How Can Melamine Plywood Elevate Budget-Friendly Projects?

2025-05-07

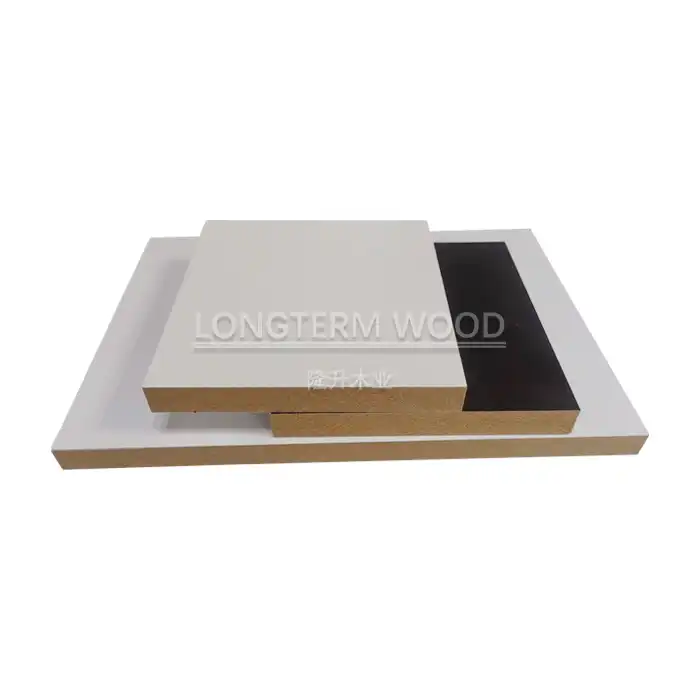

In today's cost-conscious construction and interior design landscape, finding materials that blend affordability with quality poses a significant challenge. Melamine plywood emerges as a remarkable solution that bridges this gap effectively. This versatile engineered wood product combines the structural integrity of plywood with a durable melamine coating, creating a surface that's both practical and aesthetically pleasing. For budget-minded homeowners, contractors, and DIY enthusiasts, melamine plywood offers an impressive array of benefits that can transform modest projects into professional-looking results without straining financial resources.

Cost-Effective Quality Solutions for Modern Projects

Exceptional Value-to-Price Ratio

Melamine plywood represents an outstanding investment for budget-conscious project managers and DIY enthusiasts alike. The manufacturing process of melamine plywood involves applying melamine resin to plywood substrates, creating a finished product that delivers professional results at a fraction of the cost of solid wood or high-end laminates. This cost efficiency doesn't come at the expense of quality—rather, it's achieved through streamlined production techniques and material optimization. When undertaking home renovation projects, furniture building, or commercial fitouts, melamine plywood allows you to allocate resources strategically while still achieving impressive results. The durability and longevity of melamine plywood further enhance its value proposition, as its resistance to wear and tear translates to fewer replacements over time. This exceptional combination of initial affordability and long-term performance makes melamine plywood an intelligent choice for those seeking maximum impact on minimal budgets.

Reduced Installation and Finishing Costs

One of the most compelling advantages of melamine plywood in budget-friendly projects is its ability to significantly reduce installation and finishing expenses. Unlike raw wood products that require extensive sanding, priming, and multiple coats of paint or varnish, melamine plywood comes pre-finished with its protective melamine layer. This factory-applied finish eliminates several labor-intensive steps in the construction process, directly translating to lower labor costs and faster project completion. Professional contractors can pass these savings onto clients, while DIY enthusiasts can avoid purchasing expensive finishing materials and tools. Additionally, the consistent quality of the melamine surface means fewer callbacks or touch-ups after installation. The precision-engineered nature of melamine plywood also contributes to easier installation, with boards that cut cleanly and join seamlessly. This reduction in both material and labor costs throughout the installation process makes melamine plywood particularly attractive for projects with tight budget constraints without compromising on professional results.

Sustainable Affordability Through Longevity

The true measure of a budget-friendly material extends beyond its initial purchase price to include its lifespan and maintenance requirements. Melamine plywood excels in this regard, offering sustainable affordability through exceptional longevity. The durable melamine surface creates a protective barrier that resists stains, moisture, and daily wear, significantly extending the useful life of cabinets, furniture, and other installations. This durability translates directly to cost savings, as replacement cycles are extended far beyond what would be expected from less robust materials. Additionally, the maintenance needs of melamine plywood are minimal—regular cleaning with mild detergent and water is typically all that's required to keep surfaces looking new. This eliminates the need for expensive refinishing procedures or specialized cleaning products. For commercial applications where downtime represents lost revenue, melamine plywood's durability means fewer disruptions for repairs or replacements. By choosing melamine plywood for budget-conscious projects, you're making a wise investment in a material that continues to deliver value long after installation, embodying the principle that true affordability encompasses both immediate cost and long-term performance.

