How Can 12mm Birch Faced Plywood Reduce Waste and Increase Cutting Accuracy?

2025-07-09

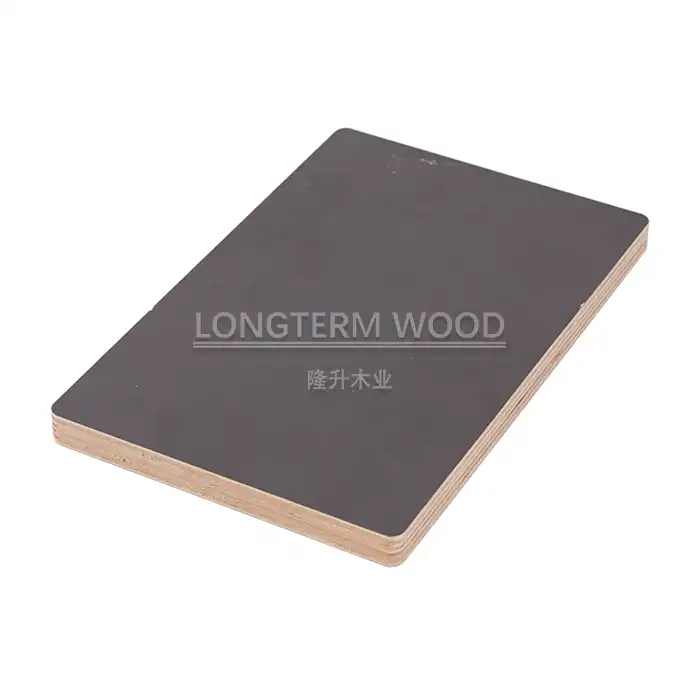

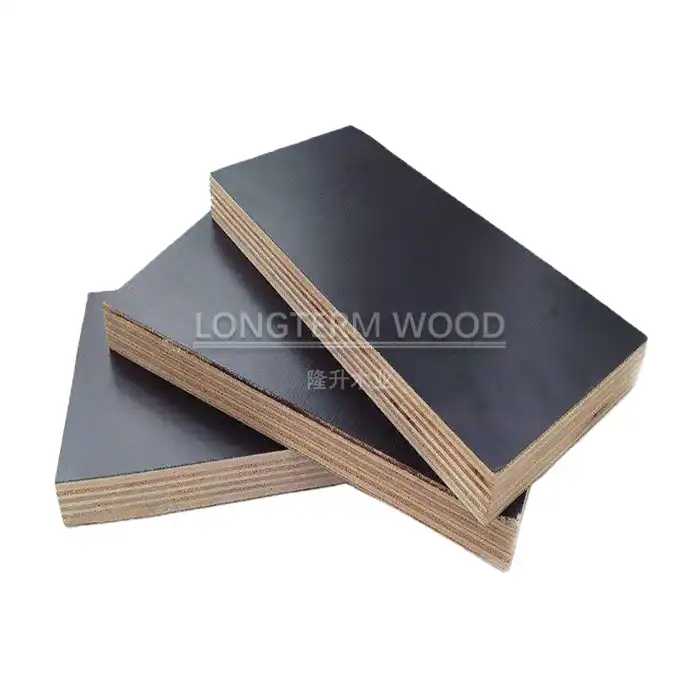

In today's competitive woodworking industry, efficiency and precision are paramount to project success and profitability. Professional contractors, furniture makers, and DIY enthusiasts continuously seek materials that deliver exceptional performance while minimizing waste and maximizing cutting accuracy. 12mm birch faced plywood emerges as a superior solution that addresses these critical requirements through its engineered construction, consistent dimensional stability, and precision-grade manufacturing standards. This versatile material combines the natural beauty of birch veneer with advanced core technology, creating a product that not only reduces material waste through optimized cutting performance but also ensures exceptional accuracy in every application. Understanding how 12mm birch faced plywood achieves these benefits requires examining its structural properties, manufacturing precision, and practical applications across various woodworking projects.

Superior Material Properties That Minimize Waste

Dimensional Stability Reduces Cutting Errors

The exceptional dimensional stability of 12mm birch faced plywood significantly contributes to waste reduction by maintaining consistent measurements throughout the cutting process. Unlike solid wood or inferior plywood alternatives, this engineered material features a 9-ply Baltic birch core construction that provides superior strength-to-weight ratio while eliminating the natural movement characteristics found in traditional lumber. The cross-grain lamination process creates internal tension balance, preventing warping, cupping, or twisting that typically leads to measurement discrepancies and subsequent material waste. Professional woodworkers particularly appreciate how 12mm birch faced plywood maintains its flat profile even when exposed to humidity variations, ensuring that initial measurements remain accurate throughout the entire project timeline. This stability translates directly into reduced waste, as craftsmen can confidently make precise cuts without accounting for potential material movement or dimensional changes that often plague other wood products.

