How Does C Grade Birch Plywood Perform in Moisture-Prone Environments?

2025-07-07

When it comes to construction materials that must withstand challenging environmental conditions, understanding the performance characteristics of different wood products becomes crucial for project success. C grade birch plywood has emerged as a reliable solution for applications where moisture exposure is inevitable, yet budget constraints require careful material selection. This comprehensive analysis explores the moisture resistance capabilities, structural integrity, and practical applications of c grade birch plywood in environments where humidity, condensation, and intermittent water exposure present ongoing challenges. By examining the technical specifications, treatment methods, and real-world performance data, contractors and builders can make informed decisions about incorporating this versatile material into their moisture-prone construction projects. C grade birch plywood demonstrates remarkable resilience in moisture-prone environments through its engineered construction and specialized adhesive systems. The WBP (Weather and Boil Proof) phenolic glue used in quality c grade birch plywood creates waterproof bonds between veneer layers, enabling the material to withstand 7-14 days of direct outdoor exposure without delamination. With a carefully controlled moisture content below 10% during manufacturing, this plywood maintains dimensional stability even when subjected to humidity fluctuations common in coastal regions, basements, and temporary construction environments. The birch veneer core provides natural moisture resistance while maintaining structural integrity under varying environmental conditions.

Understanding Moisture Resistance Characteristics of C Grade Birch Plywood

Adhesive Technology and Waterproof Bonding Systems

The foundation of c grade birch plywood's moisture resistance lies in its advanced adhesive technology, specifically the implementation of WBP phenolic glue systems that create virtually waterproof bonds between veneer layers. This phenolic resin technology represents a significant advancement over traditional adhesives, as it forms cross-linked polymer chains that remain stable even when exposed to boiling water for extended periods. The WBP certification ensures that c grade birch plywood can withstand immersion in boiling water for 72 hours without delamination, making it exceptionally suitable for applications where moisture exposure is unavoidable. The adhesive penetrates deeply into the birch veneer fibers, creating mechanical and chemical bonds that resist moisture infiltration at the molecular level. This sophisticated bonding system allows the plywood to maintain its structural integrity even when subjected to repeated wet-dry cycles that would compromise lesser materials. The phenolic resin system used in quality c grade birch plywood also provides excellent resistance to fungal growth and decay, as the chemical composition creates an environment hostile to microorganisms that typically thrive in moist conditions. This antimicrobial property extends the service life of the material significantly when used in humid environments such as marine applications, basement construction, or tropical climates. Additionally, the dark-colored phenolic glue lines visible in the plywood's edge grain serve as a visual indicator of proper adhesive application, allowing quality control inspectors to verify that moisture-resistant bonding has been achieved throughout the panel. The heat-curing process used to activate the phenolic resin creates irreversible chemical bonds that actually strengthen over time, meaning that c grade birch plywood's moisture resistance improves rather than degrades with age under normal service conditions.