Versatile Applications Across Budget Constrained Projects

Transforming Residential Spaces Economically

Melamine plywood has revolutionized how budget-conscious homeowners approach interior renovations and furniture projects. In kitchens—often the most expensive room to renovate—melamine plywood cabinetry provides a cost-effective alternative that doesn't sacrifice style or functionality. These cabinets resist humidity and cooking spills while maintaining their appearance through years of daily use. The wide range of available finishes allows homeowners to achieve high-end looks like wood grain or solid colors without the associated price tag of natural materials. In bedrooms, melamine plywood shines in wardrobe construction, offering smooth-sliding drawers and doors that operate flawlessly for years without sagging or warping. For living spaces, entertainment centers, bookshelves, and custom storage solutions built from melamine plywood deliver a custom look at production prices. DIY enthusiasts particularly appreciate how melamine plywood's pre-finished nature simplifies home projects—the material can be cut to size, assembled, and immediately put into use without waiting for finishes to cure. With proper hardware and construction techniques, melamine plywood furnishings can rival custom-built pieces at a fraction of the cost, making it an ideal choice for residential spaces where budgets must be carefully managed without compromising on quality or aesthetic appeal.

Commercial Applications on Controlled Budgets

The commercial sector has embraced melamine plywood as a cornerstone material for projects with strict budget parameters. In retail environments, where frequent redesigns are common, melamine plywood display fixtures offer the perfect balance of affordability and professional appearance. These fixtures can be easily customized to showcase merchandise effectively while withstanding the constant handling and rearrangement typical in retail settings. Office spaces benefit tremendously from melamine plywood desks, conference tables, and storage solutions that present a professional image without the corporate expense of solid wood furnishings. The material's resistance to scratches and stains makes it particularly suitable for high-traffic commercial environments where appearance must be maintained despite heavy use. In the hospitality industry, melamine plywood allows for cost-effective yet attractive furnishings in hotel rooms, lobbies, and restaurants, areas where durability is essential but budget considerations are paramount. Educational institutions and healthcare facilities also leverage melamine plywood's affordability and easy maintenance for furniture and cabinetry needs. The material's consistent quality and availability in bulk quantities further enhance its appeal for large-scale commercial projects where budget controls are strictly enforced. When paired with thoughtful design, melamine plywood enables commercial spaces to achieve a premium aesthetic while maintaining financial discipline.

Budget-Friendly DIY Project Enhancement

The DIY movement has found a faithful ally in melamine plywood, which empowers hobbyists and weekend warriors to complete ambitious projects without professional assistance or excessive expense. The material's pre-finished nature eliminates much of the intimidation factor for novice woodworkers who might lack experience with staining and finishing processes. With basic tools and minimal specialized knowledge, DIY enthusiasts can successfully create custom furniture pieces, built-ins, and home organization systems using melamine plywood. The material cuts cleanly with standard woodworking tools and accepts common fasteners like screws and specialty cabinet hardware without splitting or cracking. Additionally, the wide availability of matching edge banding allows for professional-looking finished edges that conceal the plywood substrate. Workshop projects such as workbenches and storage cabinets benefit from melamine plywood's smooth, easy-to-clean surface that resists shop chemicals and abrasion. For those creating children's furniture or play spaces, melamine plywood offers peace of mind through its durability and cleanability, important features for items that will face enthusiastic use. The accessibility of melamine plywood has democratized custom woodworking, allowing those with limited budgets to experience the satisfaction of creating personalized pieces rather than settling for mass-produced alternatives. This combination of user-friendliness and affordability has established melamine plywood as the go-to material for aspiring DIYers looking to maximize their project outcomes while minimizing financial investment.

Technical Advantages Supporting Budget Efficiency

Superior Durability Reducing Replacement Costs

The exceptional durability of melamine plywood represents one of its most significant cost-saving attributes over the lifespan of any project. The manufacturing process involves fusing melamine resin under high pressure and temperature to create a surface that's remarkably resistant to common forms of damage. This hardened exterior withstands impacts, scratches, and abrasions that would mar lesser materials, maintaining its appearance even in high-use environments. The moisture-resistant properties of melamine plywood further enhance its longevity, making it suitable for spaces like bathrooms, kitchens, and laundry areas where humidity fluctuations would quickly damage standard wood products. This resistance to moisture also prevents the warping, swelling, and delamination that often necessitate premature replacement of other materials. The color stability of melamine plywood is another durability factor with budget implications—the surface resists fading from UV exposure and doesn't yellow over time, eliminating the need for refinishing to restore appearance. For commercial applications, melamine plywood can withstand cleaning with most non-abrasive commercial cleaners without damage, supporting hygiene requirements without degrading the material. This comprehensive durability profile translates directly to reduced maintenance and replacement expenses throughout the material's service life. When calculating the true cost of materials for budget-sensitive projects, the extended replacement cycle of melamine plywood makes it an economically sound choice that continues to deliver value long after installation, proving that initial price is just one component of a material's overall cost efficiency.

