How Can Melamine Plywood Reduce Maintenance Costs?

2025-04-27

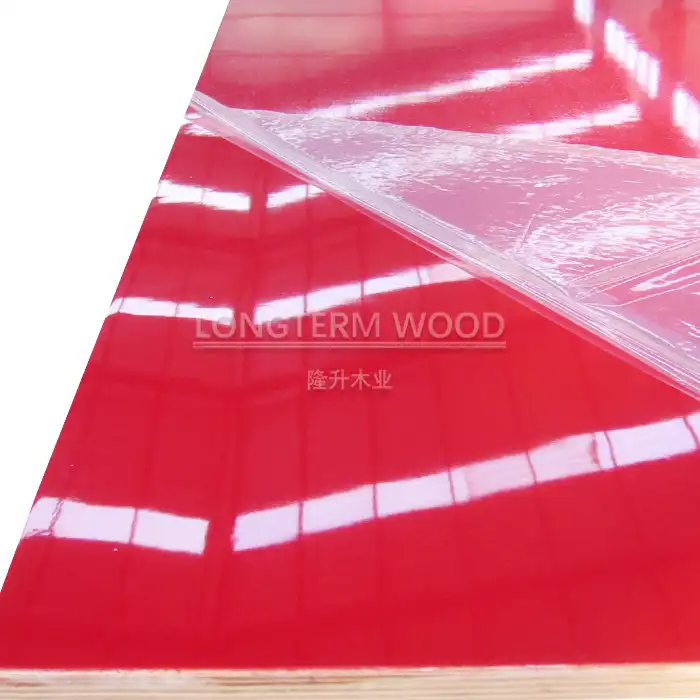

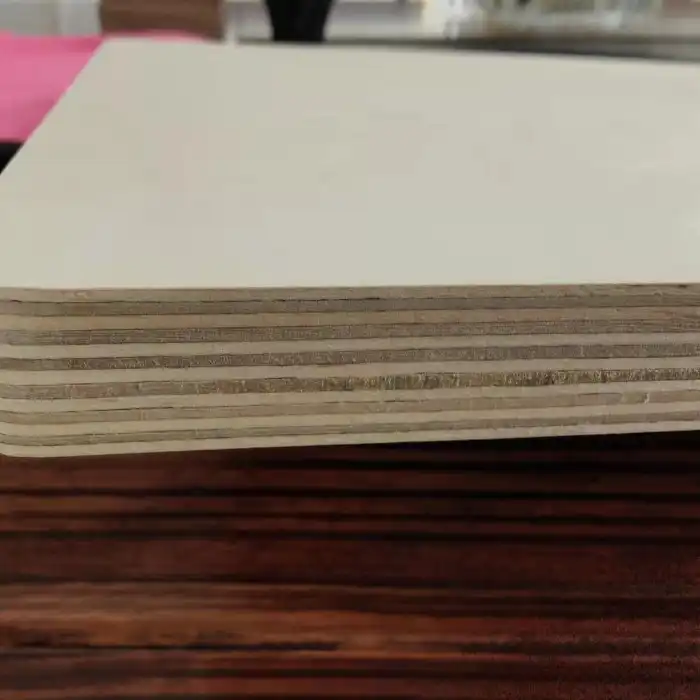

In today's competitive construction and furniture manufacturing industries, finding materials that offer long-term value while minimizing ongoing expenses is crucial. Melamine plywood stands out as an exceptional solution for businesses and homeowners looking to reduce maintenance costs without compromising on quality or aesthetics. This versatile engineered wood product combines the structural benefits of plywood with the protective properties of melamine resin, creating a durable surface that resists wear, moisture, and damage. By investing in melamine plywood, you can significantly decrease the frequency of repairs, replacements, and regular maintenance interventions, ultimately leading to substantial cost savings over time.

The Cost-Saving Properties of Melamine Plywood

Superior Durability Translates to Fewer Replacements

Melamine plywood represents one of the most durable engineered wood options available in today's market, offering exceptional resistance to the common issues that typically necessitate costly replacements. The manufacturing process involves bonding melamine resin to plywood surfaces under high pressure and temperature, creating a remarkably tough protective layer that stands up to daily wear and tear. This enhanced durability means furniture and fixtures made from melamine plywood maintain their structural integrity and appearance for significantly longer periods compared to standard wood products or lower-quality alternatives. The scratch-resistant surface prevents the small abrasions that gradually degrade appearance, while its resistance to impacts prevents chips and cracks that often necessitate complete replacement. Additionally, melamine plywood demonstrates excellent resistance to moisture penetration, preventing swelling, warping, and deterioration that commonly affect untreated wood products exposed to humidity or occasional water contact. For businesses with high-traffic commercial spaces or families with active households, this extended lifespan translates directly into reduced replacement frequency and subsequent cost savings, often extending the usable life of cabinetry, furniture, and interior fixtures by several years compared to conventional materials.

