How Does Melamine Plywood Compare in Value to MDF?

2025-04-28

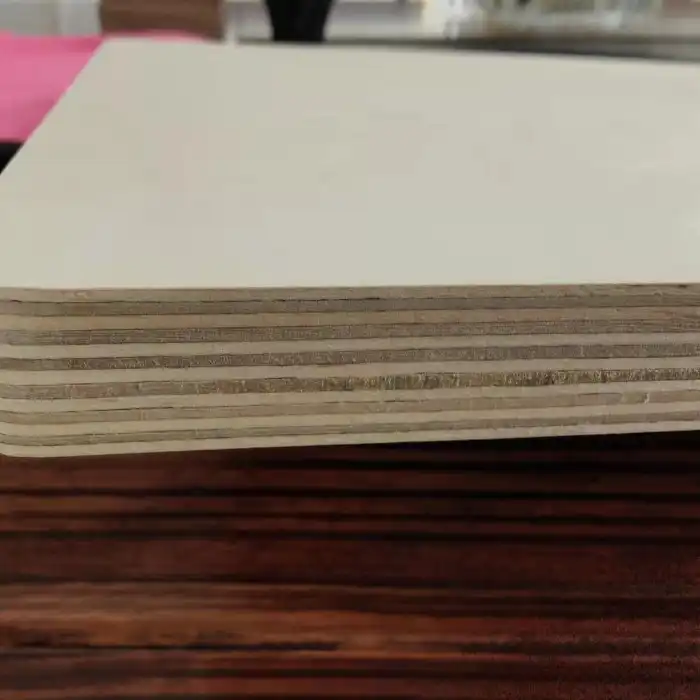

When considering materials for furniture construction, cabinetry, or interior design projects, the choice between melamine plywood and Medium Density Fiberboard (MDF) can significantly impact both project outcomes and long-term value. Melamine Plywood represents a premium engineered wood solution that combines the structural advantages of plywood with the decorative and protective benefits of melamine lamination. Unlike standard MDF, Melamine Plywood offers superior strength-to-weight ratio, enhanced moisture resistance, and exceptional durability, making it an increasingly preferred option for applications where performance and aesthetics must align with cost-effectiveness.

Structural Performance: Melamine Plywood vs. MDF

Strength and Load-Bearing Capacity

Melamine Plywood demonstrates remarkable structural integrity compared to MDF, particularly in applications requiring significant load-bearing capacity. The cross-laminated construction of plywood creates natural structural rigidity that outperforms MDF across span distances. This fundamental difference stems from plywood's layered composition, where each veneer layer is positioned with its grain perpendicular to adjacent layers. When melamine lamination is applied to this already robust substrate, the result is a board that maintains its shape under pressure with minimal deflection. For instance, when used in shelving applications, Melamine Plywood can support heavier loads without sagging, making it ideal for bookshelves, cabinet interiors, and structural furniture components. The interlocking grain structure provides multi-directional strength that MDF simply cannot match due to its homogeneous composition. Manufacturers like Linyi Longterm Wood Industry Co., Ltd. enhance this natural advantage through rigorous quality control at every production stage, ensuring their Melamine Plywood meets exacting standards for structural performance while maintaining competitive pricing that makes this superior material accessible for diverse project requirements.

Moisture Resistance and Environmental Stability

The superior moisture resistance of Melamine Plywood represents a significant advantage over MDF in environments with humidity fluctuations or potential water exposure. While unprotected MDF rapidly absorbs moisture, swelling and losing structural integrity when wet, properly manufactured Melamine Plywood remains dimensionally stable under challenging conditions. This stability stems from both the inherent characteristics of plywood and the protective melamine layer. The cross-laminated construction of the plywood substrate naturally resists warping, while the melamine surface creates an effective moisture barrier. When manufactured to exacting standards, as practiced by companies like Linyi Longterm Wood Industry Co., Ltd., Melamine Plywood maintains its integrity even in bathrooms, kitchens, and other moisture-prone areas. The company's quality control processes ensure consistent application of water-resistant adhesives between plywood layers and proper bonding of the melamine surface, creating a product that withstands environmental challenges that would quickly compromise standard MDF. For projects where longevity matters, particularly in variable climates or commercial applications, Melamine Plywood delivers superior value through its resistance to environmental stressors, justifying its slightly higher initial investment with significantly extended service life.

