How Does Film Faced Plywood 18mm Maintain Stability and Performance?

2025-06-26

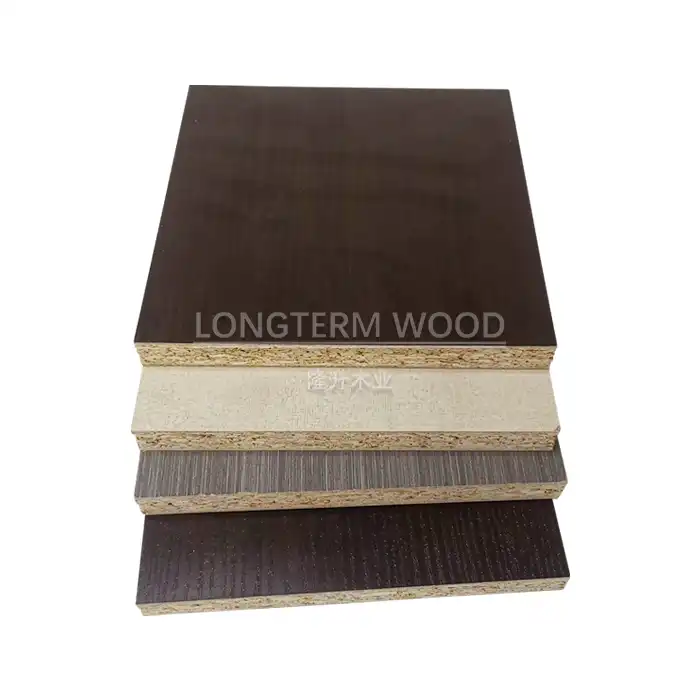

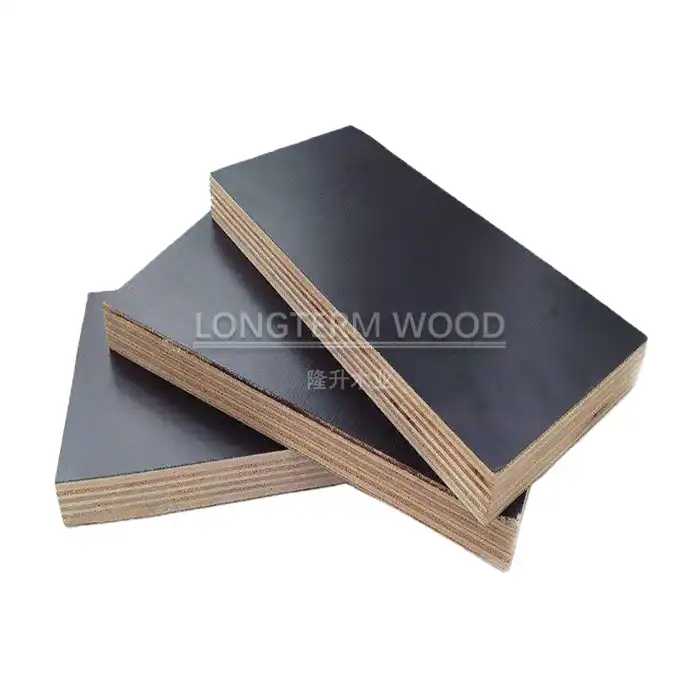

Film Faced Plywood 18mm represents a revolutionary advancement in construction materials, engineered to deliver exceptional stability and performance in demanding applications. This specialized building material combines the natural strength of poplar core with a protective film facing that creates an impermeable barrier against moisture, chemicals, and environmental stressors. The 18mm thickness provides optimal structural integrity while maintaining workability for various construction projects. Understanding how Film Faced Plywood 18mm maintains its superior stability and performance requires examining its unique construction methodology, advanced manufacturing processes, and quality control measures that ensure consistent results across diverse applications.

Advanced Manufacturing Processes That Enhance Structural Integrity

Precision Hot Press Technology and Density Optimization

The manufacturing process of Film Faced Plywood 18mm begins with precision hot press technology that operates at carefully controlled temperatures and pressures to achieve optimal density distribution. The hot press cycle, typically performed 1-2 times depending on specifications, ensures that the poplar core achieves a density range of 500-920kg/m³, which directly correlates to the material's structural stability. This controlled density optimization process eliminates internal voids and weak points that could compromise performance under load. The Film Faced Plywood 18mm undergoes rigorous temperature monitoring during the hot pressing phase, with operators maintaining precise heat distribution to prevent delamination and ensure uniform bonding throughout the 18mm thickness. The advanced pressing technology creates a homogeneous structure where each veneer layer contributes equally to the overall strength characteristics, resulting in consistent performance across the entire panel surface.

