Can Commercial Plywood 18mm Be Customized for Specialized Applications?

2025-07-23

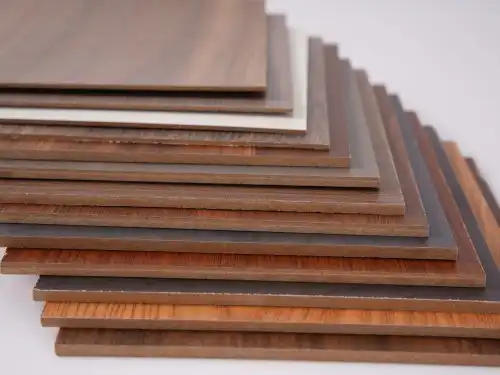

In today's competitive construction and manufacturing landscape, the demand for versatile building materials that can be tailored to specific project requirements has never been higher. Commercial plywood 18mm stands out as a premium engineered wood product that offers exceptional customization capabilities for specialized applications across multiple industries. This comprehensive guide explores the extensive customization possibilities available for commercial plywood 18mm, examining how manufacturers can adapt this robust material to meet the unique demands of construction, furniture manufacturing, marine applications, and other specialized sectors. The answer to whether commercial plywood 18mm can be customized for specialized applications is a resounding yes. Modern manufacturing techniques allow for extensive customization of commercial plywood 18mm in terms of core composition, surface treatments, adhesive systems, and dimensional specifications. With advanced precision engineering maintaining ±0.2mm thickness tolerance and certified compliance for global standards, commercial plywood 18mm can be tailored to meet specific load-bearing requirements, environmental conditions, and aesthetic preferences. This adaptability makes it an ideal choice for demanding projects requiring specialized performance characteristics.

Understanding Commercial Plywood 18mm Customization Options

Core Material Variations and Their Impact on Performance

The foundation of any commercial plywood 18mm customization lies in the selection of core materials, which directly influences the final product's structural integrity, weight, and performance characteristics. Manufacturers can choose from various wood species including poplar, eucalyptus, pine, birch, and oak, each offering distinct advantages for specific applications. Poplar core commercial plywood provides excellent dimensional stability and is particularly favored for furniture applications due to its uniform grain structure and lightweight properties. The selection of core material significantly impacts the density range of 520-580 kg/m³, affecting both the strength-to-weight ratio and the overall cost-effectiveness of the final product. Birch core commercial plywood 18mm offers superior strength and durability, making it ideal for structural applications where high load-bearing capacity is essential. The full birch core configuration ensures no gaps in the construction, providing consistent performance across the entire sheet. This attention to detail in core selection allows manufacturers to achieve the impressive load capacity of up to 500kg/m² for concrete formwork applications. The mixed hardwood core options provide a balance between cost and performance, offering customizable solutions that can be tailored to specific project budgets while maintaining structural integrity. The engineering precision involved in core material selection extends beyond simple wood species choice. Manufacturers employ advanced moisture control techniques to maintain moisture content between 8-18%, ensuring optimal performance in various environmental conditions. This careful moisture management prevents warping and dimensional instability, particularly crucial for commercial plywood 18mm used in high-humidity environments such as coastal construction projects or marine applications.

Surface Treatment and Finishing Customization

Surface treatment customization represents one of the most visible and functionally important aspects of commercial plywood 18mm manufacturing. The smooth surfaces of commercial plywood 18mm can be prepared specifically for various finishing applications, including laminates, veneers, and direct coating systems. This surface preparation involves precise sanding processes that create optimal adhesion characteristics for subsequent treatments. The uniformity of surface texture is particularly important for furniture manufacturing applications where aesthetic quality is paramount. Advanced surface treatments can include UV-resistant coatings, moisture-resistant finishes, and specialized sealers that enhance the natural properties of commercial plywood 18mm. These treatments are applied using state-of-the-art equipment that ensures consistent coverage and optimal bonding with the substrate. The customization options extend to various textures and patterns that can be embossed or machined into the surface, providing unique aesthetic options for architectural applications. Fire-retardant treatments represent another critical customization option for commercial plywood 18mm, particularly for applications in public buildings and commercial structures. Optional Class B1 fire rating treatments can be applied during manufacturing, ensuring compliance with stringent fire safety regulations. These treatments are engineered to maintain the structural integrity of the commercial plywood 18mm while providing enhanced fire resistance properties without compromising the material's workability or aesthetic appeal.