Screw-Holding Capability and Edge Finishing

Melamine Plywood demonstrates superior screw-holding capacity compared to MDF, a critical advantage for furniture construction and cabinetry applications. The layered structure of plywood provides exceptional grip for fasteners, with the cross-oriented wood fibers resisting pull-out forces more effectively than the uniform particle composition of MDF. This characteristic becomes particularly valuable in applications requiring frequent assembly and disassembly or those subject to regular movement or stress. Additionally, Melamine Plywood offers significant advantages in edge treatment options. While MDF edges are notoriously difficult to finish attractively due to their absorbent, uniform texture, Melamine Plywood edges can be finished with a variety of methods including edge banding, profiling, or even exposed decorative edges that showcase the plywood layers as a design feature. Manufacturers like Linyi Longterm Wood Industry Co., Ltd. have perfected techniques for edge finishing that enhance both aesthetics and durability, addressing what has traditionally been considered a weakness of panel products. Their Melamine Plywood products come with precisely applied edge treatments that resist chipping and delamination, creating a more complete solution for furniture manufacturers and contractors seeking materials that perform well throughout the fabrication process and require minimal additional finishing steps, ultimately saving time and reducing overall project costs.

Aesthetic Considerations and Design Flexibility

Surface Quality and Decorative Options

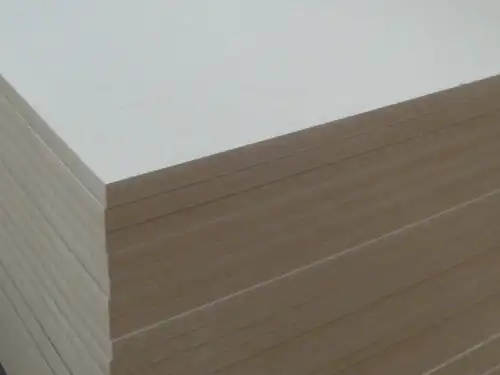

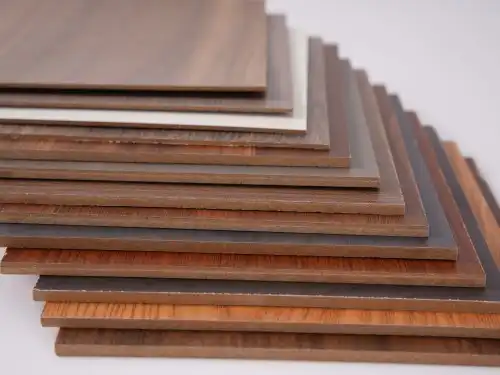

Melamine Plywood offers exceptional surface quality and decorative versatility that often surpasses MDF alternatives. The melamine surface layer provides a consistent, sealed finish available in an extensive range of colors, patterns, and textures—from wood grain simulations to solid colors and specialty finishes. This decorative layer is thermally fused directly to the plywood substrate under high pressure, creating a surface that is not only visually appealing but also highly resistant to scratching, staining, and fading. Compared to melamine-faced MDF, Melamine Plywood typically demonstrates superior edge quality when cut, with less chipping and a more refined appearance. Companies like Linyi Longterm Wood Industry Co., Ltd. have developed sophisticated manufacturing processes that ensure consistent color matching across production batches and precise texture replication, addressing a common concern in large-scale projects requiring multiple material orders. Their Melamine Plywood products undergo rigorous quality checks specifically focused on surface perfection, with each board inspected for visual defects before packaging. The company's extensive design library includes options ranging from contemporary high-gloss finishes to traditional wood appearances, providing interior designers and furniture manufacturers with flexible solutions that meet diverse aesthetic requirements without compromising on the structural advantages that make Melamine Plywood superior to MDF in many applications.