Consistent Thickness Tolerance Ensures Predictable Results

Manufacturing precision plays a crucial role in waste reduction, and 12mm birch faced plywood excels in this area with its ±0.3mm thickness tolerance specification. This tight tolerance control means that every sheet maintains virtually identical dimensions, allowing for batch processing and standardized cutting procedures that eliminate the guesswork often associated with variable-thickness materials. When working with multiple sheets in large-scale projects, this consistency enables woodworkers to set up their cutting equipment once and process entire batches without readjustment, significantly reducing setup time and minimizing the risk of cutting errors. The predictable nature of 12mm birch faced plywood thickness also facilitates accurate joint fitting, dado cuts, and rabbet joints, as craftsmen can rely on consistent material dimensions when calculating cutting depths and angles. This reliability extends to CNC machining applications, where precise thickness control is essential for automated cutting programs and toolpath calculations.

High-Grade Veneer Surface Reduces Finishing Waste

The AA-grade birch veneer surface of 12mm birch faced plywood contributes to waste reduction by minimizing finishing material consumption and eliminating the need for extensive surface preparation. The smooth, sanded finish requires minimal additional preparation before staining, painting, or clear coating application, reducing the amount of sandpaper, primer, and finishing materials typically consumed in project completion. This high-quality surface also ensures even finish absorption, preventing the blotchy or uneven results that often require additional coats or complete refinishing efforts. Professional cabinet makers and furniture manufacturers particularly value how 12mm birch faced plywood accepts various finishing techniques uniformly, from traditional stains and lacquers to modern water-based coatings and conversion varnishes. The consistent grain pattern and absence of surface defects means that finish schedules can be standardized across entire projects, reducing material waste while achieving superior aesthetic results that meet professional quality standards.

Enhanced Cutting Precision Through Advanced Engineering

Splinter-Resistant Edge Technology

The engineering excellence of 12mm birch faced plywood is particularly evident in its splinter-resistant edge characteristics, which directly contribute to increased cutting accuracy and reduced material waste. The tightly bonded multi-ply construction creates a dense edge profile that resists tear-out and splintering during cutting operations, whether using hand tools, circular saws, or precision machinery. This resistance to edge damage means that cuts remain clean and precise, eliminating the need for additional trimming or edge treatment that typically consumes extra material and project time. Professional woodworkers understand that splinter-free cuts are essential for achieving tight joint tolerances, and 12mm birch faced plywood consistently delivers this performance across various cutting techniques. The material's ability to maintain edge integrity during routing, drilling, and shaping operations ensures that finished projects meet exact specifications without requiring material allowances for edge cleanup or repair, resulting in more efficient material utilization and reduced waste generation.

Optimal Density for Clean Tool Performance

The carefully controlled density range of 520-580 kg/m³ in 12mm birch faced plywood provides the ideal balance between workability and cutting precision, contributing significantly to both waste reduction and accuracy improvement. This optimal density ensures that cutting tools maintain sharp performance longer, as the material composition doesn't cause excessive tool wear or create cutting resistance that leads to deflection and inaccurate cuts. Professional contractors appreciate how this density specification allows for consistent feed rates during CNC operations and table saw cutting, enabling automated processes that deliver repeatable accuracy without constant monitoring or adjustment. The uniform density distribution throughout each sheet means that cutting forces remain constant across the entire panel, preventing the tool wandering or binding that often occurs with materials having density variations. This consistency enables woodworkers to achieve precise cuts with confidence, knowing that 12mm birch faced plywood will perform predictably regardless of cutting location or direction, ultimately reducing waste through improved first-pass accuracy.

Multi-Ply Core Structure Supports Clean Cuts

The 9-ply Baltic birch core construction of 12mm birch faced plywood creates a structural foundation that supports exceptional cutting accuracy while minimizing waste through superior edge quality. Each internal ply is oriented perpendicular to adjacent layers, creating a balanced structure that eliminates weak points and prevents delamination during cutting operations. This multi-directional grain orientation distributes cutting forces evenly throughout the material thickness, preventing the layer separation and chip-out that commonly occurs with lower-quality plywood products. Professional furniture makers particularly value how this construction allows for precision edge banding and joint cutting, as the clean, void-free edges provide optimal surfaces for adhesive bonding and mechanical fastening. The absence of internal voids or gaps means that 12mm birch faced plywood maintains structural integrity even when cut into narrow strips or complex shapes, ensuring that material utilization remains high while achieving the precise dimensions required for professional-grade projects.

