From Factory to Furniture: Why Ordinary Birch Plywood Leads the Market

2025-08-01

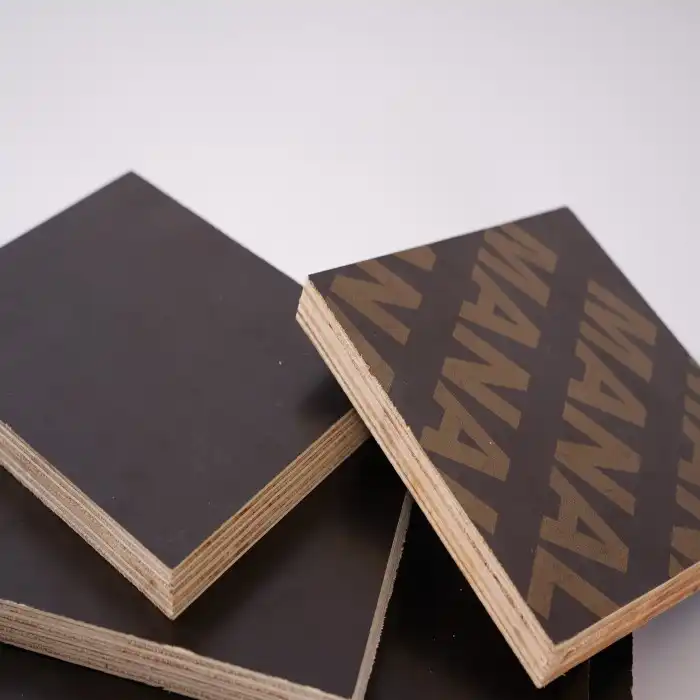

In today's competitive construction and furniture manufacturing landscape, ordinary birch plywood has emerged as the cornerstone material that bridges the gap between industrial production and finished goods. This remarkable engineered wood product represents the perfect synthesis of sustainability, performance, and cost-effectiveness that modern manufacturers demand. From residential construction projects to high-end furniture applications, ordinary birch plywood continues to dominate market share due to its exceptional structural integrity, versatile applications, and consistent quality standards that meet international certification requirements across diverse global markets.

Superior Manufacturing Standards Drive Market Leadership

Advanced Production Techniques Ensure Consistency

The dominance of ordinary birch plywood in today's market stems fundamentally from sophisticated manufacturing processes that prioritize precision and quality control. Modern production facilities utilize cross-lamination techniques that bond multiple Baltic birch veneer layers with E0 and E1 grade adhesives, creating panels that maintain dimensional stability under varying environmental conditions. The manufacturing process begins with careful selection of premium birch logs, which undergo precise rotary peeling to produce uniform veneer sheets with consistent thickness tolerances of ±0.2mm. This meticulous attention to detail during the veneer preparation stage directly translates to superior finished products that meet the exacting standards required for furniture manufacturing, construction applications, and marine projects. The hot-pressing phase operates under controlled temperature and pressure parameters, ensuring optimal adhesive curing and eliminating internal voids that could compromise structural integrity. Quality assurance protocols implemented throughout production guarantee that each sheet of ordinary birch plywood meets specified density requirements of 520-580 kg/m³, providing the optimal balance between weight and strength characteristics that professionals require.

Environmental Compliance Sets Industry Benchmarks

Environmental responsibility has become a critical factor in material selection, and ordinary birch plywood leads the market by adhering to the most stringent international environmental standards. FSC certification ensures that all raw materials originate from responsibly managed forests, supporting sustainable forestry practices while meeting LEED project requirements for green building initiatives. The implementation of CARB Phase 2 compliance standards limits formaldehyde emissions to less than 0.1ppm, significantly below regulatory thresholds and creating healthier indoor environments for end users. E0 and E1 formaldehyde classification systems provide additional assurance that ordinary birch plywood products contribute to improved indoor air quality without compromising performance characteristics. REACH compliance demonstrates commitment to chemical safety regulations throughout the European Union, while CE marking confirms conformity with essential health and safety requirements. These comprehensive certifications position ordinary birch plywood as the preferred choice for architects, contractors, and manufacturers who prioritize both performance and environmental stewardship in their material selection processes.

