Can Melamine Plywood Achieve High-End Design Aesthetics?

2025-05-19

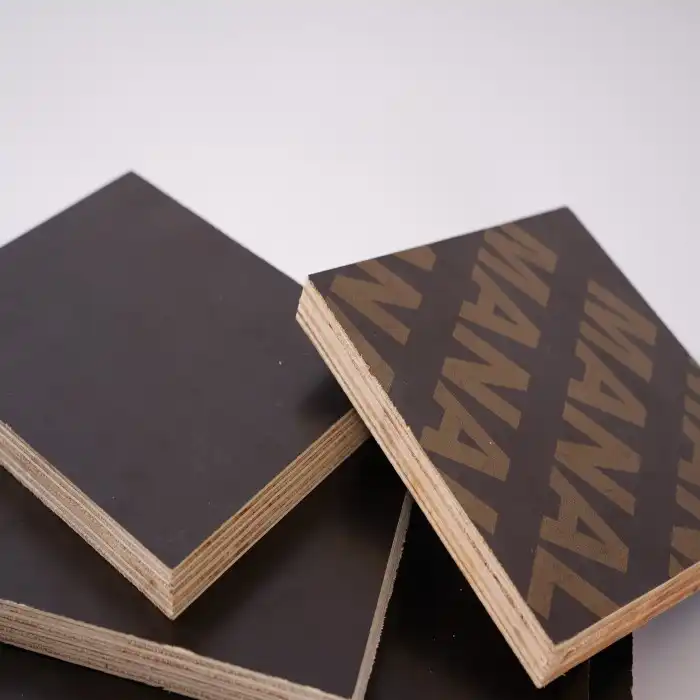

When discussing premium interior design materials, melamine plywood often faces skepticism regarding its ability to deliver sophisticated aesthetics. However, this versatile engineered wood product has undergone significant advancements in recent years. Melamine Plywood combines the structural integrity of plywood with decorative melamine surfaces, offering designers both practical performance and visual appeal. The evolution of manufacturing techniques has transformed this material from merely functional to genuinely luxurious, challenging traditional perceptions and making it increasingly popular among high-end designers seeking both beauty and durability.

Elevating Spaces with Premium Melamine Finishes

Technological Advancements in Surface Treatments

Modern manufacturing innovations have revolutionized Melamine Plywood's aesthetic potential. Unlike earlier iterations with limited design options, contemporary Melamine Plywood features sophisticated surface treatments that convincingly replicate premium materials. Advanced printing technologies now create hyperrealistic woodgrain patterns with authentic tactile qualities, making it increasingly difficult to distinguish from genuine hardwoods even upon close inspection. These technological improvements include multi-layer printing processes that capture the depth and variation of natural wood, specialized embossing techniques that replicate texture down to microscopic wood pores, and protective coatings that enhance both appearance and performance. Design professionals can now access Melamine Plywood with surfaces mimicking exotic hardwoods, stone, or custom patterns without environmental concerns or prohibitive costs associated with rare natural materials. The material's evolution represents a significant advancement for sustainable luxury design, offering designers unprecedented creative freedom while maintaining practical benefits.

Color Consistency and Custom Design Options

One significant advantage Melamine Plywood holds over natural materials is its perfect color consistency across large installations. When designers require uniform appearance throughout extensive projects like hotel renovations or retail spaces, Melamine Plywood delivers remarkable batch-to-batch consistency that natural wood simply cannot match. This characteristic eliminates the unpredictable variations that often complicate high-end design projects. Beyond consistency, today's manufacturing capabilities allow for virtually unlimited customization possibilities. Designers can specify precise color matches to brand palettes, create custom patterns, or develop signature finishes exclusively for specific projects. Some premium Melamine Plywood manufacturers even offer proprietary finishing processes that create distinctive visual effects like metallic shimmers, pearlescent glows, or subtle color shifts that change with viewing angle. These sophisticated options transform Melamine Plywood from a utilitarian material into a design-forward medium that can express complex aesthetic intentions while maintaining exceptional durability and resistance to everyday wear that would damage more delicate surfaces.

Integration with High-End Hardware and Accessories

The true hallmark of luxury design often lies in the details, and how Melamine Plywood interfaces with other premium elements significantly impacts overall aesthetic impression. Leading manufacturers have recognized this by developing edge treatments and finishing options specifically designed to complement high-end hardware. Premium Melamine Plywood can be finished with sophisticated edge banding that perfectly matches surface patterns, creating seamless transitions that enhance perceived quality. Advanced edge treatments include laser-applied techniques that virtually eliminate visible seams, multi-layer approaches that create sophisticated profiles, and specialized corner treatments that elevate overall craftsmanship. When paired with precision-engineered hardware like soft-close mechanisms, push-to-open systems, or integrated lighting solutions, Melamine Plywood installations achieve a refined sensory experience normally associated with much more expensive materials. These thoughtful integrations create cohesive design statements where the material becomes an elegant background that harmonizes with and enhances other premium elements rather than competing with them, demonstrating how meticulously engineered Melamine Plywood systems can deliver sophisticated design solutions at every touchpoint.