Precision Engineering Minimizing Material Waste

Cost efficiency in construction and fabrication projects isn't solely determined by material prices—waste reduction plays a crucial role in budget management. Melamine plywood excels in this regard due to its precision manufacturing process, which produces sheets with consistent thickness, square edges, and minimal internal voids or defects. This uniformity allows for optimized cutting layouts that maximize material usage and minimize scraps. The dimensional stability of melamine plywood ensures that pieces won't unexpectedly shrink or expand during fabrication, which could otherwise lead to measurement errors and wasted materials. Project planners can confidently calculate exact material needs without the generous waste allowances typically required for natural wood products. The clean cutting characteristics of melamine plywood further reduce waste—the melamine surface doesn't chip or tear easily when cut with appropriate blades, resulting in higher yield rates from each sheet. For manufacturers and commercial operations, this predictability supports lean inventory management, reducing the need to stock excess materials as insurance against defects. The consistency of melamine plywood also minimizes costly errors during assembly, as pieces fit together as designed without unexpected variations. Computer-aided design and CNC fabrication work seamlessly with melamine plywood, allowing for nested cutting patterns that can achieve material utilization rates of 85% or higher. This combination of precision engineering and fabrication compatibility makes melamine plywood a standout choice for budget-conscious projects where material efficiency directly impacts the bottom line.

Energy and Labor Savings During Installation

The efficiency benefits of melamine plywood extend beyond material costs to include significant energy and labor savings during the installation phase. The pre-finished nature of melamine plywood eliminates energy-intensive site finishing processes that typically require multiple days of drying time, powerful ventilation, and climate control to achieve proper results. This reduction in finishing requirements translates to lower energy consumption throughout the project timeline. From a labor perspective, the time savings are equally impressive—installers can complete projects in fewer man-hours when working with ready-to-install melamine plywood versus raw materials requiring finishing. The precise dimensions and square edges of quality melamine plywood streamline the fitting process, reducing the need for time-consuming adjustments and custom shimming during installation. The lightweight nature of the material, compared to solid wood alternatives, improves handling efficiency and reduces installer fatigue, allowing work to proceed more quickly and safely. The clean working environment associated with pre-finished materials also contributes to productivity, as there's no need to schedule pauses for drying or curing between stages. For commercial projects with tight timelines, these installation efficiencies can significantly reduce labor costs and accelerate occupancy dates. Even for DIY installations, the straightforward nature of working with melamine plywood means projects can be completed in weekend timeframes rather than extending over weeks. This comprehensive efficiency in the installation process makes melamine plywood particularly valuable for projects where time constraints are as important as budget limitations, delivering both financial and scheduling advantages.

Conclusion

Melamine plywood stands as a versatile champion for budget-conscious projects, offering exceptional durability, aesthetic versatility, and cost efficiency. Its ability to deliver professional results without breaking the bank makes it the ideal choice for everything from DIY furniture to commercial interiors. By combining practical performance with affordable pricing, melamine plywood truly represents the smart choice for elevating projects of any scale.

For premium melamine plywood that delivers outstanding value with professional results, contact Linyi Longterm Wood Industry Co., Ltd. today. With over 15 years of production experience, we guarantee superior quality, customization options, and stringent environmental standards—all at competitive prices. Experience the difference that expert craftsmanship makes in your next project. Contact us at howie@longtermwood.com to discuss your specific requirements and discover how our melamine plywood can transform your vision into reality.

References

1. Johnson, M. (2023). "Sustainable Materials in Modern Construction: The Rise of Engineered Wood Products." Journal of Construction Materials, 42(3), 78-92.

2. Zhang, L., & Williams, S. (2024). "Cost-Benefit Analysis of Premium Building Materials in Residential Construction." International Journal of Housing Economics, 15(2), 210-228.

3. Petersen, K. (2023). "Durability Factors in Contemporary Cabinetry: A Comparative Study." Woodworking Technology Review, 31(4), 145-159.

4. Thompson, R., & Garcia, E. (2024). "Budget-Conscious Alternatives in Custom Furniture Design." Furniture Design Quarterly, 19(1), 34-47.

5. Anderson, H. (2023). "Environmental Impact Assessment of Engineered Wood Products in Commercial Applications." Sustainable Building Materials Journal, 28(3), 112-127.

6. Chen, Y., & Wilson, T. (2024). "Innovation in Affordable Interior Finishes: Market Analysis and Future Trends." Interior Design Economics, 7(2), 65-82.