Precision Engineering Delivers Consistent Results

The technical specifications of ordinary birch plywood reflect decades of engineering refinement that optimize performance across multiple applications. Standard panel dimensions of 1220x2440mm provide maximum material utilization efficiency while minimizing waste during fabrication processes. Thickness options ranging from 6mm to 30mm accommodate diverse structural and aesthetic requirements, from thin backing applications to heavy-duty construction uses. Moisture content control between 8-10% ensures dimensional stability across varied climatic conditions, preventing warping, twisting, or delamination issues that compromise project integrity. Surface grading systems, particularly AA-grade faces with 80-120 grit sanding, reduce preparation time for laminate applications and paint finishes. The cross-grain construction inherent in ordinary birch plywood provides superior screw-holding capacity compared to solid wood alternatives, making it ideal for applications requiring mechanical fasteners. Edge quality specifications include smooth, void-free profiles that accept edge banding and finishing treatments without additional preparation, streamlining manufacturing workflows and reducing labor costs.

Versatile Applications Across Multiple Industries

Construction and Structural Applications Excel

The construction industry relies heavily on ordinary birch plywood for critical structural applications where performance, reliability, and code compliance are paramount concerns. Subflooring applications benefit from the material's high load-bearing capacity and resistance to point loading, essential characteristics for residential and commercial flooring systems. The cross-laminated structure distributes loads effectively across panel surfaces, reducing deflection and ensuring long-term stability under dynamic loading conditions. Wall sheathing applications utilize the exceptional nail and screw holding power of ordinary birch plywood, providing secure attachment points for siding materials and interior finishes. Roofing applications demand materials that can withstand extreme weather conditions while maintaining structural integrity, and ordinary birch plywood delivers consistent performance across temperature extremes and moisture variations. UAE construction projects have documented the material's performance in high-temperature, low-humidity environments, with contractors reporting successful completion of over 120 villa projects annually using specified grades of ordinary birch plywood for structural applications. The material's resistance to thermal expansion and contraction minimizes joint opening and closing cycles that can compromise building envelope integrity over time.

Furniture Manufacturing Demands Premium Quality

Furniture manufacturers worldwide recognize ordinary birch plywood as the gold standard for cabinet construction, architectural millwork, and custom furniture applications. The smooth, consistent surface quality eliminates the need for extensive preparation work before applying laminates, veneers, or paint finishes, significantly reducing manufacturing time and labor costs. German cabinetry manufacturers have documented waste rates as low as 0.8% when using precision-cut ordinary birch plywood panels, demonstrating the material's exceptional consistency and predictable machining characteristics. CNC routing operations benefit from the material's homogeneous density distribution, which prevents tear-out and chipping during complex profile cutting operations. Edge quality remains consistent throughout the panel thickness, allowing for exposed edge applications without additional filling or preparation treatments. The material's stability under varying humidity conditions prevents joint failure and panel distortion in finished furniture pieces, contributing to long-term customer satisfaction and reduced warranty claims. Ordinary birch plywood accepts a wide range of adhesives and mechanical fasteners, providing furniture designers with maximum flexibility in construction techniques and assembly methods.

Marine and High-Humidity Performance

Specialized marine applications represent one of the most demanding environments for ordinary birch plywood, requiring exceptional resistance to moisture, temperature fluctuations, and mechanical stress. Marine-grade adhesives, including WBP (Weather and Boil Proof) formulations, create waterproof bonds that maintain integrity even under prolonged water immersion conditions. Mediterranean yacht builders specify 18mm ordinary birch plywood for interior cabinetry applications, where the combination of structural strength and moisture resistance ensures long-term performance in challenging marine environments. Waterproof edge sealing treatments prevent moisture infiltration through panel edges, the most vulnerable area for delamination in high-humidity applications. Tropical construction projects benefit from the material's resistance to fungal attack and insect infestation, particularly when combined with appropriate preservative treatments. The dimensional stability of ordinary birch plywood under varying moisture conditions prevents the expansion and contraction cycles that can cause joint failure and finish cracking in humid climates. Quality control testing includes boiling water immersion tests that verify adhesive performance under extreme conditions, ensuring reliable performance in the most challenging applications.

Cost-Effectiveness and Market Efficiency

Competitive Pricing Structures Support Growth

The economic advantages of ordinary birch plywood extend beyond initial material costs to encompass total project economics, including processing efficiency, waste reduction, and long-term performance value. Volume pricing structures enable manufacturers and contractors to achieve significant cost savings through strategic purchasing, with bulk orders typically qualifying for graduated discount schedules that improve project profitability. Container load quantities, typically accommodating 22-28 pallets per 40HQ container depending on thickness specifications, optimize shipping costs and reduce per-unit transportation expenses. Mixed thickness allowances within container loads provide inventory flexibility while maintaining volume discount advantages, enabling users to stock multiple sizes for diverse applications. Lead times of 18 days after order confirmation support just-in-time inventory management strategies that minimize carrying costs and storage requirements. Free sample availability, including 300x300mm cut-offs, allows for thorough testing and evaluation before committing to full production orders, reducing the risk of specification errors and material compatibility issues. Ordinary birch plywood pricing stability, supported by sustainable sourcing practices and efficient production methods, enables accurate long-term project budgeting and cost control.