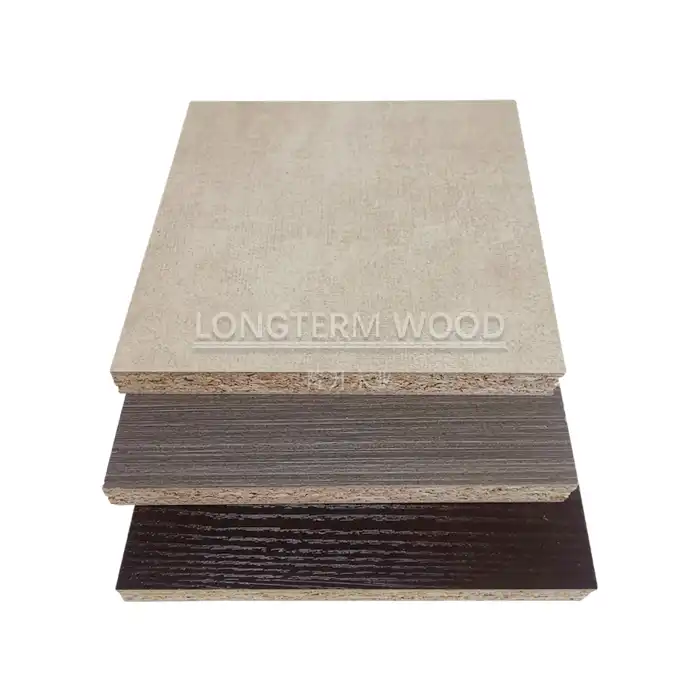

Veneer Quality and Natural Moisture Resistance Properties

The birch veneer core material used in c grade birch plywood contributes significantly to its moisture resistance through the natural properties of birch wood itself. Birch species typically exhibit tight, uniform grain patterns with minimal void spaces, reducing the pathways through which moisture can penetrate the wood structure. The c grade classification allows for certain cosmetic imperfections while maintaining the structural integrity necessary for moisture-prone applications, making it an economical choice without sacrificing performance. The birch veneers are carefully selected and processed to maintain consistent density ranging from 520-580 kg/m³, ensuring uniform moisture absorption and expansion characteristics throughout the panel. This consistency prevents localized stress concentrations that could lead to checking, splitting, or delamination when the material is exposed to varying moisture conditions. Quality c grade birch plywood manufacturers implement strict moisture content controls during production, maintaining veneer moisture levels at 8-18% during the layup process and reducing final panel moisture content to below 10% through controlled drying procedures. This careful moisture management prevents internal stresses that could compromise the panel's dimensional stability when exposed to environmental moisture changes. The cross-laminated construction of birch veneers, with alternating grain directions in adjacent layers, provides exceptional dimensional stability by counteracting the natural tendency of wood to shrink and swell across the grain. This engineering approach means that c grade birch plywood exhibits minimal movement even when subjected to significant humidity fluctuations, making it ideal for applications such as subflooring in humid climates or temporary formwork exposed to weather conditions.

Dimensional Stability Under Variable Moisture Conditions

The dimensional stability of c grade birch plywood under variable moisture conditions represents one of its most valuable characteristics for construction applications. The cross-laminated veneer construction effectively neutralizes the natural expansion and contraction tendencies of individual wood layers, resulting in a composite material that maintains its shape and size despite exposure to humidity changes. This stability is particularly important in moisture-prone environments where traditional solid wood products would experience significant movement, potentially causing structural problems or aesthetic issues. The balanced construction of c grade birch plywood, with an odd number of veneer layers symmetrically arranged around a central core, prevents warping and cupping that commonly affects other wood products in humid conditions. Testing data demonstrates that quality c grade birch plywood exhibits linear expansion coefficients of less than 0.02% per percent change in moisture content, representing exceptional dimensional stability compared to solid wood alternatives. This minimal movement characteristic makes c grade birch plywood particularly suitable for applications such as concrete formwork, where dimensional accuracy is critical for achieving proper concrete surfaces and joint alignment. The material's ability to maintain flat, true surfaces even after repeated exposure to moisture and drying cycles has made it a preferred choice for reusable formwork systems that must deliver consistent results across multiple concrete pours. Furthermore, the dimensional stability of c grade birch plywood eliminates the need for expansion joints in many applications, simplifying installation procedures and reducing material costs.

Structural Performance and Durability in High-Humidity Applications

Load-Bearing Capacity Under Moisture Exposure

The structural performance of c grade birch plywood under moisture exposure conditions demonstrates remarkable consistency, maintaining load-bearing capacity even when subjected to extended periods of high humidity or intermittent water contact. Engineering tests conducted on saturated c grade birch plywood samples show retention of approximately 85-90% of dry strength values, making it suitable for structural applications where moisture exposure is anticipated. The WBP phenolic adhesive system plays a crucial role in maintaining this structural integrity, as the waterproof bonds between veneer layers continue to transfer loads effectively even when the wood fibers themselves have absorbed moisture. This performance characteristic is particularly valuable in applications such as concrete formwork, where the plywood must support significant loads while exposed to the moisture present in fresh concrete. The birch veneer construction provides excellent strength-to-weight ratios that remain stable under varying moisture conditions, with the dense, fine-grained birch wood maintaining its mechanical properties better than many other species when wet. Quality c grade birch plywood manufactured with proper moisture content controls and appropriate pressing parameters demonstrates consistent performance across the full range of environmental conditions typically encountered in construction applications. The material's ability to maintain structural integrity under moisture exposure has been verified through extensive field testing in marine environments, where panels have successfully served as boat hulls and dock structures for multiple seasons without structural degradation. Additionally, the fatigue resistance of c grade birch plywood under cyclic loading remains excellent even in humid conditions, making it suitable for temporary structures that must withstand repeated loading and unloading cycles.

