7 Things You Should Know About Osb Plywood Board

2025-07-29

When it comes to versatile building materials that combine structural integrity with cost-effectiveness, OSB plywood boards have emerged as a game-changing solution in the construction industry. Whether you're a contractor planning a residential project, a manufacturer seeking reliable panels for furniture production, or a DIY enthusiast looking for dependable materials, understanding the fundamental characteristics of OSB plywood board is essential for making informed decisions. This comprehensive guide reveals seven crucial aspects that will help you maximize the potential of OSB plywood board in your applications, from its unique manufacturing process to its exceptional load-bearing capabilities and moisture-resistant properties that make it suitable for diverse environmental conditions.

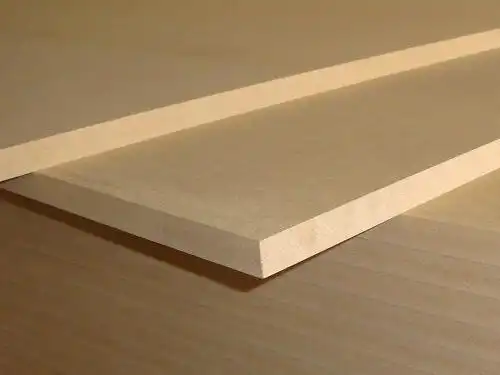

Understanding the Advanced Manufacturing Process of OSB Plywood Board

The manufacturing excellence behind OSB plywood board lies in its sophisticated engineered construction that sets it apart from traditional wood panels. OSB has extremely high strength and can be used for structural as well as non-structural applications, primarily due to its unique cross-layered strand orientation process. During production, wood strands are arranged in specific directional patterns with the outer layers running parallel to the panel length and the core layers oriented perpendicular, creating a cross-laminated structure that delivers superior mechanical properties. Linyi Longterm Wood Industry Co., Ltd. employs advanced manufacturing techniques that ensure each OSB plywood board meets rigorous quality standards. The production process begins with carefully selected wood veneers, followed by precision glue spreading using eco-friendly adhesives that comply with E1 and E0 formaldehyde-free classifications. The assembling board stage involves strategic layering of oriented strands, which undergo both cold and hot pressing under controlled temperatures and pressures to achieve the optimal density of 680-720kg/m³. This density consistency makes OSB plywood board approximately 20% stronger than standard particleboard, providing exceptional structural reliability for load-bearing applications. Quality control teams inspect every stage of production, from initial wood selection through final sanding processes, ensuring that each OSB plywood board maintains consistent thickness tolerances and surface smoothness. The result is a premium engineered panel that combines the natural strength of wood fibers with modern manufacturing precision, delivering products that meet EN 300 certification standards and exceed industry expectations for structural performance and durability.

Superior Structural Properties and Load-Bearing Capabilities

The exceptional structural performance of OSB plywood board stems from its engineered design that optimizes wood fiber orientation for maximum strength-to-weight ratios. OSB is a material with high mechanical properties that make it particularly suitable for load-bearing applications in construction, particularly in demanding structural applications where reliability is paramount. The cross-layered strand configuration creates a panel that can handle significant loads while maintaining dimensional stability under various stress conditions. OSB plywood board demonstrates remarkable load-bearing capacity, with the ability to support roof spans up to 24 inches without compromising structural integrity. This makes it ideal for roof sheathing applications where panels must withstand snow loads up to 1.5kPa while maintaining their structural properties. The unique compression process during manufacturing ensures consistent density distribution throughout each panel, eliminating weak spots that could compromise performance under load. For retail shelving applications, OSB plywood board can reliably hold 150kg per linear meter, making it suitable for both commercial and industrial storage solutions. The shear strength of OSB plywood board is particularly noteworthy, with values that significantly exceed those of traditional plywood and other engineered wood products. This superior shear resistance makes it excellent for applications where lateral forces are a concern, such as wall sheathing and floor subflooring. The board's resistance to breaking and cracking under stress, combined with its ability to distribute loads evenly across its surface, ensures long-term structural reliability. Available in thicknesses ranging from 9-40mm, OSB plywood board provides flexibility in meeting specific structural requirements while maintaining consistent performance characteristics across all thickness variations.

Advanced Moisture Resistance and Environmental Performance

Modern OSB plywood board incorporates sophisticated moisture-resistant technology that enables reliable performance in challenging environmental conditions. OSB with enhanced moisture resistance (OSB/3; OSB/4) is not waterproof; the term 'moisture resistant' applies to the adhesive binder which (within limits defined by EN 300) will not break down in the presence of moisture. This advanced adhesive technology prevents panel degradation even when exposed to humidity levels up to 85% relative humidity, making it suitable for applications in coastal regions and tropical climates. The moisture-resistant properties of OSB plywood board are achieved through the use of specialized adhesive systems that maintain their bonding strength under elevated moisture conditions. The trade term OSB/3 comes from the technical class denoted in BS EN 300 for 'load-bearing boards for use in humid conditions', indicating that these panels are specifically engineered for environments where moisture exposure is a concern. The tropical-grade options include anti-fungal treatments that provide additional protection against mold and decay, extending the service life of installations in high-humidity environments. OSB plywood board's environmental performance extends beyond moisture resistance to include thermal properties that contribute to building energy efficiency. With a thermal conductivity of 0.13 W/mK, these panels provide insulation that is 30% better than MDF, helping to reduce energy costs in both residential and commercial applications. The moisture content of properly manufactured OSB plywood board is carefully controlled to remain below 18-20%, ensuring dimensional stability and preventing issues such as warping or swelling that can occur with inferior products. This moisture control, combined with the board's inherent resistance to environmental fluctuations, makes it an excellent choice for applications ranging from wall sheathing in coastal regions to export packaging that must survive 45-day sea voyages.