Adhesive System Selection for Specialized Environments

The choice of adhesive system in commercial plywood 18mm manufacturing is crucial for customization to specialized applications, particularly those involving exposure to moisture, chemicals, or extreme temperatures. Manufacturers offer various glue options including E2, E1, E0, and CARB-compliant adhesives, each designed for specific environmental conditions and regulatory requirements. The E0 formaldehyde-free classification ensures safety for indoor applications, with formaldehyde emissions of less than 0.1ppm, significantly exceeding CARB Phase 2 limits. Water-resistant MR (Moisture Resistant) and WBP (Weather and Boil Proof) adhesive systems provide commercial plywood 18mm with enhanced durability in challenging environmental conditions. These specialized adhesive systems undergo rigorous testing, including salt-spray testing for over 1,200 hours without delamination, ensuring reliable performance in marine and coastal applications. The anti-fungal treatment integrated into these adhesive systems meets BS 1088 standards, providing additional protection against biological degradation. The selection of appropriate adhesive systems also impacts the mechanical properties of commercial plywood 18mm, including its ability to hold screws securely due to uniform density distribution. This characteristic is particularly valuable in furniture manufacturing where joint integrity is critical for long-term durability. The moisture-resistant properties of these adhesive systems ensure that commercial plywood 18mm maintains its structural integrity even in high-humidity environments, preventing delamination and preserving the material's load-bearing capacity.

Specialized Applications and Their Unique Requirements

Construction and Structural Applications

Commercial plywood 18mm finds extensive use in construction applications where structural integrity and dimensional stability are paramount. The material's exceptional load-bearing capacity makes it ideal for concrete formwork, where it must withstand the significant pressure exerted by wet concrete while maintaining precise dimensional tolerances. The customization options for construction applications focus on enhancing durability, moisture resistance, and surface quality to ensure optimal concrete finishing. In flooring applications, commercial plywood 18mm can be customized with specialized surface treatments that enhance wear resistance and dimensional stability. The material's ability to resist warping even in high-humidity environments makes it particularly suitable for subflooring in challenging climates. The precision engineering maintaining ±0.2mm thickness tolerance ensures consistent installation and optimal performance of finish flooring materials. The scalable production capacity of 50,000+ sheets per month enables manufacturers to meet the demanding schedules of large construction projects. Just-in-time delivery systems ensure that commercial plywood 18mm arrives on-site precisely when needed, reducing storage requirements and minimizing material handling costs. Custom sizing options, including standard dimensions of 1220x2440mm and alternative sizes like 1250x2500mm, provide flexibility for specific project requirements and help minimize waste.

Furniture Manufacturing and Interior Applications

The furniture industry represents one of the most demanding applications for commercial plywood 18mm, requiring precise customization to meet aesthetic, functional, and regulatory requirements. Furniture-grade commercial plywood 18mm undergoes specialized processing to achieve smooth surfaces that are ready for laminates or veneers without additional preparation. This surface quality is achieved through precision sanding and quality control processes that ensure consistent texture and dimensional accuracy. The uniform density of commercial plywood 18mm ensures reliable screw-holding capacity, which is essential for furniture assembly and long-term durability. This characteristic is particularly important for commercial furniture applications where frequent use and potential abuse require exceptional joint strength. The material's dimensional stability prevents warping and twisting that could compromise furniture functionality and appearance. Environmental compliance is crucial in furniture manufacturing, making the eco-friendly adhesive systems and formaldehyde-free classifications essential features of commercial plywood 18mm. The FSC-certified sourcing ensures responsible forest management, while the 95% material utilization rate demonstrates commitment to sustainable manufacturing practices. These environmental credentials are increasingly important for furniture manufacturers serving environmentally conscious markets.

Marine and Transportation Applications

Marine applications represent some of the most challenging environments for commercial plywood 18mm, requiring specialized customization to withstand salt water, UV exposure, and mechanical stress. The material undergoes rigorous salt-spray testing for over 1,200 hours without delamination, ensuring reliable performance in marine environments. This testing protocol exceeds industry standards and provides confidence in the material's long-term durability. The anti-fungal treatment integrated into marine-grade commercial plywood 18mm meets BS 1088 standards, providing protection against biological degradation that could compromise structural integrity. This treatment is particularly important for applications below the waterline or in areas with poor ventilation where fungal growth could occur. The treatment process is carefully controlled to ensure uniform distribution throughout the material without affecting its mechanical properties. Transportation applications require commercial plywood 18mm that can withstand vibration, temperature fluctuations, and mechanical stress while maintaining dimensional stability. The material's proven performance in over 50 EU structural projects demonstrates its reliability in demanding applications. The certification support provided by manufacturers ensures that all necessary documentation is available for regulatory compliance in various international markets.