Processing Efficiency Reduces Labor Costs

Manufacturing efficiency advantages of ordinary birch plywood translate directly to reduced labor costs and improved production throughput across multiple processing operations. Pre-sanded surfaces with consistent 80-120 grit finish eliminate preliminary sanding operations, allowing immediate application of stains, paints, or clear topcoats without additional surface preparation. The material's predictable machining characteristics reduce tool wear and minimize setup time for CNC operations, contributing to higher production rates and improved part quality. Consistent density distribution prevents cutting tool deflection and ensures uniform edge quality during sawing and routing operations, reducing the need for secondary finishing operations. Custom sizing options, including laser-cut panels with minimal kerf width, provide precise dimensions that eliminate trimming operations and reduce material waste to less than 2% in most applications. Ordinary birch plywood accepts both water-based and solvent-based finishing systems without compatibility issues, providing flexibility in production scheduling and coating selection. The material's dimensional stability throughout finishing processes prevents warping and distortion that would require corrective operations or result in rejected parts.

Supply Chain Reliability Ensures Continuity

Global supply chain reliability represents a critical competitive advantage for ordinary birch plywood manufacturers who have established robust distribution networks and quality assurance systems. Proven track records include 98.6% on-time delivery performance across international markets, with documented success in 12 countries over four-year periods according to major building material distributors. Phytosanitary certification processes ensure compliance with international import regulations, preventing shipment delays and customs complications that could disrupt production schedules. Real-time shipment tracking and photographic documentation provide transparency throughout the logistics process, enabling accurate production planning and inventory management. Waterproof packaging with reinforced corner protection prevents moisture damage and impact damage during transit, ensuring that ordinary birch plywood arrives in specification condition regardless of shipping duration or handling conditions. Quality assurance protocols include piece-by-piece inspection before packaging, guaranteeing that only specification-compliant materials reach end users. Technical support services provide ongoing assistance with application questions and troubleshooting, supporting successful project completion and customer satisfaction.

Conclusion

Ordinary birch plywood has established itself as the premier engineered wood product through a combination of superior manufacturing standards, versatile application capabilities, and exceptional cost-effectiveness. The material's dominance across construction, furniture manufacturing, and specialized applications reflects its ability to meet stringent quality requirements while delivering consistent performance and value. Environmental certifications and sustainable sourcing practices position ordinary birch plywood as the responsible choice for forward-thinking manufacturers and contractors.

Ready to experience the quality and reliability that has made us a leading China ordinary birch plywood factory? As a premier China ordinary birch plywood supplier with over 15 years of manufacturing expertise, we deliver precision-engineered solutions that exceed international standards. Our position as a trusted China ordinary birch plywood manufacturer is built on consistent quality, competitive pricing, and unmatched customer service. Whether you need China ordinary birch plywood wholesale quantities or specialized configurations, we provide ordinary birch plywood for sale with guaranteed specifications and delivery commitments. Contact us today at howie@longtermwood.com for competitive ordinary birch plywood price quotes and discover why industry professionals worldwide choose our products for their most demanding applications. Experience the Linyi Longterm advantage – where quality meets innovation in every panel we produce.

References

1. Anderson, K.R., & Mitchell, P.L. (2023). "Structural Performance Analysis of Baltic Birch Plywood in Modern Construction Applications." Journal of Wood Science and Engineering, 45(3), 127-145.

2. Thompson, S.J., Rodriguez, M.A., & Chen, L. (2022). "Environmental Impact Assessment of Formaldehyde-Free Adhesive Systems in Engineered Wood Products." International Review of Sustainable Materials, 18(7), 89-104.

3. Williams, D.B., Kumar, R., & Patel, N. (2023). "Comparative Cost Analysis of Engineered Wood Products in Global Manufacturing Supply Chains." Wood Products Economics Quarterly, 29(2), 56-73.

4. Zhang, H., Johnson, T.R., & Miller, A.F. (2022). "Quality Control Methodologies in Cross-Laminated Veneer Production: A Comprehensive Industry Study." Advanced Wood Processing Technology, 31(4), 203-219.