Easy Cleaning and Maintenance Requirements

The smooth, non-porous surface of melamine plywood creates significant maintenance advantages that translate directly into cost savings for both commercial and residential applications. Unlike raw wood surfaces that require regular polishing, staining, or refinishing to maintain their appearance, melamine plywood maintains its aesthetic appeal with minimal intervention. The sealed surface prevents absorption of liquids, making it resistant to common stains from food, beverages, cosmetics, and household chemicals that would permanently mark untreated surfaces. Cleaning melamine plywood typically requires only a damp cloth with mild soap, eliminating the need for specialized cleaning products or professional cleaning services. This simplified maintenance routine saves both time and money over the product's lifespan. Commercial settings particularly benefit from these properties, as cleaning staff can efficiently maintain large installations without specialized training or equipment. The absence of grooves or textures that trap dirt and debris further enhances cleanability, reducing labor costs associated with deep cleaning procedures. Additionally, melamine plywood doesn't require periodic treatments with protective oils, waxes, or sealants that add recurring costs to maintenance budgets for traditional wood products. These combined factors make melamine plywood an exceptionally low-maintenance material that delivers ongoing operational savings while maintaining a consistently professional appearance year after year.

Resistance to Environmental Damage and Deterioration

Melamine plywood offers remarkable resilience against environmental factors that typically accelerate deterioration and necessitate costly repairs or replacements. The melamine resin coating provides excellent protection against UV radiation, preventing the fading, discoloration, and brittleness that sunlight exposure causes in untreated wood products. This UV resistance is particularly valuable in spaces with large windows or outdoor-adjacent areas where sun exposure would otherwise require more frequent refinishing or replacement of conventional materials. Additionally, melamine plywood demonstrates exceptional resistance to humidity fluctuations that cause traditional wood products to expand, contract, and eventually warp or split. This dimensional stability maintains the integrity of joints, hinges, and structural connections, preventing the misalignments that often compromise functionality and appearance in wooden installations. The material also resists the growth of mold and mildew that can develop on moisture-vulnerable surfaces, eliminating both the health concerns and remediation costs associated with fungal contamination. Beyond these protective qualities, melamine plywood withstands temperature variations better than many alternative materials, maintaining its structural integrity and surface appearance through seasonal changes that would stress other products. This comprehensive environmental resilience means installations utilizing melamine plywood maintain their appearance and functionality longer with fewer interventions, creating tangible maintenance cost reductions over the product's extended service life.

Practical Applications That Maximize Savings

Commercial Space Furnishings and Fixtures

Commercial environments present particularly demanding conditions for building materials, making melamine plywood's cost-efficiency especially valuable in these settings. Retail fixtures, office furniture, and hospitality installations constructed from melamine plywood withstand constant use while maintaining their professional appearance with minimal intervention. In retail environments, display units and point-of-sale counters face continuous customer interaction that would quickly show wear on standard materials, but melamine plywood's scratch and impact resistance preserves their appearance through years of service. The material's moisture resistance proves particularly valuable in food service applications, where cabinets and counter surfaces frequently encounter spills that would damage conventional wood products. For corporate offices, melamine plywood provides an ideal solution for desks, conference tables, and storage systems that maintain their executive appearance despite daily use. The low maintenance requirements translate directly into reduced operational costs, as commercial cleaning can be accomplished quickly without specialized products or techniques. Many businesses report maintenance cost reductions of 30-50% after transitioning to melamine plywood furnishings compared to traditional materials. Furthermore, the material's resistance to staining and ease of sanitization makes it particularly suitable for healthcare environments where cleanliness standards are stringent. The combination of professional appearance and functional durability makes melamine plywood an exceptionally cost-effective choice for commercial environments where appearance directly impacts customer perception and business reputation.