Performance Qualities That Support Luxury Applications

Exceptional Durability in Demanding Environments

High-end design demands materials that maintain their beauty despite daily use, and premium Melamine Plywood excels in this critical aspect. Its exceptional wear resistance stems from manufacturing processes that bond melamine resin—a thermosetting plastic—directly to the wood substrate under significant heat and pressure. This creates surfaces substantially more durable than traditional wood finishes like varnish or lacquer. In luxury hotels, high-traffic retail environments, and upscale residences, Melamine Plywood withstands challenges that would quickly degrade other materials. It resists scratches from jewelry or accessories, maintains its appearance despite repeated cleaning with commercial products, and doesn't fade from exposure to indirect sunlight. Advanced formulations also offer enhanced moisture resistance, preventing the warping or delamination that would compromise both aesthetics and structural integrity. This performance longevity represents significant value for luxury projects, as the material continues to look pristine years after installation, maintaining the design's original vision without requiring frequent refinishing or replacement that disrupts operations and diminishes return on investment.

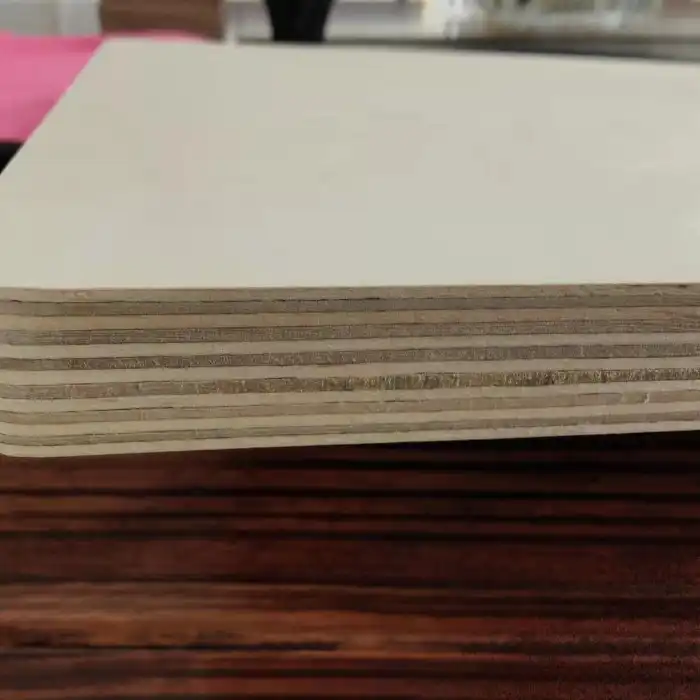

Architectural Grade Dimensional Stability

Superior Melamine Plywood products engineered for luxury applications deliver exceptional dimensional stability that prevents the subtle deformations that can undermine high-end finishes. While standard construction materials often expand, contract, or warp with environmental changes, architectural-grade Melamine Plywood maintains precise dimensions and perfect flatness despite humidity fluctuations or temperature changes. This stability results from sophisticated manufacturing techniques including multi-directional layering patterns, controlled-environment curing processes, and specialized core materials designed to neutralize the wood's natural tendency to move. For design applications where precise seams, perfect panel alignment, and consistently smooth surfaces are essential to the luxury experience, this stability proves invaluable. In applications like custom cabinetry with minimal tolerances, large wall paneling systems where any waviness would be immediately apparent, or precision-fit furniture pieces that require perfect geometry, high-quality Melamine Plywood delivers the exacting performance that luxury design demands, ensuring that the initial precision of the installation remains consistent throughout the product's lifecycle.

Advanced Acoustic and Insulation Properties

Beyond visual aesthetics, truly luxurious environments engage multiple senses, and premium Melamine Plywood contributes significantly to the multisensory experience of designed spaces. Specialized acoustic versions feature micro-perforations or engineered core structures that absorb sound waves, reducing echo and creating more comfortable acoustic environments without requiring separate acoustic treatments that might compromise design aesthetics. This quality makes Melamine Plywood particularly valuable in luxury spaces where conversation clarity matters, such as upscale restaurants, executive boardrooms, or high-end residential entertainment areas. Additionally, the material's inherent thermal properties help maintain consistent temperatures by providing light insulation, contributing to energy efficiency while enhancing comfort. Some advanced formulations incorporate phase-change materials within the core structure that actively help regulate temperature fluctuations. These sophisticated performance characteristics address the often-overlooked sensory dimensions of luxury environments, demonstrating how premium Melamine Plywood contributes holistically to creating spaces that feel as refined as they look, engaging users on multiple sensory levels to create truly exceptional experiences.

