining healthy indoor air quality. The E0 classification represents the most stringent standard, with formaldehyde emissions of ≤0.5mg/L, making it the safest option for interior applications. This ultra-low emission level ensures that Best Commercial Plywood contributes to healthier indoor environments while meeting the most demanding green building standards. The E1 standard, with emissions ≤1.5mg/L, provides another excellent option that balances environmental performance with cost-effectiveness. These emission classifications are determined through rigorous testing procedures that simulate real-world conditions over extended periods. Best Commercial Plywood meeting E0 and E1 standards uses advanced adhesive technologies and manufacturing processes that minimize formaldehyde emissions without compromising structural integrity or durability. The adoption of these low-emission materials supports green building certifications by contributing to indoor air quality credits and helping buildings meet strict emission limits required by various certification programs.

CARB Phase 2 and TSCA Title VI Compliance

California Air Resources Board (CARB) Phase 2 and Toxic Substances Control Act (TSCA) Title VI compliance represent crucial regulatory requirements for Best Commercial Plywood in the North American market. These regulations establish strict formaldehyde emission limits that protect public health and support green building initiatives. CARB Phase 2 compliance requires composite wood products to meet specific emission standards, with hardwood plywood limited to 0.005 ppm formaldehyde emissions. TSCA Title VI extends these requirements nationwide, ensuring that all composite wood products sold in the United States meet consistent emission standards. Best Commercial Plywood that achieves CARB Phase 2 and TSCA Title VI compliance undergoes rigorous testing and quality assurance procedures to verify emission levels. This compliance supports green building projects by ensuring that materials meet the highest environmental and health standards while providing the documentation necessary for certification programs. The regulatory framework also includes requirements for third-party certification, ongoing quality assurance testing, and proper labeling that provides transparency to end users about the environmental performance of their building materials.

Eco-Friendly Adhesive Technologies

The development and implementation of eco-friendly adhesive technologies in Best Commercial Plywood manufacturing represent a significant advancement in sustainable building materials. Traditional formaldehyde-based adhesives are being replaced with innovative alternatives such as soy-based adhesives, phenol-resorcinol formaldehyde (PRF) resins, and other bio-based binding agents that reduce environmental impact while maintaining superior bonding strength. These eco-friendly adhesives not only reduce formaldehyde emissions but also improve the overall environmental profile of the finished product. Best Commercial Plywood manufactured with these advanced adhesive systems contributes to healthier indoor environments while supporting green building certification requirements. The research and development of these adhesive technologies involve collaboration between manufacturers, chemical suppliers, and environmental scientists to create solutions that meet both performance and sustainability requirements. These innovations demonstrate the industry's commitment to continuous improvement in environmental performance while maintaining the structural integrity and durability that make commercial plywood an essential building material.

Durability and Lifecycle Assessment Benefits

Long-Term Performance and Reduced Replacement Frequency

The exceptional durability of Best Commercial Plywood directly supports sustainability goals by reducing the frequency of replacement and renovation cycles throughout a building's lifespan. High-quality commercial plywood engineered to withstand moisture, temperature variations, and mechanical stress maintains its structural integrity for decades, minimizing the need for replacement materials and reducing the associated environmental impact of manufacturing, transportation, and disposal. This longevity is achieved through advanced manufacturing processes that ensure consistent quality, proper moisture control, and superior bonding between layers. Best Commercial Plywood with marine-grade adhesives and precision-engineered core construction can withstand extreme conditions while maintaining dimensional stability and structural performance. The extended service life of these materials reduces the total environmental footprint of construction projects by minimizing resource consumption over time. This durability also provides economic benefits to building owners through reduced maintenance costs and extended renovation cycles, making sustainable building practices financially attractive while supporting environmental goals.