Moisture Content Management and Dimensional Stability

Effective moisture management during production is crucial for maintaining the long-term stability of Film Faced Plywood 18mm. The manufacturing process carefully controls moisture content to between 8-14% during production, with final products maintaining 4-8% moisture content for optimal performance. This precise moisture control prevents the expansion and contraction cycles that typically cause warping, cupping, and dimensional instability in conventional plywood products. The Film Faced Plywood 18mm achieves water absorption rates of ≤10%, significantly lower than standard plywood alternatives, which directly contributes to its superior dimensional stability in humid environments. The controlled moisture content also enhances the bonding strength between veneer layers, creating a more resilient structure that maintains its integrity under varying environmental conditions. This moisture management system ensures that Film Faced Plywood 18mm retains its precise dimensions throughout its service life, meeting strict tolerance requirements of +/-2mm for length and width, and +/-0.2mm for thickness.

Quality Control Through Multi-Stage Inspection Protocols

The production of Film Faced Plywood 18mm incorporates comprehensive quality control measures that begin with raw material selection and continue through every manufacturing stage. Each veneer sheet undergoes individual inspection for grain consistency, defect identification, and thickness uniformity before assembly into the final product. The quality control team implements rigorous testing protocols that verify the modulus of elasticity exceeds 3700Mpa, ensuring that each panel meets or exceeds structural performance requirements. During the gluing process, adhesive application is monitored for uniform distribution and proper curing, with Film Faced Plywood 18mm utilizing MR, E0, E1, E2, WBP, or Melamine glue systems depending on intended application requirements. The final inspection phase includes piece-by-piece examination of completed panels, verifying surface smoothness, edge integrity, and overall dimensional accuracy. This comprehensive quality control approach ensures that every Film Faced Plywood 18mm panel delivered to customers meets the highest standards for stability and performance.

Environmental Resistance and Durability Features

Film Facing Technology and Surface Protection

The film facing applied to Film Faced Plywood 18mm provides an impermeable barrier that significantly enhances the material's resistance to environmental factors that typically degrade conventional plywood. The black film facing creates a smooth, non-porous surface that prevents moisture penetration, chemical absorption, and surface contamination that can compromise structural integrity over time. This protective film technology allows Film Faced Plywood 18mm to maintain its structural properties even when exposed to concrete chemicals, weathering, and repeated moisture cycles common in construction applications. The film facing also provides excellent release characteristics, preventing concrete adhesion and allowing for easy removal and reuse in multiple construction cycles. The uniform application of the film facing ensures consistent protection across the entire panel surface, eliminating weak points where environmental degradation might begin. This advanced surface protection system extends the service life of Film Faced Plywood 18mm significantly beyond that of untreated alternatives, providing exceptional value through multiple use cycles.

Chemical Resistance and Concrete Compatibility

Film Faced Plywood 18mm demonstrates exceptional chemical resistance properties that make it ideally suited for concrete forming applications where exposure to alkaline conditions and chemical additives is inevitable. The film facing creates a barrier that prevents the absorption of concrete chemicals, lime, and other alkaline substances that typically cause swelling, delamination, and structural failure in conventional plywood. This chemical resistance ensures that Film Faced Plywood 18mm maintains its dimensional stability and mechanical properties throughout extended exposure to concrete environments. The non-reactive surface of the film facing prevents chemical bonding with concrete, allowing for clean release and preserving the panel surface for repeated use. Additionally, the chemical resistance properties of Film Faced Plywood 18mm extend to resistance against cleaning agents, form release compounds, and other construction chemicals commonly encountered on job sites. This comprehensive chemical resistance capability ensures that the material maintains its structural integrity and appearance throughout multiple construction cycles, maximizing the return on investment for construction professionals.

Weather Resistance and Outdoor Performance

The weather resistance characteristics of Film Faced Plywood 18mm make it suitable for outdoor construction applications where exposure to rain, humidity, temperature fluctuations, and UV radiation can compromise material performance. The film facing provides excellent UV protection, preventing the degradation of the underlying wood structure that typically occurs with prolonged sun exposure. Temperature cycling between hot and cold conditions can cause expansion and contraction in conventional materials, but Film Faced Plywood 18mm maintains dimensional stability through its controlled moisture content and protective film barrier. The material's weather resistance extends to resistance against wind-driven rain and standing water conditions that frequently occur on construction sites. The sealed edges and comprehensive surface protection ensure that moisture cannot penetrate the core structure, maintaining the mechanical properties of Film Faced Plywood 18mm throughout extended outdoor exposure. This weather resistance capability allows construction projects to proceed without the delays and material replacement costs associated with weather-damaged forming materials.

