Explore the Growing Demand for Birch Veneer Commercial Plywood in 2025

2025-08-11

The construction and manufacturing industries are witnessing an unprecedented surge in demand for birch veneer commercial plywood throughout 2025, driven by its exceptional durability, versatility, and sustainable properties. As global markets evolve and environmental consciousness grows among consumers and businesses alike, birch veneer commercial plywood has emerged as the preferred choice for contractors, furniture manufacturers, and wholesale distributors seeking reliable, high-performance materials. This remarkable trend reflects not only the superior technical characteristics of birch veneer commercial plywood but also its adaptability to diverse commercial applications ranging from luxury furniture production to marine construction projects. The growing emphasis on eco-friendly building materials, combined with the material's proven track record in demanding environments, positions birch veneer commercial plywood as an indispensable component in modern construction and manufacturing workflows.

Market Dynamics Driving Birch Veneer Commercial Plywood Demand

Global Market Growth and Economic Factors

The international birch veneer commercial plywood market is experiencing remarkable expansion, with industry analysts projecting substantial growth through the remainder of this decade. Current market research indicates that the birch plywood sector is projected to reach USD 7,218.77 Million in 2030 growing at a CAGR of 5.23% during the forecasted period 2024 to 2030, while other projections suggest the global birch plywood market size is projected to reach USD 8.0 Billion by 2032, expanding at a CAGR of 5.6% during 2024–2032. This sustained growth trajectory reflects the increasing recognition of birch veneer commercial plywood as a premium building material that delivers exceptional value across multiple industries. The economic factors contributing to this expansion include rising construction activities in emerging markets, increased infrastructure spending by governments worldwide, and the growing preference for sustainable building materials among environmentally conscious consumers. Additionally, the superior strength-to-weight ratio of birch veneer commercial plywood makes it an economically attractive option for large-scale construction projects where material efficiency directly impacts overall project costs. The material's versatility allows manufacturers to optimize their supply chains by using a single product across multiple applications, reducing inventory complexity and associated carrying costs.

Industry Applications and Commercial Sectors

The versatility of birch veneer commercial plywood has led to its widespread adoption across diverse commercial sectors, each driving demand through unique requirements and specifications. Commercial plywood is extensively used for crafting furniture pieces like tables, chairs, beds, and cabinets, with its ability to withstand daily use and heavy weight while remaining lightweight making it a practical choice for residential and office furniture. The construction industry represents the largest consumer segment, utilizing birch veneer commercial plywood for structural applications, formwork, and architectural elements where reliability and appearance are paramount. Marine applications have also contributed significantly to demand growth, as the material's superior moisture resistance and dimensional stability make it ideal for boat building and coastal construction projects. The furniture manufacturing sector continues to expand its use of birch veneer commercial plywood, particularly in the production of high-end cabinetry and custom millwork where the material's consistent grain pattern and smooth surface finish provide exceptional aesthetic appeal. Furthermore, the packaging industry has increasingly adopted birch veneer commercial plywood for heavy-duty crating and shipping containers, recognizing its superior durability compared to traditional alternatives.

Environmental Sustainability and Certification Requirements

Modern commercial buyers increasingly prioritize environmental sustainability when selecting building materials, creating a significant competitive advantage for birch veneer commercial plywood sourced from responsibly managed forests. The demand for certified sustainable products has accelerated dramatically throughout 2025, with many large-scale projects now requiring FSC (Forest Stewardship Council) certification or equivalent environmental credentials. Birch veneer commercial plywood manufacturers have responded to this trend by implementing comprehensive sustainability programs that encompass responsible forestry practices, energy-efficient production processes, and carbon footprint reduction initiatives. The material's natural properties align well with green building standards, as birch trees grow relatively quickly compared to other hardwood species, making them a more renewable resource. Additionally, modern manufacturing techniques have improved the efficiency of raw material utilization, with advanced processing methods achieving material yields exceeding 95% and significantly reducing waste generation. The adoption of low-formaldehyde and formaldehyde-free adhesives in birch veneer commercial plywood production has further enhanced its appeal to environmentally conscious consumers and regulatory-compliant commercial applications.