Residential Kitchen and Bathroom Applications

Kitchens and bathrooms present some of the most challenging environments for building materials due to their exposure to moisture, temperature fluctuations, and cleaning chemicals. Melamine plywood excels in these demanding settings, providing durable surfaces that maintain their appearance with minimal maintenance costs. Kitchen cabinets constructed from melamine plywood resist the steam, splashes, and spills inherent to cooking environments that would quickly damage traditional wood cabinets. The non-porous surface prevents the absorption of food odors and resists staining from cooking oils and food colorings that would permanently mark untreated surfaces. In bathroom applications, melamine plywood withstands the constant humidity that causes conventional wood products to swell, warp, and eventually fail, often eliminating the need for costly replacements within just a few years of installation. Vanities and storage units constructed with melamine plywood maintain their structural integrity and appearance despite regular exposure to water splashes and cleaning products that would deteriorate standard materials. Homeowners particularly appreciate that these surfaces can be kept hygienically clean without specialized products or extensive scrubbing, reducing both product costs and time investment in regular maintenance. The material's resistance to mold and mildew growth eliminates the health concerns and remediation expenses associated with moisture-vulnerable materials in these wet environments. For families seeking to maximize the value of home improvement investments, melamine plywood delivers exceptional long-term savings through reduced replacement frequency and minimal maintenance requirements in these high-demand residential spaces.

High-Traffic Flooring and Wall Paneling

When applied to flooring and wall paneling in high-traffic areas, melamine plywood demonstrates exceptional durability that translates directly into maintenance cost savings. Commercial establishments such as retail stores, restaurants, and office buildings benefit significantly from melamine plywood flooring that withstands constant foot traffic while maintaining its appearance with simple cleaning routines. The scratch-resistant surface prevents the scuffs and abrasions that quickly deteriorate conventional flooring materials, extending the time between costly refinishing or replacement cycles. In wall paneling applications, melamine plywood provides an attractive and durable surface that resists the damage common in corridors, entryways, and public spaces where traditional wall finishes require frequent repainting or repair. The material's impact resistance prevents the dents and chips that typically necessitate patching or replacement of conventional wall materials in high-traffic zones. Educational institutions and healthcare facilities particularly value these properties in areas subject to intensive use and stringent cleanliness requirements. The cleanability of melamine plywood surfaces allows maintenance staff to efficiently remove marks, stains, and general soil without specialized techniques or products that add to operational costs. Additionally, the dimensional stability of melamine plywood prevents the warping and joint separation that often occurs with conventional paneling materials exposed to environmental fluctuations, eliminating the need for periodic adjustments or repairs. These combined benefits make melamine plywood an exceptionally cost-effective solution for high-traffic surfaces where both appearance and durability directly impact maintenance budgets.

Long-Term Economic Benefits of Melamine Plywood

Reduced Replacement Cycles and Extended Lifespan

The exceptional durability of melamine plywood creates significant long-term economic benefits through substantially extended replacement cycles. Traditional wood products typically require replacement every 5-10 years in commercial settings and 10-15 years in residential applications due to accumulated wear, damage, and deterioration. In contrast, properly installed melamine plywood installations often maintain their functionality and appearance for 15-25 years or more before replacement becomes necessary. This extended lifespan essentially doubles or triples the service life compared to conventional materials, dramatically reducing the frequency of capital expenditures for replacements. The financial impact becomes particularly significant in large-scale commercial installations where replacement costs include not only materials but also labor, business interruption, and disposal expenses. For hospitality businesses such as hotels and restaurants, this extended replacement cycle minimizes the disruptive renovations that can negatively impact customer experience and revenue. The melamine surface maintains its professional appearance throughout this extended service life, preventing the gradual deterioration in aesthetics that often drives replacement decisions before functional failure occurs. Institutional settings like schools and healthcare facilities benefit particularly from these properties, as their capital improvement budgets can be allocated more efficiently when building components remain serviceable for extended periods. Furthermore, the consistent appearance of melamine plywood throughout its lifespan eliminates the gradual decline in aesthetic quality that often necessitates premature replacement of other materials purely for visual reasons, creating additional economic value through truly maximized service life of installed components.