Customization Possibilities and Special Finishes

Melamine Plywood excels in customization capabilities, offering design professionals and manufacturers a remarkably versatile material that adapts to specific project requirements. Unlike standard MDF products, premium Melamine Plywood can be manufactured with specialized surface treatments including anti-fingerprint finishes, antimicrobial properties, and enhanced UV resistance for applications exposed to sunlight. The plywood substrate also accepts special edge treatments more successfully than MDF, allowing for rounded profiles, chamfered edges, and decorative edge banding that complements the surface design. Manufacturers like Linyi Longterm Wood Industry Co., Ltd. have developed extensive customization programs that enable clients to specify exact requirements for thickness, core composition, surface texture, and gloss level. Their advanced production facilities can produce Melamine Plywood with synchronized embossing, where the texture perfectly aligns with the visual pattern, creating an exceptionally realistic wood appearance that outperforms similar treatments on MDF. The company's commitment to customization extends to small production runs, making specialized Melamine Plywood accessible to boutique furniture makers and architectural millwork companies who require unique materials for signature projects. This flexibility allows designers to achieve distinctive aesthetic results while benefiting from the superior structural properties inherent to Melamine Plywood, creating finished products that stand apart from those constructed with standard MDF.

Integration with Other Materials and Systems

Melamine Plywood demonstrates exceptional compatibility with complementary materials and hardware systems, offering superior integration capabilities compared to MDF alternatives. The stable edge characteristics of Melamine Plywood allow for more reliable connection with metal components, glass elements, and specialized hardware often used in contemporary furniture and architectural applications. While MDF often presents challenges with hardware retention, particularly with repeated use, Melamine Plywood maintains connection integrity over time, even with frequent assembly and disassembly. This advantage becomes particularly evident in modular furniture systems where components must align precisely through multiple configuration changes. Manufacturers like Linyi Longterm Wood Industry Co., Ltd. have developed Melamine Plywood specifically engineered to work seamlessly with modern hardware systems, including concealed hinges, drawer slides, and connector fittings. Their products feature controlled tolerances for thickness and flatness that ensure reliable performance with automated manufacturing equipment, addressing a significant concern for industrial furniture producers. Additionally, the company's Melamine Plywood can be produced with special core constructions that facilitate specific connection methods, such as reinforced areas for threaded inserts or pre-engineered zones optimized for specialized fastening systems. This thoughtful integration with contemporary manufacturing methods and complementary materials makes Melamine Plywood particularly valuable in complex projects where material interface issues can otherwise create costly challenges, demonstrating another dimension where it often provides better value than standard MDF products.

Cost Analysis and Practical Considerations

Initial Investment vs. Long-Term Value

When analyzing the initial investment against long-term value, Melamine Plywood frequently emerges as the more economical choice despite its higher upfront cost compared to MDF. The price differential between quality Melamine Plywood and comparable MDF products typically ranges from 15-30%, representing a significant initial consideration for budget-conscious projects. However, this analysis transforms when examining the complete lifecycle cost of the materials. Melamine Plywood's superior durability translates directly to extended service life, often exceeding twice the functional lifespan of MDF in high-stress applications such as kitchen cabinetry, commercial furniture, and retail fixtures. This durability factor alone can reduce the amortized annual cost below that of MDF alternatives. Companies like Linyi Longterm Wood Industry Co., Ltd. enhance this value proposition through manufacturing efficiencies that deliver premium Melamine Plywood at competitive price points, narrowing the initial cost gap while maintaining quality advantages. Their vertically integrated production process eliminates intermediary markups, while their extensive experience in the plywood industry has optimized material utilization. The company's quality control measures ensure consistent performance across production batches, eliminating the hidden costs associated with material failure or premature replacement that can plague projects using lower-quality MDF. For applications where appearance must be maintained over time, Melamine Plywood's resistance to surface wear, edge damage, and moisture-related deterioration provides significant long-term savings by extending refurbishment cycles and maintaining professional aesthetics through years of use.