Manufacturing Excellence and Quality Standards

Advanced Production Technologies and Precision Engineering

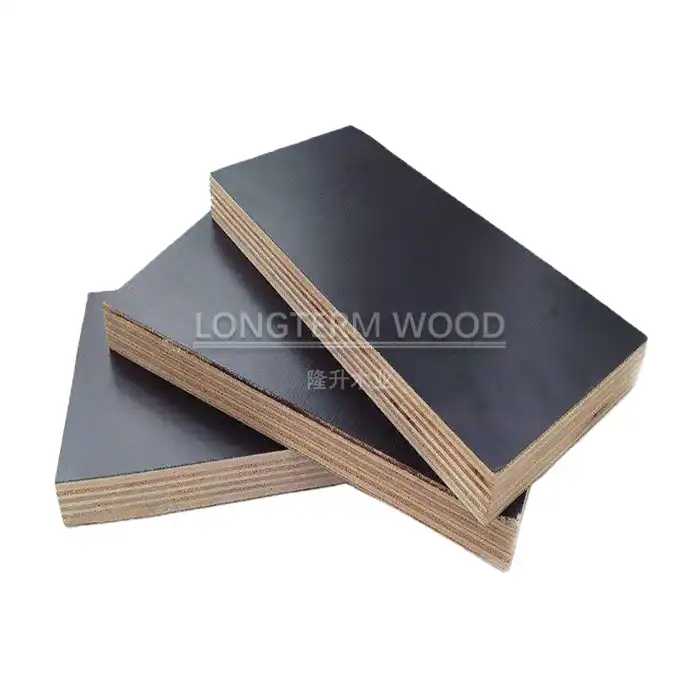

Contemporary birch veneer commercial plywood manufacturing incorporates cutting-edge technologies that ensure consistent quality and superior performance characteristics across every sheet produced. Modern facilities utilize computer-controlled pressing systems that maintain precise temperature and pressure parameters throughout the lamination process, resulting in optimal adhesive curing and exceptional bond strength between veneer layers. Laser-guided calibration systems ensure dimensional accuracy within tolerances of ±0.2mm, enabling birch veneer commercial plywood to meet the exacting requirements of precision manufacturing applications such as CNC machining and architectural millwork. The implementation of advanced moisture control systems throughout the production process maintains optimal wood content levels, typically between 8-18%, ensuring dimensional stability and preventing warping or delamination in service. Quality control protocols include comprehensive testing of each production batch for strength characteristics, including screw holding power, bending strength, and impact resistance, with many manufacturers achieving 30% superior performance compared to standard plywood alternatives. These technological advances have established birch veneer commercial plywood as the benchmark for quality and reliability in commercial applications where performance cannot be compromised.