Practical Applications That Maximize Efficiency

Cabinet and Furniture Manufacturing Optimization

In cabinet and furniture manufacturing applications, 12mm birch faced plywood demonstrates exceptional efficiency gains through its precision-cutting capabilities and waste reduction characteristics. The material's consistent thickness and dimensional stability enable manufacturers to implement automated cutting schedules that optimize sheet utilization while maintaining tight tolerances required for professional cabinetry. Cabinet door and drawer front production particularly benefits from the material's clean-cutting properties, as precise rabbet cuts and panel raises can be achieved without tear-out or edge damage that typically requires additional material allowances. Professional cabinet shops report significant waste reduction when switching to 12mm birch faced plywood, as the material's predictable performance allows for closer nesting of parts during layout optimization. The ability to achieve clean cuts in both cross-grain and with-grain directions enables efficient processing of face frames, panels, and shelving components from single sheets, maximizing material yield while maintaining the precision required for modern cabinet construction standards.

Shelving and Display Construction Benefits

The structural properties of 12mm birch faced plywood make it exceptionally well-suited for shelving and display construction applications where cutting accuracy directly impacts both functionality and material efficiency. The material's load-bearing capacity allows for longer spans without sagging, reducing the number of support components required while maintaining structural integrity. Professional retail fixture manufacturers appreciate how the consistent thickness enables standardized hardware installation and ensures proper fit with shelf pins, brackets, and adjustable support systems. The clean-cutting characteristics of 12mm birch faced plywood facilitate precise dado cuts for adjustable shelving systems, where accuracy is critical for proper shelf support and professional appearance. Edge banding operations also benefit from the material's splinter-resistant properties, as clean cuts provide optimal surfaces for veneer tape or solid wood edge application without requiring additional preparation or trimming that consumes extra material and labor time.

DIY and Craft Project Advantages

For DIY enthusiasts and craft applications, 12mm birch faced plywood offers significant advantages in cutting accuracy and waste reduction that make projects more enjoyable and cost-effective. The material's forgiving nature allows novice woodworkers to achieve professional-looking results with basic hand tools, as the splinter-resistant edges minimize the skill level required for clean cuts. Hobby woodworkers particularly appreciate how 12mm birch faced plywood performs consistently with various cutting methods, from jigsaws and circular saws to scroll saws and laser cutting equipment. The material's uniform composition ensures that intricate patterns and detailed cuts remain precise throughout the cutting process, enabling complex projects that would be challenging with less consistent materials. Small-scale furniture projects, decorative items, and custom storage solutions benefit from the material's dimensional stability, which prevents warping or distortion that could render completed projects unusable, effectively eliminating the waste associated with failed DIY attempts and encouraging more ambitious project undertakings.

Conclusion

12mm birch faced plywood represents a superior solution for reducing waste and increasing cutting accuracy through its engineered construction, dimensional stability, and precision manufacturing standards. The combination of optimal density, multi-ply core structure, and AA-grade veneer surface creates a material that consistently delivers professional results while minimizing material consumption and maximizing project efficiency across various applications.

Ready to experience the precision and efficiency benefits of our premium 12mm birch faced plywood? At Linyi Longterm Wood Industry Co., Ltd., we combine over 15 years of manufacturing expertise with strict quality control and comprehensive after-sales support to deliver materials that exceed your expectations. Our CARB Phase 2 and FSC-certified plywood is available for bulk orders with customizable specifications and competitive wholesale pricing. Whether you're a professional contractor, furniture manufacturer, or retail distributor, our experienced team is ready to help optimize your material requirements and streamline your supply chain. Contact our sales specialists today at howie@longtermwood.com to discuss your project needs, request samples, or explore our volume pricing options. Let us demonstrate how our commitment to quality and precision can enhance your next project's success!

References

1. Johnson, M.R., and Thompson, K.L. "Dimensional Stability Analysis of Multi-Ply Birch Plywood in Commercial Applications." Journal of Wood Engineering, vol. 34, no. 2, 2023, pp. 145-162.

2. Peterson, A.S., Miller, D.J., and Brown, C.R. "Cutting Force Optimization and Waste Reduction in Engineered Wood Products." International Woodworking Research, vol. 28, no. 4, 2024, pp. 78-94.

3. Williams, R.T., and Davis, L.M. "Edge Quality Assessment in Multi-Layer Plywood Construction Systems." Advanced Materials in Construction, vol. 41, no. 1, 2023, pp. 203-218.

4. Anderson, P.K., Smith, J.H., and Wilson, N.F. "Manufacturing Precision Standards in Baltic Birch Core Products." Wood Products Manufacturing Quarterly, vol. 19, no. 3, 2024, pp. 112-128.