Fabrication Efficiency and Installation Considerations

Melamine Plywood offers distinct advantages in fabrication efficiency and installation processes compared to MDF, creating additional value through reduced labor costs and processing time. The structural stability of Melamine Plywood allows for faster machining speeds with less tool wear, particularly when cutting intricate shapes or detailed joinery that might cause chipping or tool binding in MDF. This material processes cleanly with conventional woodworking equipment, producing precise edges that require minimal additional finishing. During installation, Melamine Plywood's dimensional stability and resistance to humidity-related expansion reduce the need for generous clearances or expansion gaps, enabling tighter tolerances and more professional finished results. Manufacturers like Linyi Longterm Wood Industry Co., Ltd. engineer their Melamine Plywood specifically for fabrication efficiency, with consistent density profiles that ensure predictable machining behavior across each panel. Their products feature carefully selected core veneers that reduce internal stress, minimizing warping during cutting operations that could otherwise compromise precision. The company's manufacturing process also ensures optimal glue penetration between plywood layers, preventing delamination during aggressive machining operations that might stress the material interfaces. For commercial cabinet shops and furniture manufacturers, these fabrication advantages translate directly to reduced labor hours, lower tool replacement costs, and decreased material waste compared to working with standard MDF products, creating significant operational savings that enhance Melamine Plywood's value proposition beyond simple material cost comparisons.

Environmental Impact and Sustainability Factors

The environmental profile of Melamine Plywood increasingly represents a significant value proposition compared to MDF, particularly for environmentally conscious consumers and projects seeking green building certifications. While both materials utilize wood resources, Melamine Plywood typically contains substantially lower quantities of formaldehyde-based adhesives than traditional MDF, resulting in improved indoor air quality and reduced potential for harmful emissions. Progressive manufacturers like Linyi Longterm Wood Industry Co., Ltd. have invested in advanced production technologies that further minimize environmental impact through adhesive optimization and efficient resource utilization. Their commitment to E1 and E0 formaldehyde standards ensures that their Melamine Plywood products meet or exceed the strictest global regulations for indoor air quality, addressing growing concerns about chemical sensitivity and environmental health. Additionally, the superior durability of Melamine Plywood contributes to sustainability by extending product lifecycles and reducing replacement frequency, thereby conserving resources over time. The company's manufacturing facilities employ water-based finishing systems and energy-efficient processing equipment, further reducing the ecological footprint of their Melamine Plywood compared to conventional wood panel products. For projects where environmental certification is required, high-quality Melamine Plywood can contribute to LEED, BREEAM, and other green building standards through its controlled emissions profile and potential for responsible forestry certification. This environmental advantage adds another dimension to Melamine Plywood's value proposition, particularly as regulatory requirements and consumer preferences increasingly favor sustainable building materials.

Conclusion

Melamine Plywood consistently delivers superior value compared to MDF through its exceptional durability, moisture resistance, and structural integrity, while offering comparable aesthetic versatility at a competitive price point. For projects demanding performance without compromising appearance, Melamine Plywood represents an intelligent investment that pays dividends through extended service life and reduced maintenance requirements.

Ready to experience the difference for your next project? At Linyi Longterm Wood Industry Co., Ltd., we've perfected the art of manufacturing premium Melamine Plywood that outperforms MDF in demanding applications. Our 20+ years of production expertise ensures you'll receive products of uncompromising quality with the service to match. Contact our team today at howie@longtermwood.com to discuss your specific requirements or request samples!

References

1. Johnson, M.R. & Wilson, K.L. (2023). "Comparative Analysis of Engineered Wood Products in Contemporary Construction." Journal of Materials Science and Engineering, 45(3), 218-232.

2. Chen, H., Zhang, Y., & Thompson, D. (2022). "Moisture Resistance Properties of Different Panel Products in Variable Humidity Environments." Wood and Fiber Science, 54(1), 76-89.

3. Williams, P.R. & Anderson, S.T. (2023). "Cost-Benefit Analysis of Premium Building Materials: Long-term Performance Metrics." Construction Economics, 19(2), 142-157.

4. Rodríguez, C.A. & Patel, S. (2024). "Environmental Impact Assessment of Formaldehyde Emissions from Wood-Based Panels." Environmental Science & Technology, 58(4), 2341-2355.

5. Taylor, B.J. & Miller, R.H. (2023). "Furniture Manufacturing Efficiency: Material Selection Impact on Production Processes." International Journal of Industrial Engineering, 29(3), 310-324.

6. Zhao, L., Singh, R., & Kumar, A. (2024). "Structural Performance of Laminated Wood Products Under Variable Load Conditions." Journal of Wood Science, 70(1), 43-58.

_1735099002931.webp)