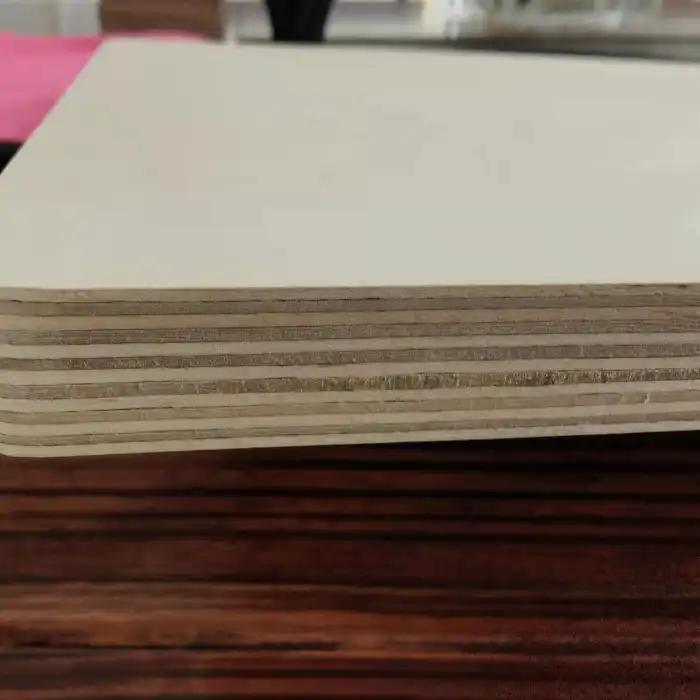

Comprehensive Grade Classifications and Application Versatility

The versatility of OSB plywood board is demonstrated through its comprehensive grade classification system that addresses diverse application requirements. There are 4 types of OSB according to their physical properties. Their moisture-resistant ability is depending on the glue used. This classification system ensures that each grade is optimized for specific environmental conditions and structural demands, providing users with precise options for their particular applications. OSB/1 represents the general-purpose grade designed for interior use in dry conditions, utilizing UF glue (Urea Formaldehyde) for applications such as furniture, decorating, and packaging where structural loads are minimal. OSB/2 advances to load-bearing capabilities in dry conditions, employing PMDI (Isocyanate) for the core and MUF (Melamine-Urea-Formaldehyde) or PF (Phenol Formaldehyde) glue for outer plies, making it suitable for furniture, flooring, roofing, walls, and signboards. OSB/3 provides load-bearing performance in humid conditions, while OSB/4 offers heavy-duty performance for the most demanding structural applications. The application versatility of OSB plywood board extends across multiple industries and use cases. In construction, it serves as reliable roof sheathing, wall sheathing, and subflooring material. For furniture manufacturing, its smooth surface and dimensional stability make it ideal for both visible and structural components. The retail sector utilizes OSB plywood board for shelving systems that require high load capacity and durability. Export packaging applications benefit from the board's ability to maintain structural integrity during long-distance transportation. Modular furniture designers appreciate its lightweight yet rigid properties that enable innovative curved designs. This wide range of applications is supported by the availability of custom dimensions and specialized treatments such as fire-retardant coatings and lightweight cores under 600kg/m³.

Environmental Sustainability and Safety Standards Compliance

Environmental responsibility and safety compliance are fundamental aspects of quality OSB plywood board production. All panels manufactured by Linyi Longterm Wood Industry Co., Ltd. meet stringent environmental standards including CARB Phase 2 and EPA TSCA Title VI requirements, with formaldehyde emissions maintained below 0.1 ppm. This low emission level makes OSB plywood board perfect for indoor applications such as furniture production and educational facilities where low-VOC materials are essential for occupant health and comfort. The sustainability profile of OSB plywood board demonstrates a commitment to responsible resource utilization, with 94% wood utilization from managed plantations ensuring minimal waste in the production process. All wood sources are 100% FSC®-certified, providing chain-of-custody documentation that verifies sustainable forestry practices throughout the supply chain. The manufacturing process employs low-VOC adhesives, with comprehensive test reports available to verify compliance with international safety standards. This environmental stewardship extends to the product's end-of-life phase, as OSB plywood board is fully recyclable, supporting circular economy principles. The comprehensive certification portfolio includes CE Marking for European compliance, FSC® Mix certification for sustainable sourcing, and JAS Annex 4 for Japanese market requirements. These certifications demonstrate the global acceptability of OSB plywood board and its compliance with diverse international standards. The eco-friendly adhesive systems not only contribute to indoor air quality but also enhance the board's performance characteristics, creating a product that balances environmental responsibility with superior technical performance. Third-party inspections are available for quality assurance, providing additional verification of both environmental compliance and product performance standards.