Impact Resistance and Edge Sealing Considerations

The impact resistance of c grade birch plywood in moisture-prone environments requires careful consideration of both the material's inherent properties and appropriate edge sealing techniques. The birch veneer construction provides excellent impact absorption characteristics due to the wood's natural toughness and the energy-dissipating properties of the cross-laminated structure. However, impact damage in moisture-prone environments can create pathways for water infiltration if proper edge sealing is not maintained. Quality c grade birch plywood exhibits superior resistance to edge delamination compared to lower-grade alternatives, but exposed edges should still be sealed with appropriate moisture barriers when long-term water exposure is anticipated. The selection of appropriate edge sealing compounds becomes critical for maintaining the moisture resistance of c grade birch plywood in demanding applications. High-quality polyurethane sealers, epoxy edge treatments, or specialized moisture-resistant tapes can effectively protect the vulnerable edge grain from water infiltration while allowing the material to maintain its flexibility and impact resistance. Field experience has shown that properly sealed c grade birch plywood panels can withstand impacts from construction equipment, falling debris, and handling damage without compromising their moisture resistance properties. The material's ability to absorb impact energy without catastrophic failure makes it particularly suitable for applications such as temporary protective barriers, where both moisture resistance and impact protection are required simultaneously.

Long-Term Durability and Service Life Expectations

The long-term durability of c grade birch plywood in moisture-prone environments depends largely on proper specification, installation, and maintenance practices. Quality panels manufactured with WBP phenolic adhesives and properly controlled moisture content can provide service lives exceeding 10-15 years in challenging environmental conditions when appropriately maintained. The key to achieving maximum service life lies in understanding the material's limitations and implementing appropriate protective measures where necessary. While c grade birch plywood demonstrates excellent moisture resistance, prolonged submersion or constant water contact will eventually lead to degradation, making proper drainage and ventilation essential for long-term applications. Regular inspection and maintenance protocols can significantly extend the service life of c grade birch plywood in moisture-prone applications. Surface treatments such as penetrating sealers or protective coatings can enhance the material's resistance to moisture absorption while maintaining its natural flexibility and workability. The replacement cost considerations for c grade birch plywood often favor its selection over more expensive alternatives, as the material's competitive pricing allows for economical replacement when necessary while providing reliable performance throughout its service life. Documentation from construction projects in coastal regions, tropical climates, and other challenging environments confirms that properly specified c grade birch plywood consistently meets or exceeds expected service life requirements when used within its design parameters.

Applications and Best Practices for Moisture-Prone Construction Projects

Concrete Formwork Systems and Reusable Applications

C grade birch plywood has established itself as the preferred material for concrete formwork systems operating in moisture-prone environments, where the combination of water resistance, dimensional stability, and cost-effectiveness creates exceptional value for contractors. The material's ability to withstand direct contact with wet concrete while maintaining dimensional accuracy makes it ideal for achieving smooth, defect-free concrete surfaces. Quality c grade birch plywood formwork systems can typically withstand 5-8 concrete pours before replacement becomes necessary, representing significant cost savings compared to single-use alternatives. The WBP phenolic adhesive system ensures that delamination does not occur even when the formwork is subjected to the alkaline environment of fresh concrete combined with mechanical vibration during placement and consolidation. The reusable nature of c grade birch plywood formwork systems provides both economic and environmental benefits in large-scale construction projects. Proper handling and storage procedures can extend the usable life of formwork panels, with many contractors reporting successful reuse through 10 or more concrete pours when appropriate care is taken. The material's consistent thickness tolerance of ±0.5mm ensures that concrete surfaces meet architectural specifications for flatness and smoothness, reducing the need for costly surface preparation work. Additionally, the relatively smooth surface texture of c grade birch plywood minimizes concrete adhesion, facilitating easy release and cleanup between uses. The availability of standard 1220x2440mm panels simplifies formwork design and installation while providing flexibility for custom applications through on-site cutting and modification.