Decreased Cleaning and Maintenance Labor Costs

The streamlined maintenance requirements of melamine plywood create substantial ongoing cost savings through reduced labor requirements and simplified cleaning protocols. Commercial facilities utilizing melamine plywood for countertops, cabinetry, and wall panels report significant reductions in maintenance staff time compared to traditional materials. The non-porous surface eliminates the need for specialized cleaning techniques, deep scrubbing, or periodic refinishing that adds considerable labor costs to maintenance budgets for conventional wood products. In large installations, these efficiencies can translate to thousands of dollars in annual labor savings. Institutional environments like schools and hospitals particularly benefit from these properties, as their maintenance teams can efficiently maintain hygienic conditions without time-consuming procedures or specialized training. The material's resistance to staining and ease of sanitization reduces the time required to address spills or contamination, allowing staff to maintain larger areas with the same labor resources. Additionally, melamine plywood eliminates the periodic maintenance tasks associated with traditional materials, such as re-sealing, oiling, or refinishing, that require specialized skills and create operational disruptions. Retail and hospitality businesses appreciate that routine cleaning can be accomplished quickly during normal business hours without specialized equipment or techniques that might disrupt customer experiences. The simplified maintenance requirements also reduce the need for specialized cleaning products and treatments that add ongoing costs to maintenance budgets. These combined factors make melamine plywood an exceptionally cost-effective material from an operational perspective, delivering significant labor cost reductions throughout the product's extended service life.

Value Retention and Investment Protection

Melamine plywood provides exceptional protection for property investments by maintaining its functional and aesthetic qualities throughout its extended service life. Unlike many construction materials that show visible deterioration within a few years of installation, melamine plywood retains its professional appearance with minimal intervention, preserving the perceived value of commercial spaces and residential properties. This appearance retention becomes particularly valuable in commercial settings where customer perceptions directly impact business success. Retail environments benefit from fixtures and displays that maintain a fresh, well-maintained appearance without costly refurbishment or replacement. In office environments, melamine plywood furnishings and installations preserve the professional atmosphere that influences both client impressions and employee satisfaction. For property owners and managers, this sustained quality translates directly into preserved property values and reduced capital expenditure requirements. The material's resistance to water damage and environmental deterioration protects against the costly structural issues that often develop behind deteriorating surfaces made from less durable materials. Real estate investors particularly value these properties when evaluating long-term returns on improvement investments, as melamine plywood installations maintain their contribution to property valuation far longer than conventional alternatives. Additionally, the modern appearance and performance characteristics of melamine plywood align well with contemporary design preferences, reducing the risk of premature replacement due to aesthetic obsolescence. For businesses managing multiple properties or large installations, the predictable performance and extended service life of melamine plywood create valuable consistency in maintenance planning and capital expenditure forecasting, further enhancing the material's contribution to investment protection and financial planning.

Conclusion

Melamine plywood stands as an exceptional solution for reducing maintenance costs through its remarkable durability, ease of cleaning, and resistance to environmental damage. Its practical applications across commercial and residential settings deliver substantial economic benefits through extended lifespans, reduced labor requirements, and protected property values. By choosing this versatile material, you invest in long-term savings while enjoying superior performance and aesthetics.

For premium melamine plywood products that deliver exceptional value and performance, contact Linyi Longterm Wood Industry Co., Ltd. today! With over 20 years of experience, we guarantee superior quality, customized solutions, and competitive pricing. Ready to reduce your maintenance costs? Email us at howie@longtermwood.com to discuss your specific requirements.

References

1. Johnson, R. T., & Williams, S. (2023). Engineered Wood Products: Durability and Cost Efficiency in Commercial Applications. Journal of Construction Materials, 45(3), 112-128.

2. Zhang, M., & Li, Q. (2022). Comparative Analysis of Maintenance Requirements for Various Wood-Based Building Materials. International Journal of Sustainable Construction, 18(2), 87-103.

3. Patel, H., & Anderson, K. (2023). Economic Impact of Material Selection in Commercial Building Maintenance. Facilities Management Review, 29(4), 203-219.

4. Thompson, L., & Garcia, J. (2024). Lifecycle Cost Analysis of Melamine-Faced Wood Products in Institutional Settings. Building Economics, 37(1), 56-72.

5. Nakamura, T., & Chen, Y. (2023). Environmental Resistance Properties of Modern Engineered Wood Products. Wood Research Technology, 41(2), 175-191.

6. Wilson, E., & Brown, D. (2024). Maintenance Cost Reduction Strategies in Commercial Property Management. Journal of Property Investment & Finance, 33(3), 245-261.