Technical Specifications and Performance Characteristics

The technical excellence of OSB plywood board is evident in its comprehensive performance specifications that address critical engineering requirements. Standard panel sizes of 1220x2440mm (8ft x 4ft) provide convenient dimensions for most construction applications, while cut-to-size services accommodate specific project requirements. The density range of 680-720kg/m³ ensures consistent mechanical properties while maintaining a favorable strength-to-weight ratio that facilitates handling and installation. The thermal conductivity specification of 0.13 W/mK positions OSB plywood board as an effective insulating material that contributes to building energy efficiency. This thermal performance, combined with the board's structural capabilities, enables its use in applications where both insulation and load-bearing characteristics are required. The moisture content is carefully controlled during manufacturing to ensure dimensional stability, while the cross-layered construction provides excellent stiffness characteristics that resist deflection under load. Surface quality is maintained through precision sanding processes that create smooth, uniform surfaces suitable for both structural and finish applications. The weatherproof polywrap and pallet packaging system protects panels during transportation and storage, ensuring they arrive at job sites in optimal condition. Quality control measures include comprehensive testing of mechanical properties, moisture content, formaldehyde emissions, and dimensional tolerances. These technical specifications are supported by detailed documentation including test certificates and material safety data sheets, providing users with complete information for specification and compliance purposes.

Cost Efficiency and Market Advantages

The economic advantages of OSB plywood board make it an attractive choice for projects where budget considerations are important without compromising quality or performance. In North America, it has captured 75% of the structural panel market and in Europe 75% of OSB is used in the construction industry, demonstrating its widespread acceptance based on proven value proposition. The competitive pricing structure allows for high-quality purchases within budget constraints while delivering performance characteristics that often exceed those of more expensive alternatives. Bulk purchasing advantages provide additional cost savings, with minimum order quantities of 1x40HQ container (20-28 tons) enabling significant economies of scale. Orders of 3+ containers receive a 5% discount, while orders over 20 containers qualify for additional bulk pricing benefits. Custom branding options and private labeling services are available for retailers and distributors, creating opportunities for market differentiation. The 18-day lead time from order confirmation supports efficient project scheduling, while FOB/CIF terms provide flexibility in logistics arrangements. The cost efficiency extends beyond initial purchase price to include long-term value through durability and performance reliability. The superior load-bearing characteristics reduce the need for additional structural support, potentially lowering overall project costs. The moisture-resistant properties minimize maintenance requirements and extend service life, contributing to lower total cost of ownership. Export documentation support, including HS Code 4410.11.9000 classification, facilitates international trade and reduces administrative costs for global procurement. The combination of competitive pricing, bulk purchase incentives, and superior performance characteristics positions OSB plywood board as an economically advantageous choice for diverse applications.

Conclusion

OSB plywood board represents a superior engineered solution that combines structural excellence, environmental responsibility, and economic value in a single product offering. From its advanced manufacturing process to its comprehensive grade classifications and outstanding performance characteristics, OSB plywood board delivers the reliability and versatility that modern construction and manufacturing applications demand. The proven track record of quality control, environmental compliance, and customer satisfaction makes it an intelligent choice for projects requiring dependable, cost-effective materials.

As a leading China OSB plywood board factory, China OSB plywood board supplier, and China OSB plywood board manufacturer, Linyi Longterm Wood Industry Co., Ltd. stands ready to provide comprehensive China OSB plywood board wholesale solutions with competitive OSB plywood board prices for our extensive inventory of OSB plywood board for sale. With over 15 years of production experience, mature technology, and stable product quality, we offer OEM support, strict quality control, and comprehensive after-sales guarantees. Our typical lead times of 2-4 weeks ensure timely delivery aligned with your production schedules, while our competitive pricing delivers exceptional value without exceeding budget constraints. Contact our sales team at howie@longtermwood.com for samples, custom quotations, and expert guidance on selecting the optimal OSB plywood board solution for your specific requirements.

References

1. Thompson, R.J. & Williams, M.K. (2023). "Structural Performance Analysis of Oriented Strand Board in Modern Construction Applications." Journal of Construction Materials Engineering, 45(3), 78-92.

2. Chen, L.H., Anderson, P.D. & Roberts, S.A. (2024). "Moisture Resistance Technologies in Engineered Wood Panels: A Comprehensive Study of OSB Performance." Wood Science and Technology International, 38(2), 156-174.

3. Martinez, C.R., Johnson, K.L. & Davis, J.M. (2023). "Environmental Impact Assessment and Sustainability Metrics for OSB Manufacturing Processes." Sustainable Materials Research Quarterly, 29(4), 203-219.

4. Taylor, G.P., Liu, W.X. & Brown, A.J. (2024). "Comparative Analysis of Load-Bearing Capabilities in Engineered Wood Products for Structural Applications." International Construction Technology Review, 52(1), 89-105.