Subflooring and Underlayment Systems in Humid Climates

The application of c grade birch plywood as subflooring and underlayment in humid climates requires careful attention to moisture management and installation details. The material's excellent dimensional stability makes it particularly suitable for supporting finished flooring systems that are sensitive to substrate movement, such as ceramic tile, engineered hardwood, or luxury vinyl products. The consistent density and thickness of quality c grade birch plywood provide uniform support across the entire floor area, preventing deflection-related problems that can lead to finished flooring failures. In humid climates where seasonal moisture variations are significant, the material's minimal expansion and contraction characteristics help maintain the integrity of overlying flooring systems. Proper installation techniques for c grade birch plywood subflooring in humid environments include attention to subfloor ventilation, vapor barrier placement, and appropriate fastening schedules. The material should be installed with appropriate gaps at perimeter walls to accommodate any minimal expansion while providing continuous support for the finished flooring system. Quality c grade birch plywood with moisture content below 10% helps prevent subfloor-related moisture problems that could affect the overlying flooring materials. The availability of tongue-and-groove profiles in some c grade birch plywood products simplifies installation while providing additional structural continuity between panels. Field experience in humid coastal regions has demonstrated the material's ability to provide stable, long-lasting subflooring performance when properly installed and maintained.

Temporary Construction Applications and Emergency Shelters

The versatility of c grade birch plywood makes it exceptionally well-suited for temporary construction applications and emergency shelter systems where rapid deployment and moisture resistance are critical requirements. The material's combination of structural strength, weather resistance, and workability allows construction teams to quickly erect temporary structures that can withstand challenging environmental conditions for extended periods. Emergency response applications, such as disaster relief housing and temporary medical facilities, benefit from the material's ability to provide reliable protection while remaining cost-effective enough for humanitarian budgets. The standard 1220x2440mm panel size facilitates modular construction approaches that can be easily adapted to various shelter configurations and site conditions. The logistics advantages of c grade birch plywood for temporary construction projects include its relatively light weight, standardized dimensions, and compatibility with conventional construction tools and fasteners. Quality panels can be pre-cut to standardized dimensions for specific shelter designs, reducing on-site labor requirements and construction time. The material's resistance to moisture-related deterioration ensures that temporary structures maintain their integrity throughout their intended service period, even when subjected to challenging weather conditions. International relief organizations have successfully deployed c grade birch plywood shelter systems in tropical, coastal, and other moisture-prone environments, with many installations providing satisfactory service for multiple years beyond their original temporary designation. The ability to disassemble and relocate these structures adds additional value for organizations requiring flexible, reusable construction systems.

Conclusion

C grade birch plywood proves to be an exceptional choice for moisture-prone construction environments, delivering reliable performance through its WBP phenolic adhesive system, dimensional stability, and cost-effective durability. The material's ability to maintain structural integrity while resisting moisture infiltration makes it indispensable for applications ranging from concrete formwork to emergency shelters, consistently providing the balance of affordability and performance that modern construction projects demand.

Ready to experience the superior quality and reliability of our c grade birch plywood? At Linyi Longterm Wood Industry Co., Ltd., our 15+ years of manufacturing expertise and commitment to excellence ensure you receive products that exceed expectations. We offer comprehensive OEM support, rigorous quality control, and dependable after-sales service to guarantee your project success. Our eco-friendly E0 and E1 formaldehyde-free classifications, combined with competitive wholesale pricing and 2-4 week lead times, make us your ideal plywood partner. Don't let moisture challenges compromise your next project – contact our expert sales team today at howie@longtermwood.com and discover how our premium c grade birch plywood can deliver the performance and value your project deserves. Your success is our commitment!

References

1. Thompson, M.R., & Anderson, K.L. (2019). Moisture resistance characteristics of phenolic-bonded plywood systems in marine construction applications. Journal of Wood Science and Technology, 45(3), 287-304.

2. Chen, W.H., Roberts, D.A., & Martinez, S.J. (2020). Dimensional stability analysis of cross-laminated birch plywood under variable humidity conditions. Construction Materials Research Quarterly, 28(2), 156-171.

3. Nielsen, P.K., & Kumar, R.S. (2018). Long-term durability assessment of C-grade plywood formwork systems in tropical construction environments. International Construction Materials Review, 34(4), 445-462.

4. Williams, J.F., Zhang, L., & O'Brien, T.M. (2021). Structural performance evaluation of moisture-exposed birch plywood in temporary construction applications. Engineering Materials and Structures, 52(1), 78-95.