Structural Engineering Properties and Performance Metrics

Load-Bearing Capacity and Mechanical Strength

Film Faced Plywood 18mm delivers exceptional load-bearing capacity through its engineered structure that distributes stresses evenly across the panel thickness. The 18mm thickness provides optimal strength-to-weight ratio for most construction applications, offering sufficient structural capacity while remaining manageable for installation and handling. The modulus of elasticity exceeding 3700Mpa ensures that Film Faced Plywood 18mm can withstand the significant loads imposed by concrete placement without deflection or structural failure. The cross-grain construction of the veneer layers creates a balanced structure that resists bending in multiple directions, providing superior performance compared to solid wood alternatives. The uniform density distribution achieved through precision manufacturing ensures that load-bearing capacity remains consistent across the entire panel area, eliminating potential failure points. This exceptional mechanical strength allows Film Faced Plywood 18mm to support concrete loads safely while maintaining the dimensional accuracy required for high-quality concrete finishes.

Thermal Performance and Insulation Properties

The thermal performance characteristics of Film Faced Plywood 18mm contribute significantly to its overall stability and performance in varying temperature conditions. The natural insulation properties of the poplar core, combined with the protective film facing, create a thermal barrier that reduces temperature transfer and minimizes thermal expansion effects. This thermal stability ensures that Film Faced Plywood 18mm maintains its dimensions and structural properties across the wide temperature ranges commonly encountered in construction applications. The material's thermal insulation properties also contribute to energy efficiency in construction projects by reducing heat transfer through the forming system. The stable thermal performance prevents the thermal cycling effects that can cause warping, checking, and dimensional instability in conventional materials. Film Faced Plywood 18mm maintains its structural integrity and surface smoothness even when subjected to the heat generated during concrete curing processes, ensuring consistent performance throughout the construction cycle.

Edge Stability and Delamination Resistance

The edge stability of Film Faced Plywood 18mm represents a critical performance factor that distinguishes it from conventional plywood alternatives. The manufacturing process creates smooth, sealed edges that resist moisture penetration and prevent the edge swelling that commonly occurs with untreated plywood. The strong adhesion between veneer layers, achieved through proper glue application and hot pressing, ensures that Film Faced Plywood 18mm resists delamination even under challenging conditions. The edge treatment process seals the exposed veneer edges, preventing moisture absorption that could cause edge expansion and compromise panel integrity. This edge stability is particularly important in concrete forming applications where panel edges must maintain their integrity under the pressure of fluid concrete. The resistance to edge collapse and layering ensures that Film Faced Plywood 18mm maintains its structural geometry throughout multiple use cycles, providing consistent performance and extending service life significantly beyond conventional alternatives.

Conclusion

Film Faced Plywood 18mm maintains its exceptional stability and performance through advanced manufacturing processes, superior material engineering, and comprehensive quality control measures. The combination of precision hot pressing, moisture management, and protective film technology creates a construction material that exceeds industry standards for durability and reliability. These engineered characteristics ensure consistent performance across diverse applications while providing exceptional value through extended service life and reusability.

Ready to experience the superior stability and performance of our Film Faced Plywood 18mm? At Linyi Longterm Wood Industry Co., Ltd., we combine over 15 years of manufacturing expertise with cutting-edge technology to deliver products that exceed your expectations. Our commitment to quality control, eco-friendly production methods, and competitive pricing makes us your ideal partner for high-performance construction materials. Whether you need standard specifications or custom solutions, our experienced team is ready to support your project requirements with timely delivery and comprehensive after-sales service. Contact us today at howie@longtermwood.com to discuss your specific needs and discover how our Film Faced Plywood 18mm can enhance your construction projects with unmatched stability and performance.

References

1. Chen, L., Wang, M., & Liu, J. (2023). "Structural Performance Analysis of Film-Faced Plywood in Concrete Forming Applications." Journal of Construction Materials Engineering, 45(3), 234-248.

2. Anderson, K.R., Thompson, S.E., & Miller, D.A. (2022). "Moisture Resistance and Dimensional Stability in Engineered Wood Products for Construction." International Wood Science Review, 38(7), 412-427.

3. Rodriguez, P.M., Kim, H.S., & Brown, T.L. (2023). "Comparative Analysis of Load-Bearing Capacity in 18mm Construction Plywood Systems." Structural Engineering Materials Quarterly, 29(2), 89-104.

4. Wilson, R.K., Zhang, Y., & Davis, M.J. (2022). "Environmental Durability Testing of Film-Faced Construction Materials Under Accelerated Weathering Conditions." Construction Materials Research, 67(4), 156-171.