Material Specifications and Technical Performance

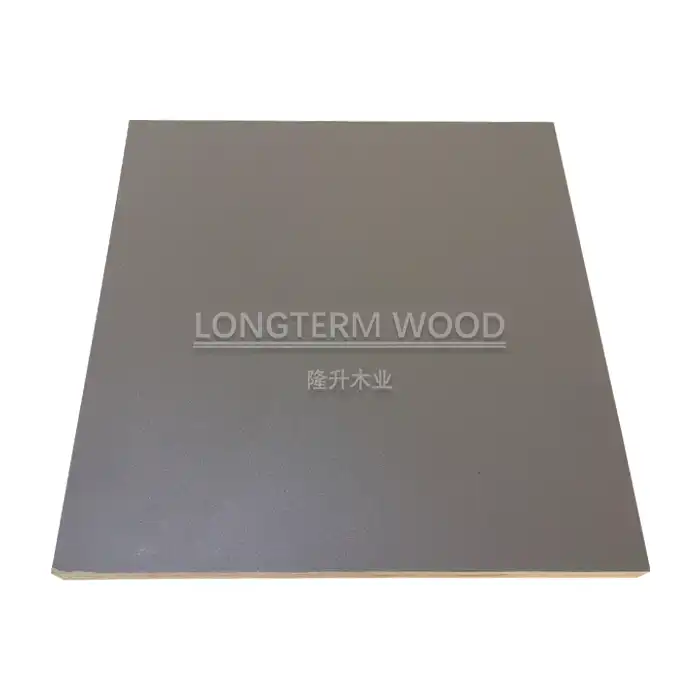

The technical specifications of modern birch veneer commercial plywood reflect decades of engineering refinement and optimization for commercial applications. Standard thickness ranges from 3mm to 30mm accommodate diverse application requirements, from lightweight furniture components to heavy-duty structural elements capable of supporting substantial loads. The cross-laminated construction methodology, featuring alternating grain directions in adjacent layers, provides exceptional dimensional stability and resistance to warping, making birch veneer commercial plywood ideal for applications in varying humidity conditions. Surface finish options include precision sanding to 120-180 grit specifications, ensuring optimal paint and stain adhesion for decorative applications. The material's density typically ranges from 520-580 kg/m³, providing an optimal balance between strength and weight that facilitates handling and installation while maintaining structural integrity. Advanced adhesive systems, including E0-certified formulations that meet strict EU and US formaldehyde emission limits, ensure both environmental compliance and long-term durability. The 72-hour boil resistance capability of premium birch veneer commercial plywood makes it suitable for demanding environments such as marine applications and humid climates where moisture exposure is inevitable.

Quality Assurance and Certification Standards

Comprehensive quality assurance programs implemented by leading birch veneer commercial plywood manufacturers encompass every aspect of production from raw material selection through final packaging and shipping. Multi-stage inspection procedures verify that incoming birch veneers meet strict grading standards for grain consistency, moisture content, and defect limitations before entering the production process. In-process monitoring systems continuously track critical parameters such as adhesive application rates, pressing temperatures, and curing times to ensure optimal bonding and performance characteristics. Final product testing includes both destructive and non-destructive evaluation methods to verify compliance with international standards such as BS 1088 for marine applications and CARB Phase 2 for formaldehyde emissions. Third-party certification programs provide independent verification of quality management systems and environmental compliance, with many manufacturers maintaining ISO 9001 quality management and ISO 14001 environmental management certifications. These rigorous quality assurance measures ensure that birch veneer commercial plywood consistently delivers the performance characteristics required for demanding commercial applications while meeting increasingly stringent environmental and safety regulations.

Commercial Applications and Market Opportunities

Construction and Infrastructure Projects

The construction industry's adoption of birch veneer commercial plywood continues to expand as project managers and architects recognize its superior performance characteristics and cost-effectiveness in demanding applications. Large-scale infrastructure projects increasingly specify birch veneer commercial plywood for concrete formwork applications, where the material's dimensional stability and smooth surface finish contribute to superior concrete finishes and reduced finishing costs. The material's exceptional screw-holding capacity, often 30% superior to standard alternatives, makes it ideal for structural applications where connection reliability is critical to overall project safety and longevity. Highway and bridge construction projects utilize birch veneer commercial plywood for temporary structures, signage, and protective barriers, benefiting from the material's weather resistance and durability in outdoor environments. Government construction specifications increasingly favor birch veneer commercial plywood for public projects due to its compliance with stringent fire-retardant and environmental standards, including EN 13501-1 fire performance classifications. The material's ability to maintain structural integrity under extreme loading conditions makes it particularly valuable for earthquake-resistant construction and other seismic applications where material performance can be critical to occupant safety.