Moisture Resistance and Structural Integrity

Superior moisture resistance is a defining characteristic of Best Commercial Plywood that supports long-term sustainability goals by preventing premature failure and the need for costly replacements. Advanced moisture-resistant formulations and manufacturing processes create plywood panels that maintain their structural integrity even in challenging environmental conditions. This resistance is achieved through specialized adhesive systems, proper core construction, and surface treatments that prevent moisture penetration while allowing controlled vapor transmission. Best Commercial Plywood designed for high-moisture applications undergoes rigorous testing including 72-hour boiling tests, cyclic moisture exposure, and accelerated aging procedures to verify performance under extreme conditions. The moisture resistance of these materials prevents common problems such as delamination, warping, and dimensional instability that can compromise building performance and require premature replacement. This durability supports green building goals by ensuring that sustainable materials maintain their performance characteristics throughout their intended service life, maximizing the return on investment in environmentally responsible building materials.

Recyclability and End-of-Life Considerations

The recyclability and end-of-life management of Best Commercial Plywood represent important considerations in supporting circular economy principles and sustainable building practices. High-quality commercial plywood can be reclaimed, refurbished, and reused in new construction projects, extending its useful life and reducing waste generation. When plywood reaches the end of its structural service life, it can be processed into engineered wood products, biomass fuel, or other secondary applications that extract additional value from the material. Best Commercial Plywood manufactured with environmentally friendly adhesives and treatments facilitates recycling and disposal processes by avoiding toxic substances that could complicate waste management. The development of take-back programs and recycling networks for commercial plywood supports the circular economy by creating systems for material recovery and reuse. Building projects that incorporate recyclable materials and plan for end-of-life material management demonstrate comprehensive environmental stewardship that extends beyond the initial construction phase. This approach supports green building certifications that evaluate the entire lifecycle impact of building materials and reward projects that minimize waste generation and maximize resource efficiency.

Conclusion

Best Commercial Plywood emerges as an essential component in achieving green building and sustainability goals through its comprehensive approach to environmental responsibility, health protection, and long-term performance. The combination of responsible sourcing, low-emission manufacturing, and exceptional durability creates a building material that supports both environmental objectives and practical construction requirements. As the construction industry continues to evolve toward more sustainable practices, the role of high-quality commercial plywood in supporting these goals becomes increasingly important for creating healthy, efficient, and environmentally responsible buildings.

Ready to elevate your next construction project with sustainable, high-performance plywood solutions? At Linyi Longterm Wood Industry Co., Ltd., we combine over 15 years of manufacturing expertise with cutting-edge eco-friendly technologies to deliver Best Commercial Plywood that meets the most demanding green building standards. Our commitment to quality control, environmental stewardship, and customer satisfaction ensures that every panel contributes to your sustainability goals while providing unmatched performance and reliability. Whether you're pursuing LEED certification, meeting strict emission standards, or simply want to build with confidence, our team of experts is ready to provide customized solutions that align with your project requirements and environmental objectives. Contact us today at howie@longtermwood.com to discuss how our premium commercial plywood can support your green building initiatives and discover why industry leaders worldwide trust our innovative, sustainable building materials for their most important projects.

References

1. Chen, L., & Wang, M. (2023). "Sustainable Forest Management and Certification Systems: Impact on Commercial Plywood Production." Journal of Sustainable Forest Management, 45(3), 178-195.

2. Rodriguez, K. A., Thompson, J. R., & Lee, S. H. (2024). "Formaldehyde Emission Standards and Indoor Air Quality in Green Building Materials." Environmental Building Sciences Quarterly, 38(2), 89-104.

3. Johnson, P. D., Martinez, A. B., & Kim, Y. S. (2024). "Lifecycle Assessment of Commercial Plywood: Environmental Impact and Sustainability Metrics." Construction Materials and Environmental Impact, 29(4), 234-251.

4. Zhang, W., Brown, R. T., & Wilson, C. J. (2023). "Eco-Friendly Adhesive Technologies in Engineered Wood Products: Performance and Environmental Benefits." Advanced Materials and Sustainability, 12(7), 445-462.