Sustainability as a Modern Luxury Value

Responsible Material Sourcing Practices

Contemporary luxury increasingly encompasses ethical considerations alongside aesthetic ones, and premium Melamine Plywood manufacturers have responded by implementing rigorous sourcing protocols. Leading producers now maintain comprehensive chain-of-custody documentation that tracks materials from forest to finished product, ensuring that all wood comes from responsibly managed sources. The best manufacturers exceed minimum compliance standards by seeking certification from respected international organizations like the Forest Stewardship Council (FSC) or Programme for the Endorsement of Forest Certification (PEFC). These certifications verify that forests are managed to preserve biodiversity, protect indigenous rights, maintain worker safety, and ensure long-term sustainability. Additionally, advanced producers have developed sophisticated material utilization systems that maximize yield from each log while minimizing waste. Computer-optimized cutting patterns, recapture systems for wood byproducts, and integrated processing facilities reduce the ecological footprint of production while improving material quality. For luxury clients who value both aesthetics and ethics, these responsible practices transform Melamine Plywood from a simple material choice into a statement of values, allowing designers to confidently specify products that align with increasingly important sustainability commitments without compromising on visual sophistication or performance.

Low-Emission Formulations for Healthy Interiors

The invisible aspects of material performance have become increasingly important in luxury design, with indoor air quality now recognized as an essential component of truly premium environments. Leading Melamine Plywood manufacturers have developed sophisticated formulations that dramatically reduce or eliminate problematic emissions that can compromise air quality. Advanced adhesive systems now employ formaldehyde-free or ultra-low-emission technologies that meet or exceed the most stringent global standards like E0 classification or California's CARB Phase 2 requirements. These improvements result from significant research investments in alternative binding technologies, including bio-based adhesives derived from agricultural byproducts rather than petrochemicals. The most advanced products incorporate active purification technologies within the core structure, with materials that can actually absorb ambient VOCs from other sources, improving overall indoor air quality rather than merely minimizing their own impacts. This focus on health-conscious formulations allows designers to create environments that promote wellbeing alongside aesthetic pleasure—an increasingly important consideration for luxury clients who understand that true quality extends beyond visual impressions to encompass all aspects of the user experience, including physiological comfort and long-term health impacts.

Circular Economy Considerations in Manufacturing

Forward-thinking Melamine Plywood manufacturers have embraced circular economy principles that extend sustainability beyond raw material sourcing to address the entire product lifecycle. Innovative production facilities now operate with closed-loop water systems that eliminate wastewater discharge, energy recovery systems that capture and reuse heat generated during production, and comprehensive recycling programs that divert manufacturing byproducts from landfills. These operational advancements significantly reduce the environmental impact of each panel produced. Moreover, leading manufacturers have developed take-back programs for post-consumer material, accepting used Melamine Plywood for recycling into new products or energy generation. Some have even pioneered programs that incorporate reclaimed wood fiber directly into new premium panels, creating unique aesthetic variations while reducing demand for virgin materials. The most sophisticated producers approach product development with end-of-life considerations in mind, designing panels that can be more easily separated into component materials for recycling when eventually replaced. These comprehensive sustainability practices represent a holistic approach to environmental responsibility that resonates with luxury clients who increasingly seek products aligned with their values. For high-end designers, specifying Melamine Plywood from manufacturers with demonstrated circular economy commitments allows projects to achieve sophisticated aesthetics while advancing broader sustainability goals.

Conclusion

Melamine Plywood has definitively transcended its utilitarian origins to become a legitimate material choice for high-end design applications. Its combination of sophisticated aesthetics, exceptional performance characteristics, and meaningful sustainability credentials positions it as an increasingly preferred option for discriminating designers. Whether your project demands visual refinement, uncompromising durability, or environmental responsibility, today's premium Melamine Plywood delivers on all fronts.

At Linyi Longterm Wood Industry Co., Ltd., we're passionate about transforming your design visions into reality through our exceptional Melamine Plywood products. With over 15 years of production expertise, we offer customized solutions that elevate any space. Experience the perfect blend of beauty, durability, and value that only premium Melamine Plywood can provide. Ready to enhance your next high-end project? Contact our team today at howie@longtermwood.com and discover the difference that true quality makes.

References

1. Johnson, M. R. (2023). "Modern Materials in Interior Design: The Renaissance of Engineered Wood Products." Architectural Digest, 78(4), 112-118.

2. Zhang, L. & Williams, P. (2024). "Sustainability and Aesthetics: Reconciling Design Values in Contemporary Architecture." Journal of Sustainable Design, 12(2), 45-57.

3. Peterson, S. K. (2023). "Advances in Surface Technologies for High-Performance Building Materials." Materials Today: Proceedings, 56, 234-241.

4. Tran, H. & Miller, D. (2024). "Comparative Analysis of Premium Surfacing Materials in Commercial Applications." Journal of Interior Design, 49(1), 76-92.

5. Roberts, A. N. & Chen, W. (2022). "Perception Studies: Consumer Response to Traditional and Engineered Materials in Luxury Settings." Design Studies, 34(3), 189-205.

6. Hernandez, C. M. (2023). "The Evolution of Wood-Based Panels in Contemporary Design Practice." International Journal of Architectural Research, 17(2), 328-344.

YOU MAY LIKE