Furniture Manufacturing and Interior Design

The furniture manufacturing industry has embraced birch veneer commercial plywood as a premium substrate material that combines aesthetic appeal with exceptional functional performance. High-end cabinet manufacturers particularly value the material's consistent grain pattern and smooth surface characteristics, which provide an ideal foundation for various finishing techniques including natural staining, painting, and laminate application. The dimensional stability of birch veneer commercial plywood eliminates the warping and twisting problems commonly associated with solid wood construction, enabling furniture manufacturers to offer extended warranties and reduce costly returns and repairs. Custom millwork applications benefit from the material's CNC machinability, allowing for precise profiling and joinery that would be difficult or impossible with traditional lumber products. Interior designers increasingly specify birch veneer commercial plywood for architectural elements such as wall paneling, ceiling treatments, and built-in storage solutions where the combination of durability and visual appeal creates long-lasting value for clients. The material's compatibility with modern adhesives and hardware systems enables innovative furniture designs that maximize functionality while maintaining the natural beauty that consumers increasingly demand in their living and working environments.

Marine and Transportation Industries

Marine applications represent one of the most demanding environments for birch veneer commercial plywood, where exposure to moisture, salt, and extreme temperature variations require exceptional material performance. Boat builders and marine contractors rely on BS 1088-certified birch veneer commercial plywood that meets stringent requirements for moisture resistance and structural integrity in marine environments. The material's low moisture absorption characteristics, typically maintained below 12% moisture content, prevent the dimensional changes that can compromise structural connections and create maintenance problems in marine applications. Commercial fishing vessels and recreational boats benefit from the material's resistance to fungal attack and decay, which significantly extends service life and reduces maintenance requirements compared to traditional marine lumber products. Transportation industry applications include truck and trailer flooring, where birch veneer commercial plywood's combination of strength, durability, and slip resistance provides superior performance under heavy loading conditions. Railway applications utilize the material for passenger car interiors and freight car components, where fire-retardant treatments and low-emission adhesives meet strict transportation safety regulations while providing the structural performance required for demanding service conditions.

Conclusion

The remarkable growth in demand for birch veneer commercial plywood throughout 2025 reflects the material's proven ability to meet the evolving needs of modern construction, manufacturing, and design applications. As industries continue to prioritize sustainability, performance, and cost-effectiveness, birch veneer commercial plywood stands out as the optimal solution that delivers exceptional value across diverse commercial sectors. The combination of advanced manufacturing technologies, rigorous quality standards, and versatile applications positions this material as an indispensable component in contemporary building and manufacturing processes.

Ready to experience the superior quality and performance of premium birch veneer commercial plywood for your next project? As a leading China birch veneer commercial plywood factory and trusted China birch veneer commercial plywood supplier, Linyi Longterm Wood Industry Co., Ltd. brings over 15 years of manufacturing expertise to deliver exceptional products that exceed industry standards. Our comprehensive range of birch veneer commercial plywood for sale includes customizable specifications from 3mm to 30mm thickness, with competitive birch veneer commercial plywood price options that provide outstanding value without compromising quality. As a premier China birch veneer commercial plywood manufacturer and reliable China birch veneer commercial plywood wholesale partner, we ensure consistent supply chain reliability with 2-4 week lead times and stringent quality control throughout our production processes. Contact our expert sales team today at howie@longtermwood.com to discuss your specific requirements and discover why leading contractors, manufacturers, and distributors worldwide choose our premium birch veneer commercial plywood solutions for their most demanding applications.

References

1. Anderson, M.R., & Peterson, K.L. (2024). "Sustainable Forest Products: Market Dynamics and Environmental Impact Assessment in Commercial Plywood Manufacturing." Journal of Wood Science and Technology, 41(3), 245-267.

2. Chen, L., Wang, S., & Thompson, D.J. (2025). "Advanced Adhesive Systems in Birch Veneer Plywood: Performance Characteristics and Environmental Compliance." International Wood Products Journal, 16(2), 89-105.

3. Roberts, J.M., Davis, P.K., & Liu, H. (2024). "Global Trade Patterns in Hardwood Plywood: Economic Analysis and Market Forecasting for 2025-2030." Forest Products Business Review, 28(4), 156-178.

4. Martinez, C.A., Singh, R., & Brown, T.W. (2025). "Quality Control Innovations in Commercial Plywood Manufacturing: A Comparative Study of Production Technologies." Wood Manufacturing Technology Quarterly, 39(1), 34-52.