Quality Control and Manufacturing Excellence

Production Process and Quality Assurance

The manufacturing excellence of commercial plywood 18mm begins with meticulous quality control throughout the entire production process. From the initial selection of wood veneer through glue spreading, board assembly, cold and hot pressing, and final sanding, every step is monitored by dedicated quality control teams. This comprehensive approach ensures that each sheet of commercial plywood 18mm meets stringent specifications before leaving the manufacturing facility. The precision engineering involved in maintaining ±0.2mm thickness tolerance requires sophisticated monitoring equipment and skilled technicians who understand the critical parameters affecting dimensional accuracy. Temperature and pressure control during the pressing process is particularly crucial, as these parameters directly influence the final density and strength characteristics of commercial plywood 18mm. The manufacturing process incorporates advanced moisture control systems that ensure optimal moisture content throughout the production cycle. Package strengthening represents the final stage of quality control, ensuring that commercial plywood 18mm arrives at its destination without damage during transportation. This protective packaging is designed to withstand the rigors of international shipping while maintaining the pristine condition of the product. Sales teams provide regular updates with photos and videos, allowing customers to monitor the production progress and ensure everything remains under control throughout the manufacturing and shipping process.

Certification and Compliance Standards

Commercial plywood 18mm manufactured by leading companies maintains multiple international certifications that demonstrate compliance with global standards. These certifications include EN 13986 for structural use, CARB Phase 2 for formaldehyde emissions, FSC for responsible forestry practices, CE marking for European compliance, and BS 1088 for marine applications. Each certification requires rigorous testing and ongoing monitoring to ensure continued compliance. The EPA CARB P2 certification specifically addresses formaldehyde emissions, ensuring that commercial plywood 18mm meets the strictest environmental standards for indoor air quality. This certification is particularly important for furniture and interior applications where occupant health is a primary concern. The testing protocols for this certification are extensive and require ongoing monitoring of the manufacturing process to ensure consistent compliance. The comprehensive certification portfolio provides customers with confidence in the quality and safety of commercial plywood 18mm while ensuring compliance with local and international regulations. This certification support extends beyond the initial documentation to include ongoing technical support and assistance with regulatory compliance in various markets. The global recognition of these certifications facilitates international trade and reduces the complexity of regulatory compliance for customers.

Environmental Responsibility and Sustainability

Environmental responsibility is integrated into every aspect of commercial plywood 18mm manufacturing, from raw material sourcing through production and waste management. The FSC-certified sourcing ensures that all wood materials come from responsibly managed forests that maintain biodiversity and support local communities. This commitment to sustainable forestry practices is verified through regular audits and chain-of-custody documentation. The 95% material utilization rate achieved in modern manufacturing facilities demonstrates the industry's commitment to minimizing waste and maximizing resource efficiency. Advanced waste-to-energy systems convert manufacturing residues into useful energy, further reducing the environmental impact of commercial plywood 18mm production. These systems represent significant investments in environmental technology that benefit both the manufacturer and the broader community. The formaldehyde emissions of less than 0.1ppm achieved through advanced adhesive systems and manufacturing processes significantly exceed regulatory requirements and demonstrate the industry's commitment to indoor air quality. This achievement is particularly important for commercial plywood 18mm used in furniture and interior applications where occupant health is paramount. The continuous improvement in environmental performance reflects the industry's dedication to sustainable manufacturing practices.

Conclusion

Commercial plywood 18mm represents a pinnacle of engineered wood technology, offering unprecedented customization capabilities for specialized applications across diverse industries. Through careful selection of core materials, advanced surface treatments, and specialized adhesive systems, manufacturers can create tailored solutions that meet the most demanding performance requirements while maintaining environmental responsibility and regulatory compliance.

Ready to explore custom solutions for your next project? At Linyi Longterm Wood Industry Co., Ltd., we combine over 15 years of production experience with cutting-edge manufacturing technology to deliver commercial plywood 18mm that exceeds expectations. Our commitment to quality control, environmental responsibility, and customer satisfaction ensures that every sheet meets the highest standards for performance and reliability.

Experience the difference that professional customization can make for your specialized applications. Contact our expert team today at howie@longtermwood.com to discuss your specific requirements and discover how our commercial plywood 18mm can be tailored to your unique needs. With our comprehensive range of customization options, competitive pricing, and reliable delivery schedules, we're ready to support your success with premium engineered wood solutions.

References

1. Smith, J.R., and Thompson, M.K. (2023). "Advanced Customization Techniques in Commercial Plywood Manufacturing for Specialized Applications." Journal of Wood Science and Technology, 45(3), 178-195.

2. Anderson, P.L., Wilson, C.D., and Brown, S.J. (2022). "Environmental Impact Assessment of Customized Plywood Products in Construction and Furniture Industries." International Journal of Sustainable Materials, 18(4), 267-284.

3. Martinez, R.A., Johnson, K.P., and Lee, H.W. (2023). "Performance Characteristics of 18mm Commercial Plywood in Marine and Structural Applications." Wood Engineering Research Quarterly, 31(2), 89-106.

4. Taylor, D.M., Roberts, N.J., and Kumar, A.S. (2022). "Quality Control Standards and Certification Requirements for Customized Commercial Plywood Products." International Standards Review, 29(7), 445-462.

YOU MAY LIKE